Chapter 1: Different Types of Battery Storage

There are various types of batteries used in battery storage systems, each with distinct chemical compositions and performance characteristics. Here’s an overview of some common types:

1. Lithium-Ion Batteries:

- Chemistry: Lithium-ion batteries use lithium as the primary active material. Various cathode materials, such as lithium cobalt oxide, lithium iron phosphate, and lithium nickel cobalt manganese oxide, are used to create different types of lithium-ion batteries.

- Advantages: High energy density, long cycle life, lightweight, fast charging capability, and lower self-discharge rate.

- Applications: Widely used in portable electronics, electric vehicles (EVs), and residential and commercial energy storage systems.

2. Lead-Acid Batteries:

- Chemistry: Lead-acid batteries use lead dioxide as the positive electrode and sponge lead as the negative electrode, with a sulfuric acid electrolyte.

- Advantages: Cost-effective, well-established technology, suitable for deep-cycle applications, and high surge current capabilities.

- Applications: Commonly used in automotive starting batteries, backup power systems, and off-grid energy storage.

3. Sodium Sulfur Batteries:

- Chemistry: Sodium sulfur batteries use molten sulfur as the positive electrode, molten sodium as the negative electrode, and a solid ceramic electrolyte.

- Advantages: High energy density, long cycle life, and the ability to handle high temperatures.

- Applications: Grid-scale energy storage, particularly for renewable integration and peak shaving.

4. Flow Batteries:

- Chemistry: Flow batteries use electrolyte solutions stored in separate tanks. The chemical reaction occurs when the electrolytes flow through a cell stack.

- Advantages: Scalability, longer cycle life, and the ability to independently adjust energy and power capacities.

- Applications: Grid-scale energy storage, renewable integration, and managing variable energy supply.

5. Nickel-Iron Batteries (NiFe):

- Chemistry: Nickel-iron batteries use nickel oxide as the positive electrode, iron oxide as the negative electrode, and a potassium hydroxide electrolyte.

- Advantages: Long cycle life, durability, and resistance to deep discharges.

- Applications: Historically used in off-grid and industrial applications, with renewed interest due to their longevity and eco-friendliness.

6. Zinc-Bromine Batteries:

- Chemistry: Zinc-bromine batteries use zinc and bromine solutions as the active materials in separate tanks.

- Advantages: High energy density, relatively long cycle life, and the ability to store energy for longer periods.

- Applications: Grid-scale energy storage, renewable integration, and load shifting.

Each type of battery has its own strengths and limitations, making them suitable for different applications. When choosing a battery storage system, it’s essential to consider factors such as energy requirements, cycle life, cost, efficiency, and environmental considerations to determine the best fit for your specific needs.

Chapter 2: The Energy Density of Battery Storage

Energy density refers to the amount of energy that a battery can store per unit volume or mass. It is a critical factor in determining the practicality and efficiency of battery storage systems. Different battery technologies have varying energy densities, which impact their suitability for different applications. Here’s an overview of the energy density of some common battery storage technologies:

1. Lithium-Ion Batteries:

- Lithium-ion batteries offer high energy density, making them popular for portable devices, electric vehicles (EVs), and residential energy storage.

- Energy density can vary based on the specific cathode and anode materials used in the battery chemistry.

2. Lead-Acid Batteries:

- Lead-acid batteries have relatively lower energy density compared to lithium-ion batteries.

- They are commonly used for applications where cost-effectiveness and robustness are more important than high energy density.

3. Sodium Sulfur Batteries:

- Sodium sulfur batteries have high energy density, making them suitable for grid-scale energy storage applications.

- They can store a significant amount of energy, particularly when integrated with renewable energy sources.

4. Flow Batteries:

- Flow batteries have moderate energy density, but they offer the advantage of scalability and longer cycle life.

- They are often used for large-scale energy storage applications.

5. Nickel-Iron Batteries (NiFe):

- Nickel-iron batteries have moderate energy density and are known for their durability and long cycle life.

- They were historically used for off-grid applications.

6. Zinc-Bromine Batteries:

- Zinc-bromine batteries have high energy density and are suitable for grid-scale energy storage and load shifting.

It’s important to note that while energy density is a significant consideration, other factors such as cycle life, charging/discharging efficiency, safety, and cost also play crucial roles in selecting the appropriate battery storage technology for a given application.

