China is currently in a period of rapid industrial development, and all industries cannot do without the support of electricity. The demand for electricity in industrial production and residents’ daily lives is rapidly increasing, resulting in an increasing day and night peak valley difference in electricity consumption and a larger load curve peak valley. The energy storage battery system provides a new path to solve the imbalance between supply and demand in the power system caused by the difference in peak and valley power consumption. It plays an important role in charging and power supply during the generation, transmission, distribution, and use of the power system, and has a positive impact on the construction and operation of the power system.

Specifically, the existence of energy storage systems can reduce the peak valley difference of inconsistent electricity usage during the day and night, thereby achieving the goal of improving the utilization rate and stability of power equipment, further reducing power supply costs, saving energy consumption, and more effectively meeting the demand side’s electricity usage; Secondly, it can provide independent power supply in the event of power supply difficulties or important loads, equipment maintenance, or power outages in the main network, reducing the impact of external environment on the system and improving the reliability of power supply; Finally, energy storage systems can reduce the randomness of grid output power and meet the technical requirements of new energy generation.

The advantages of energy storage technology have attracted great attention from countries around the world, and national policies related to energy storage technology research have been introduced. For example, in 2005, China released the earliest strategic layout of the energy storage industry – the “Renewable Energy Development Guidance Catalogue”; The United States Congress passed the Renewable and Green Energy Storage Technology Act of 2009 in May 2009 and the Renewable and Green Energy Storage Technology Act of 2010 in July 2010; In 2013, Germany introduced and implemented the “New Policy to Support Distributed Photovoltaic Energy Storage”; In 2017, the National Energy Administration pointed out in the article “Guiding Opinions on Primary Energy Storage Technology and Industrial Development” that energy storage should transition from research and development demonstration to commercialization mode, in order to promote the development of energy storage technology and industry; In 2019, State Grid of China proposed to build an energy internet based on smart grids for energy flow, business flow, and data flow in order to build hub, platform, and shared enterprises; In 2020, the Ministry of Education, the National Development and Reform Commission, and the National Energy Administration issued the “Action Plan for the Development of Energy Storage Technology Disciplines (2020 to 2024)”. The various policies issued intensively are based on the significant needs of the development of energy storage technology industry, addressing the commonalities and bottlenecks of various professional technical fields involved in the development of energy storage technology, and rapidly promoting the high-quality development of the energy storage industry and energy.

Furthermore, with the leapfrog construction of the State Grid of China, its requirements for energy storage technology are constantly increasing. This involves a containerized energy storage system, which consists of several tightly arranged batteries. During the charging and discharging process of the energy storage system, the batteries inside the system generate a large amount of heat. Due to the compact arrangement and small gaps of the batteries, it is difficult to quickly discharge the heat generated by the batteries. Heat accumulation and large operating temperature differences may occur between the conductive battery packs. Over time, it will lead to serious inconsistencies in internal resistance and capacity between batteries, seriously affecting the performance and lifespan of battery packs, and also posing safety hazards. In power battery systems with lithium batteries as the core, safety accidents caused by improper thermal management of lithium batteries are not uncommon. In July 2011, Shanghai One Car “Lithium ion battery+supercapacitor” bus ignited spontaneously. On April 21, 2019, a Tesla electric vehicle ignited spontaneously, causing multiple vehicles in the garage to explode in series, causing great economic losses. In 2020, a Chery Areze ignited spontaneously when charging late at night, without causing casualties. Ouyang Minggao, an academician of the CAS Member, clearly pointed out that frequent electric vehicle fire accidents in China Battery thermal runaway is the main cause of the accident. Compared to power batteries, energy storage batteries have a larger battery capacity and higher heat generation, thus placing higher demands on heat dissipation. In addition, when the temperature of the battery pack is lower than the safe operating temperature limit, the reaction efficiency of the battery decreases, and the power also decreases, thereby failing to meet the target voltage usage requirements. When the battery is in the range of 0 to 25 ℃, the capacitance will decrease by 1% for every degree of temperature decrease. When the ambient temperature of the battery is below 0 ℃, the capacitance will decrease by more than 1% for every 1 ℃ decrease in temperature. Therefore, based on a full understanding of the temperature characteristics and heat release characteristics of lithium batteries, researching and developing safe and efficient battery thermal management technologies is of great significance for the widespread application of lithium batteries.

