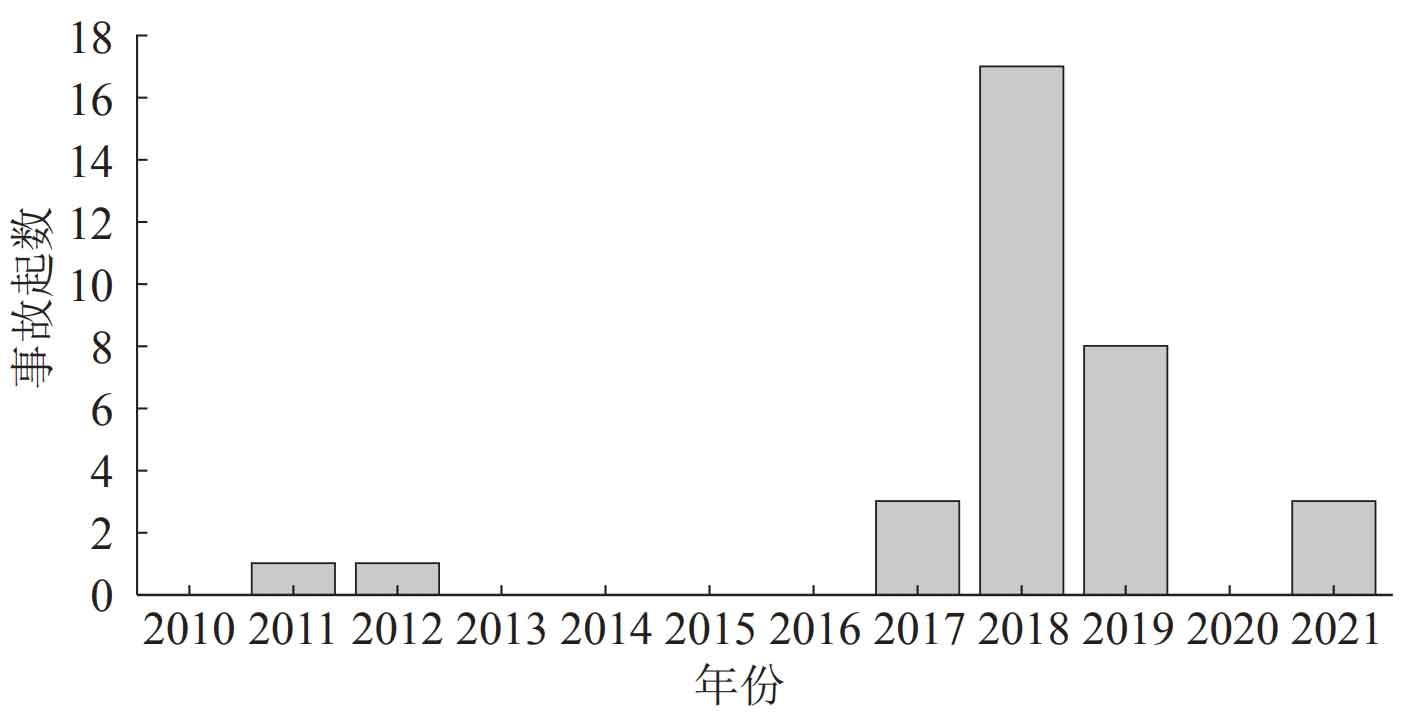

Lithium ion batteries are increasingly favored by the consumer market and industry due to their excellent charging and discharging performance, high energy density, and other excellent characteristics. In the field of electrochemical energy storage, lithium-ion batteries have gradually become the mainstream of energy storage system construction, with the emergence of a large number of station and prefabricated energy storage power stations. At the same time, in the face of the “dual carbon” target demand, the peak shaving, frequency modulation, new energy grid connection and other issues in the grid also need to build energy storage power stations to increase the stability and flexibility of the grid supply. Although electrochemical energy storage power stations have developed rapidly, their gap space is still large. According to the “Guiding Opinions on Accelerating the Development of New Energy Storage”, the target for the installed capacity of new energy storage beyond pumped storage is over 30 million kW by 2025. However, the continuous occurrence of combustion and explosion accidents caused by the failure of the battery body or energy storage system has limited the development of energy storage power plants. According to incomplete statistics, there have been 34 incidents of fire and explosion at energy storage power stations worldwide in recent years, and nearly 30 incidents have occurred since 2017, as shown in Figure 1. Among them, the Beijing “4.16” Dahongmen accident and the Australian energy storage power station fire accident have caused serious consequences.