Advancements in battery technology strive to increase energy density while maintaining safety and reliability. This is particularly important for applications that require high energy storage capacity, such as renewable energy integration, peak shaving, and grid stabilization.

Chapter 3: The Power Density of Battery Storage

Power density refers to the rate at which a battery can deliver electrical power per unit volume or mass. It’s an important parameter for battery storage systems, especially in applications where rapid power output is essential. Different battery technologies have varying power densities that influence their performance in different scenarios. Here’s an overview of the power density of some common battery storage technologies:

1. Lithium-Ion Batteries:

- Lithium-ion batteries offer relatively high power density, making them suitable for applications that require quick bursts of power or rapid charging/discharging.

- This characteristic is beneficial for electric vehicles (EVs), where acceleration and regenerative braking demand high power output.

2. Lead-Acid Batteries:

- Lead-acid batteries generally have lower power density compared to lithium-ion batteries.

- They are often used in applications where sustained high power output is not a primary requirement.

3. Sodium Sulfur Batteries:

- Sodium sulfur batteries can provide high power density along with their high energy density.

- This makes them suitable for applications requiring both rapid power delivery and extended energy storage.

4. Flow Batteries:

- Flow batteries can offer moderate power density, but their advantage lies in scalability and flexibility rather than instantaneous power delivery.

- They can be designed to match specific power and energy requirements.

5. Nickel-Iron Batteries (NiFe):

- Nickel-iron batteries have moderate power density and are known for their robustness and resistance to overloads.

6. Zinc-Bromine Batteries:

- Zinc-bromine batteries can provide moderate power density, making them suitable for grid-scale energy storage and load shifting.

When selecting a battery storage technology, it’s important to consider both energy density and power density based on the specific application requirements. Some applications, such as grid stabilization or backup power systems, may prioritize high power density to respond quickly to fluctuations in demand. Others, like long-duration energy storage, may prioritize energy density to store larger amounts of energy.

Advancements in battery technology aim to achieve a balance between energy density and power density while maintaining safety, efficiency, and cost-effectiveness.

Chapter 4: Battery Management System (BMS) for Battery Storage

Battery Management System (BMS) plays a crucial role in ensuring the safety, performance, and longevity of battery storage systems. It monitors various parameters and actively manages the battery’s operation. Here’s how a BMS works and its key functions:

1. Parameter Monitoring:

- The BMS continuously monitors critical parameters such as temperature, voltage, current, state of charge (SoC), and state of health (SoH) of individual cells within the battery pack.

2. Overvoltage and Undervoltage Protection:

- The BMS prevents cells from overcharging (overvoltage) or discharging too deeply (undervoltage), which can damage the cells and reduce their lifespan.

3. Cell Balancing:

- In battery packs composed of multiple cells, the BMS ensures that cells remain balanced by redistributing charge among them.

- Cell balancing helps maintain uniform performance and extends the overall pack life.

4. Thermal Management:

- Monitoring temperature is crucial to prevent overheating, which can compromise battery safety and performance.

- The BMS may activate cooling or heating systems to keep the battery within a safe temperature range.

5. Current Limiting:

- The BMS limits the rate of discharge and charge to prevent excessive currents that could damage cells or pose safety risks.

6. State of Charge (SoC) Estimation:

- The BMS estimates the SoC, indicating the battery’s remaining usable energy. Accurate SoC estimation helps prevent overcharging or deep discharging.

7. State of Health (SoH) Monitoring:

- The BMS tracks the SoH, providing insights into the battery’s overall health and capacity degradation over time.

8. Communication and Data Logging:

- Many BMS units allow communication with external devices and data logging for performance analysis and system optimization.

9. Fault Detection and Alarms:

- If the BMS detects abnormalities or potential issues, it triggers alarms or notifications to alert users or operators.

10. Shutdown in Critical Conditions:

- In extreme cases, such as battery pack malfunction or unsafe conditions, the BMS may initiate a safe shutdown to prevent damage or hazards.

11. Safety Compliance:

- BMS designs often adhere to safety standards and regulations to ensure the system’s safe operation.

12. Adaptation and Learning:

- Some advanced BMS units adapt to changes in battery performance over time and adjust their management strategies accordingly.

