With the changes in global energy development, the proportion of renewable energy generation will be increasing, such as photovoltaic, wind power, hydropower, etc. According to China’s dual carbon plan, the 14th Five Year Plan will be a critical period, and it is necessary to vigorously increase the proportion of renewable energy in the overall energy structure. At present, coal still occupies a high position in China’s energy structure. However, according to the national energy development plan, the proportion of coal-fired power installed in China’s total installed capacity is decreasing year by year, from 65.7% in 2012 to less than 50% in 2020. This change demonstrates that China’s energy power system will become more diversified, with a greater emphasis on the introduction of non fossil fuels. In the mid-20th century, the proportion of renewable energy in China is likely to reach 78% or even higher. In the process of changing the energy structure, China’s power system will face a huge challenge – large-scale grid connection of renewable energy, and efforts must be made to solve the problems of ultra-low load deep peak shaving, frequent start stop peak shaving, etc. that occur during the grid connection process.

In order to solve the problem of large-scale grid connection of renewable energy, Western countries first adopted energy storage technology in the late 20th century, such as Italy and Switzerland, mainly pumped storage. Energy storage technology simply means using large capacity and fast charging and discharging energy storage facilities or physical media to convert one type of energy that is difficult to store into another type of energy that can be stored for a long time. In recent years, with the large-scale installation of renewable energy at home and abroad, the development of energy storage technology has become increasingly mature, and there are also more and more energy storage methods. Energy storage technology involves a wide range of fields, and can be roughly divided into physical energy storage, electromagnetic energy storage, electrochemical energy storage, etc. based on the energy consumption forms involved in the energy storage process.