Lithium ion batteries have a high energy density and are prone to generate a large amount of flammable and explosive gases in case of abnormal conditions. Under large-scale application conditions, thousands of lithium-ion batteries are connected together through series (parallel) connection. If the connection is not secure or virtual, it can lead to electrical faults and electrical fires. At the same time, the imperfect battery management system during the charging and discharging process can lead to faults such as overcharging and discharging of the battery, leading to thermal runaway of the battery and serious accidents such as fire and explosion. Due to the lack of necessary separation measures between a large number of batteries, it is easy to cause fires to spread rapidly within the energy storage system, and a large amount of flammable and explosive gases generated by combustion accumulate in the system. Improper disposal can lead to serious consequences such as detonation. Meanwhile, the application of electrochemical energy storage systems in densely populated areas further increases the risk of fire accidents. Compared to the on-board power battery system of new energy vehicles, electrochemical energy storage has a larger energy level, higher fire load, and more complex application environment. Unlike traditional fire types, lithium-ion battery energy storage system accidents include multiple processes such as thermal runaway, fire, and explosion, involving two levels of fire hazard: lithium-ion battery fire hazard and electrical system fire hazard. Therefore, it is necessary to analyze the thermal runaway fire mechanism and safety design methods of electrochemical energy storage systems, and further clarify their fire hazards based on experimental and simulation results.

1.Hazard analysis

As a widely used energy storage device, lithium-ion batteries have a basic structure consisting of multiple parts such as positive electrode, negative electrode, separator, electrolyte, and fixed structure. Under SOC 100% full charge state, due to the presence of a large amount of electrical energy, the risk of thermal runaway accidents is greater. Meanwhile, the large amount of combustible gas generated during the thermal runaway process of lithium-ion batteries poses a high risk of explosion. Research has shown that abuse such as heating, overcharging, piercing, over discharge, short circuit, and squeezing are important factors that can cause thermal runaway, fire, and explosion accidents in lithium-ion batteries.

The existing research on lithium-ion battery energy storage systems mainly focuses on battery thermal management and lithium-ion batteries themselves, and the research on fire safety is still incomplete. In terms of thermal safety of lithium iron phosphate batteries for energy storage, research shows that square lithium iron phosphate batteries begin to self release heat from 86.0 ℃, and at 173.4 ℃, the battery vent valve opens. After 17 minutes, the battery reaches its maximum temperature of 325.2 ℃, and the thermal runaway process ends. In terms of the explosion risk of lithium-ion batteries’ pyrolysis gas, when the state of charge of lithium-ion batteries is 100%, the lower limit of pyrolysis gas explosion is 6.22%, and the upper limit is 38.4%. The explosion limit range increases with the increase of the state of charge.

Scholars have conducted research on the design of fire protection systems for container type lithium-ion battery energy storage systems, which is limited to design concepts and simulation, lacking real experimental support. Electrochemical energy storage has the advantages of high energy density, high conversion efficiency, short construction period, and strong site adaptability. Currently, research is still focused on the fire hazard and fire extinguishing strategy analysis of small-scale individual batteries, and fire characteristics analysis of lithium-ion energy storage cabinets, energy storage containers, and other levels has not been carried out.

1.1 Hazards of energy storage systems

GB 51048-2014 “Code for Design of Electrochemical Energy Storage Power Stations” fails to fully consider the risk of thermal runaway and fire explosion accidents in electrochemical energy storage power stations, and determines the fire hazard of lithium-ion batteries as Class E, which poses a significant fire prevention and control risk. The urgent demand for electrochemical energy storage construction in the market and the contradiction between outdated and incomplete standards and specifications have led to high risks in the surrounding scenes and environment of electrochemical energy storage power station construction.

Regarding the lithium iron phosphate battery itself, the GB/T 36276-2018 “Lithium ion Batteries for Electric Energy Storage” has incomplete regulations on the safety performance indicators and testing methods related to thermal runaway of energy storage batteries, and lacks mandatory regulations on product safety, resulting in a mixed quality of battery management systems, low monitoring accuracy, and incomplete monitoring indicators. The design of the energy storage system, the safety standards of the battery itself, and the lack of sound technology have led to a high risk of electrochemical energy storage systems. It is necessary to improve the safety warning and protection standards, technology, and product development.

1.2 Hazards of fire emergency response

In terms of emergency response for electrochemical energy storage systems, due to the compact and relatively enclosed battery layout in the battery room of the energy storage station, existing handheld fire extinguishers or dry sand are difficult to reach the ignition site. Although commonly used gas fire extinguishing systems can effectively extinguish a combustion, they have not blocked the thermal runaway of the battery, which cannot suppress the reignition of lithium batteries and even lead to explosions. At the same time, due to the lack of extinguishing and explosion suppressants tailored to the fire characteristics of lithium batteries, there is currently no effective response method or operating procedure for electrochemical energy storage power plant fires.