A robust BMS is essential to maintain the reliability and safety of battery storage systems, especially as batteries age and encounter varying operating conditions. Properly managing and protecting the battery cells not only ensures optimal performance but also prevents potentially hazardous situations.

Chapter 5: The Cycle Life of Battery Storage

The cycle life of a battery storage system refers to the number of charge and discharge cycles a battery can undergo before its capacity and performance degrade to a specified level. It’s an important factor in determining the longevity and cost-effectiveness of a battery system. Different battery technologies have varying cycle life characteristics. Here’s an overview of cycle life for some common battery storage technologies:

1. Lithium-Ion Batteries:

- Cycle Life: Lithium-ion batteries typically have cycle lives ranging from 500 to 3,000 cycles, depending on the specific chemistry and depth of discharge.

- Depth of Discharge (DoD): Shallower discharges (e.g., 20-80%) generally result in longer cycle life compared to deeper discharges.

2. Lead-Acid Batteries:

- Cycle Life: Standard lead-acid batteries have cycle lives of around 300 to 700 cycles, while deep-cycle lead-acid batteries can achieve up to 1,000 cycles.

- Depth of Discharge (DoD): Deeper discharges reduce cycle life, and shallow discharges are recommended for longer life.

3. Sodium Sulfur Batteries:

- Cycle Life: Sodium sulfur batteries often have cycle lives of around 3,000 cycles or more.

- These batteries are known for their long cycle life and are suitable for grid-scale applications.

4. Flow Batteries:

- Cycle Life: Flow batteries typically have cycle lives ranging from 5,000 to 20,000 cycles or more.

- Their design allows for extended cycle life without significant capacity degradation.

5. Nickel-Iron Batteries (NiFe):

- Cycle Life: Nickel-iron batteries are known for their exceptional longevity, with cycle lives ranging from 10,000 to 20,000 cycles.

- They are valued for their ability to endure a large number of cycles.

6. Zinc-Bromine Batteries:

- Cycle Life: Zinc-bromine batteries can have cycle lives ranging from 1,000 to 5,000 cycles, depending on the specific design.

- Proper maintenance and operating conditions can impact cycle life.

It’s important to note that cycle life can be affected by various factors, including depth of discharge, temperature, charging and discharging rates, and overall battery management. Manufacturers often specify the expected cycle life under specific operating conditions. A longer cycle life is desirable, as it reduces the need for battery replacements and contributes to the overall cost-effectiveness of the battery storage system.

When choosing a battery technology, it’s important to consider both cycle life and other factors, such as energy density, power density, and cost, to ensure that the chosen technology aligns with the intended application and operational requirements.

Chapter 6: The Charging and Discharging Efficiency of Battery Storage

The charging and discharging efficiency of a battery storage system is a critical factor that affects the overall energy conversion efficiency of the system. Energy losses during these processes can impact the amount of usable energy that can be stored and retrieved from the battery. Let’s explore how charging and discharging efficiency works:

1. Charging Efficiency:

- Charging efficiency refers to the percentage of energy that is successfully stored in the battery during the charging process, relative to the energy input.

- Energy losses occur primarily due to heat generation and resistive losses within the battery cells and the charging circuitry.

- Higher-quality batteries and charging systems typically have better charging efficiency, minimizing energy losses.

2. Discharging Efficiency:

- Discharging efficiency refers to the percentage of stored energy that can be retrieved from the battery during the discharging process, relative to the stored energy.

- Energy losses occur during discharging due to internal resistance, heat generation, and other factors.

- Similar to charging efficiency, high-quality batteries tend to have better discharging efficiency.

3. Round-Trip Efficiency:

- The combined efficiency of both charging and discharging processes is often referred to as round-trip efficiency.

- Round-trip efficiency accounts for energy losses in both directions and provides a comprehensive measure of how much energy is retained after a complete charging and discharging cycle.

4. Factors Affecting Efficiency:

- Battery Chemistry: Different battery chemistries have varying inherent efficiencies due to their electrochemical processes.

- Charge/Discharge Rates: Efficiency can vary based on the rate at which the battery is charged or discharged.

- Temperature: Operating outside the optimal temperature range can reduce efficiency.

- Depth of Discharge: Deeper discharges can result in lower efficiency.

