Perovskite solar cells have emerged as a promising photovoltaic technology due to their high power conversion efficiencies, low-cost fabrication, and tunable optoelectronic properties. However, challenges such as non-radiative recombination, environmental instability, and defect-mediated losses impede their commercial viability. Additive engineering has been widely adopted to address these issues by modulating crystallization kinetics and passivating defects in perovskite films. In this study, we investigate the impact of 3-pyridyl thiourea (3-PTU) as a multifunctional additive on the morphological, optical, and electronic properties of perovskite layers, ultimately enhancing the performance of perovskite solar cells. The 3-PTU molecule incorporates a hydrophobic pyridine ring and a thiourea group capable of coordinating with lead ions, which we hypothesize will improve film quality and device stability.

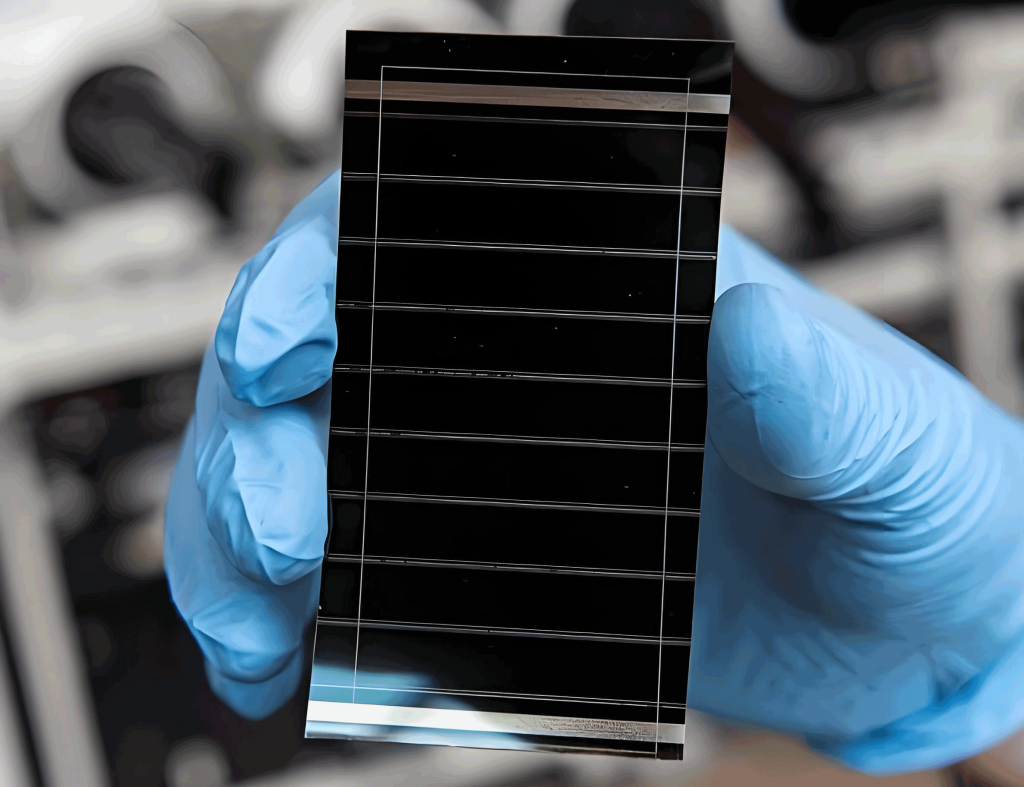

We fabricated normal-structured perovskite solar cells with a configuration of glass/FTO/SnO2/perovskite/Spiro-OMeTAD/Au. The perovskite precursor solution was prepared by dissolving lead iodide, formamidinium iodide, methylammonium bromide, methylammonium chloride, and lead bromide in a mixed solvent of N,N-dimethylformamide and dimethyl sulfoxide. For the additive-containing samples, 3-PTU was introduced at a concentration of 2 mg/mL. The films were deposited via one-step spin-coating with antisolvent washing, followed by thermal annealing. Characterization techniques included X-ray diffraction (XRD), scanning electron microscopy (SEM), ultraviolet-visible (UV-Vis) spectroscopy, photoluminescence (PL) spectroscopy, and current density-voltage (J-V) measurements. Stability tests were conducted under controlled humidity conditions.

