In order to maintain the safe and reliable operation of the microgrid and improve the power quality, it is necessary to have a certain understanding of the performance of the microgrid integrated energy storage system of different types of energy storage batteries, and based on this, select the appropriate battery. Based on the experimental comparison of the performance of lead-acid batteries and lead-carbon batteries, the understanding of the performance of different types of energy storage batteries is realized, and thus the battery with high cost performance is selected. The experimental results show that compared with lead-acid batteries, lead-carbon batteries have higher cycle life and rated charge-discharge rate, lower cost, and better performance. In order to effectively control the pure battery charge and discharge, a charge and discharge control method for the microgrid energy storage system is proposed, and the simulation analysis of its application is carried out. The results show that this system can not only ensure the normal operation of the battery, but also effectively alleviate the charge and discharge pressure and improve the efficiency operation time of the energy storage system. In the development of the microgrid, distributed power sources such as photovoltaics are the main ones, and the optical storage microgrid has become the main development direction, which can effectively meet the safety and personalized needs of the majority of users, and has important promotion and application value.

At present, at home and abroad, more attention is paid to the performance and control strategy research of different types of energy storage battery energy storage systems, and active control systems for various microgrid energy storage systems are actively proposed. Based on the limitation conditions of battery capacity and charge-discharge times, the optimal control of energy storage battery charge and discharge is realized, which can optimize the charge and discharge curve of energy storage batteries. On the basis of improving the performance of energy storage batteries, it also helps to effectively improve the quality of grid-connected power. This time, a comparative analysis of the performance of the lead-carbon battery and the lead-acid battery microgrid integrated energy storage system is carried out to realize the selection of the battery, and the corresponding control strategy is proposed.

1.Performance Comparison of Different Types of Energy Storage Batteries

In this study, lead-acid batteries and lead-carbon batteries are taken as the research objects. As one of the new types of batteries, lead-carbon batteries combine carbon materials with double-layer capacitance characteristics and spongy lead to form the negative electrode, which is a composite electrode, and lead dioxide is the positive electrode material. Lead-carbon batteries combine the characteristics of lead-acid batteries and supercapacitors, which can effectively suppress the sulfation of the negative electrode plate during battery discharge and the early hydrogen evolution during charging. Compared with lead-acid batteries, lead-carbon batteries significantly improve the cycle life and rated charge-discharge rate, and also help to reduce the battery cost [2]. However, in order for lead-carbon batteries to have a longer cycle life, the discharge depth cannot be too large, and there are certain restrictions on the maximum charge and discharge power of lead-carbon batteries, which also affects the breadth of their application.

1.1 Index Selection

In this study, lead-carbon batteries and lead-acid batteries are taken as the research objects. Since both can meet the requirements of microgrid stability, the focus of this study is to analyze the microgrid economy of the energy storage system. Since the available capacities of the two batteries are relatively close, the type of battery has little effect on the revenue of the microgrid, but it has a greater impact on the battery configuration cost and the number of replacements. Therefore, in this analysis, the total cost of the battery within the full life span of 15 years of the microgrid is analyzed to explore the performance of the two batteries.

1.2 Calculation of Battery Expected Life

The cycle life of the battery (NB) is directly affected by the depth of discharge (DOD) during battery use. Generally, the greater the depth of discharge, the shorter the cycle life of the battery. The representation of the correlation between the cycle life and the depth of discharge of the two batteries in this study is as follows.