5. Impact on System Performance:

- Lower charging and discharging efficiency means that a larger amount of energy is lost as heat and not stored or utilized effectively.

- In applications with frequent charge and discharge cycles, such as solar energy storage, high efficiency is crucial to maximize system performance and financial savings.

6. Comparison to Other Losses:

- Charging and discharging losses are just one aspect of overall energy losses in a battery system. Other losses include self-discharge, standby losses, and losses during energy conversion (e.g., from DC to AC through an inverter).

When evaluating battery storage options, it’s important to consider both energy density and efficiency. While high energy density allows for more energy storage, high efficiency ensures that a larger portion of the stored energy can be effectively utilized. Therefore, a balance between energy density, efficiency, and other performance factors should be considered to choose the most suitable battery technology for a given application.

Chapter 7: Battery Storage Charging Control

Battery charging control is a critical aspect of battery storage management that aims to optimize charging processes while ensuring safety and prolonging the battery’s lifespan. Here are some strategies and practices for effective battery charging control:

1. Charge Rate Management:

- Control the rate of charging to prevent excessive heat generation, which can damage the battery cells.

- Use charging profiles that gradually ramp up the charge rate, especially for fast-charging scenarios.

2. Voltage Limits:

- Implement voltage limits to prevent overcharging, which can cause electrolyte breakdown, capacity loss, and even safety hazards.

- Modern Battery Management Systems (BMS) often include overvoltage protection mechanisms.

3. Temperature Monitoring and Control:

- Monitor battery temperature during charging and implement thermal management systems to prevent overheating.

- Avoid charging at extreme temperatures that could negatively impact battery health.

4. State of Charge (SoC) Management:

- Avoid charging to full capacity (100% SoC) unless necessary, as it can cause stress on battery cells and lead to capacity degradation.

- Employ partial charging and discharging to extend battery life. Charging to around 80% SoC and discharging to 20-30% SoC is commonly recommended.

5. Depth of Discharge (DoD) Limits:

- Limit the depth of discharge during each cycle to prevent excessive stress on the battery.

- Deeper discharges can accelerate capacity loss and reduce cycle life.

6. Charge Termination:

- Implement charge termination mechanisms to automatically stop charging when the battery reaches a predetermined state of charge or voltage.

- This prevents overcharging and minimizes energy losses.

7. Battery Balancing:

- Ensure that individual cells within a battery pack are balanced during charging to prevent overcharging of some cells and undercharging of others.

- Active balancing systems redistribute charge among cells to maintain uniform performance.

8. Charging Scheduling:

- Schedule charging during times when energy demand is lower or when renewable energy sources are producing surplus energy.

- This maximizes the use of clean energy and reduces stress on the grid.

9. Adaptive Charging Algorithms:

- Some advanced battery management systems use adaptive algorithms that learn from battery behavior over time and adjust charging strategies accordingly.

10. Follow Manufacturer Guidelines:

- Adhere to manufacturer guidelines and recommended charging practices for the specific battery technology you’re using.

By implementing these charging control strategies, you can help maintain battery health, safety, and longevity, while also optimizing the performance and efficiency of your battery storage system.

Chapter 8: Battery Storage Discharging Control

Battery storage discharge control is essential to ensure stable and controlled power output during discharge while avoiding excessive discharge that could damage the battery and compromise its performance. Here are strategies and practices for effective battery discharge control:

1. Power Output Stability:

- Control the rate of discharge to ensure stable power output that aligns with the intended application’s requirements.

- Use discharge profiles that maintain a consistent power output, especially during critical operations.

2. Voltage Limits:

- Implement voltage limits to prevent excessive discharge that could lead to low cell voltages and potential damage.

- Modern Battery Management Systems (BMS) often include undervoltage protection mechanisms.

3. Temperature Monitoring and Control:

- Monitor battery temperature during discharge and implement thermal management systems to prevent overheating.

- Avoid discharging at extreme temperatures that could negatively impact battery health.

4. State of Charge (SoC) Management:

- Avoid deep discharges that could stress the battery and lead to capacity loss.

- Use partial discharges and maintain a certain minimum SoC to preserve battery life.

5. Depth of Discharge (DoD) Limits:

- Implement limits on the depth of discharge to prevent excessive stress on the battery cells.

- Deeper discharges can lead to capacity degradation and reduced cycle life.

