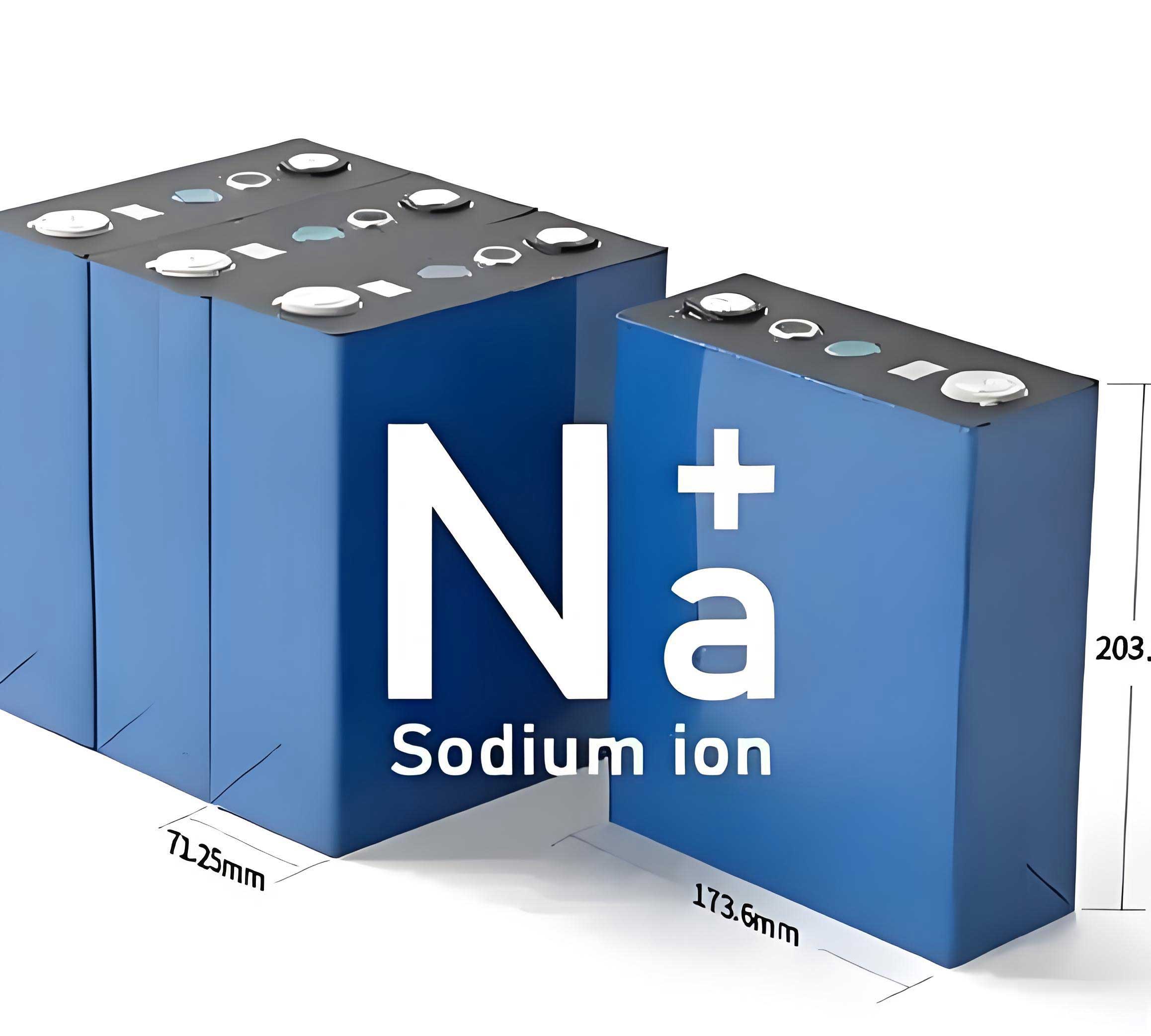

As the world transitions towards a carbon-neutral future, the demand for efficient and sustainable energy storage solutions has surged. I have observed that lithium-ion batteries (LIBs) have dominated the market for decades, powering everything from electric vehicles to portable electronics. However, the increasing scarcity and price volatility of lithium resources pose significant risks to the global supply chain. In this context, sodium-ion batteries (SIBs) have emerged as a promising alternative, offering abundant raw materials and potential cost advantages. From my perspective, the development of SIBs is not just a scientific endeavor but a strategic move to diversify energy storage technologies and enhance energy security. This article delves into the commercialization journey of sodium-ion battery, examining its historical evolution, key materials, cost dynamics, and future prospects. I will explore how sodium-ion battery can complement or even replace LIBs in specific applications, while addressing the technical and economic hurdles that lie ahead.

