Introduction

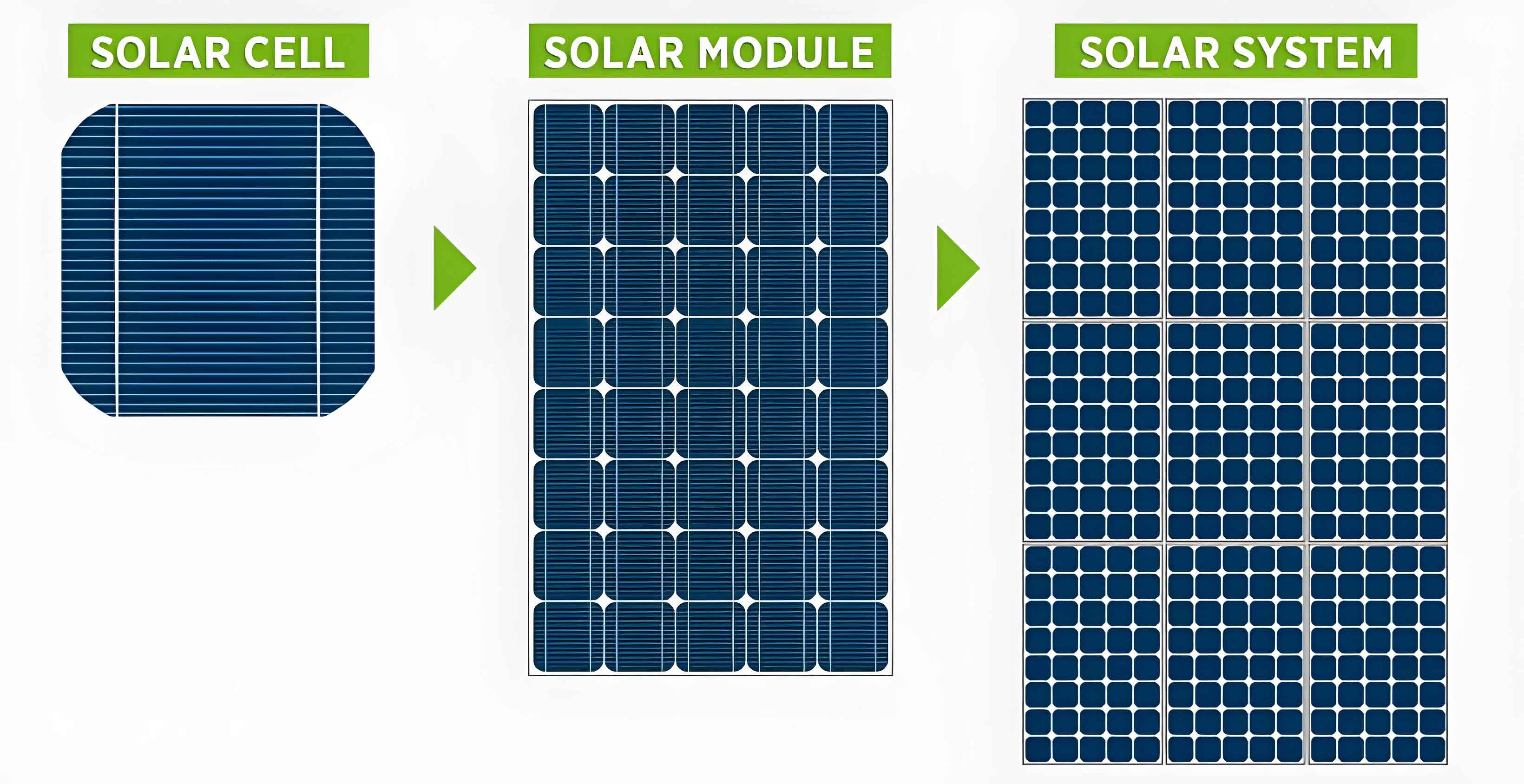

Solar cells, also known as photovoltaic cells, are semiconductor devices that convert sunlight directly into electricity using the photovoltaic effect. In physics, this effect is referred to as the internal photoelectric effect, where light energy is absorbed by a material, leading to the generation of electron-hole pairs and subsequently an electric current. The efficiency of solar cells depends on various physical factors, including the material’s band structure, light absorption, carrier generation, transport, and recombination. In this article, I will explore several key physical issues related to solar cells, focusing on silicon wafer thickness, surface texturing, anti-reflection coatings, and the prediction of solar cell efficiency.

1. Determining the Thickness of Silicon Wafers

1.1 Optical Properties of Silicon

The thickness of silicon wafers used in solar cells is a critical factor that affects the light absorption and overall efficiency of the cell. To understand how the thickness is determined, we need to examine the optical properties of silicon, specifically its refractive index and extinction coefficient. The absorption coefficient (α) and absorption rate (A) are related to the extinction coefficient (κ) and the thickness of the silicon wafer (x) by the following equations:α=4πκλα=λ4πκA=1−e−αxA=1−e−αx

where λ is the wavelength of light.