Taking the fire accident at an energy storage power plant in Australia as an example, due to the lack of necessary disposal measures, the energy storage box continued to burn for more than 4 days; The Arizona energy storage power plant fire in the United States was mishandled without an open flame, resulting in personal injury. Faced with the emergence of a large number of electrochemical energy storage systems and the increasing scale and energy density of energy storage systems, how to improve the fault handling of electrochemical energy storage systems through technical means has become a key issue that needs to be urgently solved. A large amount of systematic scientific research and practical exploration are needed to develop simple, reliable, and efficient firefighting and rescue technology equipment.

2. Comparison of Standards

Although domestic and European energy storage systems mostly use lithium iron phosphate batteries as energy storage units, Japan and South Korea mainly use ternary lithium-ion batteries, presenting various battery forms. However, the technical standards and testing procedures related to lithium-ion battery energy storage systems have not further subdivided the different types of lithium-ion batteries. Therefore, it is urgent to carry out relevant experimental research to provide basic data for the formulation and revision of standard specifications.

2.1 Foreign standards

The safety standards for electrochemical energy storage systems mainly include IEC standards, UL and NFPA standards in the United States, etc. Among them, the IEC 62619-2017 standard divides into two areas: fixed energy storage and mobile energy storage (non electric vehicles, etc.). Battery performance testing involves battery cells, battery packs, and battery systems, but safety testing only focuses on the safety of battery management systems, without fully considering the safety issues of battery cells and battery packs themselves. The US UL 9450A standard is a testing method standard for thermal runaway fire propagation in electrochemical energy storage systems, involving testing at the cell, module, unit, and system levels. Its installation level is relatively low, making it difficult to use for the safety of large-scale electrochemical energy storage power plants. NFPA 855 specifies the design and installation of general electrochemical energy storage systems, which are only set up for conventional Class C fire hazards in fire protection facilities.

2.2 Domestic standards

In October 2018, the National Energy Administration issued a letter soliciting opinions on the Implementation Plan for Strengthening the Standardization of Energy Storage Technology, requesting further focus on promoting the establishment of energy storage standards, including the operation, maintenance, and design of energy storage systems. In response to the rapid development of the domestic energy storage market, enterprise standards and group standards have been gradually revised, such as the “Technical Specification for Fire Protection of Prefabricated Lithium Iron Phosphate Battery Energy Storage Power Stations” T/CEC 373-2020, etc. However, there is no mandatory requirement for energy storage batteries in the current national standard, and there is also a lack of safety standards for electrochemical energy storage systems. Therefore, it is necessary to further propose safety and performance regulations for electrochemical batteries based on the development of energy storage technology. The relevant parameters and conclusions obtained in this study can effectively support the formulation and revision of relevant industry standards and national standards for prefabricated lithium iron phosphate battery energy storage systems.