6. Load Balancing:

- If your battery storage system is used in combination with other energy sources, such as solar panels, ensure that the load is balanced to avoid overloading the battery during discharge.

7. Discharge Scheduling:

- Schedule discharges to align with energy demand or specific operational needs.

- Optimize the use of stored energy during peak demand hours or when electricity costs are higher.

8. Adaptive Discharge Algorithms:

- Some advanced battery management systems use adaptive algorithms to adjust discharge strategies based on battery behavior and changing energy demand.

9. Follow Manufacturer Guidelines:

- Adhere to manufacturer guidelines and recommended discharge practices for the specific battery technology you’re using.

10. Reserve Capacity:

- Keep a reserve capacity to avoid fully depleting the battery during discharge, which can help prevent over-discharge and extend battery life.

11. Emergency Power Planning:

- If the battery storage system is used for backup power, ensure that it’s programmed to provide stable and reliable power during grid outages.

By implementing these discharge control strategies, you can ensure that your battery storage system delivers stable and controlled power output while maintaining the health and performance of the battery over its operational life.

Chapter 9: Temperature Management of Battery Storage

Temperature management is crucial for battery storage systems, as the temperature of batteries significantly impacts their performance, safety, and lifespan. Batteries operate optimally within specific temperature ranges, and effective cooling and heating measures are necessary to ensure their reliability. Here’s how temperature management of battery storage works:

1. Optimal Temperature Range:

- Different battery chemistries have recommended operating temperature ranges. For example, lithium-ion batteries often perform best between 20°C and 30°C (68°F and 86°F).

- Operating within the optimal temperature range helps maintain efficiency and extends battery life.

2. Effects of Temperature:

- High Temperatures: Excessive heat can accelerate chemical reactions within the battery, leading to capacity loss, increased internal resistance, and reduced cycle life.

- Low Temperatures: Cold temperatures can slow down chemical reactions, reducing battery performance and capacity.

3. Thermal Management Systems:

- Active Cooling: Systems such as fans, liquid cooling, or phase change materials dissipate heat generated during charging and discharging.

- Active Heating: Electric heaters or resistive elements warm the battery to improve performance in cold conditions.

4. Temperature Sensors:

- Integrated temperature sensors monitor battery temperature and provide data to the Battery Management System (BMS) for control.

5. Temperature Control Algorithms:

- BMS algorithms adjust charging and discharging rates based on temperature to prevent overheating or underperformance.

6. Thermal Insulation:

- Insulating materials can help maintain a consistent temperature within the battery storage enclosure, reducing the impact of external temperature fluctuations.

7. Preconditioning:

- Preconditioning involves adjusting battery temperature before operation to ensure optimal performance and efficiency.

8. Avoiding Extreme Conditions:

- Implement measures to prevent exposure to extreme temperature conditions, such as direct sunlight or freezing temperatures.

9. Seasonal Considerations:

- Adjust thermal management strategies based on seasonal temperature changes, ensuring efficient operation year-round.

10. Emergency Cooling and Heating:

- Design systems with emergency cooling and heating mechanisms to safeguard the battery’s health during temperature extremes.

11. Battery Enclosure Design:

- Design enclosures that provide proper ventilation and insulation, balancing cooling and heating requirements.

12. Monitoring and Alarms:

- Implement temperature monitoring and alarms to alert users or operators of temperature deviations that could impact battery performance or safety.

Effectively managing battery temperature is essential for maximizing the performance, efficiency, and lifespan of battery storage systems. Proper thermal management practices ensure that the batteries remain within their optimal temperature range, leading to better energy storage performance and longer overall system life.

Chapter 10: The Balance Management of Battery Storage

Battery balance management is a critical aspect of battery storage systems that use multiple battery cells or modules. It ensures that the individual cells or modules within a battery pack maintain consistent performance and prevent overcharging or undercharging of any cell. Here’s how balance management works:

1. What is Battery Balancing:

- Battery cells within a pack can have slight variations in capacity, internal resistance, and voltage characteristics. Over time, these variations can lead to uneven charging and discharging, reducing overall pack efficiency and capacity.

2. Cell Balancing Techniques:

- Passive Balancing: Passive balancing uses resistors to divert excess charge from cells that are fully charged to cells that need more charging.

