As the oil and gas pipeline networks expand into increasingly remote regions, the reliance on traditional grid power for valve chambers has become a significant challenge. These chambers are critical for monitoring and controlling pipeline operations, including parameters like temperature and pressure, and ensuring swift valve closure during emergencies. However, grid coverage in these areas is often insufficient or economically unviable. In this context, the off-grid solar system emerges as a sustainable solution to power valve chambers, ensuring uninterrupted communication, automation, and data transmission. This article provides a comprehensive technical analysis of an integrated off-grid solar system designed for valve chamber telecommunication and instrumentation, focusing on its structure, components, and performance metrics. By leveraging solar energy, this system addresses power scarcity while reducing dependency on conventional grids, thereby enhancing the safety and efficiency of oil and gas infrastructure.

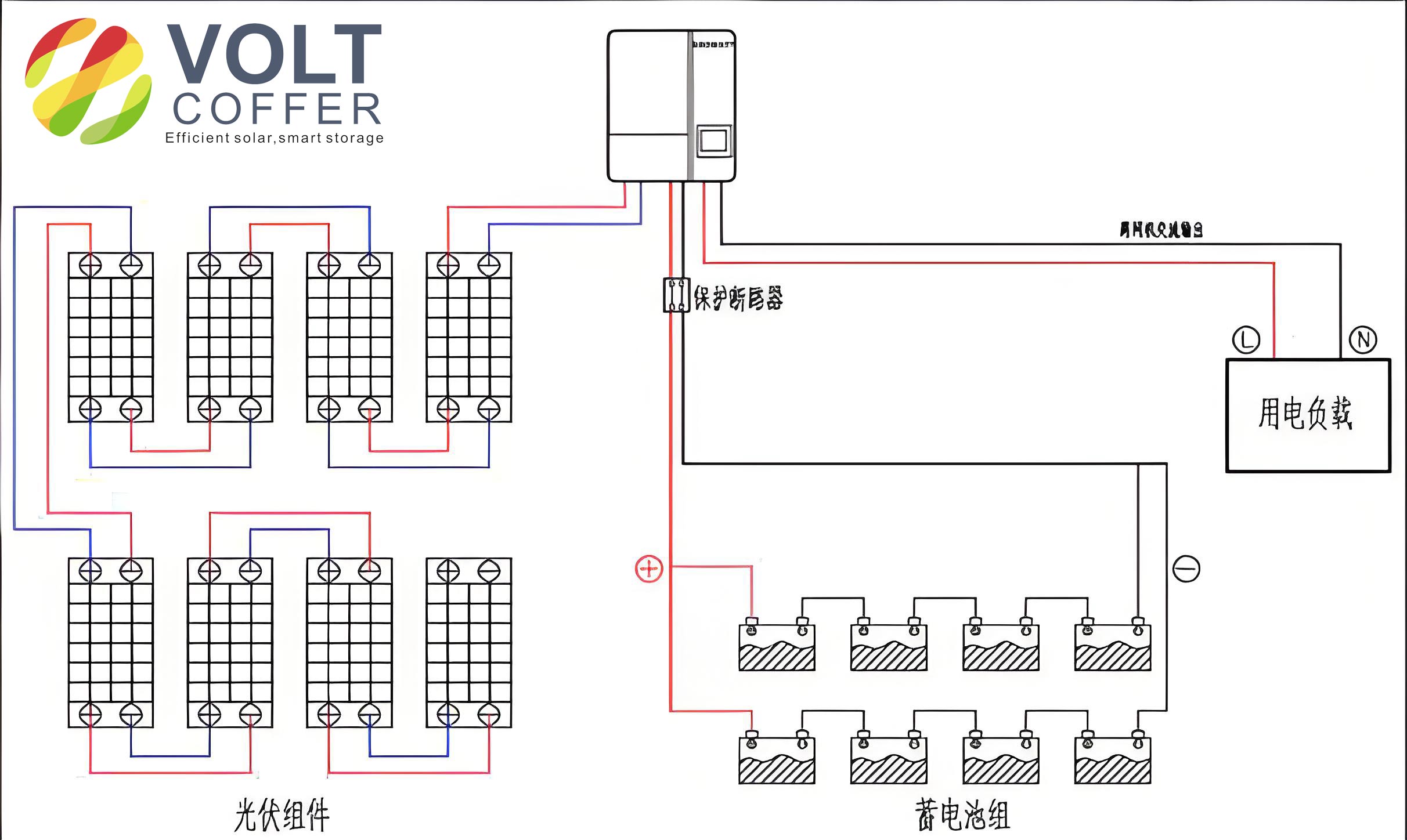

The integrated off-grid solar system for valve chambers combines solar power generation, distribution, control, and communication functionalities into a unified setup. It comprises data acquisition modules, control units, and communication systems that enable real-time monitoring, remote operation, and data transfer. The core of this off-grid solar system is the solar photovoltaic array, which harnesses sunlight to generate electricity, stored in batteries for continuous operation during periods of low solar irradiance. This approach not only mitigates the limitations of grid connectivity but also supports the deployment of valve chambers in geographically challenging environments. The following sections delve into the structural design, solar energy system components, and technical specifications, supplemented with formulas and tables to illustrate key aspects.

The structural layout of the off-grid solar system for valve chambers includes a main chamber housing with a solar array mounted on top to maximize space utilization. Internally, the chamber is divided into two compartments: a battery room and a control room, each equipped with dedicated access doors. The control room contains essential cabinets such as the solar power cabinet, communication cabinet for interfacing with remote monitoring systems, and an RTU (Remote Terminal Unit) cabinet for control operations. This design ensures efficient organization and