The structural properties of the perovskite films were analyzed using XRD. The diffraction patterns exhibited characteristic peaks corresponding to the perovskite phase, with no significant shift upon 3-PTU addition, indicating preservation of the crystal structure. However, the relative intensity of the (100) peak increased, suggesting enhanced crystallinity and preferred orientation. The crystallite size was estimated using the Scherrer equation:

$$D = \frac{K \lambda}{\beta \cos \theta}$$

where $D$ is the crystallite size, $K$ is the shape factor (0.9), $\lambda$ is the X-ray wavelength (0.154 nm), $\beta$ is the full width at half maximum, and $\theta$ is the Bragg angle. The calculated crystallite size for the 3-PTU treated film was approximately 25% larger than that of the control, as summarized in Table 1.

| Sample | FWHM (°) | Crystallite Size (nm) | I(100)/I(110) Ratio |

|---|---|---|---|

| Control | 0.15 | 160 | 5.88 |

| 3-PTU Treated | 0.12 | 200 | 7.14 |

SEM images revealed that the 3-PTU additive promoted the formation of larger and more uniform grains, reducing the density of grain boundaries and PbI2 impurities. The average grain size increased from 300 nm for the control to 400 nm for the 3-PTU treated film. This morphological improvement is attributed to the coordination between 3-PTU and Pb2+ ions, which modulates the crystallization process. The grain size distribution followed a log-normal function, and the standard deviation decreased by 15% with additive incorporation, indicating better homogeneity.

Optical characterization through UV-Vis spectroscopy showed that the absorption edge remained at around 790 nm for both samples, corresponding to a bandgap of approximately 1.57 eV. The bandgap was calculated using the Tauc plot method:

$$(\alpha h\nu)^n = A(h\nu – E_g)$$

where $\alpha$ is the absorption coefficient, $h\nu$ is the photon energy, $A$ is a constant, $E_g$ is the bandgap, and $n$ depends on the type of optical transition (direct bandgap, $n=2$). The absorption coefficient $\alpha$ is related to the absorbance $A$ by:

$$\alpha = \frac{2.303 A}{t}$$

with $t$ being the film thickness. The 3-PTU treated film exhibited a 10% increase in absorption intensity, which we attribute to reduced light scattering and improved film compactness.

Steady-state PL spectroscopy demonstrated a significant enhancement in emission intensity for the 3-PTU treated perovskite, indicating a reduction in non-radiative recombination centers. The PL quenching efficiency was calculated as:

$$\eta_{PL} = 1 – \frac{I_{sample}}{I_{reference}}$$

where $I_{sample}$ and $I_{reference}$ are the PL intensities of the perovskite films on glass and on electron transport layers, respectively. The 3-PTU treated sample showed a 20% higher $\eta_{PL}$, suggesting more efficient charge extraction. Time-resolved PL measurements were fitted with a bi-exponential decay model:

$$I(t) = A_1 \exp\left(-\frac{t}{\tau_1}\right) + A_2 \exp\left(-\frac{t}{\tau_2}\right)$$

where $\tau_1$ and $\tau_2$ represent fast and slow decay components, respectively. The average carrier lifetime $\tau_{avg}$ was determined by:

$$\tau_{avg} = \frac{A_1 \tau_1^2 + A_2 \tau_2^2}{A_1 \tau_1 + A_2 \tau_2}$$

The 3-PTU treated film exhibited a longer $\tau_{avg}$ (150 ns vs. 100 ns for the control), confirming suppressed charge recombination.