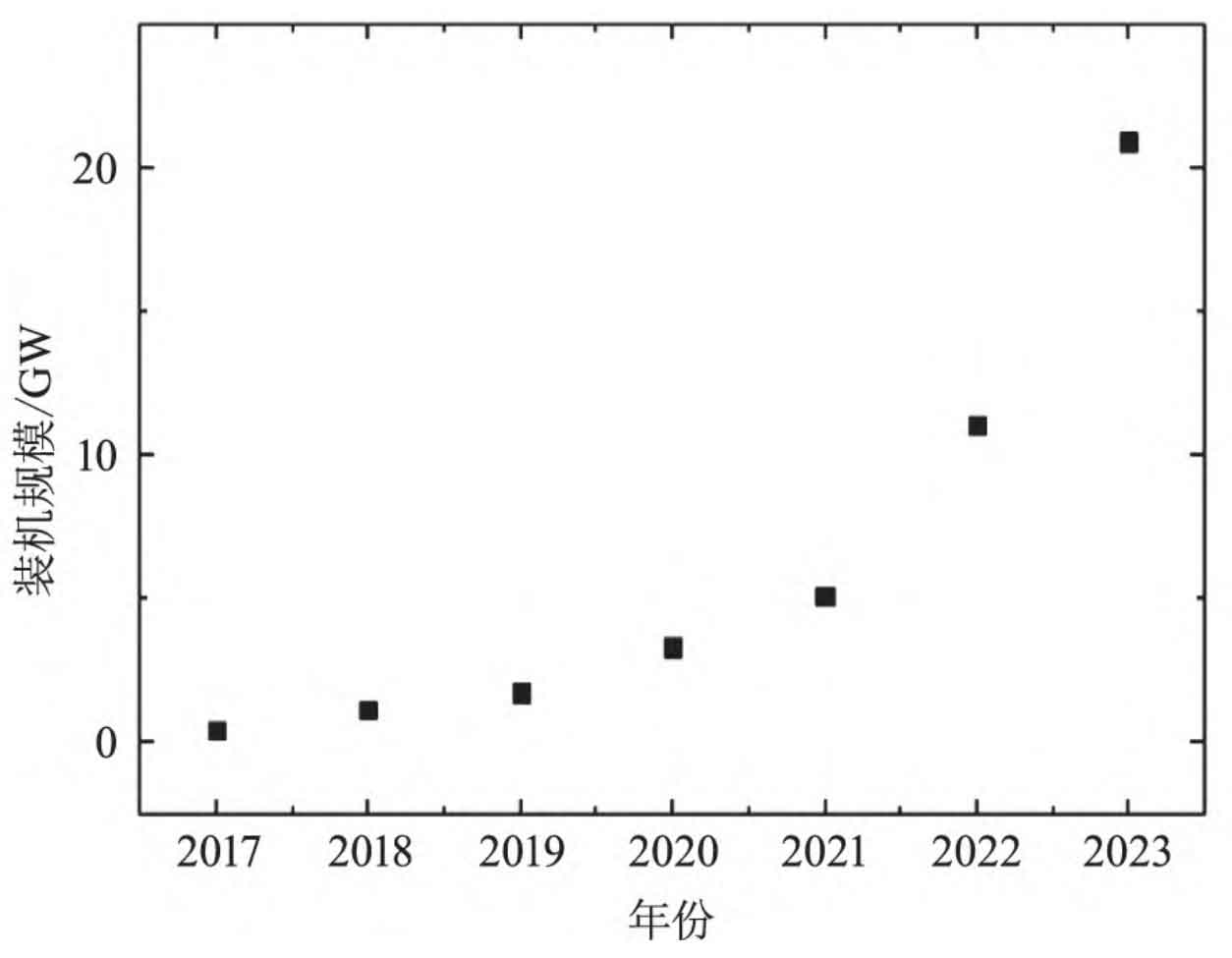

Figure 1 shows the change curve of the newly added and put into operation scale of new energy storage in China in recent years. Although the international market has been relatively turbulent in recent years and there has been the impact of the epidemic, the domestic energy storage market has still maintained a relatively high growth rate. In 2022, the newly added operation scale of new energy storage in China exceeded 14 GW, a year-on-year increase of nearly double, and the newly installed capacity was about 5.93 GW. Among them, electrochemical energy storage is the main new form of energy storage. According to calculations, the cumulative installed capacity of electrochemical energy storage in China reached 11 GW in 2022, with a significant increase in the share of electrochemical energy storage. Electrochemical energy storage is a device that directly converts electrical energy through chemical reactions, mainly consisting of lithium-ion batteries, sodium sulfur batteries, and liquid flow batteries. Among them, lithium-ion battery energy storage accounts for an increasing proportion in the energy storage market, approaching 90%, due to its significant advantages.

In 2021, the cumulative installed capacity of electrochemical energy storage in China was 5.1 GW, of which 4.7 GW was installed for lithium-ion battery energy storage technology, accounting for 92.0% of the total installed capacity. The challenges faced by electrochemical energy storage in the development process mainly include the following: (1) frequent accidents in electrochemical energy storage power plants; (2) There are difficulties in the development of energy storage technology; (3) Lack of safety management norms and industry standards; (4) There are deficiencies in the early project planning and design.

Because lithium-ion battery energy storage in electrochemical energy storage has the characteristics of small footprint, high efficiency, fast conversion, safety and reliability, flexible operation, and simple maintenance, this article will focus on researching the detection and management system of lithium-ion battery energy storage methods. The energy storage battery detection and management system is the foundation and key to achieving large-scale battery energy storage, with the following advantages: (1) effectively increasing the service life of energy storage batteries; (2) Reduce battery loss during use, identify and solve problems early, improve battery efficiency and safety, and avoid various accidents; (3) Save the entire process data of each battery unit for query purposes.