The internal spatial environmental factors of container energy storage systems are relatively complex, and there are many factors that affect battery temperature. Therefore, when conducting thermal simulation observations on them, it is difficult to accurately obtain the parameters that affect battery temperature one by one; At the same time, there is very little research on the optimization layout and energy conservation of the system. Currently, there is relatively little research on the flow field and temperature characteristics of the energy storage system using thermal simulation analysis method. The main reason is that the internal structure of the container energy storage system is complex, involving a huge scale of grid models, and requires high computer performance. Therefore, this article takes the container type energy storage system as the research object, conducts research on its flow and heat distribution laws based on CFD simulation technology, and explores the influencing factors of the above laws. In addition, conduct research on the design and parameter optimization of thermal management schemes, and obtain several thermal design schemes that meet the requirements. On this basis, economic and energy consumption analysis is conducted to obtain efficient thermal design solutions and provide technical references for the development of containerized energy storage systems.

1. Temperature and humidity characteristics of container energy storage batteries

Lithium batteries are the core components of container energy storage systems. Before conducting thermal management on container energy storage systems, it is necessary to conduct research on the temperature and humidity characteristics of lithium batteries. At present, researchers have conducted extensive research on the temperature characteristics of lithium batteries, mainly in the following four aspects.

1.1 The influence of temperature on the capacity and lifespan of lithium batteries

Research has shown that the capacity and lifespan of lithium batteries vary significantly with temperature, mainly due to changes in internal resistance and voltage caused by temperature changes. Zhao et al. found that for every 1 ℃ increase in temperature, the battery life decreases by about 60 days. Feng et al. found that high temperature environments can reduce battery capacity and pointed out that the main reason for the decrease is that high temperature can lead to an increase in battery internal resistance, loss of active materials and effective lithium ions. As for the reason for the increase in internal resistance, some studies suggest that this is due to the dissolution of metal ions in the positive electrode under high temperature conditions and entering the electrolyte, which then passes through the diaphragm and deposits on the negative electrode, resulting in an increase in internal resistance of the negative electrode. Similar to high-temperature environments, low-temperature environments can also lead to a decrease in the capacity of lithium batteries. For example, the capacity retention rate of lithium iron phosphate batteries is 60%~70% at 0 ℃, while it decreases to 20%~40% at -20 ℃. This is mainly due to a significant decrease in the transmission performance of electrolytes under low-temperature conditions.

1.2 Effect of temperature on the thermal stability of lithium batteries

The main impact of temperature on the stability of lithium batteries is that at high temperatures, the internal materials of the battery undergo decomposition reactions. Spotnit and Dahn et al. found that under continuous high temperature environments, the SEI film inside lithium batteries first decomposes, followed by a reaction between the negative electrode material and the electrolyte, resulting in the melting of the membrane. Finally, the positive electrode material and electrolyte decompose. The decomposition temperature range of SEI membrane is generally between 80~120 ℃. These changes in the battery can cause blockage of lithium-ion channels, causing direct contact and short circuit between the positive and negative electrodes, thereby releasing a large amount of heat. In addition, during the decomposition process of these materials, a large amount of gas and heat will be generated, and the internal pressure of the battery will rapidly increase, resulting in thermal runaway phenomena such as battery bulging, rupture, pressure relief valve rupture, and aluminum foil melting. Once thermal runaway occurs, the temperature difference inside the battery can reach 520 ℃. Obviously, this will bring significant harm to the safety of battery use. In addition, when the battery is exposed to extreme low temperature conditions for a long time, it can cause lithium precipitation at the negative electrode of the battery, forming lithium dendrites, and in severe cases, piercing the SEI film, leading to the phenomenon of the battery not working.

