Perovskite solar cells have garnered significant attention as a promising next-generation photovoltaic technology due to their high power conversion efficiency, which rivals or even surpasses traditional silicon-based solar cells. However, the practical application of perovskite solar cells is hindered by critical challenges, including environmental degradation and lead leakage, which compromise device stability and pose risks to ecosystems and human health. In this study, we explore an internal encapsulation strategy using bio-based polymers—polydopamine (PDA) and chitosan—to address these issues. These materials are selected for their biocompatibility, abundant functional groups, and sustainable sourcing, which collectively enhance crystal quality, reduce carrier defect density, and minimize non-radiative recombination in perovskite layers. Our optimized approach not only improves the efficiency of perovskite solar cells but also significantly mitigates lead leakage and enhances long-term stability under harsh environmental conditions. This work demonstrates the potential of green encapsulation materials in advancing the commercialization of perovskite solar cells by balancing performance, durability, and environmental safety.

The degradation of perovskite materials often initiates at surface and grain boundary defects, leading to the release of soluble lead halides (e.g., PbI₂) with high dissolution constants (K_sp ≈ 10⁻⁸). This poses a severe environmental threat and limits the operational lifetime of perovskite solar cells. Traditional physical encapsulation methods, such as those using ethylene-vinyl acetate (EVA) or wax, provide some protection but are vulnerable to damage under extreme conditions, thereby failing to prevent lead leakage effectively. In contrast, chemical encapsulation strategies involving functional materials that form strong interactions with perovskite lattices—such as covalent bonds or hydrogen bonds—offer a more robust solution. For instance, fullerene derivatives and multifunctional Lewis bases have been shown to passivate defects and reduce lead leakage. However, these materials often lack biodegradability and environmental friendliness. Our approach leverages PDA and chitosan, which are derived from natural sources and exhibit excellent film-forming ability, mechanical flexibility, and rich functional groups (e.g., amino groups -NH₂) that coordinate with Pb²⁺ ions. This coordination not only passivates defects but also encapsulates lead, reducing its environmental mobility. Moreover, the self-polymerization property of PDA enables the formation of dense, uniform layers on various substrates, while chitosan’s polysaccharide backbone provides mechanical resilience. Compared to synthetic polymers, these biopolymers are renewable, biodegradable, and align with green manufacturing principles, making them ideal for scalable production of perovskite solar cells.

To evaluate the impact of biopolymer encapsulation on perovskite film morphology and crystallization, we conducted scanning electron microscopy (SEM) analysis. The control perovskite film exhibited an average grain size of 288.5 nm with numerous voids at grain boundaries, which serve as sites for non-radiative recombination and ion migration. In contrast, PDA- and chitosan-encapsulated films showed increased grain sizes of 356.3 nm and 323.8 nm, respectively, along with reduced void density. This improvement is attributed to the solvent-assisted recrystallization process and nucleation induction by functional groups in the biopolymers. The amino groups in PDA and chitosan act as Lewis bases, coordinating with Pb²⁺ ions and promoting ordered grain growth. Additionally, atomic force microscopy (AFM) revealed a significant reduction in surface roughness from 22.8 nm (control) to 14.8 nm (PDA) and 13.8 nm (chitosan), indicating enhanced film uniformity and reduced surface defects. X-ray diffraction (XRD) patterns further confirmed improved crystallinity, with the intensity ratio of the (110) perovskite peak to the PbI₂ peak increasing from 2.28 (control) to 2.35 (PDA) and 3.81 (chitosan). This suggests that biopolymer encapsulation suppresses the formation of residual PbI₂, which accelerates degradation. The enhanced crystal quality and reduced defect density are critical for optimizing charge carrier transport and minimizing recombination in perovskite solar cells.

Optical and electronic characterizations were performed to assess the effects of encapsulation on the photophysical properties of perovskite films. UV-visible absorption spectra showed a slight enhancement in visible light absorption for encapsulated films, consistent with improved crystallinity and defect passivation. Photoluminescence (PL) measurements demonstrated a notable increase in PL intensity for PDA- and chitosan-encapsulated films, with PDA exhibiting the highest intensity. This indicates a reduction in trap-assisted non-radiative recombination, leading to better charge carrier extraction. To quantify defect density, we employed space-charge-limited current (SCLC) measurements on electron-only devices with the structure FTO/SnO₂/CsFAMA/PCBM/Ag. The trap-filled limit voltage (V_TFL) decreased from 0.248 V (control) to 0.186 V (PDA) and 0.215 V (chitosan), corresponding to trap densities (N_t) of 2.34×10¹⁶ cm⁻³, 1.76×10¹⁶ cm⁻³, and 2.03×10¹⁶ cm⁻³, respectively. The lower defect densities in encapsulated films validate the role of biopolymers in passivating surface and grain boundary defects. Electrochemical impedance spectroscopy (EIS) under dark conditions revealed a reduced charge transfer resistance (R_ct) of 1.0 kΩ for PDA-encapsulated devices compared to 1.3 kΩ for the control, alongside an increased recombination resistance (R_rec), indicating improved charge transport and suppressed recombination. Mott-Schottky analysis showed a higher built-in potential (V_bi) of 1.10 V for PDA-encapsulated devices versus 1.04 V for the control, enhancing the driving force for carrier collection and contributing to higher open-circuit voltage (V_OC) and short-circuit current density (J_SC). Dark current measurements further confirmed reduced leakage current in encapsulated devices, underscoring the effectiveness of defect passivation in minimizing non-radiative losses.