1.Electrochemical energy storage of lithium batteries

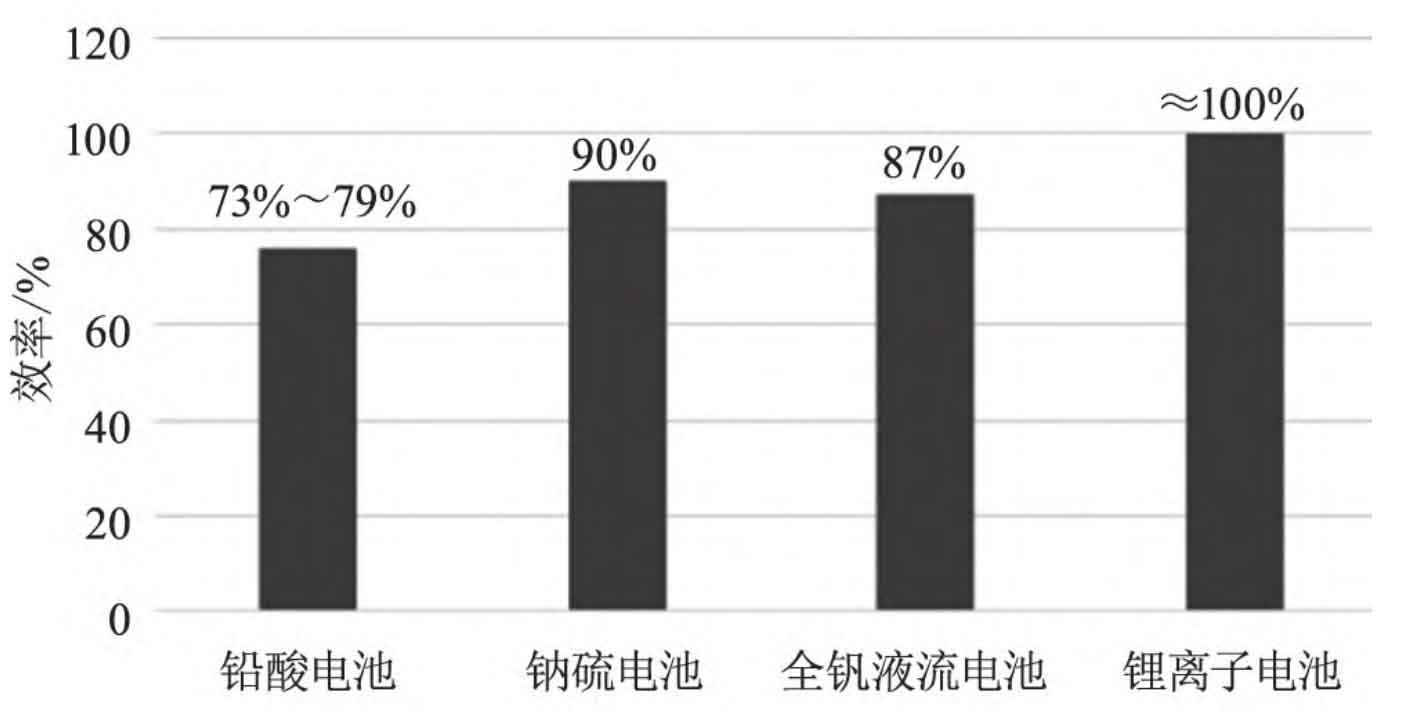

Energy storage media are containers for energy storage, which directly affect the efficiency and safety of the entire system. Figure 2 shows the energy storage efficiency of several common energy storage media. The efficiency of lead-acid batteries is around 76%, which is the lowest compared to other types; The efficiency of lithium-ion batteries is close to 100%, which is the highest compared to other types. In addition, the specific energy of lithium-ion batteries ranges from 70 to 200 W · h/kg, which is relatively high. The minimum operating temperature can reach -30 ℃, and there is no disadvantage of other batteries being unable to store energy normally at low temperatures. Therefore, lithium-ion batteries can serve as ideal energy storage media due to their high specific energy and ability to operate in working environments with large temperature differences. Due to the low energy of a single lithium-ion battery, multiple lithium-ion batteries are usually integrated together to meet new development requirements, appearing in large-scale energy storage systems in the form of battery clusters. The shipment volume of lithium batteries for energy storage in China in 2017 was 74.8 GW · h, reaching 130 GW · h in 2022, a year-on-year increase of approximately 74%. From the perspective of the application of shipped products, electric energy storage is still the largest application field, accounting for over 70%, and the performance of household and portable energy storage has also exceeded expectations. The rapid development of lithium battery electrochemical energy storage in energy storage technology can be seen from the shipment volume of energy storage batteries.

In practical engineering, the composition of lithium-ion energy storage batteries mainly includes organic electrolyte, positive and negative electrodes, and a separator separating the positive and negative electrodes. Externally, to maintain the stability of the internal structure of the battery, a hard metal shell is used for sealing. Based on the basic structure of lithium-ion batteries, it can be known that their heat dissipation performance is poor. Moreover, due to the fact that lithium-ion batteries operate in clusters, in some cases, a large amount of heat can accumulate inside the battery in a short period of time, which cannot be diffused out in a timely manner, leading to uncontrolled battery performance and serious safety accidents. For example, in the past five years, the energy storage industry in South Korea has experienced a total of 23 fire accidents, including 14 after charging and discharging, 6 during charging and discharging, and 3 during installation. In 2021, a serious energy storage battery accident occurred in China at a company in Beijing. The lithium-ion energy storage battery power station caught fire and experienced explosions, poisoning, and electric shock, resulting in the deaths of two firefighters and one injury. The frequent occurrence of safety accidents has brought a warning to the rapidly developing energy storage battery industry worldwide. Operational safety must be taken seriously, and safety is paramount. Therefore, it is urgently necessary to build a fire safety monitoring system for energy storage batteries, and add emergency rescue mechanisms to provide early warning of battery runaway, timely identify and solve problems, in order to reduce the probability of thermal runaway of energy storage batteries.