1.2 Solar Spectrum and Absorption

The solar spectrum consists of ultraviolet (UV), visible, and infrared (IR) light, each contributing differently to the total energy. Silicon has a bandgap energy (Eg) of 1.12 eV, corresponding to a cutoff wavelength of 1110 nm. This means that silicon can ideally absorb about 78% of the solar spectrum. The absorption coefficient and absorption depth vary with wavelength. For wavelengths between 360 nm and 800 nm, the absorption coefficient is high, and the absorption depth ranges from 0.1 to 50 μm. For wavelengths between 800 nm and 1000 nm, the absorption coefficient is lower, and the absorption depth increases to 50-300 μm. For wavelengths above 1000 nm, the absorption coefficient is even smaller, requiring a silicon thickness of over 500 μm for complete absorption.

1.3 Optimal Thickness

To balance high absorption rates, material savings, and cutting technology, the mainstream thickness of silicon wafers is typically between 150-240 μm. This thickness ensures that most of the solar spectrum is absorbed while minimizing material costs.

Table 1: Absorption Characteristics of Silicon at Different Wavelengths

| Wavelength Range (nm) | Absorption Coefficient (α) | Absorption Depth (μm) | Contribution to Efficiency |

|---|---|---|---|

| 360 – 800 | High | 0.1 – 50 | High |

| 800 – 1000 | Medium | 50 – 300 | Medium |

| > 1000 | Low | > 500 | Low |

2. Surface Texturing and Anti-Reflection Coatings

2.1 Reducing Surface Reflection

A polished silicon surface reflects more than 35% of incident sunlight, which significantly reduces the efficiency of solar cells. To minimize reflection, anti-reflection coatings (ARCs) are applied to the silicon surface. These coatings are typically made of materials with refractive indices between that of air and silicon, such as silicon nitride (Si₃N₄). The thickness of the ARC is designed to minimize reflection across a broad range of wavelengths.

2.2 Reflection and Transmission

The reflection (R) and transmission (T) of light at the interface between two media can be calculated using the following equations:R=(n2−n1)2+k2(n2+n1)2+k2R=(n2+n1)2+k2(n2−n1)2+k2T=(1−R)2exp(−αx)1−R2exp(−2αx)T=1−R2exp(−2αx)(1−R)2exp(−αx)

where n1n1 and n2n2 are the refractive indices of the two media, and kk is the extinction coefficient.

2.3 Surface Texturing

In addition to ARCs, surface texturing is another effective method to reduce reflection. By creating microstructures on the silicon surface, such as pyramids or inverted pyramids, the light is scattered and undergoes multiple reflections, increasing the chances of absorption. The reflection rate can be reduced to as low as 9.04% with optimal texturing.

Table 2: Reflection Rates with and without Anti-Reflection Coatings

| Surface Type | Reflection Rate (%) |

|---|---|

| Polished Silicon | 35 |

| Silicon with ARC | 13.8 |

| Textured Silicon | 9.04 |

3. Predicting Solar Cell Efficiency from Material Properties

3.1 Shockley-Queisser Limit

The Shockley-Queisser (S-Q) limit is a theoretical maximum efficiency for a single-junction solar cell under ideal conditions. For a material with an optimal bandgap of 1.3-1.4 eV, the maximum theoretical efficiency is around 33%. The S-Q limit is based on the balance between the energy of absorbed photons and the thermalization losses.

3.2 J-V Characteristics

The current-voltage (J-V) characteristics of a solar cell can be predicted using the following equation:J(V)=Jsc−e(n2+1)Eg2kT4π2h3c2exp(−eV−EgkT)J(V)=Jsc−4π2h3c2e(n2+1)Eg2kTexp(−kTeV−Eg)

where JscJsc is the short-circuit current density, ee is the elementary charge, nn is the refractive index, EgEg is the bandgap energy, kk is the Boltzmann constant, TT is the temperature, and hh is the reduced Planck constant.

3.3 Simulation Results

Using the above equation, we can simulate the J-V characteristics of a silicon solar cell. For a silicon thickness of 200 μm, the short-circuit current density is 32 mA/cm², and the open-circuit voltage is 0.98 V. The maximum power output is 27.6 mW, with a fill factor of 0.88 and an efficiency of 27.6%.

Table 3: Simulated J-V Characteristics of a Silicon Solar Cell

| Parameter | Value |

|---|---|

| Short-Circuit Current (Jsc) | 32 mA/cm² |

| Open-Circuit Voltage (Voc) | 0.98 V |

| Maximum Power (Pmax) | 27.6 mW |

| Fill Factor (FF) | 0.88 |

| Efficiency (η) | 27.6% |

4. Conclusion

Understanding the physical principles behind solar cells is crucial for optimizing their efficiency and reducing costs. By carefully selecting the thickness of silicon wafers, applying anti-reflection coatings, and texturing the surface, we can significantly enhance the light absorption and overall performance of solar cells. Additionally, predicting the J-V characteristics based on material properties allows us to design more efficient photovoltaic devices. As the demand for renewable energy sources continues to grow, advancements in solar cell technology will play a vital role in meeting global energy needs.