3. Experimental research

3.1 Scenario Design

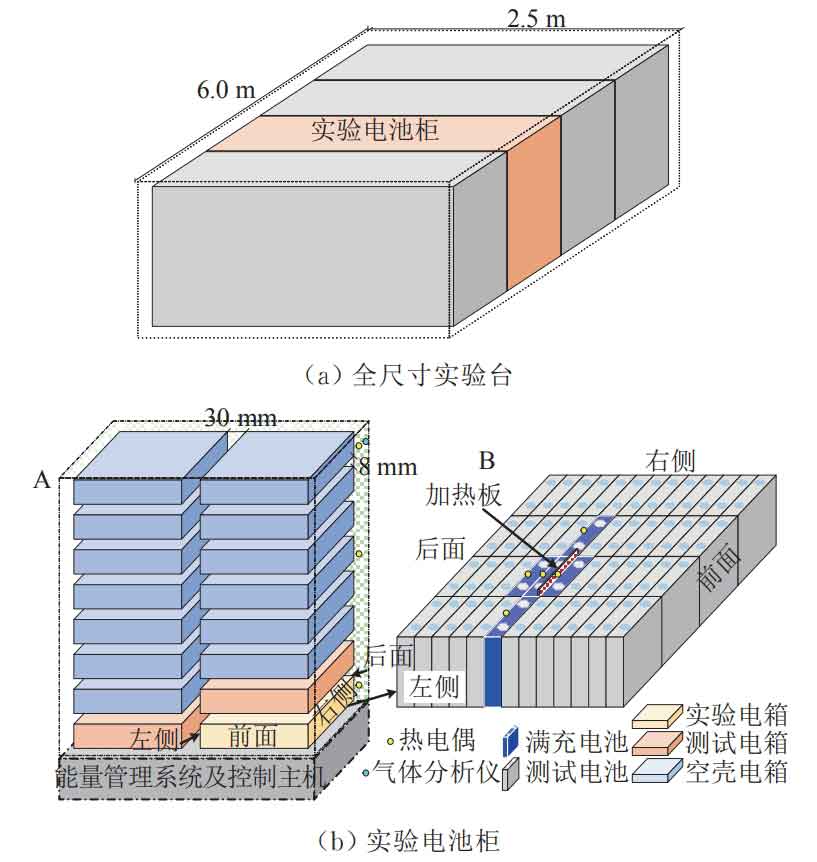

Build a full-scale lithium-ion energy storage cabinet experimental platform with a ratio of 1:1 to the actual energy storage box, to simulate the laws of smoke spread, heat and mass transfer after thermal runaway of lithium-ion batteries in the energy storage cabinet. The test bench is approximately 6 meters long and 2.5 meters wide, which is a standard energy storage cabinet size of 6.7 meters. Below the energy storage cabinet is the energy management system and control host, above which are two rows of battery boxes with a spacing of 30 mm. Each row includes eight battery boxes with a spacing of 8 mm. The internal space of the energy storage cabinet is relatively enclosed. Place 5 square lithium-ion batteries in the experimental box for battery thermal runaway, with the center 5 being fully charged lithium-ion batteries and the rest being uncharged test batteries. The internal layout of the test box above the experimental box is the same as that of the experimental box. The test box on the side of the experimental box is only equipped with a row of fully charged batteries on the side near the experimental box. The lower part of the battery module is fixed to the liquid cooling plate through heat transfer adhesive, and the heat dissipation of the lithium-ion battery is achieved through the liquid cooling circulation system. The heating plate has a thickness of 1 mm and a heating power of 500 W. The specific arrangement is shown in Figure 2.

