In recent years, perovskite solar cells have emerged as a promising next-generation photovoltaic technology due to their exceptional optoelectronic properties, compatibility with solution-based processing, and low manufacturing costs. The power conversion efficiency of perovskite solar cells has now surpassed 26%, making them highly competitive with traditional silicon-based and other photovoltaic technologies. A key advantage of perovskite solar cells lies in the ability to fabricate thin films through simple solution methods, where the choice of solvent plays a critical role in determining the chemical environment of precursor solutions, crystallization kinetics, and the overall morphology and quality of the perovskite layer. However, conventional solvents such as N,N-dimethylformamide (DMF), dimethyl sulfoxide (DMSO), and N-methylpyrrolidone (NMP) often require anti-solvent-assisted crystallization and pose challenges related to toxicity and complex processing, hindering the commercialization of perovskite solar cells.

Ionic liquids (ILs), which are molten salts liquid at room temperature, offer a green and efficient alternative to traditional solvents. Composed of various organic cations (e.g., imidazolium, pyrrolidinium, and ammonium) and organic or inorganic anions (e.g., halides, acetates, and formates), ionic liquids exhibit unique physicochemical properties such as low vapor pressure, high thermal stability, tunable acidity, and excellent solubility. These characteristics make them ideal for applications in perovskite solar cells, where they can act as solvents, additives, and passivating agents to enhance both performance and stability. In this article, we explore the multifaceted roles of ionic liquids in the fabrication of perovskite solar cells, discuss underlying mechanisms, and provide insights into future directions for large-scale production.

The application of ionic liquids in perovskite solar cells began with pioneering work that demonstrated their ability to dissolve perovskite precursors and facilitate the formation of high-quality films without intermediate phases. For instance, methylammonium acetate (MAAc) has been widely used as a solvent for various perovskite compositions, including organic-inorganic hybrids, all-inorganic variants, and two-dimensional layered structures. Unlike conventional solvents, MAAc interacts with lead ions through coordination bonds (e.g., Pb-O) and with halides via hydrogen bonds (e.g., N-H⋯I), leading to stable colloidal solutions with uniform particle size distribution. This uniformity is crucial for achieving dense, pinhole-free perovskite films with large grain sizes, which are essential for high-performance perovskite solar cells. The following equation represents the dissolution process in MAAc:

$$ \text{PbI}_2 + \text{CH}_3\text{NH}_3\text{I} + \text{CH}_3\text{COONH}_3\text{CH}_3 \rightarrow \text{Pb(CH}_3\text{COO)}_2 \cdot \text{CH}_3\text{NH}_3\text{I} $$

During film formation, the evaporation of MAAc allows for direct crystallization into the perovskite phase, bypassing intermediate stages and reducing defect density. This process can be summarized as:

$$ \text{Pb(CH}_3\text{COO)}_2 \cdot \text{CH}_3\text{NH}_3\text{I} \rightarrow \text{CH}_3\text{NH}_3\text{PbI}_3 + \text{CH}_3\text{COOH} + \text{CH}_3\text{NH}_2 $$

This direct crystallization mechanism contributes to the enhanced stability and efficiency of perovskite solar cells fabricated with ionic liquids. Moreover, ionic liquids like MAAc have enabled the development of simplified device architectures, such as electron-transport-layer-free perovskite solar cells, by modifying interface properties and promoting favorable energy level alignment. For example, MAAc can physically adsorb onto conductive substrates like ITO, forming dipole layers that lower work functions and facilitate charge extraction, leading to efficiencies exceeding 21% without additional transport layers.

In addition to serving as solvents, ionic liquids can be engineered to function as additives or co-solvents to optimize crystallization kinetics and film quality. For instance, the introduction of propylammonium acetate (PAAc) or butylammonium acetate (BAAc) in precursor solutions has been shown to regulate colloidal size distribution and promote the growth of phase-pure two-dimensional perovskite quantum wells. These advancements have resulted in highly stable perovskite solar cells with open-circuit voltages over 1.3 V and power conversion efficiencies approaching 18%. The versatility of ionic liquids is further demonstrated in the fabrication of formamidinium-based perovskites (e.g., α-FAPbI3), which are prone to phase instability under ambient conditions. By using ionic liquids like methylammonium formate (MAFa), researchers have achieved rapid and stable phase transformation to the black perovskite phase in humid air, yielding devices with efficiencies near 24% and exceptional long-term stability.