For lead-carbon batteries, it is expressed as: N_i(DOD) = 4469 × DOD^(-0.8919) – 4054

For lead-acid batteries, it is expressed as: N_B(DOD) = 5967 × DOD^(-0.467) – 4653

For the battery, assuming that the depth of discharge in the i-th cycle is DODi, the equivalent cycle number Neq of each charge and discharge in the battery operation is specifically expressed as: N_eq(DOD) = N_d(I) / N_d(DOD)

Within the entire project operation cycle, the equivalent cycle number Nsum of the battery is specifically expressed as: N_sur = Σ_(i=1)^n N_eq(DOD)

If Nsum = NB(I), that is, the service life of this battery pack has ended and needs to be replaced. For the DOD in each cycle of the battery, it can be extracted from the SOC change curve in the time-varying process of the battery by applying the rain flow counting method. The relevant process in the actual operation is as follows: First, rotate the SOC time-varying curve 90° clockwise to ensure that the time axis is in the vertical downward direction, and the relevant data is like rain dripping from the roof, and recording starts at the starting point and at each eaves (peak value) afterwards . Second, the rain flow drips vertically at the eaves until a peak greater than the peak is reached, and then it can end. Once the rain flow on the upper eaves is found, the rain flow will stop, and a cycle is formed in the process . Third, draw a cycle period by combining the starting point and the end point of the rain flow, and record the peak and valley values of each cycle in detail. The discharge depth in the cycle period is the horizontal length of each rain flow . Therefore, to analyze the performance of each battery, to extract the DOD, it is necessary to obtain the SOC curve over time, and the calculation methods of SOC during battery charging and discharging can be expressed as: SOC(k) = SOC(k – 1) + P_k(k – 1) × K_E × Δt / Q_E

SOC(k) = SOC(k – 1) + P_l(k – 1) / K_R × Δt / Q_n

In Formulas (5) and (6), SOC(k) represents the SOC at the current sampling moment, and SOC(k – 1) is the SOC at the previous sampling moment; KB represents the charge/discharge efficiency of the battery; PB(k – 1) represents the battery output power at the previous sampling moment; QB represents the battery capacity; Δt represents the sampling time interval.

1.3 Performance Comparison Results

For the study of the equivalent cycle times of the two batteries within one year, the meteorological data of a company’s microgrid for one year is used as the data, and the analysis of the battery’s one-year SOC curve is realized based on the Meteonorm software. Assuming that the usage of the two types of batteries is the same every year, the calculation method of the expected service life of the battery is NB(I) / the annual equivalent cycle times of the battery, and through this method, the number of battery replacements within 15 years can be obtained. Under this calculation mode, the results are shown in Table 1.

| Type | Expected Service Time of the Battery (years) | Number of Battery Replacements (times) | Cost of the Battery Body within the Full Life Cycle (ten thousand yuan) | Cost of PCS Equipment (ten thousand yuan) | Total Cost within the Full Life Cycle (ten thousand yuan) |

|---|---|---|---|---|---|

| Lead-acid Battery | 4.26 | 3 | 6200 | 80 | 6280 |

| Lead-carbon Battery | 5.71 | – | 500 | 80 | 4580 |

Through the above analysis, it is found that as the service life of the two batteries increases, the number of replacements gradually decreases. In the comparison of the costs of the two batteries, the total cost of the lead-carbon battery is significantly lower than that of the lead-acid battery, so the lead-carbon battery becomes the optimal choice for the microgrid integrated energy storage system in the two groups of comparisons.

2. Charge and Discharge Control of the Microgrid Energy Storage System

Regarding the charge and discharge control of the microgrid energy storage system, it is necessary to monitor the charge and discharge status of each energy storage unit in the system to reasonably reduce the overcharge or overdischarge of the battery, improve the working efficiency of the energy storage system, and further extend the service life of the battery. In the process of this control research, for the power margin of each energy storage unit, the real-time SOC of the lead-carbon battery and the supercapacitor in the hybrid energy storage unit is estimated and analyzed to reasonably arrange the successful discharge tasks.

2.1 When PHESS < 0

In this case, if the DOD value of the i-th battery in the hybrid energy storage module can meet the condition of DODi ≥ DODmax, that is, the corresponding battery cannot continue to discharge, and the power flowing on the converter of both parties can be expressed as P_mess(t) = 0 (7)

If the DOD value of the j-th battery in the hybrid energy storage module can meet the condition of DODi < DODmax, that is, the corresponding battery unit can continue to discharge, and the corresponding discharge power can be expressed as: P_HESS – j = -P_HES(t) × C_HESS – j(DODmax – DOD) / Σ[C_HSS – j(DODmax – DOD)]

In Formula (8), C_HESS – j represents the basic capacity of the j-th energy storage unit, and C_HESS – j(DODmax – DODi) is the remaining capacity of the j-th energy storage unit.

