The rapid evolution of new energy vehicles, heavily supported by national industrial policies, has positioned the lithium-ion battery as the indispensable “heart” of this technological revolution. The performance, capacity, and cycle life of a lithium-ion battery pack are profoundly influenced by the quality of its electrodes, specifically their energy density and thickness uniformity. The manufacturing of battery electrodes, involving processes like coating, calendering, and slitting, accounts for over 70% of the impact on the final battery’s performance. Among these, the calendering process plays a particularly critical role in enhancing key battery characteristics.

As market demand for power lithium-ion batteries continues to grow, there is an escalating need for higher electrode quality and production efficiency. However, persistent challenges in current production, such as imprecise control of calendering pressure, poor thickness uniformity, and pronounced edge effects, severely limit further improvements in lithium-ion battery performance. This underscores the necessity for a comprehensive design and in-depth study of calendering production lines. This article aims to synthesize recent advancements and present a novel overall design for a lithium-ion battery electrode calendering line, focusing on improving quality, efficiency, and energy density.

1. Analysis of Lithium-Ion Battery Electrode Calendering Process

1.1 Principle of Electrode Calendering

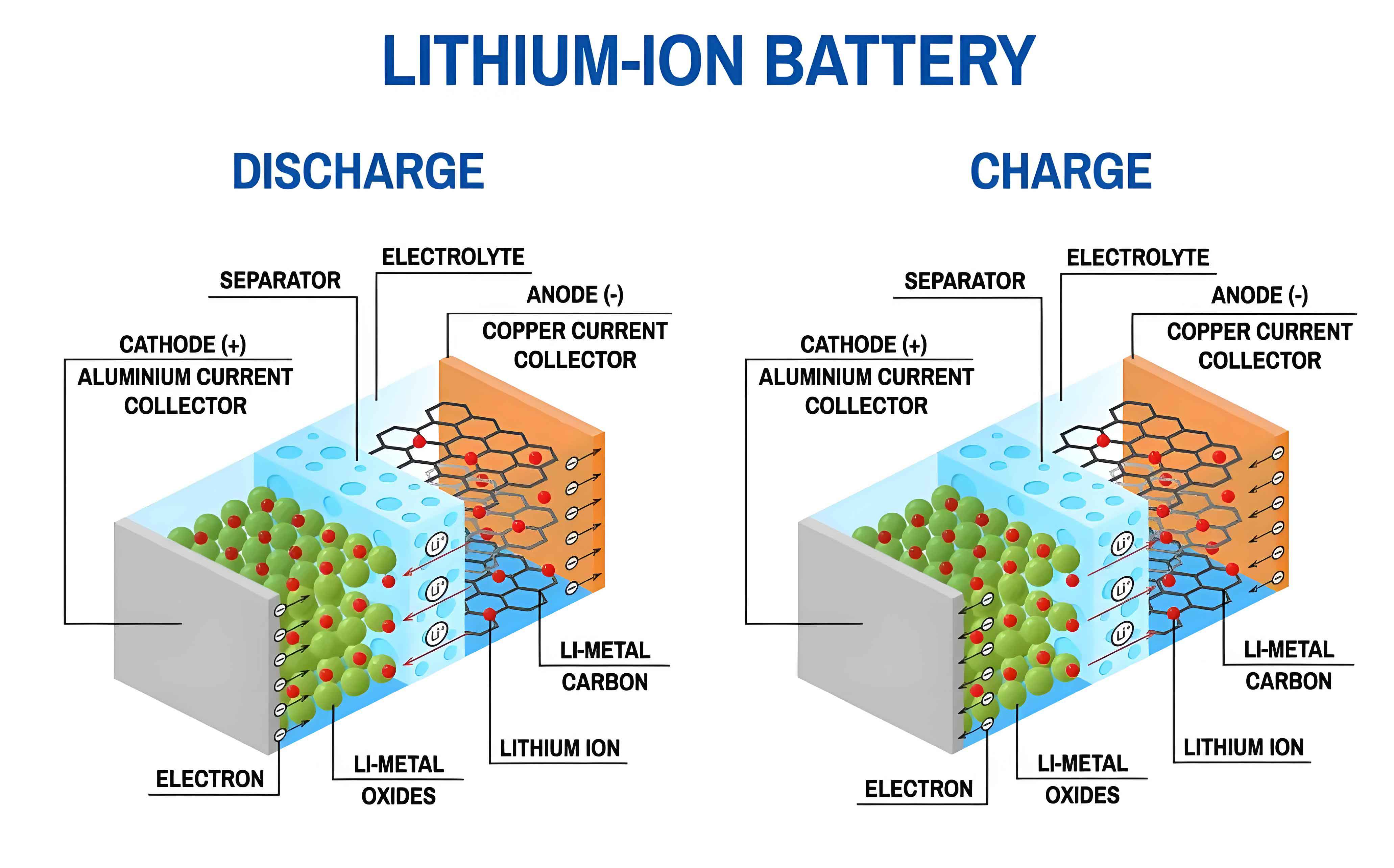

The calendering process follows the coating and drying stages in lithium-ion battery electrode manufacturing. The electrode substrate, typically copper or aluminum foil, is coated with active materials like graphite (anode) or lithium iron phosphate (cathode). Post-drying, this coated foil enters the calender.