protection of components against environmental factors. The solar array, typically composed of monocrystalline silicon panels, is supported by a robust支架结构 that withstands harsh conditions, including high winds up to 60 m/s. The支架材料, made from hot-dip galvanized steel or anodized aluminum, provides durability and corrosion resistance, with specifications detailed in Table 1. This off-grid solar system is engineered for longevity, with components like the solar panels having a design life exceeding 25 years, ensuring reliable performance in remote valve chamber applications.

| Material Type | Minimum Coating Thickness (μm) |

|---|---|

| Aluminum Alloy | As per industry standards (e.g., 10-25 μm for typical applications) |

| Hot-Dip Galvanized Steel | ≥55 μm average thickness |

The solar photovoltaic matrix is a pivotal component of the off-grid solar system, responsible for converting solar energy into electrical power. The total capacity of the solar array is calculated based on the daily energy consumption of the valve chamber loads and the autonomy required during cloudy periods. The formula for determining the solar panel capacity is given by:

$$ P = W_p \times N_s \times N_p $$

where \( P \) represents the total capacity in watts (W), \( W_p \) is the power rating of a single solar panel in watt-peak (Wp), \( N_s \) is the number of panels connected in series, and \( N_p \) is the number of parallel groups. To account for system losses and ensure reliability, the daily energy demand and battery storage are incorporated using:

$$ P_{\text{wh}} = \frac{C_{\text{wh}}}{T_d \times \eta} $$

Here, \( P_{\text{wh}} \) denotes the daily load energy consumption in watt-hours (Wh), \( C_{\text{wh}} \) is the total battery discharge capacity during continuous cloudy days in Wh, \( T_d \) is the equivalent daily sunshine hours in the worst-season, and \( \eta \) is the correction factor for solar panel efficiency, typically set at 0.9. For instance, in a typical off-grid solar system for valve chambers, the solar panels must meet stringent standards such as IEC 61215 or equivalent, with a minimum conversion efficiency of 14%, fill factor exceeding 85%, and ability to operate in temperatures ranging from -40°C to 85°C. The panels are encapsulated with tempered, low-iron glass for high transmittance (>95%) and feature bypass diodes to minimize power loss from shading. Table 2 summarizes the key technical requirements for solar photovoltaic components in this off-grid solar system.