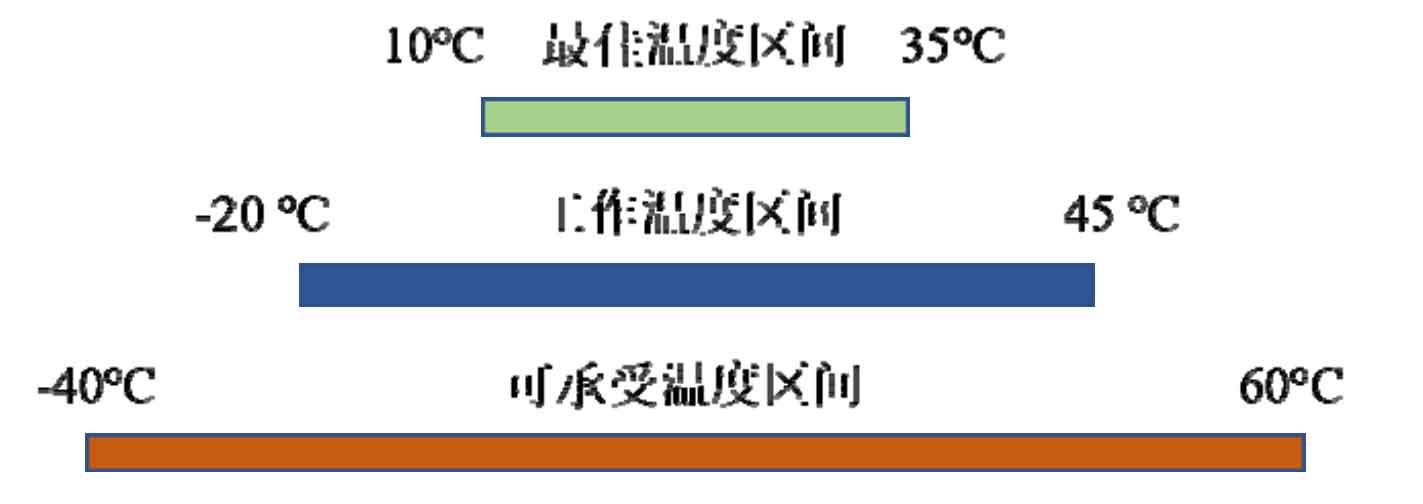

Taking into account the efficiency and safety of lithium batteries, it is currently widely believed that the temperature range that lithium batteries can withstand is -40 ℃ to 60 ℃. Low temperatures can lead to electrolyte solidification and increased impedance, while high temperatures can greatly reduce the capacity, lifespan, and safety of batteries. The optimal temperature range is between 10 ℃ and 35 ℃.

1.3 Temperature uniformity requirements for battery modules

In the actual use process of lithium battery modules, especially in the field of electric vehicle applications, due to the acceleration, deceleration, and idle state of the car, there will be current fluctuations. The fluctuation of current can cause uneven heat generation in the battery pack. After the reciprocating use of the battery pack, the aging degree of each individual battery is different, which can easily lead to overcharging and discharging of the battery, resulting in a decrease in battery performance and even safety issues. In addition, the non-uniformity between individual batteries can cause the entire battery module to experience a barrel short board effect during operation, meaning that the performance of the battery pack is determined by the worst individual battery performance. Dickinson’s research suggests that the temperature gradient between modules reduces the capacity and lifespan of the overall battery module, and they recommend maintaining temperature uniformity between individual cells within the battery pack. Therefore, during the use of lithium batteries, it is not only necessary to provide sufficient comfort to the individual batteries, but also to ensure the uniformity of each individual battery in the battery module in order to improve the overall lifespan of the battery pack. Generally, the temperature difference between each individual battery should not exceed 5 ℃.

1.4 Heat generation model of lithium batteries

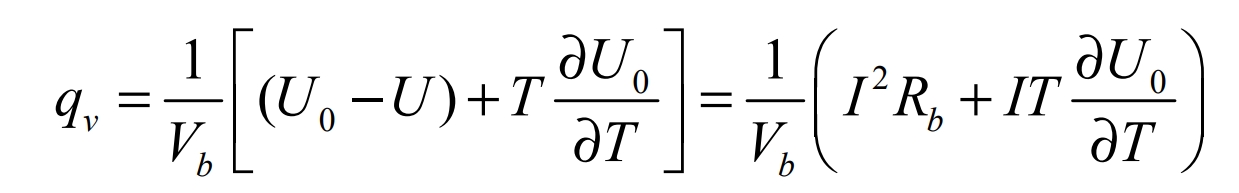

When studying the heat dissipation characteristics of batteries, it is necessary to calculate the heat flux density of the battery. Bernardi et al. proposed a simplified calculation model for battery heat generation, which can be calculated based on the external circuit characteristics of the battery. This model suggests that the mixed heat rate and phase change heat rate of lithium batteries are relatively small in terms of the total amount compared to reversible and irreversible heat, so these two types of heat generation are ignored.

