In the global energy transition, solar energy has emerged as a cornerstone of sustainable development due to its cleanliness and renewability. As carbon neutrality goals advance, solar technology’s importance is increasingly prominent. Its environmental benefits and resource sustainability not only accelerate the reshaping of low-carbon energy structures but also show broad application prospects in distributed generation, building integration, and smart energy networks, providing key support for the global energy revolution. Perovskite solar cells, as representatives of third-generation photovoltaic technology, have achieved a certified photoelectric conversion efficiency exceeding 27% for single-junction devices. They offer advantages such as flexible/lightweight structural design and low-temperature solution-based processing, enabling synergistic optimization through bandgap engineering and interface defect passivation strategies, presenting potential technical advantages in the photovoltaic field. The theoretical PCE of perovskite solar cells can reach up to 33%, surpassing the upper limit of traditional silicon-based cells (29%), highlighting significant efficiency potential. Perovskite materials can be fabricated into flexible devices via low-temperature processes, applicable in building and transportation integration, wearable device power sources, and portable charging equipment, meeting lightweight and miniaturization needs. Perovskite solar cells can be manufactured using various methods such as solution processing and vapor deposition, allowing flexible production on different substrates to meet industrial-scale manufacturing demands. Currently, through efficiency breakthroughs, structural innovation, and cost advantages, perovskite solar cells offer new solutions for diversified photovoltaic applications, poised to become strong contenders in the next generation of sustainable energy.

Despite the PCE of single-junction perovskite solar cells exceeding 27%, issues such as non-radiative recombination and interface degradation induced by grain boundary defects in polycrystalline films accelerate performance decay, resulting in insufficient long-term stability that severely hinders commercialization. Current techniques, including quasi-single-crystal film formation and interface passivation, can partially suppress defect densities, but the intrinsic properties of polycrystalline structures still leave a gap between long-term stability and commercial requirements. Therefore, how to regulate defect depths and optimize interface engineering while maintaining high PCE has become a core issue in breaking the industrialization bottleneck. In this study, we introduce butylammonium iodide (BAI) as an additive to optimize film crystallization, achieving dual mechanisms of improving perovskite film quality and inducing preferred orientation growth through semi-in situ characterization. We investigate the impact of BAI on the photoelectric performance of perovskite solar cells and the underlying mechanisms by testing the photovoltaic performance and stability of devices before and after treatment. Additionally, we explore the application of BAI-treated perovskite films in flexible perovskite solar cells, providing a new optimization strategy for developing wearable photovoltaic technology.

We employed BAI as an additive during the spin-coating process of perovskite films to regulate crystallization. The perovskite layers were fabricated using a two-step spin-coating method with antisolvent engineering. The precursor solution consisted of FAI, PbI₂, MACl, and MAPbBr₃ in a DMF/DMSO mixed solvent. BAI was dissolved in antisolvent (anisole) at varying concentrations (0, 0.068, 0.136, and 0.204 mg/mL) and applied during the second spin-coating step. The films were annealed at 100°C for 60 minutes. The resulting perovskite films are denoted as xBAI-Pf, where x represents the BAI concentration. For device fabrication, we used an n-i-p structure: ITO/SnO₂/perovskite/Spiro-OMeTAD/Au for rigid cells and PET/ITO/SnO₂/perovskite/Spiro-OMeTAD/Au for flexible cells. The electron transport layer (SnO₂) and hole transport layer (Spiro-OMeTAD) were deposited following standard procedures. Characterization included scanning electron microscopy (SEM), atomic force microscopy (AFM), X-ray diffraction (XRD), X-ray photoelectron spectroscopy (XPS), ultraviolet photoelectron spectroscopy (UPS), photoluminescence (PL), time-resolved photoluminescence (TRPL), space-charge-limited current (SCLC), current density-voltage (J-V) measurements, and external quantum efficiency (EQE). Stability tests were conducted under environmental, thermal, illumination, and mechanical bending conditions.