The history of sodium-ion battery dates back to the 1970s, parallel to the early research on LIBs. Initially, studies focused on intercalation chemistry, where both lithium and sodium ions were found to reversibly insert into materials like TiS2. However, the commercialization of LIBs in the 1990s, driven by their higher energy density, overshadowed SIBs. It wasn’t until the 2000s that breakthroughs in hard carbon anodes revitalized interest in sodium-ion battery. The realization that hard carbon could provide substantial sodium storage capacity (around 300 mAh·g−1) sparked a resurgence in research. In recent years, with lithium prices soaring, companies like CATL and HiNa Battery have launched commercial SIB prototypes, signaling a new era for sodium-ion battery. I believe this timeline underscores the iterative nature of battery technology, where resource constraints often drive innovation. Today, sodium-ion battery stands at the cusp of industrialization, with pilot projects in grid storage and low-speed electric vehicles. The shared history with LIBs has accelerated progress, as many manufacturing techniques and materials are adaptable. However, the unique electrochemical properties of sodium-ion battery necessitate tailored solutions, which I will discuss in the following sections.

The performance of a sodium-ion battery hinges on its electrode materials. I have analyzed various cathode and anode options, each with distinct advantages and challenges. For cathodes, the primary contenders are layered transition metal oxides, Prussian blue analogues (PBAs), and polyanionic compounds. Layered oxides, such as NaxMeO2 (Me = transition metals), offer high specific capacities but suffer from phase transitions during cycling. PBAs, with their open framework structure, enable fast sodium ion diffusion but often contain lattice water that compromises stability. Polyanionic compounds, like Na3V2(PO4)3, provide excellent thermal safety but have lower electronic conductivity. To compare these materials, I have compiled a table summarizing their key properties.

| Cathode Material Type | Chemical Formula Example | Specific Capacity (mAh·g−1) | Average Voltage (V vs. Na/Na+) | Advantages | Challenges |

|---|---|---|---|---|---|

| Layered Oxide | NaNi0.33Fe0.33Mn0.33O2 | 120-140 | 3.2-3.4 | High energy density, synthesis simplicity | Phase instability, moisture sensitivity |

| Prussian Blue Analogue | NaFe[Fe(CN)6] | 120-160 | 3.1-3.3 | Low cost, fast kinetics | Lattice water, low tap density |

| Polyanionic Compound | Na3V2(PO4)3 | 100-110 | 3.4-3.7 | High safety, long cycle life | Low conductivity, high cost of vanadium |

The electrochemical behavior of these cathodes can be described using fundamental equations. For instance, the intercalation reaction in a layered oxide cathode during discharge is: $$\text{Na}_x\text{MeO}_2 + y\text{Na}^+ + y e^- \rightarrow \text{Na}_{x+y}\text{MeO}_2$$ where Me represents transition metals, and y is the number of sodium ions inserted. The voltage profile is influenced by the redox potentials of the transition metals, which can be tuned through doping. I have found that iron-based compounds are particularly attractive for sodium-ion battery due to their low cost and environmental friendliness. However, optimizing the composition to balance capacity, voltage, and cycle life remains a key research focus for sodium-ion battery.