3.2 Lithium ion batteries

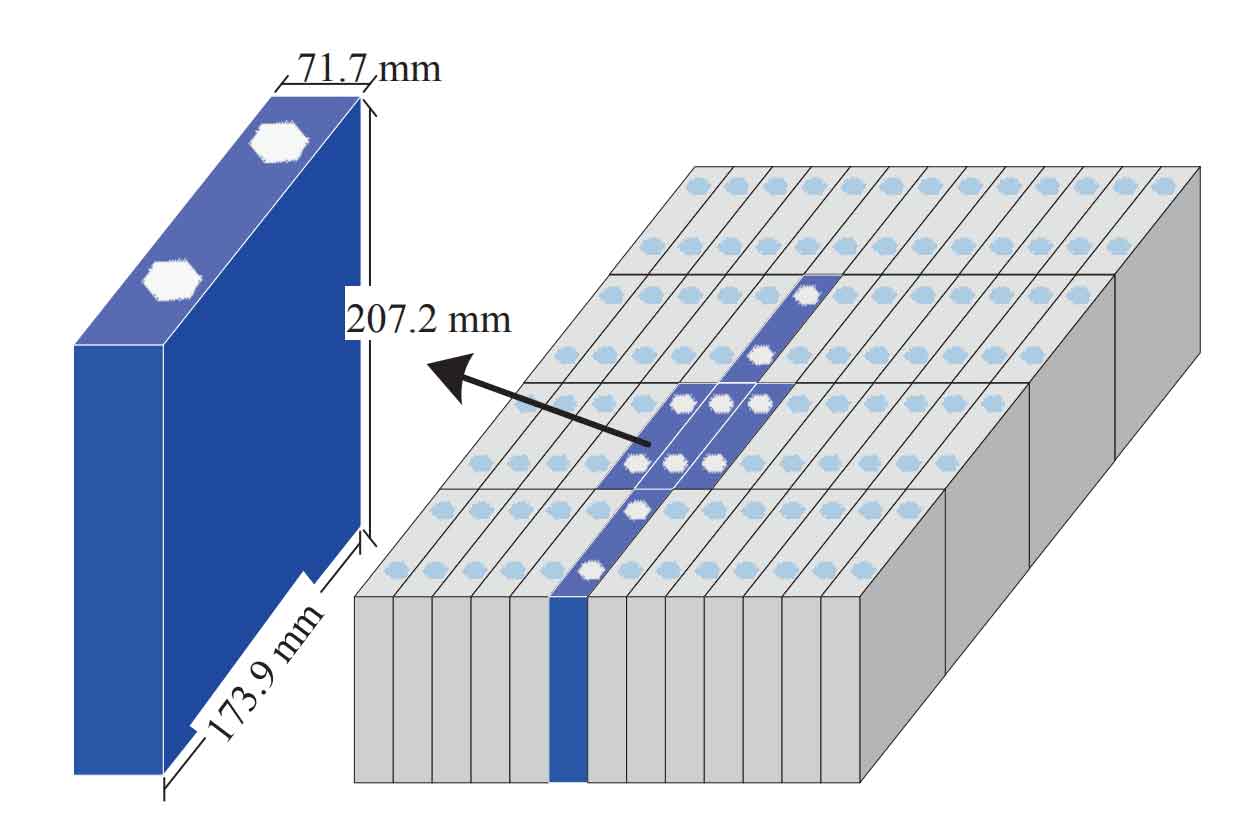

A 280 Ah, 3.2 V rechargeable lithium iron phosphate battery with an internal resistance of (0.18 ± 0.05) m Ω, a working temperature (charging) of 0-65 ℃, a working temperature (discharging) of -35-65 ℃, and a battery mass of 5.51kg were selected as the lithium-ion battery monomer, as shown in Figure 3.