To investigate the crystallization regulation effect of BAI on perovskite films, we performed SEM analysis on films treated with different BAI concentrations. Compared to the untreated film (0BAI-Pf), BAI treatment reduced the number of small surface grains and significantly increased the perovskite grain size. The 0.136BAI-Pf exhibited the most optimal surface morphology, with larger and more uniform grains. Statistical analysis of grain size distribution revealed that the average grain size increased from 0.62 μm for 0BAI-Pf to 1.21 μm for 0.136BAI-Pf. Water contact angle measurements showed that BAI treatment enhanced the hydrophobic properties of the perovskite surface, with contact angles initially increasing and then decreasing with higher BAI concentrations, indicating improved environmental stability. AFM results demonstrated that the surface roughness decreased initially with BAI concentration, reaching a minimum for 0.136BAI-Pf (Rq = 35.5 nm) compared to 0BAI-Pf (Rq = 42.9 nm). These findings confirm that BAI treatment effectively regulates perovskite crystallization, yielding larger, more uniform grains, optimized surface morphology, reduced roughness, and increased hydrophobicity.

XRD measurements were conducted to examine the influence of BAI on the crystallization process. The XRD patterns showed characteristic peaks at 2θ = 14.1°, 24.5°, and 28.3°, corresponding to the (100), (111), and (200) planes of perovskite, respectively. No new diffraction peaks or peak shifts were observed, indicating that BAI did not incorporate into the perovskite lattice or alter crystal properties. The full width at half maximum (FWHM) of the (100) peak decreased with BAI treatment, with the smallest value for 0.136BAI-Pf (0.1271°), indicating improved crystallinity. The intensity ratio of (100)/(111) planes increased significantly for BAI-treated films, suggesting promoted preferential orientation along the (100) plane. Semi-in situ 3D XRD analysis during annealing revealed that BAI treatment enhanced the diffraction intensities of (100) and (111) planes from the initial crystallization stages, demonstrating effective induction of (100) orientation. The preferential (100) orientation in cubic perovskite crystals is associated with higher carrier mobility and lower defect density, beneficial for photoelectric performance.

XPS analysis of 0BAI-Pf and 0.136BAI-Pf showed shifts in Pb4f and N1s peaks, indicating interactions between BAI and PbI₂. The Pb4f₅/₂ peak shifted from 143.0 eV to 143.2 eV, Pb4f₇/₂ from 138.0 eV to 138.2 eV, and N1s from 400.5 eV to 400.7 eV. These interactions retard perovskite crystallization, as confirmed by optical microscopy during annealing, where 0.136BAI-Pf exhibited a slower transition to the black phase, correlating with larger grain sizes. UV-Vis absorption spectra and Tauc plots revealed a consistent bandgap of 1.55 eV for both films, indicating no significant change in optical bandgap. UPS measurements determined the energy level structures. The valence band maximum (EVB) shifted from -5.33 eV for 0BAI-Pf to -5.25 eV for 0.136BAI-Pf, improving the energy level alignment with Spiro-OMeTAD and facilitating hole carrier extraction and transport.

| Sample | Ecutoff (eV) | EFermi (eV) | EVB (eV) | ECB (eV) | EF (eV) | Eg (eV) |

|---|---|---|---|---|---|---|

| 0BAI-Pf | 17.16 | 1.27 | -5.33 | -3.78 | -4.06 | 1.55 |

| 0.136BAI-Pf | 17.27 | 1.30 | -5.25 | -3.70 | -3.95 | 1.55 |

Steady-state PL and TRPL spectra were measured to assess carrier recombination. BAI treatment enhanced the PL intensity, indicating reduced non-radiative recombination due to improved film quality and fewer defects. TRPL decay curves were fitted with a bi-exponential function, and the average carrier lifetime (τave) was calculated. The τave increased from 37.18 ns for 0BAI-Pf to 109.80 ns for 0.136BAI-Pf, confirming suppressed carrier recombination. SCLC measurements on electron-only devices (ITO/SnO₂/perovskite/PCBM/Ag) were used to estimate the trap density (Ntrap). The trap-filled limit voltage (VTFL) decreased from 0.25 V for 0BAI-Pf to 0.16 V for 0.136BAI-Pf, corresponding to a reduction in Ntrap from 6.91 × 1015 cm−3 to 4.42 × 1015 cm−3. This demonstrates that BAI treatment lowers defect density, inhibiting non-radiative recombination in perovskite solar cells.