On the anode side, hard carbon is the material of choice for sodium-ion battery. Unlike graphite in LIBs, which has a limited interlayer spacing (0.335 nm) for sodium ions, hard carbon features a disordered structure with micropores that facilitate sodium storage. The storage mechanism is often described as adsorption-intercalation-filling, though it is still debated. The capacity of hard carbon can be expressed as: $$C_{\text{total}} = C_{\text{adsorption}} + C_{\text{intercalation}} + C_{\text{pore filling}}$$ where each component contributes to the overall sodium storage. I have evaluated various precursors for hard carbon, including biomass waste like coconut shells and synthetic polymers. Biomass-derived hard carbon offers a sustainable route, with capacities reaching up to 300 mAh·g−1. However, the first-cycle Coulombic efficiency and long-term stability need improvement for commercial sodium-ion battery. Other anode materials, such as titanium-based compounds and alloys, are being explored but face issues like volume expansion and high cost.

The electrolyte is another critical component in sodium-ion battery. I have studied organic electrolytes based on sodium salts like NaPF6 and NaFSI in carbonate or ether solvents. The ionic conductivity (σ) of an electrolyte can be modeled using the Arrhenius equation: $$\sigma = A \exp\left(-\frac{E_a}{RT}\right)$$ where A is a pre-exponential factor, Ea is activation energy, R is the gas constant, and T is temperature. For sodium-ion battery, ether-based electrolytes often show better kinetics due to lower desolvation energy, but ester-based systems provide wider voltage windows. Additives like fluoroethylene carbonate (FEC) are crucial to form stable solid-electrolyte interphase (SEI) layers. Aqueous and solid-state electrolytes are also promising for enhancing safety in sodium-ion battery, though they come with trade-offs in energy density and interface resistance. The table below compares different electrolyte types for sodium-ion battery.

| Electrolyte Type | Typical Composition | Ionic Conductivity (mS·cm−1) | Voltage Window (V) | Advantages | Challenges |

|---|---|---|---|---|---|

| Organic Liquid | 1 M NaPF6 in EC/DEC | 5-10 | 1.5-4.5 | High conductivity, compatible with electrodes | Flammability, cost of salts |

| Aqueous | Water-in-salt with NaOTF | 10-20 | 2.0-3.3 | Non-flammable, low cost | Limited voltage, electrode dissolution |

| Solid-State | NASICON-type Na3Zr2Si2PO12 | 0.1-1 | Up to 5.0 | High safety, no leakage | Interface resistance, brittleness |

Beyond active materials, other components like current collectors and separators influence the cost and performance of sodium-ion battery. I have noted that aluminum foil can be used for both electrodes in sodium-ion battery, unlike LIBs where copper is required for the anode. This reduces material costs and weight. The cost advantage of sodium-ion battery is a central point in its commercialization narrative. To quantify this, I have developed a cost model based on material consumption. The total cost per kilowatt-hour (kWh) for a sodium-ion battery can be expressed as: $$C_{\text{SIB}} = \sum_{i} (m_i \times p_i) + C_{\text{manufacturing}}$$ where mi is the mass of material i per kWh, pi is its price, and Cmanufacturing includes labor, equipment, and overhead. For comparison, the cost of LIBs follows a similar formula but with different material sets. Assuming current market prices, I have estimated the breakdown for a typical sodium-ion battery with a layered oxide cathode and hard carbon anode.

| Component | Material | Mass per kWh (kg) | Price per kg (USD) | Cost Contribution (USD/kWh) |