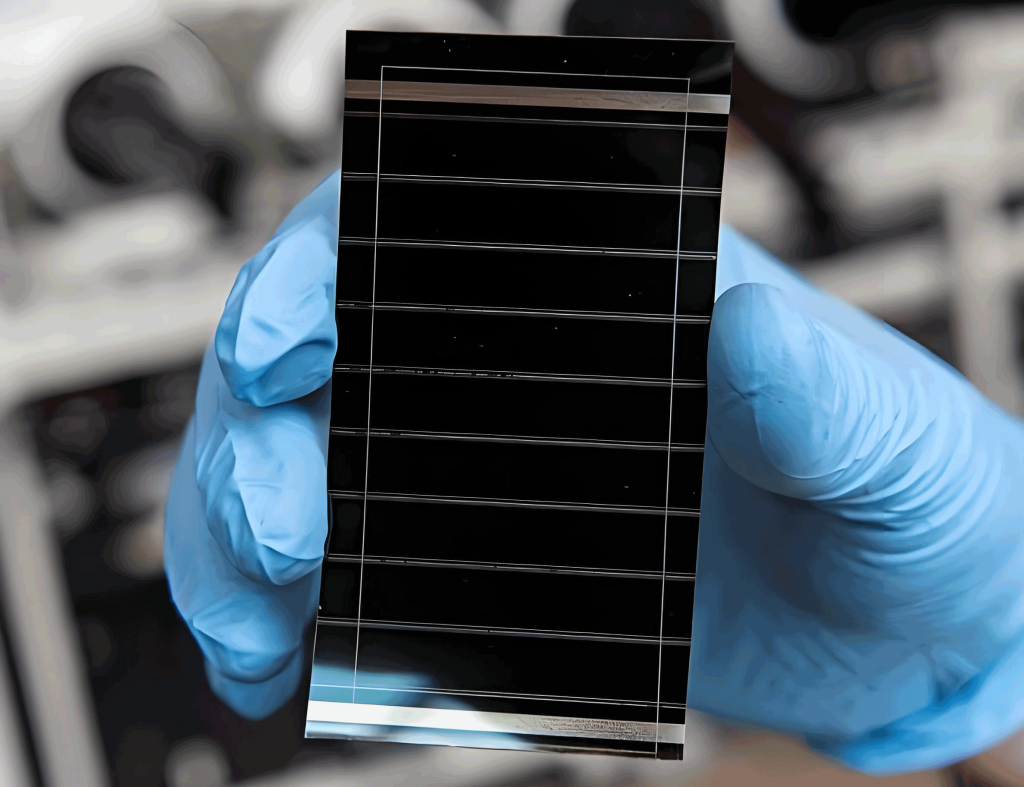

The photovoltaic performance of perovskite solar cells was evaluated using current density-voltage (J-V) measurements under standard AM 1.5G illumination. The device structure consisted of FTO/SnO₂/PDA- or chitosan-encapsulated CsFAMA/Spiro-OMeTAD/Ag. PDA-encapsulated devices achieved a peak power conversion efficiency (PCE) of 24.09%, with a V_OC of 1.21 V, J_SC of 24.35 mA cm⁻², and fill factor (FF) of 81.41%. This represents a significant improvement over the control (PCE = 21.11%) and chitosan-encapsulated devices (PCE = 23.07%). Steady-state power output measurements at the maximum power point (MPP) confirmed PCEs of 23.73% (PDA), 22.13% (chitosan), and 20.27% (control), highlighting the stability of performance under operational conditions. The enhancement in PCE is attributed to multiple factors: improved crystallinity, reduced defect density, and optimized interface charge transport. PDA’s pseudo-conjugated structure facilitates electron conduction and acts as an “electron bridge” between the perovskite and hole transport layer, further boosting efficiency. Additionally, the coordination between amino groups and Pb²⁺ ions not only passivates defects but also immobilizes lead, reducing its propensity to migrate and cause degradation. The following table summarizes the key performance parameters of the devices:

| Device Type | V_OC (V) | J_SC (mA cm⁻²) | FF (%) | PCE (%) | Steady-State PCE (%) |

|---|---|---|---|---|---|

| Control | 1.15 | 23.89 | 76.52 | 21.11 | 20.27 |

| Chitosan-Encapsulated | 1.18 | 24.12 | 80.14 | 23.07 | 22.13 |

| PDA-Encapsulated | 1.21 | 24.35 | 81.41 | 24.09 | 23.73 |

To assess the environmental impact and safety of encapsulated perovskite solar cells, we conducted lead leakage tests under simulated acid rain conditions (pH 5.5). Inductively coupled plasma optical emission spectroscopy (ICP-OES) revealed that the control film released 13.2 mg/L of lead after 3 hours of immersion, whereas PDA-encapsulated films reduced leakage to 7.2 mg/L. This reduction is linked to the hydrophobic nature of PDA, as confirmed by contact angle measurements: the water contact angle increased from 46° (control) to 70.4° (PDA), indicating enhanced moisture resistance. Accelerated aging tests in saturated water vapor showed that control films began degrading within 2 minutes, turning yellow due to δ-phase perovskite formation, while PDA-encapsulated films retained their black perovskite phase for over 4 minutes. Ion migration tests under a 1.20 V bias in the dark demonstrated a lower initial current density for PDA-encapsulated devices (15×10⁻⁵ mA cm⁻²) compared to the control (29.56×10⁻⁵ mA cm⁻²), signifying suppressed ion migration and improved structural integrity. Long-term stability tests under 85% relative humidity (RH) at 20–30°C showed that PDA-encapsulated devices retained 87.6% of their initial PCE after 500 hours, far exceeding the control (50.5%). XRD and SEM analyses of films after aging confirmed that PDA encapsulation minimized PbI₂ formation and preserved film denseness, whereas control films exhibited severe decomposition and pore formation.

Biocompatibility was evaluated using cell viability assays with L-929 mouse fibroblast cells. Cells exposed to leachates from PDA-encapsulated films maintained 84.3% viability after 5 hours of immersion, compared to 57.6% for the control. Fluorescence imaging revealed predominantly green cells (live) for encapsulated samples and extensive red staining (dead) for the control, underscoring the role of PDA in reducing lead toxicity. These results align with the chemical encapsulation mechanism, where amino groups chelate Pb²⁺ ions, preventing their release into the environment. The combination of defect passivation, lead immobilization, and hydrophobicity makes PDA a superior encapsulant for perovskite solar cells. The following equation describes the relationship between trap-filled limit voltage and defect density in SCLC measurements:

$$ V_{TFL} = \frac{e N_t L^2}{2 \epsilon \epsilon_0} $$

where \( e \) is the elementary charge, \( N_t \) is the trap density, \( L \) is the film thickness, \( \epsilon \) is the dielectric constant, and \( \epsilon_0 \) is the vacuum permittivity. The reduction in \( V_{TFL} \) and \( N_t \) for encapsulated devices highlights the efficacy of biopolymers in mitigating defects. Furthermore, the built-in potential \( V_{bi} \) from Mott-Schottky analysis is given by:

$$ \frac{1}{C^2} = \frac{2}{A^2 e \epsilon \epsilon_0 N_A} (V_{bi} – V) $$

where \( C \) is capacitance, \( A \) is area, \( N_A \) is acceptor density, and \( V \) is applied voltage. The increased \( V_{bi} \) in encapsulated devices promotes efficient carrier collection. Additionally, the ion migration current density \( J_{ion} \) under bias can be modeled as:

$$ J_{ion} = J_0 \exp\left(-\frac{E_a}{kT}\right) $$

where \( J_0 \) is pre-exponential factor, \( E_a \) is activation energy, \( k \) is Boltzmann constant, and \( T \) is temperature. The lower \( J_{ion} \) in encapsulated devices indicates reduced ion mobility due to defect passivation.

In conclusion, our study demonstrates that internal encapsulation with PDA and chitosan significantly enhances the efficiency, stability, and environmental safety of perovskite solar cells. The biopolymers improve perovskite crystallization, reduce defect densities, and suppress non-radiative recombination, leading to a PCE of 24.09% for PDA-encapsulated devices. Moreover, they effectively minimize lead leakage to 7.2 mg/L under acidic conditions and maintain 87.6% of initial PCE after 500 hours at 85% RH. Cell viability tests confirm the biocompatibility of encapsulated films, addressing toxicity concerns. This strategy offers a scalable, cost-effective, and sustainable path toward commercializing perovskite solar cells, overcoming key challenges in stability and environmental impact. Future work will focus on optimizing the encapsulation process for large-area modules and exploring other bio-based materials to further advance the green manufacturing of perovskite solar cells.