In the simplified calculation formula, it mainly consists of two parts. The first part is the difference between the working voltage and the open circuit voltage, and the second part is the influence of entropy coefficient with temperature. The expression is shown in the formula.

In the formula: U0 is the open circuit voltage; U is the working voltage; I is the charging/discharging current of the battery, with discharge being positive and charging being negative U0/Partial T is the entropy heat coefficient. Research has shown that the entropy heat coefficient has an important impact on the heat generation and temperature changes of the battery, and the value of the entropy heat coefficient of the battery is related to the SOC of the battery, and is not significantly affected by temperature; Rb is the internal resistance of the battery; Vb is the battery volume. Due to the complex internal structure of batteries and the fact that many parameters change with changes in operating conditions, in order to reduce the difficulty of simulation, the following assumptions are generally made for batteries [24]: 1) The physical properties of the internal materials of batteries are always the same; 2) The same material has the same thermal conductivity in the same direction; 3) Neglecting internal radiation heat transfer.

1.5 The Effect of Humidity on the Performance of Lithium Batteries

At present, relevant standards have put forward corresponding specifications and requirements for the environmental temperature and humidity during the production and storage of lithium batteries. However, scholars have relatively little research on the mechanism of thermal runaway of lithium batteries caused by different humidity environments. Research has shown that as environmental humidity increases, it can exacerbate internal reactions in batteries, leading to bulging and shell rupture, ultimately reducing the thermal stability of the electrolyte. Research by Zhang Peihong et al. shows that as environmental humidity increases, the time to reach the critical temperature of thermal runaway gradually decreases. The critical time under 100% ambient humidity is 7.2% earlier than that under 50% humidity. The humidity within a certain range exacerbates the process of battery thermal runaway. Nie Lei et al. pointed out that excessive moisture can cause the decomposition of the electrolyte in the battery to produce hydrofluoric acid, which can corrode metal parts and cause leakage. Furthermore, hydrofluoric acid can damage the SEI membrane, causing irreversible chemical reactions of lithium ions and reducing the energy of the battery. Therefore, humidity control should not be ignored in the design of battery thermal management schemes, especially when the energy storage battery system operates in high temperature and humidity environments.

2. Current status of thermal management research on energy storage batteries at home and abroad

Energy storage technology is one of the core technologies that drives global energy cleanliness, electrification, and efficiency, breaks energy resource and environmental constraints, and achieves global energy transformation and upgrading. With the development of new energy technology, battery energy storage technology has gradually stepped onto the historical stage. As early as around 1840, Grove proposed the concept of hydrogen oxygen fuel cells, which is still a research hotspot to this day. According to statistics, in 2010, the global energy storage battery industry began to gradually grow, achieving a compound growth rate of 33% in 2017. In 2018, compared to 2010, it increased by 45%, and the installed capacity of energy storage batteries reached 175.4 GW. According to the “Energy Storage Industry Research White Paper 2020” released by CNESA in June 2020, as of the end of March 2020, the cumulative installed capacity of power storage projects that have been put into operation globally reached 184.7 GW, a year-on-year increase of 1.9%. Considering the impact of the epidemic in early 2020, it can still be seen that energy storage technology maintains a high growth momentum. For China alone, according to the Energy Storage Application Branch (CESA) of the China Chemical and Physical Power Industry Association, a total of 2586.1 MW of newly added energy storage installed capacity was put into operation throughout 2020. Relevant data shows that energy storage technology has been vigorously promoted in more than 30 countries, including China, the United States, Germany, and others.