|---|---|---|---|---|

| Cathode | Layered Oxide (NaNi0.33Fe0.33Mn0.33O2) | 2.5 | 15 | 37.5 |

| Anode | Hard Carbon | 1.8 | 20 | 36.0 |

| Electrolyte | NaPF6 in Carbonates | 1.2 | 25 | 30.0 |

| Current Collectors | Aluminum Foil | 0.5 | 5 | 2.5 |

| Separator | Polyolefin | 0.3 | 10 | 3.0 |

| Total Material Cost | 109.0 | |||

| Manufacturing Cost (estimated) | 40.0 | |||

| Total Cost (USD/kWh) | 149.0 | |||

In contrast, a lithium iron phosphate (LFP) battery, a common LIB for storage, might have a total cost of around 130 USD/kWh when lithium carbonate prices are moderate. This suggests that sodium-ion battery can be competitive, especially if material prices decrease with scale. However, the energy density of sodium-ion battery is lower, typically 120-160 Wh/kg compared to 150-200 Wh/kg for LFP batteries. This means that for the same energy storage, a sodium-ion battery pack may be larger and heavier, affecting application suitability. I have analyzed the levelized cost of storage (LCOS) to account for lifetime and efficiency: $$\text{LCOS} = \frac{C_{\text{capital}} + \sum_{t=1}^{n} \frac{C_{\text{O&M}}}{(1+r)^t}}{\sum_{t=1}^{n} \frac{E_{\text{output}}}{(1+r)^t}}$$ where Ccapital is initial cost, CO&M is operation and maintenance, Eoutput is energy output per year, r is discount rate, and n is lifetime in years. For sodium-ion battery, long cycle life (over 3000 cycles) and good safety can offset lower energy density in stationary storage, making LCOS favorable.

The application landscape for sodium-ion battery is evolving. I foresee that sodium-ion battery will first gain traction in large-scale energy storage systems (ESS) and low-speed electric vehicles (e.g., scooters, micro-cars), where cost and safety outweigh energy density concerns. In ESS, the ability of sodium-ion battery to operate in a wide temperature range and resist thermal runaway is a significant advantage. The power capability can be described by the Ragone plot, which relates energy density to power density. For sodium-ion battery, the trade-off is less steep than for LIBs, enabling better performance at high discharge rates. This is due to the faster ionic diffusion of Na+ in certain electrodes, as per the Nernst-Planck equation: $$J_i = -D_i \nabla c_i – \frac{z_i F D_i}{RT} c_i \nabla \phi$$ where Ji is flux of species i, Di is diffusion coefficient, ci is concentration, zi is charge number, F is Faraday constant, and φ is electric potential. For sodium-ion battery, DNa+ can be higher than DLi+ in porous carbon anodes, enhancing rate performance.

However, challenges remain for the widespread adoption of sodium-ion battery. I have identified several technical hurdles: (1) Improving the energy density of sodium-ion battery to match or exceed that of commercial LIBs. This requires breakthroughs in cathode materials, such as developing high-voltage compounds or multi-electron reactions. (2) Enhancing the cycle life and first-cycle efficiency of hard carbon anodes. Strategies like pre-sodiation or surface coating are being explored. (3) Reducing the cost of electrolyte salts and optimizing formulations for wide-temperature operation. (4) Scaling up production while maintaining consistency and quality. The manufacturing of sodium-ion battery can leverage existing LIB infrastructure, but process adjustments are needed for material handling, especially for air-sensitive compounds. (5) Establishing a recycling ecosystem for sodium-ion battery. Unlike LIBs, sodium-ion battery may contain less critical metals, but recycling is essential for sustainability. The recovery efficiency η can be modeled as: $$\eta = \frac{m_{\text{recovered}}}{m_{\text{input}}} \times 100\%$$ where m is mass of valuable materials.

From a market perspective, the opportunity for sodium-ion battery is substantial. Global energy storage capacity is projected to grow exponentially, and sodium-ion battery could capture a significant share due to resource abundance. I have reviewed reports indicating that sodium reserves are virtually unlimited, with sodium constituting about 2.3% of the Earth’s crust. This contrasts with lithium, which is concentrated in a few regions. The price stability of sodium-based chemicals insulates sodium-ion battery from geopolitical risks. Moreover, policy support for decarbonization and energy independence in countries like China and the EU is driving investment in sodium-ion battery research. The innovation cycle for sodium-ion battery is accelerating, with new patents and startups emerging regularly.

In conclusion, the journey of sodium-ion battery from laboratory curiosity to commercial product is marked by both promise and obstacles. I am optimistic that sodium-ion battery will carve out a niche in the energy storage market, particularly for applications where cost and safety are paramount. The continued optimization of materials, coupled with economies of scale, will lower the cost of sodium-ion battery and improve performance. Collaboration across academia, industry, and government will be key to overcoming challenges. As I reflect on the evolution of battery technologies, sodium-ion battery represents a testament to human ingenuity in adapting to resource constraints. The future of sodium-ion battery is not about replacing LIBs entirely but about creating a diversified portfolio of storage solutions that enhance global energy resilience. With ongoing advances, I believe sodium-ion battery will play a pivotal role in the transition to a sustainable energy economy, powering everything from grid buffers to electric mobility in a cost-effective and environmentally friendly manner.