3.3 Testing and Phenomena

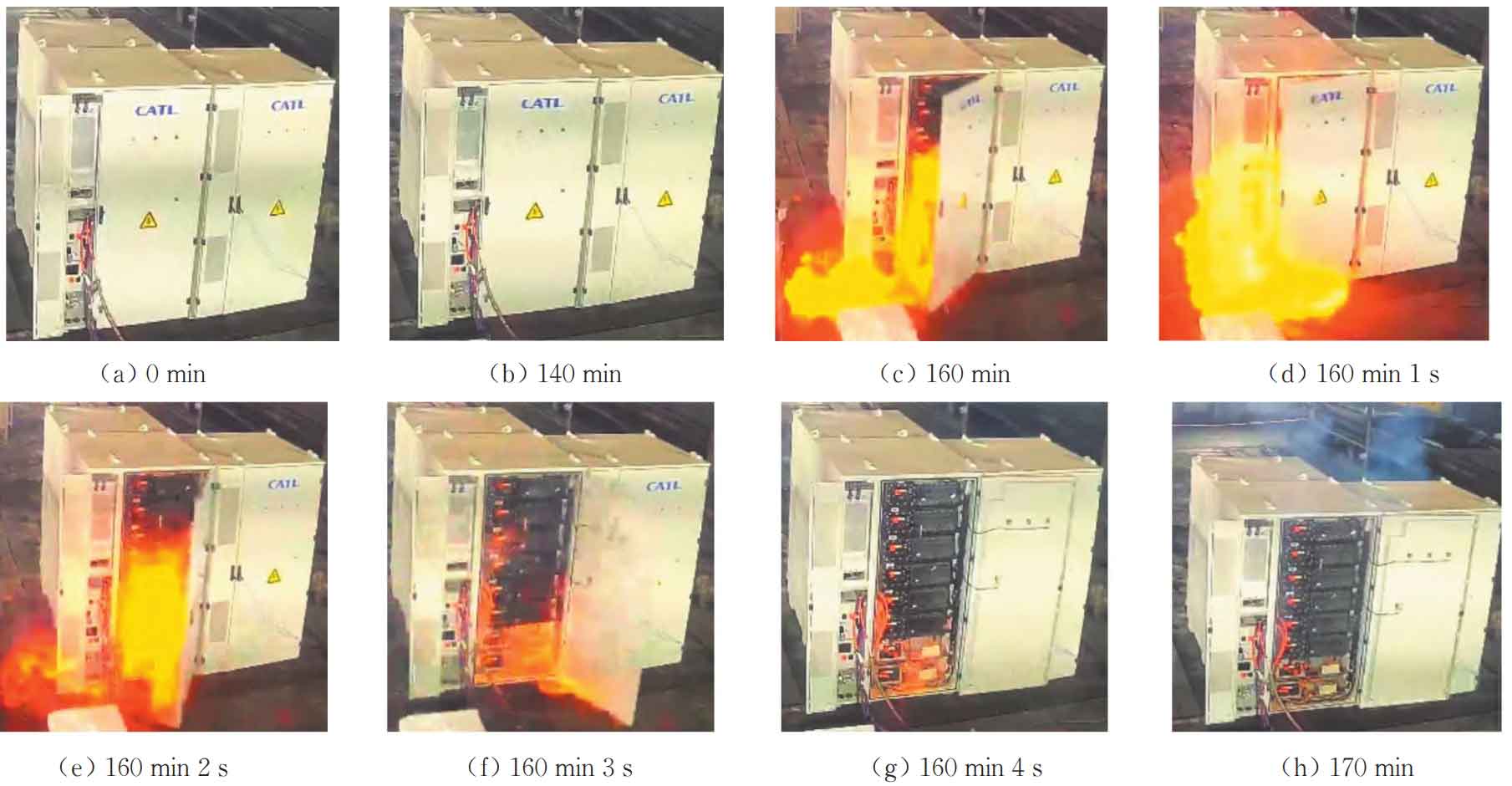

During the experiment, gas analyzers, temperature measuring thermocouples, voltage, current and other real-time parameter acquisition modules were installed in the energy storage box. Thermocouples for temperature measurement are arranged at each fully charged core, inside the module, and in the energy storage box. They are used to measure the heating plate, experimental energy storage box, middle, and top of the energy storage cabinet, respectively. The arrangement is shown in Figure 2. Real time recording of thermal runaway process through high-definition video image acquisition equipment, as shown in Figure 4.