Prior to calendering, the coating consists of a semi-flowable, semi-solid granular medium. These particles are separate or agglomerated, featuring dispersibility and flowability with voids between them. The calendering action causes small displacements of these electrochemically active particles, filling the interstitial voids and achieving mutual positioning. This process can be viewed as the continuous compaction of a semi-solid paste under unconfined conditions. The particles are carried into the nip between two counter-rotating rolls by friction and are compacted, adhering to the foil to form an electrode sheet with a defined density.

A fundamental mechanical condition for successful calendering is the “bite” condition, where the friction angle ($\phi$) must be greater than or equal to the bite angle ($\alpha$). This can be related to the coefficient of friction ($\mu$):

$$\mu \geq \tan \alpha$$

The bite angle is geometrically related to the roll radius ($R$) and the reduction in gap ($\Delta h$), which is the difference between the entry thickness ($h_0$) and the exit thickness ($h_1$):

$$\alpha \approx \sqrt{\frac{\Delta h}{R}} = \sqrt{\frac{h_0 – h_1}{R}}$$

The primary goal is to achieve a target compaction density ($\rho_c$), which is a function of the mass of active material per unit area ($M/A$) and the calendered coating thickness ($h_{coat}$):

$$\rho_c = \frac{M/A}{h_{coat}}$$

The line force or specific pressure ($P_L$), a critical process parameter, is the total roll separating force ($F$) divided by the electrode sheet width ($W$):

$$P_L = \frac{F}{W}$$

1.2 Factors Influencing Calendering Quality

The paramount quality issue arising from calendering is poor thickness consistency, which directly reflects inconsistent compaction density and ultimately impairs the performance of the lithium-ion battery. Thickness inconsistency is analyzed in two dimensions: Machine Direction (MD or longitudinal) and Transverse Direction (TD or cross-web).

| Thickness Direction | Primary Influencing Factors | Root Cause / Mechanism |

|---|---|---|

| Longitudinal (MD) | Coating Uniformity | Non-uniform wet coating mass or drying profile leads to variable input to the calender. |

| Mechanical & Assembly Precision | Errors in roll concentricity, bearing runout, and frame alignment cause periodic thickness variation. | |

| Hydraulic System Response | Pressure fluctuations, hysteresis, or instability in the hydraulic system controlling roll force. | |

| Transverse (TD) | Roll Deflection (Bending) | Under high line force, rolls bend elastically, causing a “crown” profile (thicker center, thinner edges). |

| Hydraulic Pressure Distribution | Uneven pressure across the roll face from poorly designed or adjusted hydraulic systems. | |

| Frame and Base Stiffness | Insufficient rigidity of the calender frame or foundation allows misalignment under load. | |

| Both Directions | Web Tension Control | Unstable or uneven tension from unwind/rewind systems causes slippage or stretching. |

| Web Guiding (Steering) | Poor edge guiding leads to misalignment in the nip, affecting edge quality and uniformity. |

The elastic deflection of the rolls is a major source of TD profile issues. The deflection at the center ($\delta_{center}$) relative to the ends can be approximated for a simply supported roll under uniformly distributed load (line force $P_L$ over length $L$, roll modulus $E$, moment of inertia $I$):

$$\delta_{center} \approx \frac{5 P_L L^4}{384 E I}$$

Where the moment of inertia for a solid roll of diameter $D$ is $I = \frac{\pi D^4}{64}$. This formula highlights why increasing roll diameter ($D$) is a common strategy to reduce deflection, as $I$ is proportional to $D^4$.

2. Overall Design of the Lithium-Ion Battery Electrode Calendering Line

2.1 Overall Line Layout Design

To ensure stable and high-quality production, the designed calendering line integrates several key modules in a sequential layout. The material flow is continuous from the unwind section, through processing zones, to the final rewind.