2.2 When PHESS > 0

In this case, if the SOC value of the i-th battery in the hybrid energy storage module can meet the condition of SOCi > SOCmax, that is, the corresponding battery cannot continue to discharge, and the power flowing on the converter of both parties can be expressed as: P_Hess – 1(t) = 0 (9)

If the DOD value of the j-th battery in the hybrid energy storage module can meet the condition of SOCi < SOCmax, that is, the corresponding battery unit can continue to discharge, and the corresponding discharge power can be expressed as: P_HESS – j = -P_HESS(t) × C_HSS – j(SOCmax – SOC) / Σ_j[C_HESS – j(SOCmax – SOC)]

In Formula (10), C_HESS – j represents the basic capacity of the j-th energy storage unit, and C_HESS – j(SOCmax – SOCi) is the remaining capacity of the j-th energy storage unit.

3. Experimental Analysis

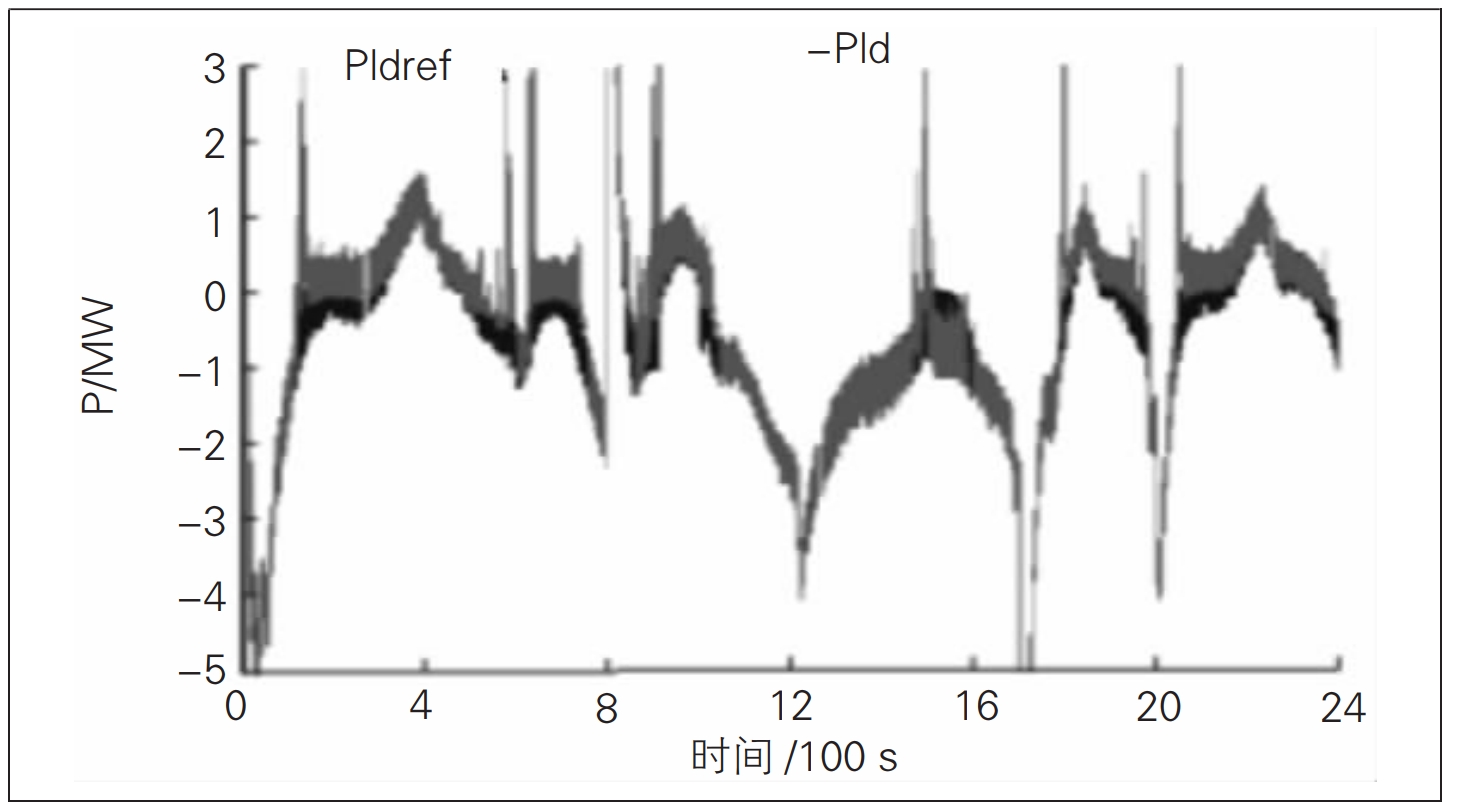

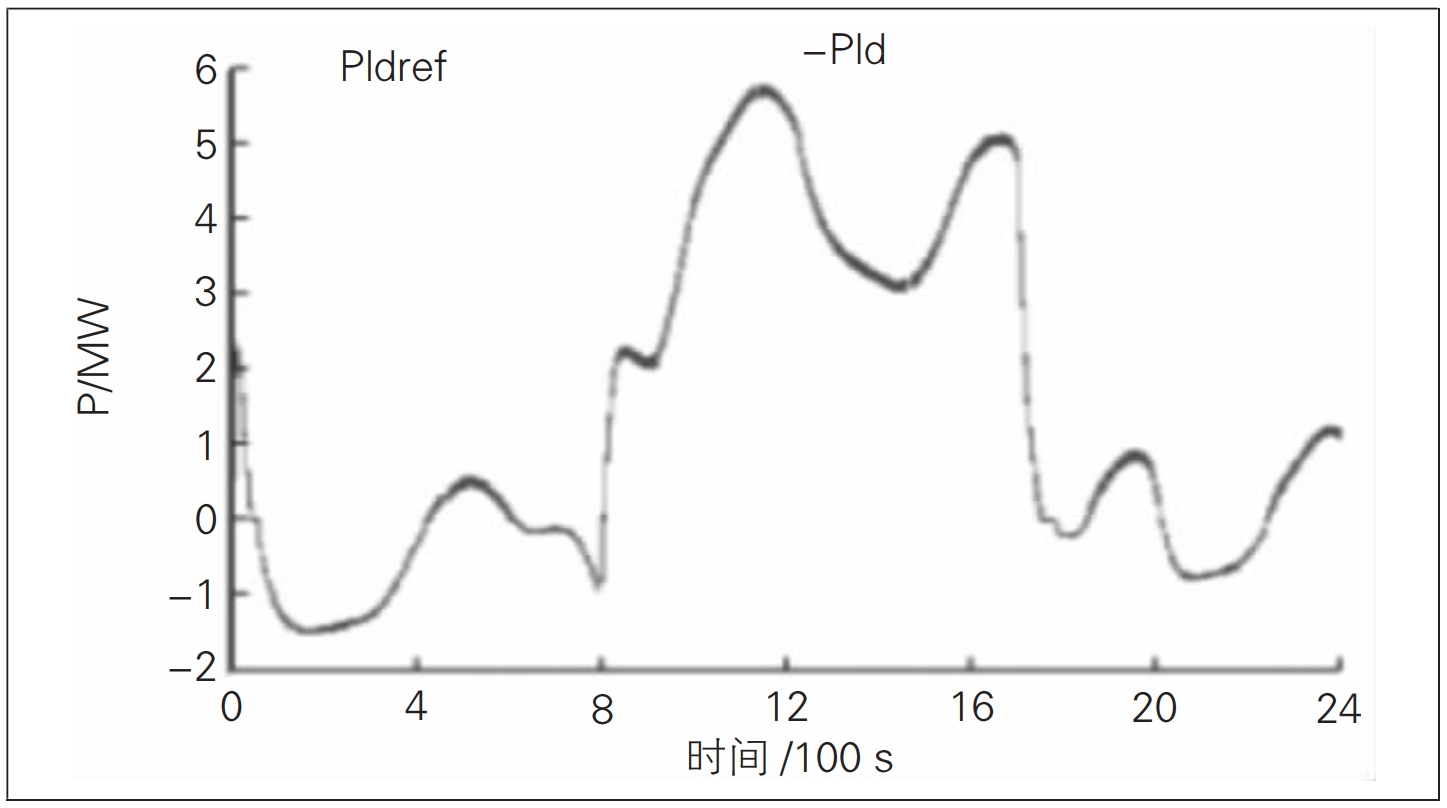

In order to analyze the rationality of the application of the above control scheme, it is applied in the microgrid, providing a fluctuation frequency similar to the moment when the microgrid is connected to the grid, and the time constant is assumed to be 2400 s. Based on the matlab platform, the original wind and photovoltaic output data is called and imported to ensure that the total capacity of the energy storage system configuration is within 10% of the distributed resources, and the specific value is 7 MW, and the rated capacity of a single module is 500 kW. Therefore, in this experiment, 10 hybrid energy storage units are connected in parallel. In the experiment, it is necessary to smooth the randomly generated wind and light uncertainty power situation. At the same time, the analysis