From the start of the heating plate operation, there was no significant change within 140 minutes. About 160 minutes, there was a sudden explosion and the cabinet door was opened by a shock wave. After about 2 seconds, the cabinet door was fully opened, and the flame continued to burn for 3 seconds. Subsequently, smoke was gradually released, and no further spreading combustion occurred.

3.4 Analysis of oxygen volume fraction

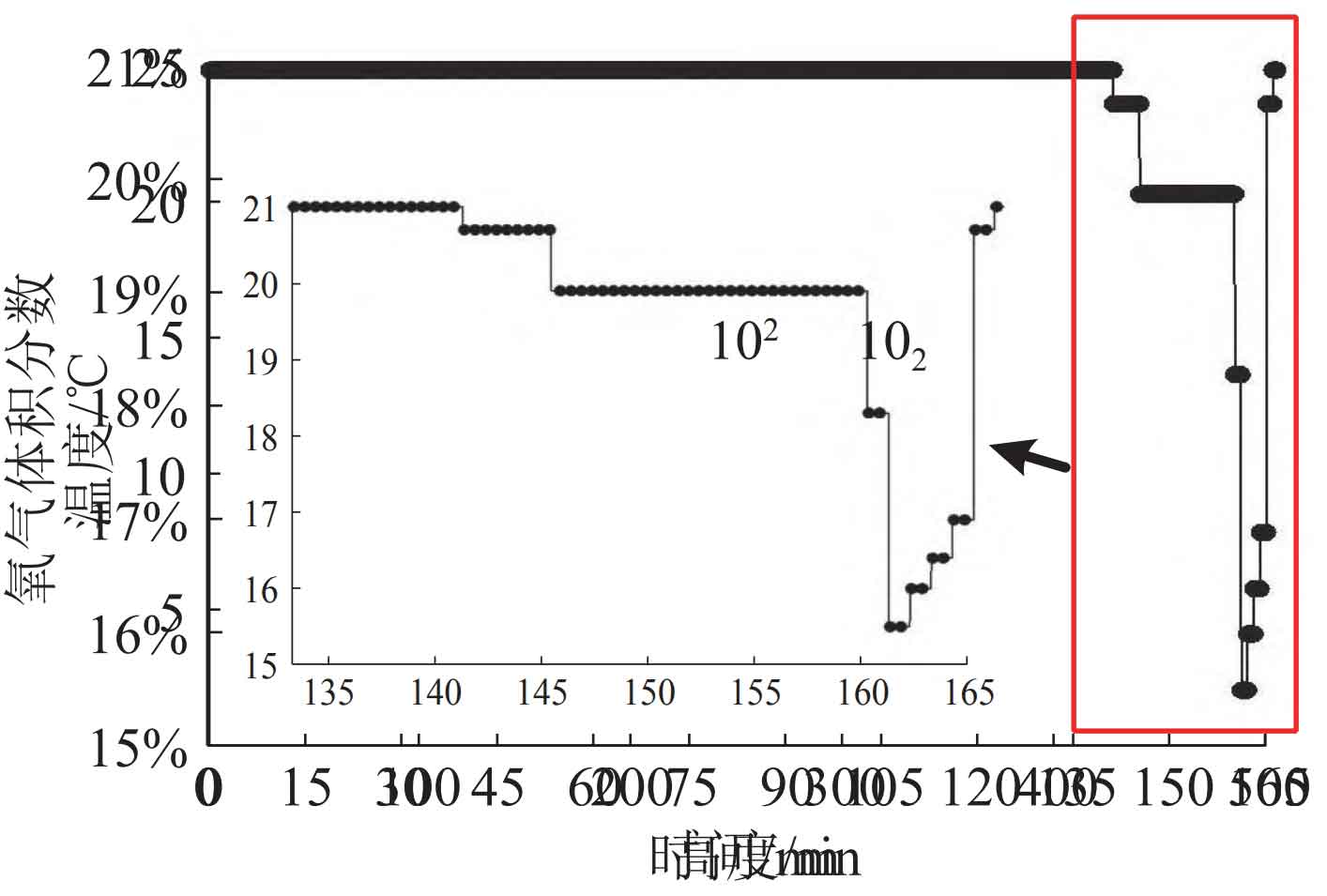

Obtain the change in oxygen volume fraction in the energy storage tank through a gas analyzer, as shown in Figure 5.