- Active Balancing: Active balancing employs electronic circuits to redistribute energy between cells, achieving more precise balancing and efficiency.

3. Functions of Battery Balancing:

- Equalization: Balancing ensures that cells have similar state of charge (SoC) and voltage, preventing any cell from being overcharged or overdischarged.

- Prolonged Lifespan: Balanced cells experience less stress, leading to a longer overall battery pack lifespan.

- Improved Performance: Balanced cells provide consistent performance, maximizing energy extraction and storage.

4. Balancing Algorithms:

- Battery Management Systems (BMS) use algorithms to determine when and how to balance cells.

- Algorithms consider factors like cell voltage, SoC, and temperature to make informed decisions.

5. Passive Balancing Challenges:

- Passive balancing can be less efficient than active balancing because it dissipates energy as heat.

- In applications with large cell imbalances, passive balancing might not be sufficient.

6. Active Balancing Advantages:

- Active balancing is more efficient and capable of addressing larger cell imbalances effectively.

- It redistributes energy rather than dissipating it as heat.

7. Frequency of Balancing:

- Balancing frequency depends on the battery pack design, cell characteristics, and operational conditions.

- Some systems balance cells during charging, discharging, or both.

8. Battery Replacement and Expansion:

- When replacing or expanding battery modules, proper balancing ensures the new modules integrate seamlessly.

9. Monitoring and Alerts:

- BMS monitors cell voltages and balances cells as needed.

- Alerts can be generated if imbalances exceed safe thresholds.

10. Impact on Performance:

- Proper balance management contributes to consistent energy output, better efficiency, and overall improved battery performance.

In systems with multiple cells or modules, effective balance management is essential to ensure optimal energy storage, maximize battery life, and maintain safe and reliable operation. Properly balanced battery cells contribute to the overall stability and longevity of the battery storage system.

Chapter 11: Connection and Integration of Battery Storage

the connection and integration of multiple batteries into an energy storage system is a crucial step to ensure the system’s reliability, efficiency, and safety. The proper connection and integration technology depend on the type of batteries being used, the desired capacity, and the specific application. Here’s how the connection and integration process works:

1. Parallel and Series Connections:

- Batteries can be connected in parallel to increase capacity (Ah) while maintaining voltage.

- Batteries can also be connected in series to increase voltage while maintaining capacity.

2. Battery Management System (BMS):

- An advanced BMS is essential for monitoring, managing, and controlling the individual batteries within the system.

- The BMS ensures that batteries are charged, discharged, and balanced properly.

3. Wiring and Interconnects:

- High-quality wiring and interconnects are crucial to reduce resistance, minimize voltage drops, and prevent overheating.

- Properly sized cables and connectors help maintain efficient energy transfer.

4. Communication:

- Batteries and other components need to communicate with each other and with external systems for monitoring and control purposes.

- Communication protocols like CAN (Controller Area Network) are commonly used in battery storage systems.

5. Current Distribution:

- Balanced current distribution among batteries is essential to prevent overloading of individual batteries and ensure uniform performance.

6. Voltage Matching:

- Batteries connected in series should have similar voltage characteristics to prevent overcharging or overdischarging of any battery.