2.Development of Battery Safety Monitoring System for Energy Storage Power Stations

The battery safety monitoring system (ESMS) for energy storage power stations, also known as the intelligent battery manager, plays a role in connecting energy storage batteries and users. Through the real-time detection records of the system platform, users can view and understand the operation status of each subunit in the battery cluster in real time, extend the service life of the battery, reduce the probability of accidents during battery operation, and ensure the healthy and stable operation of the entire power system. With the in-depth development of energy storage technology, safety monitoring systems have become an indispensable part of the entire power system. The key point in developing a battery safety monitoring system for energy storage power stations is how to monitor the status of each subunit in the energy storage battery cluster in real-time and manage it accordingly. Large capacity battery clusters require higher consistency for each battery. In actual testing, there may be a certain gap in the performance of lithium batteries after multiple runs, resulting in poor performance of the entire battery system, affecting the battery life and SOC of the battery cluster. The battery safety monitoring system developed in this article mainly includes a battery temperature acquisition module, a battery voltage acquisition module, a battery current acquisition module, an environmental humidity acquisition module, and a ZigBee communication module.

The control core of the ESMS subsystem is the microprocessor MC9S12-XS128, which integrates a microcontroller, ADC, and wireless communication inside, which can meet the requirements of collecting battery information and transmitting messages wirelessly in the system. LTC6804 is used to collect the voltage of individual batteries in the energy storage battery cluster group, Hall current sensor is used to collect current, NTC thermistor is used to collect the surface temperature of the battery cell, and humidity sensor LOR is used to collect the humidity of the environment where the battery is located. The above data is transmitted to the processor through wireless communication to estimate the SOC of each battery cluster group and the SOC of the entire battery cluster group. All data is further transmitted to the upper computer through the RS232 serial port, and compared with the set upper and lower critical values. When the battery related data is not within the normal range, the upper computer displays an alarm message and indicates the location of the problematic battery unit, facilitating subsequent processing. ZigBee communication technology is a bidirectional wireless communication technology with close range, low complexity, low power consumption, low speed, and high security, and has self-organizing and self-healing capabilities, which can form large-scale networks. ZigBee can operate in three frequency bands: 2.4 GHz (global), 868 MHz (European), and 915 MHz (United States), with a maximum transmission speed of 250 kbit/s and a minimum of 20 kbit/s, and a transmission distance of 10-75 meters.

Estimate the state of charge (SOC) of the battery using the ampere hour integration method. The ampere hour integration method does not consider the internal mechanism of the battery. Based on certain external characteristics of the system, such as current, time, temperature compensation, etc., it calculates the total amount of electricity flowing into/out of the battery by integrating time and current, and sometimes adding certain compensation coefficients, thereby estimating the state of charge of the battery. At present, the ampere hour integration method is widely used in battery management systems, and its calculation formula is as follows:

In the formula, SOC0 is the initial charge value of the battery’s state of charge; CE is the rated capacity of the battery; η The charge discharge efficiency coefficient, also known as the Coulomb efficiency coefficient, represents the internal energy dissipation of the battery during the charge discharge process, mainly based on the charge discharge rate and temperature correction coefficient; I (t) is the charging and discharging current of the battery at time t; T is the charging and discharging time.

To improve the accuracy of current measurement, high-performance current sensors are usually used to measure current, but this increases the cost. To this end, both the ampere hour integration method and the open circuit voltage method are applied, combining the two. The open circuit voltage method is used to estimate the initial state of charge of a battery, while the ampere hour integration method is used for real-time estimation, and relevant correction factors are added to the formula to improve calculation accuracy.

The program design of the upper computer of the system adopts VB6.0 visualization software, which mainly includes hardware initialization, battery status information acquisition, information transmission settings, over limit alarm, historical data storage, etc. To facilitate further upgrades of the program in the future, improve its readability and efficiency, corresponding modules are divided according to the types of functions.