| Module Name | Primary Function | Key Sub-Components |

|---|---|---|

| Unwind Unit | To feed the coated electrode web into the line under controlled tension. | Drive motor & reducer, air shaft, safety chucks, dancer/load cell tension system. |

| Web Guide System | To correct lateral (TD) web misalignment in real-time. | Edge or line scan sensor, guiding controller, pneumatic or mechanical actuator. |

| Pre-Cleaning Unit | To remove dust and ferrous particles from the web surface before calendering. | Rotary brush, static eliminator, high-power magnet rolls. |

| Calender (Press) | The core module to compact the electrode coating to target density and thickness. | Work rolls, backup rolls, housing, hydraulic system, gap adjustment drive. |

| Laser Thickness Gauge | To perform non-contact, real-time measurement of calendered electrode thickness. | C-frame scanner, laser micrometer, scanning servo drive, data interface. |

| Post-Calender Cleaning* | To clean active material (e.g., graphite) adhering to the roll surface (mainly for anode). | Oscillating doctor blades, nylon or fabric wipe rolls, vacuum extraction. |

| Rewind Unit | To wind the calendered electrode into a master roll for subsequent slitting. | Center-surface drive, lay-on roller, tension control, automatic cut & transfer. |

| Control System | To coordinate all line functions, execute process recipes, and ensure quality. | Industrial PLC, HMI, drive controllers, network for MES/SCADA integration. |

*Note: Post-calender cleaning is often integrated as part of the calender module for anode production.

2.2 Functional Description of Key Line Sections

Unwind Section: This section manages the master roll of coated electrode. The air shaft expands to lock the roll core. A closed-loop tension control system, often combining a dancer arm with a low-friction pneumatic cylinder and a load cell, maintains a precise and stable web tension. An automatic web guide corrects lateral position. A splicing table allows for uninterrupted production during roll changeovers.

The Calender: As the heart of the line, its design is paramount. Modern high-precision calenders for lithium-ion battery electrodes typically feature a vertical “H-frame” or “C-frame” structure for high rigidity. The work rolls are often supported by larger backup rolls to minimize deflection. A servo-hydraulic system applies the precise separating force. Independent servo-driven wedge systems on both sides allow for precise roll gap (nip) setting and profile correction.

Measurement & Control: The laser thickness gauge, positioned immediately after the calender nip, scans the web continuously. The measured thickness profile (both MD and TD) is fed back to the line’s master controller. This controller dynamically adjusts the calender’s hydraulic pressure (global force) and potentially the roll gap profile (e.g., via roll bending or thermal crown) to correct deviations, forming a closed-loop control system.

Rewind Section: Similar to the unwind but operating in reverse, it winds the processed web. Precise tension control is crucial to avoid damaging the now-fragile calendered structure. A surface/center drive combination with a lay-on roller ensures a tightly wound, defect-free master roll.

2.3 Overall Control System Design

The control architecture is built around a modular, PLC-centric design for robustness and precision. It integrates several critical control loops:

- Web Tension Control: PID-based loops using feedback from dancer position or load cells at unwind, inter-stand (between units), and rewind.

- Calender Force & Gap Control: A high-response servo-hydraulic system regulates the roll separating force. The gap adjustment system positions the rolls with micron-level accuracy.

- Closed-Loop Thickness Control: The system uses the laser gauge data as feedback. An advanced controller (e.g., model-predictive or adaptive PID) calculates corrections to the calender force setpoint to maintain the target thickness.

$$F_{new} = F_{set} + K_p \cdot e(t) + K_i \int e(t) dt + K_d \frac{de(t)}{dt}$$

where $e(t) = h_{target} – h_{measured}(t)$. - Supervisory & Data Integration: The PLC communicates with an HMI for operator interface and with a plant-wide Manufacturing Execution System (MES). All critical process parameters—roll force, speed, thickness statistics, tension—are logged for traceability and analysis.

| Control Loop | Sensor | Actuator | Control Objective |

|---|---|---|---|

| Tension Control | Dancer Potentiometer / Load Cell | Unwind/Rewind Drive Torque | Maintain constant web tension $T_{set} \pm \Delta T$ |

| Lateral Guide | Edge Sensor | Pneumatic Guiding Frame | Maintain web edge position within $\pm 0.5$ mm |

| Thickness Control | Laser Micrometer | Calender Hydraulic Force / Gap | Maintain thickness $h_{target} \pm 1.0 \mu m$ (3σ) |

| Speed Synchronization | Rotary Encoders on Drives | All Section Drive Speeds | Maintain speed match between sections to prevent slack or over-tension |

2.4 Line Operational Workflow

The production sequence begins by threading the leading edge of a coated electrode master roll from the unwind station, through the guiding idlers, pre-cleaning, calender nip, past the thickness gauge, and onto the core of the rewind station. Once threaded, the line starts in a slow “jog” mode to establish stable tension. The operator then initiates the production recipe on the HMI, setting the target line speed, calender force, and thickness. The line ramps up to the set speed. Throughout the run, all control systems are active: the guide maintains edge position, the tension systems maintain stable MD tension, and the closed-loop thickness control continuously adjusts calender parameters. Production data is recorded. At the end of a roll, the automatic splice sequence is triggered to join the new roll, allowing for continuous operation.