| Sample | τ1 (ns) | A1 | τ2 (ns) | A2 | τave (ns) |

|---|---|---|---|---|---|

| 0BAI-Pf | 33.13 | 0.40 | 40.49 | 0.40 | 37.18 |

| 0.136BAI-Pf | 83.67 | 0.36 | 102.27 | 0.36 | 109.80 |

The photovoltaic performance of rigid perovskite solar cells was evaluated through J-V measurements. The champion device with 0.136BAI-PSCs achieved a PCE of 23.46%, with VOC = 1.11 V, FF = 83.43%, and JSC = 25.29 mA/cm², compared to 0BAI-PSCs (PCE = 22.32%, VOC = 1.11 V, FF = 81.21%, JSC = 24.75 mA/cm²). The enhancement in PCE is primarily attributed to improved FF, resulting from higher film quality and suppressed non-radiative recombination. Hysteresis index (HI) calculations from forward and reverse scans showed reduced hysteresis for 0.136BAI-PSCs (HI = 0.02) compared to 0BAI-PSCs (HI = 0.05), indicating better charge transport and reduced ionic migration. Statistical analysis of 20 devices confirmed the reproducibility and uniformity of BAI-treated perovskite solar cells. EQE spectra and integrated current densities aligned with J-V results, validating the JSC measurements.

| Device | VOC (V) | FF (%) | JSC (mA/cm²) | PCE (%) |

|---|---|---|---|---|

| 0BAI-PSCs | 1.11 | 81.21 | 24.75 | 22.32 |

| 0.068BAI-PSCs | 1.11 | 82.67 | 24.92 | 22.85 |

| 0.136BAI-PSCs | 1.11 | 83.43 | 25.29 | 23.46 |

| 0.204BAI-PSCs | 1.09 | 82.07 | 24.96 | 22.41 |

Stability tests were conducted on unencapsulated devices. Environmental stability at 25°C and 30% relative humidity showed that 0.136BAI-PSCs retained 83.81% of initial PCE after 3000 hours, compared to 62.50% for 0BAI-PSCs. Thermal stability at 65°C in N₂ atmosphere revealed that 0.136BAI-PSCs maintained 75.07% of initial PCE after 300 hours, versus 37.45% for 0BAI-PSCs. Illumination stability under continuous one-sun light (AM 1.5G, 100 mW/cm²) demonstrated that 0.136BAI-PSCs retained 92.35% of initial PCE after 150 hours, while 0BAI-PSCs retained 71.26%. These improvements are attributed to enhanced film quality, reduced defect density, and suppressed ion migration in BAI-treated perovskite solar cells.