From Figure 5, it can be seen that around 140 minutes, the oxygen volume fraction began to slowly decrease, and around 160 minutes, there was a sharp decrease, corresponding to the phenomenon of explosion in Figure 4. Subsequently, the oxygen volume fraction slowly increased and returned to normal levels, indicating that no further combustion process occurred in subsequent experiments, which is basically consistent with the experimental phenomenon in Figure 4. The change in oxygen volume fraction can better reflect the process of thermal runaway occurrence. At the same time, in the experimental scenario of this article, there is a delay period of about 20 minutes between thermal runaway and explosion. However, due to the lack of necessary thermal insulation and emergency response measures, the serious consequences of explosion have been caused. Therefore, it is necessary to carry out early monitoring, warning, and disposal devices for thermal runaway of lithium-ion batteries based on gas composition analysis, in order to effectively improve the safety deficiencies of existing energy storage systems.

3.5 Temperature analysis

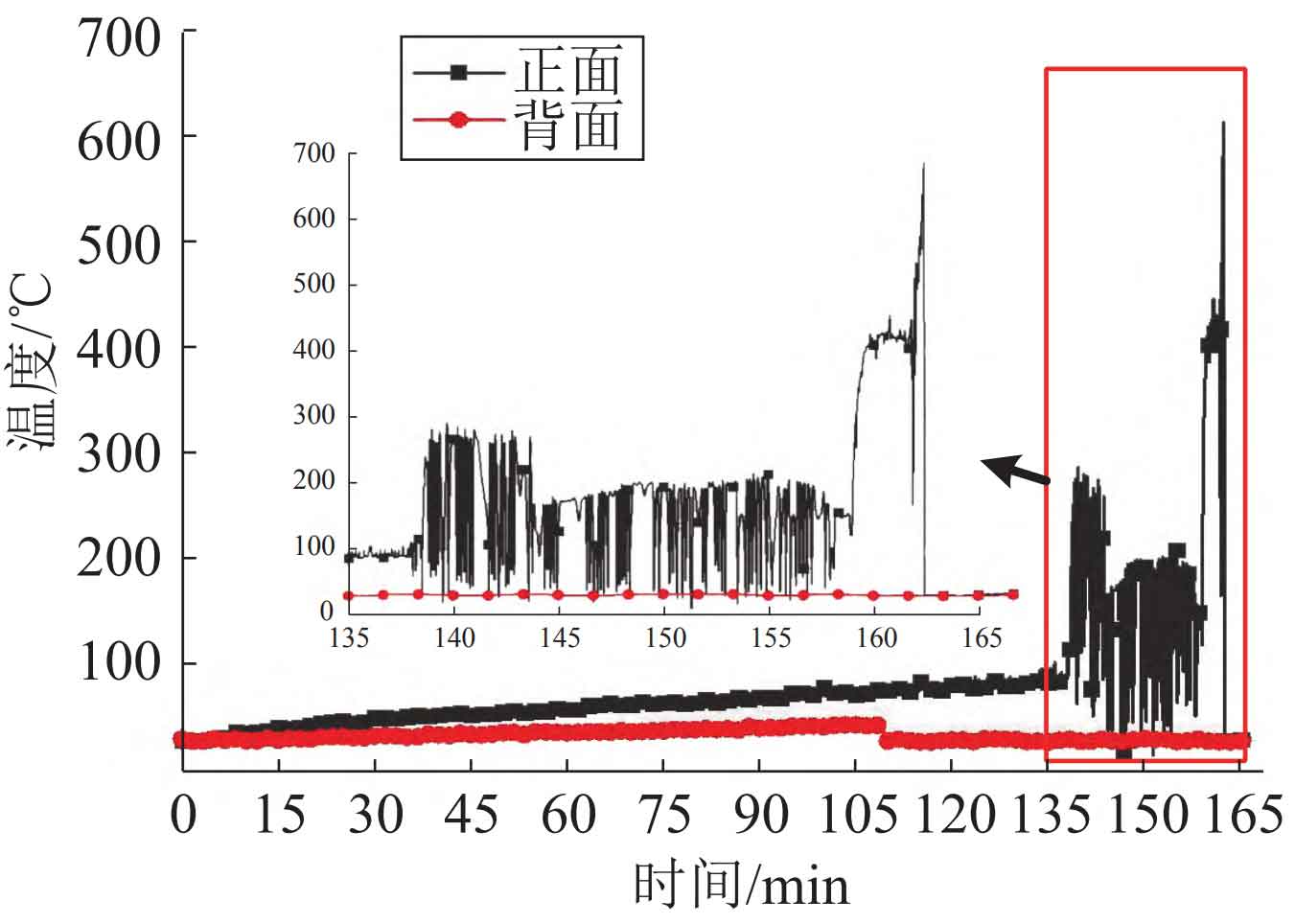

Firstly, analyze the temperature of the directly heated cell surface and back side at the heating plate, and study the temperature changes of the experimental cell during the thermal runaway process. During the entire thermal runaway process, the temperature change curves of the front and back of the experimental cell are shown in Figure 6.

From Figure 6, it can be seen that about 108 minutes ago, the thermal resistance of the cell itself caused a deviation in the temperature between the front and back of the cell. As time increased, the temperature difference increased. At 108 minutes, the temperature on the back suddenly changed, possibly due to external heating causing a change in the internal temperature of the cell. The internal temperature of the cell was close to 100 ℃, and the thermal runaway process had already started from inside the cell. At this time, due to the high internal temperature of the cell and the limitations of battery layout, The temperature on the back of the battery cell remains basically unchanged. On the front of the battery cell, there is a step change at a temperature of 160 minutes, which is basically consistent with the oxygen change and the time of flame injection. Analysis shows that during the full-scale experiment, due to the arrangement of battery modules and battery boxes, when thermal abuse leads to thermal runaway, the increase in internal temperature of the cells will suppress heat transfer between different cells.

From the experiment, it can be seen that after the temperature of the single cell is raised, due to the dense arrangement of batteries in the energy storage system, there is insufficient heat dissipation. In this experimental scenario, a liquid cooled heat transfer plate is installed below the battery pack, but the heat dissipation intensity is significantly insufficient, only causing a sudden drop in the temperature on the back of the cell, and then inevitably generating heat out of control. In view of this, it is recommended to conduct research on the temperature changes of the battery box during the process of thermal runaway of the battery cell through experimental testing and numerical simulation, and develop devices that can efficiently cool down and actively suppress thermal runaway, in order to improve the safety of existing energy storage systems.

4. Conclusion

This article analyzes and studies the current safety status of electrochemical energy storage systems, establishes an energy storage experimental platform, conducts research on the thermal runaway process of lithium-ion batteries under thermal abuse conditions, and analyzes the safety issues of electrochemical energy storage systems. The conclusions are as follows.

(1) If the electrochemical energy storage system of lithium iron phosphate batteries experiences thermal runaway, the gas generated by the volatilization of the released electrolyte has characteristics such as fast speed and high shock wave energy, which poses a risk of fire spread and continuous explosion.

(2) During the thermal runaway process, the oxygen volume fraction had already changed 10 minutes before the mutation occurred. Early warning of the thermal runaway process can be achieved by monitoring the oxygen volume fraction in the energy storage box.

(3) During the process of thermal runaway propagation, due to the obvious insufficient heat dissipation intensity of the existing system, only a sudden drop in the temperature of the back of the battery cell occurs, and then inevitably a thermal runaway fire accident occurs, indicating that the safety of the energy storage system is insufficient.

(4) It is only less than 5 seconds from the occurrence of an open fire in the energy storage cabinet to the shock wave opening of the cabinet door. The time is extremely short, and the fire and explosion warning and control gateway of the energy storage power station should be advanced. It is recommended to combine the relevant operating parameters of the battery management system (BMS) with the safety hazard characteristic parameters of the energy storage power station, determine appropriate detection methods and algorithms, formulate and revise the requirements for fire detection and alarm in electrochemical energy storage power stations, and form an early fire detection and warning system, To achieve the effectiveness and accuracy of fire detection and warning.

(5) There are various specifications, types, and structural forms of existing energy storage systems, and it is necessary to strengthen the application specifications of energy storage batteries. Based on basic research on their fire characteristics, fire hazards should be scientifically and normatively classified.

In order to improve the level of handling accidents in electrochemical energy storage systems, based on the characteristics of lithium-ion battery fires, reasonable extinguishing agents and disposal processes should be selected, with a focus on solving the problem of large amounts of toxic, flammable and explosive smoke generated by energy storage power plant fires. Efficient and safe smoke exhaust technology methods should be explored to create favorable conditions for fire extinguishing.