2.1 Development Process and Trends of Energy Storage Systems at Home and Abroad

In 1992, Japan successfully developed the first energy storage system using sodium sulfur as the energy storage material and established 50 sodium sulfur battery energy storage systems for demonstration operation. It was not until 2002 that NGK Company officially commercialized its production and supply. In 2008, Japan installed a sodium sulfur battery energy storage system with a total energy storage capacity of 34 MW/244.8 MWh at the Futamata wind farm, which was the most powerful single sodium sulfur battery energy storage system at that time. In 2011, an earthquake occurred in northeastern Japan, causing the Fukushima nuclear leak. Afterwards, Japan broke the monopoly of the traditional power industry, promulgated the Electrical Modification Law, and carried out many projects, especially feasibility studies on lithium batteries, nickel hydrogen batteries, and other energy storage technologies. The development of energy storage technology was regarded as an important component of Japan’s power system reform, which is of milestone significance. In 2016, Japan continued to promote clean technology and launched incentive plans for storage technology and energy efficiency for small businesses and factories in the commercial sector. In 2020, Japan developed a new generation of storage batteries, hoping to significantly reduce production costs through mass production. It can be seen that in recent years, Japan has made comprehensive efforts in policy, technology, and funding, providing tremendous support for the development of the energy storage industry.

The pace of industrial development in the United States is fast, and the automation production and information technology centers have high requirements for power transmission and distribution systems. The emergence of energy storage batteries has attracted widespread attention in the US market. In 2002, NGK provided the first sodium sulfur battery energy storage system with a capacity of 500 KW to the United States. In 2006, the first 1.2 MW/7.2 MWh sodium sulfur battery energy storage system in the United States was put into commercial operation. In 2011, AES Energy Storage Company constructed a 32 MW energy storage system for the 98 MW wind power project in West Virginia, USA. In 2017, the United States put into use its first large-scale battery energy storage device, and by the end of 2017, 708 MW of power generation had been put into operation. In 2020, the Soboba Fire Department in Southern California, USA deployed an all vanadium flow battery energy storage system to ensure emergency services and avoid power grid disruptions caused by wildfires. The rapid development of energy storage technology in the United States cannot be separated from the support of the US government for energy storage technology. They regard energy storage technology as a strategic technology to support the development of new energy, and have formulated a series of industrial incentive policies to support the development of the energy storage industry. For example, the main federal incentive policies are Accelerated Depreciation (MACRS) and Investment Tax Credit (ITC), among others.

In 2002, China began researching all vanadium liquid flow energy storage batteries; In 2006, with strong support from the government, China first developed a prototype of an all vanadium liquid flow energy storage battery system with a capacitance of 10 kW; In 2009, government departments began to focus on the development of the energy storage industry. In 2010, the development of the energy storage industry was first mentioned in the Renewable Energy Law Amendment. In 2013, the Guodian Longyuan Woniushi Wind Farm Dalian Rongke 5 MW/10 MWh all vanadium flow battery energy storage system was successfully connected to the grid and operated. In 2016, the 13th Five Year Plan explicitly proposed to focus on promoting energy reserve facilities, key energy technology and equipment, and accelerate the research and application of technologies such as photothermal power generation and large-scale energy storage. In January 2020, the Comprehensive Department of the National Energy Administration and others jointly formulated the “Implementation Plan for Strengthening Energy Storage Standardization Work” to strengthen the standardization construction of the energy storage industry and promote high-quality development of the energy storage industry. China’s energy storage industry started relatively late, but has developed rapidly. To this day, China is still vigorously developing and promoting the research and operation of energy storage systems.

In summary, the advancement of energy storage system work is progressing layer by layer. Currently, the research and development of energy storage materials is becoming more mature, and thermal management technology has become a bottleneck restricting the development of energy storage systems. Therefore, improving the safety, usability, and lifespan of energy storage batteries based on thermal management technology is an important issue that needs to be urgently solved in energy storage battery research.

2.2 Research status of thermal management technology for energy storage systems at home and abroad

The goal of thermal management for containerized energy storage systems is to provide a comfortable ambient temperature for battery modules. The structure of the thermal management system for batteries must meet the characteristics of compact structure, low cost, high safety, and strong universality. In addition, economic requirements also need to be considered, that is, the utilization of internal waste heat in the energy storage system to meet environmental conditions such as environmental friendliness and resource conservation.

At present, the thermal management technology for batteries mainly includes the following methods: air cooling, liquid cooling, phase change material cooling, and heat pipe cooling.