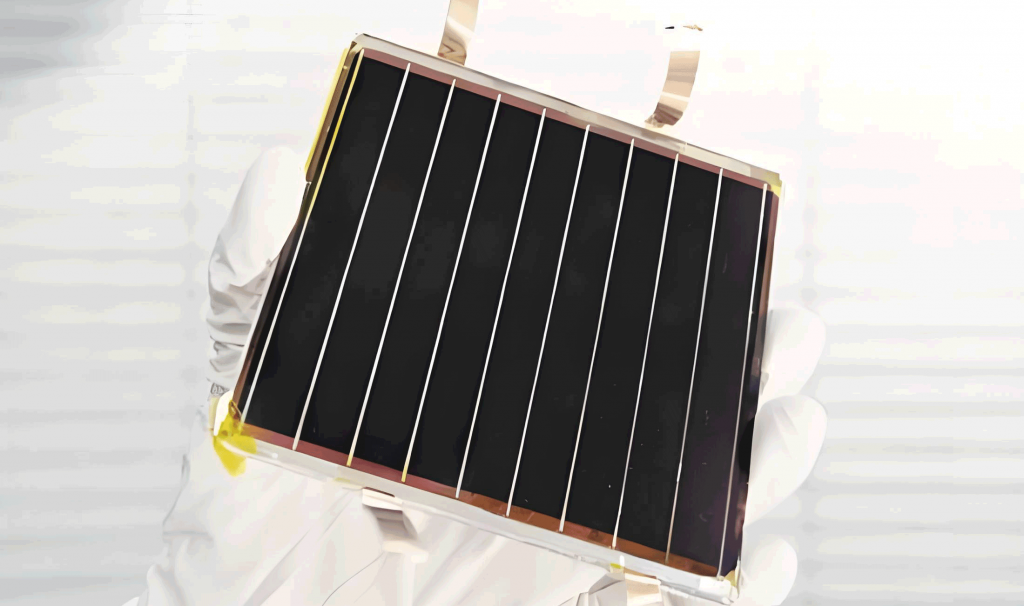

For flexible perovskite solar cells, 0.136BAI-F-PSCs achieved a champion PCE of 22.26% (VOC = 1.11 V, FF = 81.24%, JSC = 24.82 mA/cm²), outperforming 0BAI-F-PSCs (PCE = 21.51%, VOC = 1.11 V, FF = 78.64%, JSC = 24.74 mA/cm²). Hysteresis was also reduced (HI = 0.01 for 0.136BAI-F-PSCs vs. 0.02 for 0BAI-F-PSCs). Mechanical stability tests under bending with a 5 mm radius showed that 0.136BAI-F-PSCs retained 92.25% of initial PCE after 10,000 cycles and 90.75% after 15,000 cycles, compared to 69.70% and 63.86% for 0BAI-F-PSCs, respectively. The enhanced mechanical stability stems from improved film quality, larger grains, and reduced defects.

The introduction of BAI as an additive effectively regulates perovskite crystallization, enhancing film quality and resulting in perovskite solar cells with superior photoelectric performance and stability. BAI promotes preferential orientation along the (100) plane, improves crystallinity, and increases grain size. The high-quality perovskite films exhibit better optoelectronic properties, more suitable energy level structures, enhanced PL intensity, and longer carrier lifetimes. Consequently, 0.136BAI-PSCs achieved a higher PCE of 23.46% compared to 22.32% for 0BAI-PSCs, with reduced hysteresis. Similarly, 0.136BAI-F-PSCs reached a PCE of 22.26%, surpassing 21.51% for 0BAI-F-PSCs. Additionally, BAI treatment improved the environmental, thermal, and illumination stability of rigid perovskite solar cells, as well as the mechanical stability of flexible devices. This modification strategy provides a solution for perovskite photovoltaics that combines high efficiency, stability, and flexible processability, offering significant potential for industrial applications.

The enhanced performance can be modeled using the diode equation for solar cells:

$$J = J_{SC} – J_0 \left( \exp\left(\frac{q(V + J R_S)}{n k T}\right) – 1 \right) – \frac{V + J R_S}{R_{SH}}$$

where \(J\) is the current density, \(J_{SC}\) is the short-circuit current density, \(J_0\) is the reverse saturation current density, \(q\) is the electron charge, \(V\) is the voltage, \(R_S\) is the series resistance, \(n\) is the ideality factor, \(k\) is Boltzmann’s constant, \(T\) is the temperature, and \(R_{SH}\) is the shunt resistance. The improved FF and reduced hysteresis in BAI-treated perovskite solar cells correlate with lower \(R_S\) and higher \(R_{SH}\), attributable to better film quality and reduced defects.

The trap density reduction can be quantified using the SCLC method:

$$N_{trap} = \frac{2 \epsilon_0 \epsilon_r V_{TFL}}{q L^2}$$

where \(\epsilon_0\) is the vacuum permittivity, \(\epsilon_r\) is the relative permittivity of perovskite, \(V_{TFL}\) is the trap-filled limit voltage, and \(L\) is the film thickness. The decrease in \(N_{trap}\) for BAI-treated films confirms defect passivation.

In conclusion, our study demonstrates that organic amine salts like BAI effectively optimize perovskite film crystallization, leading to significant advancements in the efficiency and stability of perovskite solar cells. This approach addresses key challenges in perovskite photovoltaics and paves the way for their commercial deployment.