1. Introduction

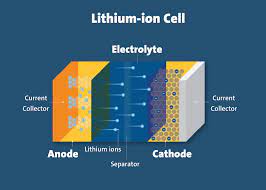

Lithium-ion batteries, especially lithium iron phosphate batteries (LiFePO4 batteries), have been widely used in various fields such as electric vehicles and energy storage systems due to their high energy density and long cycle life. However, the safety issue during the application process remains a significant challenge. Thermal runaway is a critical problem that can lead to serious consequences, including fire and explosion. This article focuses on the study of the thermal runaway behavior of large-capacity LiFePO4 batteries and the influence of test atmospheres.

1.1 Background

The development of lithium-ion battery technology has been rapid, but safety concerns have always been a key issue. Thermal runaway occurs when the lithium-ion battery is subjected to electrical abuse, thermal abuse, or mechanical abuse. It is a complex chemical reaction process that generates a large amount of heat and releases a significant amount of combustible gases, posing a threat to life and property. Many researchers have studied the thermal runaway characteristics of batteries, but most of the studies have focused on ternary nickel-cobalt-manganese system batteries and small-capacity LiFePO4 batteries, and there is a lack of research on the influence of test atmospheres.

1.2 Objectives

The main objectives of this study are to investigate the thermal runaway behavior of 120 Ah LiFePO4 batteries, including the temperature change, gas production characteristics, and the influence of different test atmospheres (inert atmosphere and air atmosphere). The results of this study will provide important guidance for the early warning and thermal disaster prevention of large-capacity LiFePO4 batteries.

2. Experimental Setup and Methods

2.1 Battery Samples

The experimental samples are square LiFePO4 batteries produced by a certain company. The basic performance parameters of lithium-ion battery are shown in Table 1.

| Name | Parameter |

|---|---|

| Positive electrode material | LiFePO4 |

| Negative electrode material | Graphite |

| Electrolyte component | (EC):(DMC)=1:1 |

| Cell capacity/Ah | 120 |

| Size/mm | 174x170x48 |

| Initial mass/g | 2860 |

| Nominal voltage/V | 3.20 |

| Specific energy/(Wh·kg -1) | 134.3 |

| Cut-off voltage lower limit/V | 2.50 |

| Cut-off voltage upper limit/V | 3.65 |

2.2 Experimental Apparatus

The experiments were carried out in a sealed pressure chamber with a volume of 82 L. The lithium-ion battery was heated laterally using a heating plate with a power of 952 W. Mica plates were attached to both sides of lithium-ion battery to reduce heat dissipation, and an aluminum clamp was used to fix lithium-ion battery. Temperature sensors, a pressure sensor, and a data acquisition instrument were installed to monitor lithium-ion battery temperature, pressure in the chamber, and other parameters. After the experiment, the gas produced during thermal runaway was collected using a gas collection bag and analyzed using a GC gas chromatograph analyzer. The experiments were conducted in an inert (nitrogen) atmosphere and an air atmosphere, and each experimental scheme was repeated twice.

2.3 Sensor Arrangement

The sensor arrangements for the two experimental schemes. Six temperature sensors (T1 – T6) were arranged on lithium-ion battery surface to monitor the temperature changes at the center of the heating surface, the center of the back surface, the center of the side surface, the positive and negative electrode tabs, and the battery exhaust valve. Five temperature sensors (T7 – T11) were arranged around lithium-ion battery to monitor the temperature changes in the horizontal and vertical directions of the jet area. A pressure sensor was installed in the chamber to monitor the pressure change during the thermal runaway process.

3. Thermal Runaway Behavior in Inert Atmosphere

3.1 Battery Characteristic Temperatures

In the inert atmosphere, the thermal runaway test was carried out, and the characteristic temperature changes of lithium-ion battery . The thermal runaway process of lithium-ion battery can be divided into four stages: heating stage (0 – 904 s), exhaust stage (904 – 1290 s), thermal runaway stage (1290 – 1750 s), and cooling stage (after 1750 s).

| Stage | Time Interval | Characteristic |

|---|---|---|

| I (Heating) | 0 – 904 s | Temperatures at all monitoring points rise continuously. The temperature near the exhaust valve and the side center is the highest, and the back temperature is the lowest. |

| II (Exhaust) | 904 – 1290 s | The exhaust valve opens, and the temperature at the exhaust valve drops slightly. The average non – heating surface temperature is 78.4 °C, and the temperature rise rate is 0.6 °C/s. |

| III (Thermal Runaway) | 1290 – 1750 s | The internal chemical reaction intensifies, and the temperatures at all monitoring points soar. The voltage drops from 3.40 V to 0 V. The temperature at the exhaust valve reaches the highest value of 162.4 °C, and the back temperature is 75.1 °C. The temperature at the positive and negative electrodes and the exhaust valve does not exceed 200 °C, and the back and side temperatures reach a peak of 218.0 °C around 2000 s. |

| IV (Cooling) | After 1750 s | The lithium-ion battery cools down. |

3.2 Environmental Temperatures

The temperature changes at 10, 20, and 30 cm above the exhaust valve and 20 cm on the left and right sides of lithium-ion battery were monitored. The environmental temperature change curve during the thermal runaway process. The environmental temperature shows a regular change. When the valve opens, the temperature curve has a small mutation. During the thermal runaway stage, the environmental temperature reaches a peak. The highest environmental temperature appears at 20 cm on the left side of lithium-ion battery, which is 131.7 °C. The environmental temperature above lithium-ion battery decreases gradually with the increase of height.