Air cooling is a heat management technology that uses gas as the heat transfer medium, abbreviated as air cooling. It sends low-temperature medium into the system, and the medium flows through the surface of the battery using two heat transfer methods: heat conduction and convection to remove the heat released by the battery, thus achieving the purpose of cooling. Air cooling is mainly divided into natural cooling and forced cooling. Natural cooling utilizes natural wind pressure, air temperature difference, air density difference, etc. to dissipate heat from the battery; Forced cooling is the process of cooling a battery through mechanical means, usually achieved through ventilation. The two cooling methods involve simple cooling structures, easy installation, and low cost, but they cannot meet the heat dissipation requirements of energy storage systems with large capacitance, and the temperature difference between the inlet and outlet battery packs is too large, which means that the battery heat dissipation is uneven.

Liquid cooling is a thermal management technology that uses liquid as the heat transfer medium, abbreviated as liquid cooling. It utilizes the high thermal capacity and heat transfer coefficient of liquids to exchange heat between low-temperature liquids and high-temperature batteries, thereby achieving the purpose of cooling. However, the cooling system involved has a complex structure, low economic benefits, and significant technical difficulties in installation and subsequent maintenance.

Phase change material cooling is the use of its own phase transition to achieve the purpose of battery heat dissipation. The biggest impact on its heat dissipation effect is the selection of phase change materials. When the specific heat capacity and heat transfer coefficient of the selected phase change material are larger, the better the cooling effect under the same conditions, and vice versa, the worse the cooling effect. This type of material itself does not have heat dissipation capacity and needs to be used in conjunction with other heat dissipation methods.

Heat pipe cooling utilizes the evaporation of the medium at the heat absorbing end of the heat pipe to carry away the heat of the battery. The heat releasing end of the heat pipe disperses the heat to the outside world through condensation, thereby achieving the purpose of cooling the battery. This cooling method can arbitrarily change the size of the heat transfer area and is suitable for heat transfer over long distances.

From the existing research, it can be seen that in the field of thermal management of container energy storage systems, liquid cooling technology, phase change heat transfer technology, and heat pipe cooling technology still remain in the laboratory stage due to their inherent challenges such as complex systems, large volumes, easy leakage of cooling media, and high prices. Therefore, air cooling technology is currently the preferred solution for heat dissipation of container energy storage batteries. The following will discuss air cooling technology based on relevant domestic and foreign literature.

Zhang Zifeng et al. combined natural ventilation with mechanical ventilation and installed louvers on the side walls of containers to form natural ventilation. At the same time, establish a sealed connection between the air wall and the container wall. The air duct guides the air conditioning outlet into the air wall. A small hole is opened on the side of the air wall near the battery for air outlet, forming mechanical ventilation. The experimental results show that this heat dissipation method makes the temperature field inside the container more uniform.

Tang Yunfeng et al. have corresponding ventilation openings in the upper and lower parts of the container battery, and install a fan system on the top of the container. The fan system is divided into three levels: strong wind, normal wind, and weak wind. The wind speed of the fan system is adjusted according to the temperature in the container to save electricity; The ventilation opening and fan system form convective heat dissipation.

Li Miaolin et al. established a model of air-cooled heat dissipation structure for lithium batteries based on CFD simulation software, simulated and analyzed the temperature field and flow field of the battery. Based on the simulation results, the three factors of inlet angle, outlet angle, and battery spacing were modified to obtain a local optimal solution. The heat dissipation effect of the battery model was optimized, and the optimized model was obtained. Compared with the initial model simulation results, Optimize the model to reduce the maximum temperature of the battery pack by 9 55%, temperature difference decreased by 25% 89%.

Wang Tianbo et al. established the air-cooled heat dissipation structure of lithium-ion battery packs as the research object, and used computational fluid dynamics (CFD) numerical calculation method to optimize the heat dissipation structure. The results showed that when the inlet and outlet areas remained unchanged, the lateral ventilation heat dissipation method was used, and the shape of the inlet and outlet was circular, the heat dissipation effect was the best.

Sun et al. conducted modeling and analysis on different cooling channel structures, and the results showed that the “z” shaped cooling channel structure can reduce the temperature difference between battery packs.

Based on CFD simulation, Yuan et al. added the optimal geometric structure of the cold plate to the thermal management system of electric vehicles to control the temperature of the battery pack, and simulated the cooling effect of different structural parameters of the cold plate on the battery pack. They conducted joint simulation using MATLAB and fluent to obtain the optimal cold plate layout structure, inlet speed, and temperature parameters.