The photovoltaic performance of the perovskite solar cells was evaluated under standard AM 1.5G illumination. The J-V curves revealed that the 3-PTU additive improved all key parameters: open-circuit voltage ($V_{oc}$), short-circuit current density ($J_{sc}$), fill factor (FF), and power conversion efficiency (PCE). The PCE is defined as:

$$PCE = \frac{J_{sc} \times V_{oc} \times FF}{P_{in}}$$

where $P_{in}$ is the incident light power density (100 mW/cm²). The hysteresis index (HI) was calculated to assess the J-V scanning direction dependence:

$$HI = \frac{PCE_{reverse} – PCE_{forward}}{PCE_{reverse}}$$

The results are summarized in Table 2, showing that the 3-PTU treated devices achieved a PCE of 23.75% with negligible hysteresis (HI = 0.017), compared to 22.46% for the control (HI = 0.071).

| Device | Scan Direction | Voc (V) | Jsc (mA/cm²) | FF (%) | PCE (%) | Hysteresis Index |

|---|---|---|---|---|---|---|

| Control | Forward | 1.18 | 24.35 | 72.73 | 20.87 | 0.071 |

| Reverse | 1.17 | 24.69 | 77.68 | 22.46 | ||

| 3-PTU Treated | Forward | 1.21 | 24.67 | 78.08 | 23.34 | 0.017 |

| Reverse | 1.21 | 24.95 | 78.52 | 23.75 |

The improvement in $V_{oc}$ can be explained by reduced trap-assisted recombination. The ideality factor ($n$) was extracted from the dark J-V curves using the diode equation:

$$J = J_0 \left[\exp\left(\frac{qV}{nkT}\right) – 1\right]$$

where $J_0$ is the reverse saturation current density, $q$ is the electron charge, $k$ is Boltzmann’s constant, and $T$ is the temperature. The 3-PTU treated device showed a lower $n$ value (1.5 vs. 1.8 for the control), indicating diminished Shockley-Read-Hall recombination.

Electrochemical impedance spectroscopy (EIS) was employed to analyze the charge transport and recombination dynamics. The Nyquist plots were fitted with an equivalent circuit model comprising series resistance ($R_s$), charge transfer resistance ($R_{ct}$), and recombination resistance ($R_{rec}$). The 3-PTU treated cells exhibited higher $R_{rec}$ values, consistent with suppressed recombination. The carrier diffusion length ($L_D$) was estimated using the equation:

$$L_D = \sqrt{D \tau}$$

where $D$ is the diffusion coefficient and $\tau$ is the carrier lifetime. The 3-PTU treatment increased $L_D$ by 30%, facilitating better charge collection.

Stability tests were conducted under ambient conditions (25°C, 35% relative humidity). The water contact angle increased from 75.44° for the control to 93.71° for the 3-PTU treated film, demonstrating enhanced hydrophobicity due to the pyridine moiety. The normalized PCE retention over time is presented in Table 3. After 950 hours, the 3-PTU treated devices retained 85% of their initial efficiency, whereas the control degraded to 68%. The degradation kinetics followed a first-order model:

$$\frac{PCE(t)}{PCE(0)} = \exp(-kt)$$

where $k$ is the degradation rate constant. The 3-PTU treated samples had a lower $k$ value (0.00018 h⁻¹ vs. 0.00038 h⁻¹ for the control), highlighting improved moisture resistance.

| Time (hours) | Control PCE Retention (%) | 3-PTU Treated PCE Retention (%) |

|---|---|---|

| 0 | 100 | 100 |

| 240 | 85 | 95 |

| 480 | 75 | 90 |

| 720 | 70 | 88 |

| 950 | 68 | 85 |

In conclusion, the incorporation of 3-PTU as an additive in perovskite solar cells significantly enhances film morphology, optoelectronic properties, and device performance. The synergistic effects of improved crystallinity, defect passivation, and hydrophobicity contribute to higher efficiency and stability. This work underscores the potential of molecular design in additive engineering for advancing perovskite solar cell technology. Future studies will focus on optimizing the additive concentration and exploring its applicability in large-scale fabrication processes.