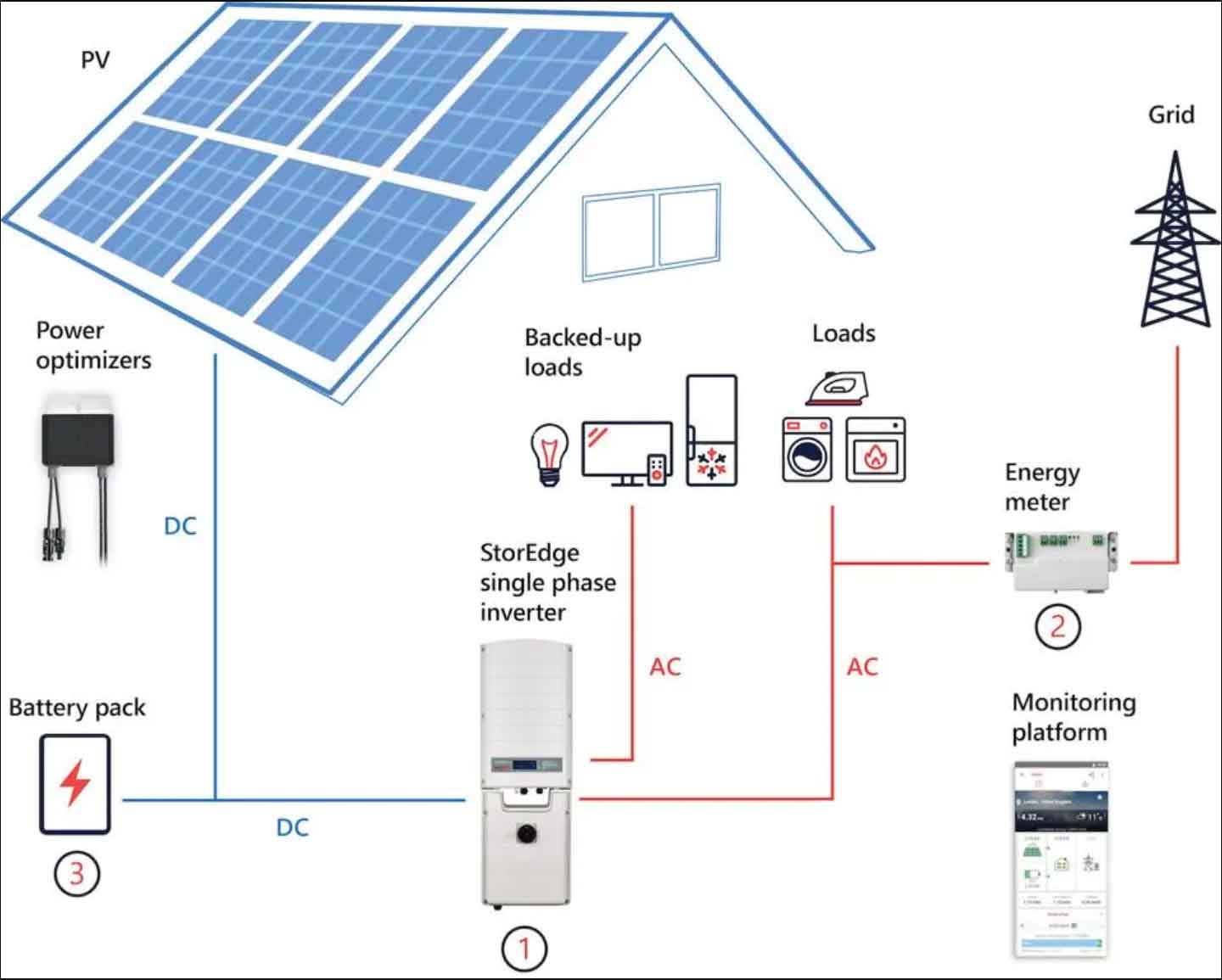

7. Inverter and Power Conversion:

- Battery storage systems are often connected to inverters that convert the stored DC energy into AC power for use in homes or the grid.

8. Safety Considerations:

- Proper fusing, overcurrent protection, and disconnect mechanisms should be integrated to ensure safety during operation and maintenance.

9. Expansion and Scalability:

- Design the system with expansion in mind, allowing for the addition of more batteries in the future.

- Ensure that the integration technology can accommodate the increased capacity.

10. Compatibility:

- Ensure that the batteries, BMS, inverter, and other components are compatible in terms of voltage, capacity, communication protocols, and control interfaces.

11. Compliance with Standards:

- Follow industry standards and regulations for the safe and reliable connection and integration of battery storage systems.

12. Professional Installation:

- Proper installation by qualified professionals ensures that all components are correctly connected and integrated.

The connection and integration of battery storage systems require careful planning and implementation to create a cohesive and efficient energy storage solution. Each component needs to work harmoniously to achieve the desired performance, energy efficiency, and safety.

Chapter 12: Intelligent Control of Battery Storage

Intelligent control of battery storage systems is a key aspect of maximizing their efficiency, performance, and overall value. This involves using advanced software and algorithms to optimize charging and discharging strategies, energy management, and other operational parameters. Here’s how intelligent control works in battery storage systems:

1. Software and Algorithms:

- Intelligent control systems rely on sophisticated software and algorithms that analyze data and make decisions to optimize system operation.