| Parameter | Requirement |

|---|---|

| Standard Compliance | IEC 61215 (or equivalent GB/T 9535) |

| Minimum Conversion Efficiency | ≥14% |

| Fill Factor | >85% |

| Operating Temperature Range | -40°C to +85°C |

| Glass Type | Tempered, low-iron, with >95% transmittance |

| Design Life | >25 years |

| Output Power Tolerance | ±3% |

In the off-grid solar system, the junction boxes and combiner boxes play a crucial role in interconnecting solar panels and managing electrical output. These components are sealed to IP67 standards, ensuring protection against dust and water ingress, and are constructed from corrosion-resistant materials. The combiner box includes protective features such as surge arresters for lightning protection, anti-reverse diodes to prevent backflow, and overcurrent protection devices. For example, the anti-reverse diode must handle currents exceeding 150% of the short-circuit current under standard test conditions and have a peak reverse voltage at least twice the open-circuit voltage of the series string. This enhances the reliability of the off-grid solar system in unpredictable environments. The solar panel支架, designed for fixed-angle installation, optimizes solar irradiance capture and is engineered to resist wind loads. The structural integrity is validated through calculations considering material strength and environmental factors, ensuring the off-grid solar system remains operational in extreme weather.

The solar control cabinet is the heart of the off-grid solar system, managing power distribution, battery charging, and system monitoring. It includes AC and DC配电 units, with the AC input supporting single-phase three-wire 220V systems, voltage range of 198V to 242V, and frequency tolerance of 50Hz ± 2Hz. Additionally, a backup input for a diesel generator (e.g., 15kW/220V) is integrated for redundancy. The DC output operates at a nominal 24V DC, adjustable from 21.6V to 28.8V, with a voltage regulation accuracy better than ±1%. The system employs整流 modules that并联 to share loads evenly, with an imbalance not exceeding ±5% of the rated current. Key performance metrics for the整流 modules include high power factor (>0.95) and efficiency (>90%), as per standards like YD/T731. The control cabinet also features comprehensive protection mechanisms: overvoltage and undervoltage shutdown for AC input (e.g., tripping at ≥253V for overvoltage and ≤176V for undervoltage), and similar protections for DC output. Furthermore, the off-grid solar system incorporates battery management functions, including float and equalization charging, temperature compensation, and capacity estimation, which are vital for maintaining battery health in remote valve chambers.

Battery storage is essential for the off-grid solar system to ensure continuous power during night-time or low-sunlight periods. The battery capacity is calculated based on the autonomy days and daily energy consumption, using the formula:

$$ B_c = \frac{A \times Q_1 \times n \times T_0}{U \times \text{DOD}} $$

where \( B_c \) is the battery capacity in ampere-hours (Ah), \( A \) is a safety factor accounting for losses (1.1 to 1.4), \( Q_1 \) is the average daily load energy in Wh, \( n \) is the number of autonomy days (e.g., 7 days), \( T_0 \) is the temperature correction factor (typically 1.0), \( U \) is the system voltage (24V DC), and DOD is the maximum allowable depth of discharge (0.8). This calculation ensures that the off-grid solar system can sustain valve chamber operations without frequent recharge cycles. Batteries used in this setup are typically lead-acid or lithium-ion, selected for their cycle life and reliability in harsh conditions. The off-grid solar system’s battery management includes monitoring individual cell voltages and implementing charge-discharge cycles to prolong lifespan, which is critical for remote applications where maintenance access is limited.

The integration of an off-grid solar system into valve chamber telecommunication and instrumentation devices offers numerous advantages, including reduced operational costs, enhanced sustainability, and improved resilience. By eliminating the need for grid extension, this off-grid solar system minimizes infrastructure investments and environmental impact. The technical analysis presented here underscores the importance of robust design, precise component selection, and adherence to international standards. As oil and gas pipelines continue to expand into underserved regions, the adoption of off-grid solar systems will play a pivotal role in ensuring reliable and safe operations. Future developments may involve advanced energy storage technologies and smart monitoring features to further optimize the performance of off-grid solar systems in critical infrastructure applications.

In summary, the off-grid solar system for valve chambers represents a innovative approach to addressing energy challenges in remote oil and gas networks. Through detailed formulas, such as those for solar capacity and battery sizing, and tables outlining component specifications, this analysis highlights the system’s technical rigor. The repeated emphasis on the off-grid solar system throughout this discussion reinforces its centrality in modernizing pipeline infrastructure. As the industry evolves, continuous improvements in solar efficiency and battery technology will further enhance the viability of off-grid solar systems, making them indispensable for sustainable energy solutions in valve chamber applications.