1. Introduction

The development of renewable energy sources such as wind and solar power is crucial for achieving “carbon peaking” and “carbon neutrality” goals. However, the intermittent and fluctuating nature of these energy sources requires the use of energy storage systems. Lithium-ion batteries, particularly lithium-iron batteries, have emerged as a prominent energy storage technology due to their high energy density and long cycle life.

1.1 The Importance of Lithium-Iron Batteries in Energy Storage

In 2023, the installed capacity of lithium-ion batteries for energy storage reached 43 GW, with lithium-iron batteries being the dominant type in the market. Their use in large-scale energy storage systems helps to stabilize the power grid and ensure a reliable supply of electricity.

1.2 Thermal Runaway Risks in Lithium-Iron Batteries

Despite their advantages, lithium-iron batteries are prone to thermal runaway under certain conditions. Thermal runaway can occur due to factors such as overcharging, overheating, or mechanical damage. During thermal runaway, a series of exothermic reactions take place within the battery, leading to a rapid increase in temperature and the release of large amounts of gas and heat. This can potentially result in fires and explosions, posing a significant safety risk to the energy storage system and its surroundings.

1.3 The Role of Sensors in Monitoring Thermal Runaway

To prevent the escalation of accidents caused by thermal runaway, it is essential to monitor the key parameters of the battery, such as gas concentration, temperature, and pressure. Sensors play a crucial role in this regard by providing real-time data on the battery’s condition. By detecting the early signs of thermal runaway, appropriate measures can be taken to mitigate the risk and ensure the safety of the energy storage system.

2. Experimental Setup

2.1 Sensor Design and Selection

In this study, five types of multi-in-one composite sensors with different detection principles were designed and fabricated. The sensors were designed to detect various parameters, including the volume fractions of H₂, CO, CO₂, and volatile organic compounds (VOC), the smoke mass fraction, and the pressure and temperature in the battery storage compartment.

| Sensor | Detection Principle | Parameters Detected |

|---|---|---|

| A | Electrochemical (H₂, CO, VOC), Thermocouple (Temperature), Semiconductor (Smoke) | H₂, CO, VOC, Temperature, Smoke |

| B | Semiconductor (H₂, CO, VOC), Thermocouple (Temperature), Semiconductor (Smoke) | H₂, CO, VOC, Temperature, Smoke |

| C | Electrochemical (H₂, CO, VOC), Thermocouple (Temperature), Semiconductor (Smoke), Pressure Sensor (Pressure) | H₂, CO, VOC, Temperature, Smoke, Pressure |

| D | Catalytic Combustion (H₂), Electrochemical (CO), Infrared Optical (CO₂), Thermocouple (Temperature), Photoion (VOC), Semiconductor (Smoke) | H₂, CO, CO₂, VOC, Temperature, Smoke |

| E | Semiconductor (H₂, CO, CO₂, VOC), Thermocouple (Temperature), Semiconductor (Smoke) | H₂, CO, CO₂, VOC, Temperature, Smoke |

