This study presents an efficient approach for recovering lithium (Li) and iron (Fe) from spent lithium iron phosphate (LiFePO4) batteries using ultrasonic-assisted glucose reduction and acid leaching. The process optimizes conventional leaching parameters and introduces ultrasound to enhance leaching efficiency, offering a sustainable solution for battery recycling.

Experimental Methodology

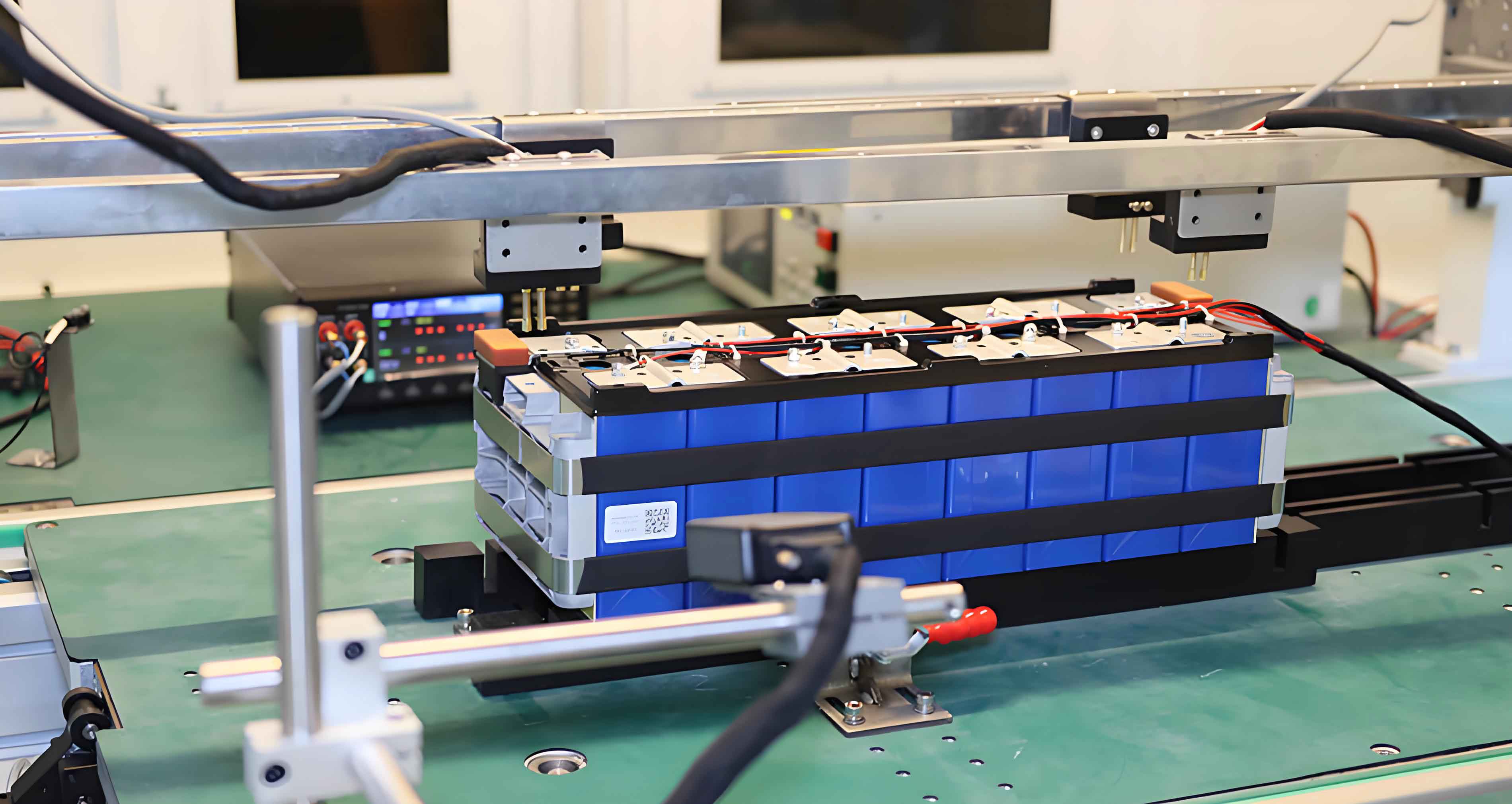

Spent LiFePO4 batteries were discharged, dismantled, and thermally treated at 450°C to remove organic binders. The cathode material was ground to 100 mesh and analyzed via ICP-OES (Table 1). Leaching experiments utilized H2SO4 and glucose under varying conditions, with ultrasonic assistance (70 W) applied to accelerate kinetics.

Results and Discussion

Conventional Leaching Optimization

The effects of critical parameters on Li/Fe recovery were systematically evaluated:

| Element | Li | Fe | P | Al | Others |

|---|---|---|---|---|---|

| Content (wt%) | 4.36 | 33.27 | 18.45 | 0.07 | 43.85 |

| Parameter | H2SO4 | Glucose | Liquid-Solid Ratio | Temperature | Time |

|---|---|---|---|---|---|

| Optimal Value | 2 mol/L | 2 mol/L | 15 mL/g | 70°C | 90 min |

| Leaching Efficiency | Li: 88.25%, Fe: 90.13% | ||||

The leaching mechanism involves:

$$ \text{LiFePO}_4 + 2\text{H}^+ \rightarrow \text{Fe}^{2+} + \text{Li}^+ + \text{H}_2\text{PO}_4^- $$

$$ \text{FePO}_4 + 2\text{H}^+ \rightarrow \text{Fe}^{3+} + \text{H}_2\text{PO}_4^- $$

Ultrasonic Enhancement

Ultrasound significantly improved leaching performance:

| Condition | Time (min) | Li Recovery (%) | Fe Recovery (%) |

|---|---|---|---|

| Conventional | 90 | 88.25 | 90.13 |

| Ultrasonic-Assisted | 60 | 95.36 | 95.83 |

Ultrasonic effects include:

- 30% reduction in process time

- 7–17% increase in metal recovery

- Enhanced particle fragmentation (SEM analysis)

Kinetic Analysis

The leaching process followed the shrinking core model:

$$ 1 – (1 – \eta)^{1/3} = k_c t \quad \text{(Chemical control)} $$

$$ 1 – \frac{2\eta}{3} – (1 – \eta)^{2/3} = k_d t \quad \text{(Diffusion control)} $$

| Element | kc (min-1) | R2 | kd (min-1) | R2 |

|---|---|---|---|---|

| Li | 0.01151 | 0.94894 | 0.00452 | 0.99141 |

| Fe | 0.01098 | 0.94628 | 0.00429 | 0.98841 |

The higher R2 values for diffusion-controlled models (>0.98) confirm intra-particle diffusion as the rate-limiting step in LiFePO4 battery recycling.

Mechanistic Insights

Ultrasonic effects on LiFePO4 battery recycling include:

$$ \text{Cavitation Energy} \propto \frac{P}{\rho c^2} $$

Where P = ultrasonic power, ρ = liquid density, c = sound velocity. Higher power (70 W) increased cavitation intensity, accelerating boundary layer disruption.

Conclusion

This study demonstrates:

- Ultrasonic-assisted leaching achieves 95%+ metal recovery from LiFePO4 batteries

- Process intensification reduces energy consumption by 33%

- Kinetic analysis guides scale-up for industrial LiFePO4 battery recycling

The methodology provides a green alternative for sustainable recovery of critical materials from spent LiFePO4 batteries, addressing both economic and environmental concerns in the lithium-ion battery lifecycle.