To illustrate the impact of ionic liquids on perovskite solar cell performance, we summarize key findings in Table 1, which compares different ionic liquid solvents and their corresponding device parameters. This table highlights how ionic liquids contribute to improvements in efficiency, stability, and processability across various perovskite compositions.

| Ionic Liquid | Perovskite Type | Power Conversion Efficiency (%) | Open-Circuit Voltage (V) | Stability (Hours at 80% Initial PCE) |

|---|---|---|---|---|

| MAAc | MAPbI3 | 22.1 | 1.12 | 1000 |

| MAFa | α-FAPbI3 | 23.8 | 1.18 | 5000 |

| BAAc | 2D (BA)2(MA)4Pb5I16 | 16.3 | 1.31 | 4680 |

| MAAc/MAPa | CsPbI2Br | 17.0 | 1.25 | 1500 |

The mechanisms underlying the success of ionic liquids in perovskite solar cells can be attributed to their triple functionality: as solvents, crystallization modifiers, and passivators. Firstly, ionic liquids dissolve perovskite precursors through strong coordination and hydrogen bonding, forming stable colloids that prevent aggregation and ensure homogeneous film deposition. Secondly, they modulate crystallization kinetics by controlling the evaporation rate and intermediate phase formation, leading to highly oriented and large-grained perovskite films. Thirdly, residual ionic liquids passivate grain boundaries and surfaces by coordinating with undercoordinated lead ions and forming hydrogen bonds with halides, thereby suppressing ion migration and non-radiative recombination. The passivation effect can be described by the following relationship for defect density reduction:

$$ D_{\text{defect}} = D_0 \exp\left(-\frac{E_a}{k_B T}\right) $$

where \( D_{\text{defect}} \) is the defect density, \( D_0 \) is a pre-exponential factor, \( E_a \) is the activation energy for ion migration, \( k_B \) is Boltzmann’s constant, and \( T \) is temperature. Ionic liquids increase \( E_a \), thereby lowering \( D_{\text{defect}} \) and enhancing stability.

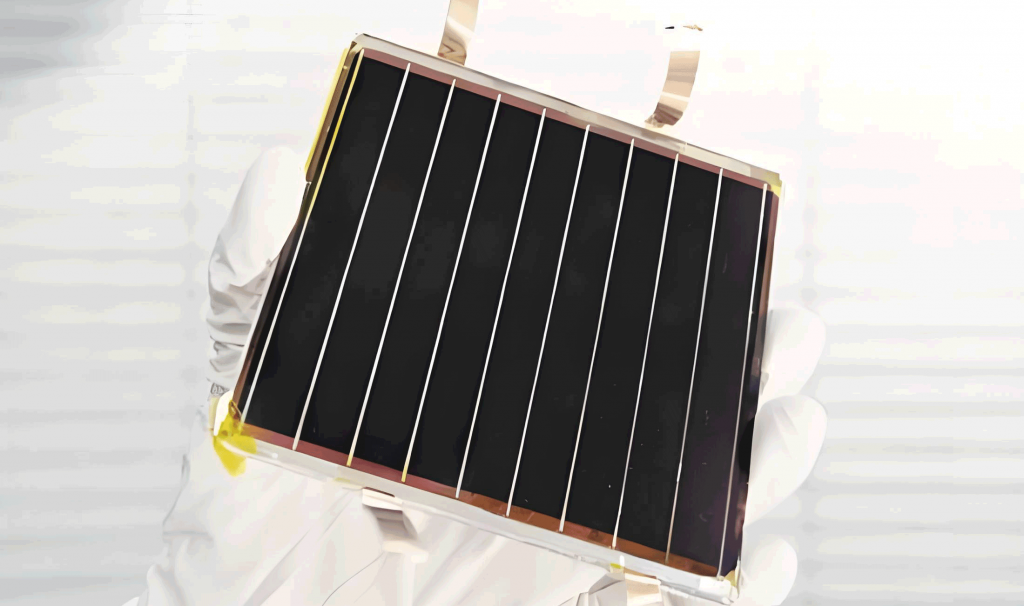

For large-scale production, ionic liquids offer significant advantages in printing techniques such as screen printing, blade coating, and slot-die coating. Their tunable viscosity and low volatility enable the fabrication of uniform perovskite films over large areas without the need for anti-solvents. For example, screen-printed perovskite solar cells using MAAc-based inks have achieved efficiencies over 20% in ambient air, demonstrating the potential for industrial manufacturing. The viscosity (\( \eta \)) of ionic liquids can be modeled as a function of temperature (\( T \)) using the Arrhenius equation:

$$ \eta = \eta_0 \exp\left(\frac{E_\eta}{RT}\right) $$

where \( \eta_0 \) is the pre-exponential factor, \( E_\eta \) is the activation energy for viscous flow, and \( R \) is the gas constant. This tunability allows for optimization of ink rheology for different deposition methods.

Despite these advancements, challenges remain in the widespread adoption of ionic liquids for perovskite solar cells. These include the need for cost-effective synthesis of functionalized ionic liquids, understanding long-term degradation mechanisms, and scaling up production while maintaining performance. Future research should focus on designing ionic liquids with tailored cations and anions to achieve specific functions, such as reducing agents for tin-based perovskite solar cells or conjugated structures for charge transport layers. Additionally, integrating ionic liquids with emerging perovskite compositions and fabrication technologies will be crucial for achieving commercial viability.

In conclusion, ionic liquids have revolutionized the fabrication of perovskite solar cells by enabling simple, green, and efficient processing routes. Their unique properties facilitate the production of high-quality perovskite films with enhanced stability and performance, paving the way for large-scale deployment of perovskite photovoltaic technology. As we continue to explore the potential of ionic liquids, we anticipate further breakthroughs in the efficiency and durability of perovskite solar cells, ultimately contributing to a sustainable energy future.