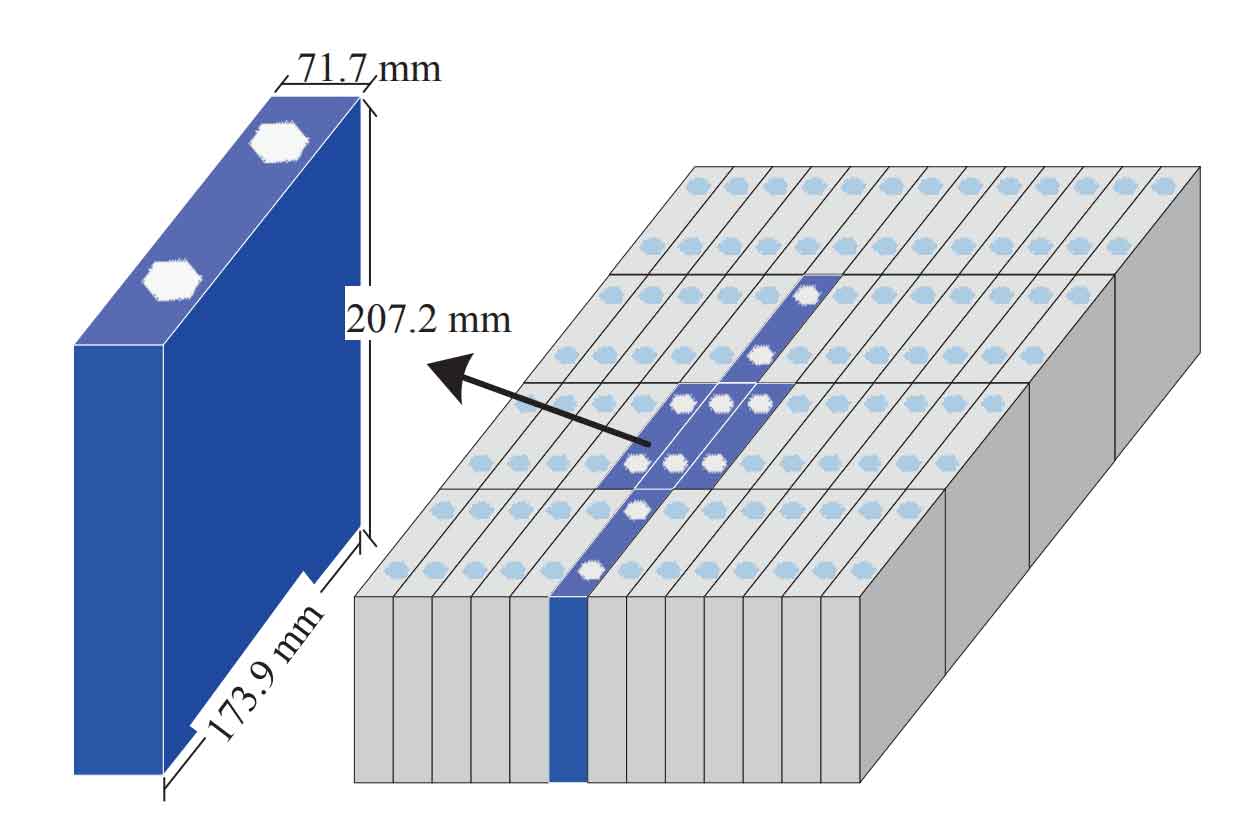

2.2 Test Compartment and Battery Specifications

The experiments were conducted in a 40-foot real energy storage compartment. The test battery used was a 280 Ah lithium-iron phosphate battery with a rated voltage of 3.2 V. The battery was charged to its full capacity using a constant current-constant voltage method before the experiments.

2.3 Experimental Procedure

The experiments involved heating the battery to trigger thermal runaway. Two types of heating positions, edge and middle, were selected to study the effect of battery location on thermal runaway. In addition, ignition tests were also carried out to investigate the impact of ignition on the thermal runaway process. During the experiments, various parameters such as gas concentration, temperature, and pressure were measured using the designed sensors.

3. Results and Analysis

3.1 Comparison of Different Sensor Principles

- H₂ Sensor: The catalytic combustion principle H₂ sensor detected H₂ faster than the electrochemical principle H₂ sensor. This indicates that the catalytic combustion sensor has a higher sensitivity and response speed for H₂ detection.

| H₂ Sensor Principle | Detection Time |

| Catalytic Combustion | Earlier |

| Electrochemical | Later |

- VOC Sensor: The photoion principle VOC sensor detected VOC earlier than the electrochemical principle VOC sensor. This suggests that the photoion sensor is more effective in detecting VOC emissions from the battery.

| VOC Sensor Principle | Detection Time |

| Photoion | Earlier |

| Electrochemical | Later |

3.2 Detection Sequence of Different Gases

- VOC was detected earlier than H₂ and CO. This can be attributed to the earlier volatilization of the electrolyte compared to the generation of H₂ and CO, as well as the production of VOC from the heating of the battery blue film.

- H₂ was detected slightly earlier than CO and smoke. The detection sequence of these gases provides important insights into the thermal runaway process of the battery and can be used to develop more effective detection strategies.

3.3 Impact of Ignition on Thermal Runaway Detection

- In the non-ignition case, the air pressure and temperature at the top of the compartment were not suitable for predicting thermal runaway. However, in the ignition case, the concentrations of CO, smoke, and CO₂ increased, while the concentrations of H₂ and VOC decreased to varying degrees, and the temperature in the compartment increased rapidly. These results highlight the importance of considering the ignition factor in thermal runaway detection and prevention.

3.4 Thermal Runaway Parameter Propagation Rates

- The propagation rates of different thermal runaway parameters were studied under different experimental conditions. It was found that the propagation rates of thermal runaway parameters were affected by factors such as battery location and ignition. For example, the propagation rates of thermal runaway parameters were higher in the edge heating case compared to the middle heating case.

| Experimental Condition | Propagation Rate Comparison |

| Edge Heating vs. Middle Heating | Edge Heating > Middle Heating |

| Ignition vs. Non-Ignition | Ignition > Non-Ignition |

4. Discussion

4.1 Sensor Selection for Thermal Runaway Monitoring

Based on the experimental results, the catalytic combustion principle H₂ sensor and the photoion principle VOC sensor are more suitable for the early detection of thermal runaway in lithium-iron batteries. These sensors offer higher sensitivity and faster response times compared to other sensor principles.

4.2 The Significance of VOC Detection

VOC detection is of particular importance in thermal runaway monitoring. VOC is detected earlier than other gases, providing an early warning signal for thermal runaway. In addition, the detection of VOC can be related to the heating of the battery blue film and the volatilization of the electrolyte, which can be used to further understand the thermal runaway mechanism.

4.3 The Role of Ignition in Thermal Runaway

The ignition factor has a significant impact on the thermal runaway process. Ignition can accelerate the release of gases and increase the temperature, leading to a more severe thermal runaway situation. Therefore, in the design of thermal runaway detection and prevention systems, the ignition factor should be carefully considered.

4.4 Sensor Placement and Spacing

The appropriate placement and spacing of sensors are crucial for effective thermal runaway monitoring. Based on the analysis of thermal runaway parameter propagation rates, the recommended spacing between sensors in the storage compartment was determined. For example, the suitable spacing between edge detectors and the compartment wall was 0.639 – 1.278 m, and the suitable spacing between middle detectors was 0.924 – 1.846 m.

5. Conclusion

5.1 Summary of Key Findings

- The catalytic combustion principle H₂ sensor and the photoion principle VOC sensor are the most effective for early detection of thermal runaway in lithium-iron batteries.

- VOC is detected earlier than other gases, providing an early warning for thermal runaway.

- Ignition has a significant impact on the thermal runaway process, increasing gas concentrations and temperature.

- Appropriate sensor placement and spacing are crucial for effective thermal runaway monitoring.

5.2 Implications for Future Research and Practice

- Future research should focus on further improving the performance of sensors and developing more advanced detection strategies.

- In practice, the findings of this study can be used to guide the design and operation of lithium-iron battery energy storage systems, improving their safety and reliability.