3.3 Gas Production Kinetics

The pressure and gas production volume changes in the sealed chamber during the thermal runaway of lithium-ion battery in the inert atmosphere . When the exhaust valve opens, the pressure in the sealed chamber has a small mutation, and the gas production volume also has a small mutation. During the thermal runaway stage, the pressure and gas production volume reach their peaks. The exhaust rate also reaches a peak during the thermal runaway process.

3.4 Gas Component Analysis

The volume fraction of the gas components produced during the thermal runaway of lithium-ion battery in the inert atmosphere. The main gas components are H2, CO2, CO, CH4, and C2H4. The generation sources of these gases are analyzed in detail.

| Gas Component | Volume Fraction/% | Generation Source |

|---|---|---|

| H2 | 52.8 | Reaction between binder and lithium ion at high temperature |

| CO2 | 26.5 | Decomposition of SEI film and reaction with active substances |

| CO | 7.4 | Reaction of SEI film decomposition products and electrolyte with lithium ion |

| CH4 | 6.2 | Reaction of binder reaction product and electrolyte |

| C2H4 | 5.0 | Reaction of graphite negative electrode collapse and electrolyte |

4. Influence of Test Atmospheres

4.1 Characteristic Temperature Differences

The thermal runaway experiments were carried out in an air atmosphere with the same experimental settings except for the atmosphere. The characteristic temperature differences between the air atmosphere and the inert atmosphere are shown in Table 2. Before lithium-ion battery thermal runaway occurs, the characteristic temperatures are not significantly affected by the test atmosphere. However, during the thermal runaway stage, the peak temperature of lithium-ion battery in the air atmosphere is 17.6% higher than that in the inert atmosphere, and the maximum temperature rise rate is increased by 5.1%.

| Test Atmosphere | Valve Opening Temperature/°C | Thermal Runaway Starting Temperature/°C | Peak Temperature/°C | Maximum Temperature Rise Rate/(°C·s -1) | Highest Environmental Temperature/°C |

|---|---|---|---|---|---|

| Inert Atmosphere | 117.5 | 99.5 | 218.0 | 3.9 | 132.0 |

| Air Atmosphere | 122.3 | 102.3 | 256.3… |

This is because before lithium-ion battery exhaust valve opens, the external air does not come into contact with the internal active substances. After the valve opens, although the internal active substances start to react with the air, due to the relatively low temperature, large-scale side reactions do not occur, so the thermal runaway starting temperature is not significantly affected. However, when the reaction progresses to the thermal runaway stage, the internal active substances in lithium-ion battery mix with the air under high temperature and undergo a violent chemical reaction, resulting in a higher peak temperature of lithium-ion battery in the air atmosphere.

4.2 Characteristic Time Differences

The characteristic time differences between the air atmosphere and the inert atmosphere are shown in Table 3. The opening time of the exhaust valve and the duration of exhaust are not significantly affected by the test atmosphere. However, the thermal runaway duration in the air atmosphere is 13.9% longer than that in the inert atmosphere because lithium-ion battery reaches the thermal runaway starting temperature earlier and the reaction is more intense during the thermal runaway stage in the air atmosphere.

This is due to the fact that in the air atmosphere, after lithium-ion battery exhaust valve opens, the internal active substances come into contact with the air and start to react chemically, enabling the battery to reach the thermal runaway starting temperature more quickly. After lithium-ion battery undergoes thermal runaway, the chemical reaction between the active substances and the air becomes more intense, leading to a higher internal temperature of lithium-ion battery and more complete reaction of the active substances, thus prolonging the thermal runaway duration.

4.3 Gas Production Characteristic Differences

The gas production volume changes during the thermal runaway of lithium-ion battery in different atmospheres. The gas production volume in the air atmosphere is 8.2% higher than that in the inert atmosphere. The gas component volume fraction ratios in different atmospheres. The types of gas components are the same in both atmospheres, but the proportions of some components are different.

In the air atmosphere, the proportion of H₂ is relatively lower, while the proportions of CH₄ and C₂H₄ are relatively higher. There are two main reasons for this. Firstly, the reaction temperature in the air atmosphere is higher, which causes more Li to react with the electrolyte to produce more C₂H₄, as shown in equations (20) – (22). This also leads to a reduction in the remaining Li content. Since H₂ is mainly generated from the reaction between the binder and Li, as shown in equations (9) – (10), the amount of H₂ generated in the air atmosphere is less. Secondly, the high-temperature reaction in the air atmosphere causes more of the generated H₂ to participate in the reduction reaction of the electrolyte, as shown in equations (14) – (15), which also leads to an increase in the CH₄ content. The flammability limits of the gas produced in different atmospheres were calculated according to equation (6) in section 1.4. The flammability limits of the gas produced in the inert atmosphere are 6.3% – 67.9%, and those in the air atmosphere are 5.9% – 62.7%. It can be seen that the gas produced during the thermal runaway of lithium-ion battery in the inert atmosphere still has a relatively high explosion hazard.