3. The Calender: Core Equipment Structure and Key Parameters

3.1 Basic Structure of the Calender

The calender is engineered for extreme precision and stability. The predominant design for high-quality lithium-ion battery electrode production is a four-high vertical mill. Its main components include:

- Base & Housing: A massive, monolithic or heavily ribbed weldment providing the foundational rigidity to resist the high separating forces without deformation.

- Roll Stack: Consists of two smaller diameter work rolls (in direct contact with the electrode) and two larger diameter backup rolls. The backup rolls support the work rolls to drastically reduce bending. Rolls are made from high-alloy steel (e.g., 9Cr3Mo), hardened (≥ 66 HRC) and ground to a mirror finish with radial runout controlled within ±2 µm.

- Drive System: Typically, a single or dual high-torque AC servo motor drives a precision reducer. A splitting gearbox or twin-output reducer then drives both top and bottom backup rolls (or work rolls) via universal joint spindles to ensure perfect speed synchronization.

- Hydraulic System: Servo-valve controlled hydraulic cylinders apply the roll separating force. Pressure transducers provide high-fidelity feedback for the force control loop.

- Gap & Profile Adjustment: Servo-motor driven wedge mechanisms at both sides of the housing allow precise initial gap setting. Some advanced designs incorporate roll bending (positive/negative) or roll heating systems for active cross-direction profile control.

- Auxiliaries: Enclosures for safety, lubrication systems for bearings, and for anode production, integrated doctor blade and web-cleaning systems to prevent graphite sticking.

3.2 Main Technical Parameters and Specifications

The selection of calender parameters is dictated by the product mix (anode/cathode, coating width) and the required quality levels.

| Parameter | Typical Range / Specification | Design Rationale / Impact |

|---|---|---|

| Work Roll Diameter | φ400 mm – φ600 mm | Smaller diameter reduces contact area, increasing specific pressure for a given force. Requires more rigidity. |

| Backup Roll Diameter | φ800 mm – φ1200 mm | Large diameter drastically increases moment of inertia ($I \propto D^4$), minimizing elastic deflection under load. |

| Roll Face Width | 650 mm – 1500 mm+ | Dictated by the width of the coated electrode web. Wider rolls require greater force and anti-deflection measures. |

| Maximum Separating Force | 2000 kN – 8000 kN (200 – 800 tonf) | Determines the maximum line pressure ($P_L = F/W$) achievable, critical for high-density electrodes. |

| Force Control Accuracy | ≤ ±0.5% of full scale | Essential for maintaining precise and consistent compaction density in the lithium-ion battery electrode. |

| Line Speed | 20 m/min – 120 m/min | Balances productivity with process stability (e.g., heat generation, hydraulic response). |

| Minimum Gap | 0 μm (Kiss Pressure) | Ability to achieve zero gap is necessary for calibration and running at “kiss pressure.” |

| Drive Power | 2 x 150 kW – 2 x 300 kW | Overcomes friction and deformation resistance. Dual-motor drive is common for high-speed, high-force applications. The required torque ($T$) is related to force ($F$), roll radius ($R$), and friction coefficient ($\mu$): $$T \approx \mu \cdot F \cdot R$$ Power $P = T \cdot \omega$, where $\omega$ is angular speed. |

The drive power calculation highlights the interdependencies. For a given line force $F$ and roll radius $R$, the required torque is roughly proportional. As the line speed $V$ increases, the required angular velocity $\omega = V/R$ increases, leading to a linear increase in required power $P$:

$$P \propto F \cdot V$$

This is why high-speed, high-force calendering lines for advanced lithium-ion battery electrodes demand very powerful drive systems.

4. Conclusion

The calendering process is a pivotal step in determining the final performance characteristics of a lithium-ion battery. This article has provided a detailed analysis of the calendering principle, identifying key factors affecting quality such as roll deflection, tension control, and hydraulic stability. Based on this analysis, a comprehensive overall design for a lithium-ion battery electrode calendering production line has been presented. The design encompasses a logically sequenced layout from unwind to rewind, integrating specialized modules for guiding, cleaning, and precision measurement.

The heart of the line, the calender, is conceptualized as a high-rigidity four-high mill with servo-hydraulic force control and precision gap adjustment. Its key parameters—roll dimensions, maximum force, speed, and power—are defined to meet the stringent requirements of modern lithium-ion battery manufacturing. The proposed integration of a laser thickness gauge into a closed-loop control system is critical for achieving the micron-level thickness uniformity demanded by high-energy-density battery designs.

This systematic design approach, focusing on mechanical stability, precise control, and integrated quality assurance, provides a framework for building calendering lines that can produce superior quality lithium-ion battery electrodes. Such advancements in production technology are essential for supporting the next generation of electric vehicles and energy storage systems, ensuring improvements in range, longevity, and safety for lithium-ion battery packs.