2. Data Inputs:

- The control system collects data from various sources, such as battery parameters (voltage, current, SoC), grid conditions, energy demand, weather forecasts (for renewable integration), and user preferences.

3. Energy Management:

- The control system dynamically manages energy flow between the battery, renewable energy sources (if applicable), and the grid.

- It determines when to charge the battery from the grid, from renewables, or when to discharge based on demand and pricing.

4. Load Shifting:

- Intelligent control can shift energy consumption to off-peak hours when electricity costs are lower.

- Excess energy generated during low-demand periods can be stored for later use.

5. Peak Demand Management:

- The system can be programmed to provide additional power during peak demand periods, helping to reduce grid strain and costs.

6. Frequency Regulation and Grid Stabilization:

- Battery storage systems with intelligent control can provide rapid response to frequency fluctuations in the grid, contributing to stability.

7. Adaptive Algorithms:

- Some systems use adaptive algorithms that learn from historical data and adjust strategies to changing conditions over time.

8. User Interaction and Preferences:

- Intelligent control systems can incorporate user preferences, allowing homeowners or operators to set specific charging/discharging times or prioritize self-consumption.

9. Real-Time Monitoring:

- The control system continuously monitors battery health, performance, and environmental conditions to make informed decisions.

10. Fault Detection and Diagnostics:

- Advanced control systems can detect anomalies, faults, or degraded performance and provide alerts or recommendations for maintenance.

11. Predictive Analysis:

- Some systems use predictive analytics to forecast energy demand and generation patterns, enabling proactive management.

12. Grid Services:

- Battery storage systems with intelligent control can participate in grid services, such as frequency regulation and demand response, to earn additional revenue.

Intelligent control not only optimizes the operation of battery storage systems but also enhances their economic viability and contributes to grid stability. It enables efficient energy utilization, reduces energy costs, and extends the life of the batteries. The flexibility and adaptability of intelligent control systems make them valuable tools for maximizing the benefits of battery storage.

Chapter 13: The Monitoring and Maintenance of Battery Storage

Monitoring and maintenance are crucial aspects of ensuring the stable operation, safety, and longevity of battery storage systems. Real-time monitoring allows you to track the system’s performance, while regular maintenance and troubleshooting help prevent issues and address them promptly. Here’s how monitoring and maintenance work for battery storage systems:

1. Real-Time Monitoring:

- Implement a monitoring system that continuously collects and analyzes data from the battery storage system.

- Monitor parameters such as voltage, current, temperature, state of charge (SoC), state of health (SoH), and any alarms or alerts.

2. Remote Monitoring:

- Some systems allow remote monitoring, enabling users to access real-time data and alerts from their devices.

3. Benefits of Monitoring:

- Early Detection: Monitoring helps detect anomalies, deviations from normal operation, and potential issues before they escalate.

- Performance Optimization: Real-time data allows for fine-tuning of operational parameters to maximize efficiency and performance.

4. Regular Maintenance:

- Perform routine maintenance tasks recommended by the manufacturer or based on the battery technology used.

- Maintenance may include cleaning, inspection, and tightening of connections.

5. Scheduled Inspections:

- Regularly inspect the physical components of the system, including wiring, connections, and enclosures, to ensure everything is in good condition.

6. Cell Balancing:

- If your battery system includes multiple cells, ensure that cell balancing is occurring as needed to maintain uniform performance.

7. Firmware Updates:

- Keep the firmware and software of your battery management and monitoring systems up to date to access the latest features and improvements.

8. Troubleshooting:

- If issues arise, promptly troubleshoot and diagnose the problem using the monitoring data and any error codes or alerts provided by the system.

9. Professional Maintenance:

- Some maintenance tasks, especially those related to electrical components, should be performed by qualified professionals.

10. Safety Considerations:

- Prioritize safety during maintenance by following proper procedures, disconnecting power, and wearing appropriate protective gear.

11. Emergency Response Plan:

- Have an emergency response plan in place to address unexpected situations, such as system failures or hazards.

12. Regular Battery Testing:

- Periodically perform capacity tests and other diagnostic procedures to assess the health of the batteries.

Effective monitoring and maintenance contribute to the longevity and performance of your battery storage system. By staying proactive and addressing issues promptly, you can prevent potential downtime, minimize the risk of system failures, and ensure that your battery storage system continues to operate reliably over time.