Liang Changjie et al. added a guide plate in the gap between battery packs and studied the temperature distribution inside the battery system by changing the structural parameters such as the shape and position of the guide plate. The simulation results obtained relatively optimal structural parameters of the guide plate, further improving the output power, safety, and lifespan of the battery.

Lou Yingying et al. proposed that in the case of large available space, the battery pack can be arranged in a wavy shape, and this arrangement of battery modules has a drainage effect, guiding more airflow to participate in the heat dissipation of the battery system.

Fan L et al. arranged 8 rectangular batteries with different spacing to verify the changes in battery temperature under different battery spacing. The experimental results showed that, with other parameters unchanged, increasing the battery spacing to a certain extent would increase the maximum temperature, but the temperature between the batteries was relatively uniform.

Wang Xiaosong et al. added a guide plate in the air duct to make the flow field and temperature field in the energy storage battery container more uniform.

Yang Kaijie et al. further studied the influence of the size and arrangement angle of the guide plate on gas flow and heat transfer characteristics, and the results showed that reasonable arrangement of the guide plate can reduce the surface temperature of the battery to below 60 ℃.

The “main air duct+riser” air supply scheme designed by Zou Yitao et al. can achieve a uniform and good air outlet effect.

In summary, research on battery thermal management systems is mainly reflected in the following aspects: firstly, the cooling of batteries mostly adopts forced cooling or a combination of natural cooling and forced cooling; 2、 The location, size, and layout shape of the inlet and outlet of the thermal management system will have an impact on the cooling effect of the battery; 3、 According to actual needs, it can be considered to arrange geometric structures such as cold plates and guide plates in the thermal management system; 4、 The arrangement and arrangement of battery modules is also one of the factors affecting the heat dissipation efficiency of batteries.

3. Summary

Although the existing research results have greatly promoted the development of air technology, due to the low specific heat capacity and thermal conductivity of air, further research is needed for the application of air cooling in energy storage battery environments with high heat flux density. In addition, in order to solve the problem of dense heat dissipation of container energy storage batteries, existing air supply schemes have the problem of excessive cooling capacity, which is not in line with the energy-saving design goal of energy storage batteries themselves. Furthermore, container energy storage batteries generally use commercial and standardized batteries, which limits the space for thermal design optimization of batteries. Therefore, under the premise of pursuing high capacity development in container energy storage technology, how to achieve efficient, energy-saving, and personalized thermal management of energy storage batteries is an urgent problem to be solved.

Taking a certain container energy storage system as the research object, an analysis and optimization study was conducted on its thermal management system, aiming to minimize the surface temperature of internal cells and DC-DC components and meet the requirements of uniformity under the specified air supply volume.

Based on the above concept, the research content and chapter arrangement of this article are as follows:

Energy storage battery system model and numerical calculation method. Establish an overall physical model of the container, propose a thermal management plan based on the working mechanism of the container energy storage system, and provide processing strategies for thermal analysis. Secondly, analyze the heat transfer and flow simulation methods and mathematical models used in the calculation. On this basis, verify the calculation algorithm and grid independence of the air duct model and battery box model to determine the grid level for simulation calculations.

Optimization design of flow field and temperature field in battery box. Based on the CFD simulation method, numerical simulation is conducted on the battery box to obtain the general laws of flow and heat transfer in the battery box. On this basis, analyze the factors that affect the above rules and optimize them accordingly to obtain a battery box thermal management plan that meets the requirements.

Design and optimization of air duct flow field. On the basis of analyzing the thermal management mode of energy storage batteries, a device comfort concept based on personalized air supply is proposed, and evaluation indicators for air duct uniformity are provided. Based on this technology, the CFD simulation calculation method is used to explore the regularity of the flow field characteristics of the main air duct and the riser. Finally, explore and optimize the uniformity of the air outlet of the merged cooling pipes.

Optimization of the overall spatial flow field and temperature field of containers. Based on the optimization results of the battery box and cooling pipeline, the overall fusion calculation of the container energy storage system is carried out, and the problems and calculation deviations caused by the fusion calculation are given, along with solutions and countermeasures.