found that the HESS has a significant advantage in smoothing the original power volatility compared with the supercapacitor, mainly because the energy density of the HESS and the single energy storage method have been significantly improved, which can ensure that the final output power waveform meets the system scheduling requirements. Among them, the charge and discharge power waveforms of the supercapacitor and the lead-carbon battery in the hybrid energy storage system are compared and analyzed separately, and the details of the charge and discharge curve distribution at each time point of the two.

Figure 1 shows that the charge and discharge amounts of the supercapacitor at each time point are relatively large and frequent, and Figure 2 shows that the relative charge and discharge amounts of the lead-carbon battery at each time point are small and the frequency is low. For the reason analysis, the second-order filtering principle is adopted this time. The first stage is to smooth the high-frequency fluctuation component of the original output power of the supercapacitor and the power response delay of the battery required by the system for rapid response. The second-stage lead-carbon battery can achieve further smoothing. In this process, on the basis of making full use of the supercapacitor and ensuring the normal operation of the lead-carbon battery, the excessive charge and discharge pressure is alleviated, so as to further improve the efficiency operation time of the lead-carbon battery.

4. Conclusion

In summary, the following conclusions are drawn through the research: First, in this study, the performance of lead-acid batteries and lead-carbon batteries is analyzed. The lead-carbon battery itself is based on the lead-acid battery. Therefore, the total operating cost within 15 years is selected for analysis. The results show that the total operating cost of the lead-carbon battery is significantly lower than that of the lead-acid battery. Thus, it can be seen that the lead-carbon battery is more selectable than the lead-acid battery. Second, through the research on the charge and discharge control of the microgrid energy storage system and the analysis of its application effect, it is found that the application of this control scheme in the microgrid can not only ensure the normal operation of the lead-carbon battery, but also alleviate the multi-charge and discharge pressure and optimize the efficiency operation time of the lead-carbon battery.

In the current development of the microgrid energy storage system, in order to meet the energy conservation and environmental protection needs in the current social environment, optical storage microgrids have begun to appear, mainly based on distributed power sources such as photovoltaics. Compared with the traditional large-scale power grid power supply method, this method can better meet the high safety and reliability needs of users, and can provide personalized power supply services for different users. “Photovoltaic power generation + energy storage system microgrid” has become an important way to implement my country’s sustainable energy development strategy, and has great development potential. Therefore, in the future development, it is necessary to increase the research on “photovoltaic power generation + energy storage system microgrid” to promote its development and realize my country’s sustainable energy development strategy.