The current global climate change situation is severe, and the greenhouse gases generated by human use of fossil fuels are increasing, resulting in frequent occurrence of extreme climate events and increasingly severe impacts. For this reason, many countries around the world have proposed the goal of “carbon peaking” and “carbon neutrality”. At the 75th United Nations General Assembly in September 2020, China proposed to strive to peak carbon dioxide emissions by 2030 and strive to achieve carbon neutrality by 2060. The transformation of energy structure is a key path to achieving carbon neutrality. In the 14th Five Year Plan of China, it is pointed out that we should promote the energy revolution, build a clean, low-carbon, safe and efficient energy system, and increase the proportion of non fossil fuels in total energy consumption to about 20%.

Renewable energy, as a green and low-carbon energy source, has been vigorously developed in recent years. The “China Renewable Energy Development Report 2020” released in June 2021 mentioned that in 2020, China added 139 million kilowatts of renewable energy power generation, including 120 million kilowatts of wind and photovoltaic power generation. The renewable energy power generation exceeded 2.2 trillion kilowatt hours, accounting for nearly 30% of the total power generation. Taking solar and wind energy as examples, they are highly sensitive to weather, influenced by light and wind speed, and inherently intermittent and fluctuating. With the increasing scale of renewable energy, the direct integration of renewable energy power generation devices into the power grid will pose a huge challenge to the stability and safe operation and maintenance of the existing power grid.

Energy storage technology can effectively enhance the grid’s acceptance of renewable energy, play a crucial role in ensuring the stability of the power system and promoting low-carbon energy transformation. In addition, energy storage technology can also be used to achieve power load balancing, peak shaving and valley filling, and improve power quality. According to different energy storage methods, energy storage technologies can be divided into four types: mechanical energy storage, electromagnetic energy storage, electrochemical energy storage, and phase change energy storage. Electrochemical energy storage has advantages such as high energy utilization efficiency and fast response rate, and its energy and power configuration is flexible and less affected by environmental factors, making it easy to achieve large-scale applications.

The batteries used in electrochemical energy storage systems mainly include lead-acid batteries, lithium-ion batteries, sodium sulfur batteries, and liquid flow batteries. Lithium ion batteries have unique advantages such as high energy density, long cycle life, low self discharge rate, and no memory effect, and are widely used in electrochemical energy storage systems.

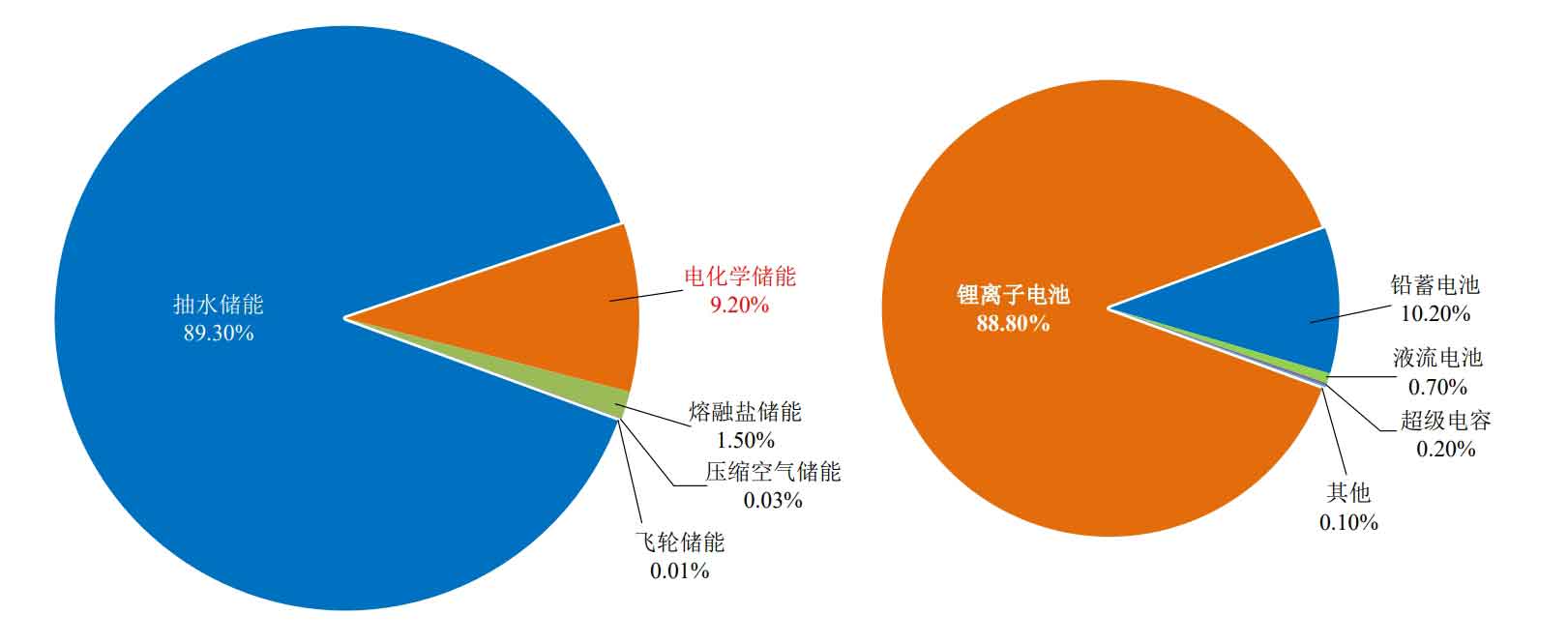

As of the end of 2020, the global cumulative installed capacity of energy storage was 191.1GW, and the cumulative installed capacity of electrochemical energy storage was 14.2GW, an increase of 49.6% year-on-year. In 2020, the global installed capacity of newly added energy storage projects was 6.44GW, an increase of 80% year-on-year. Among them, the newly added scale of electrochemical energy storage reached 4.73GW, accounting for 73.4%. Among the electrochemical energy storage projects that have been put into operation globally, the scale of lithium-ion battery energy storage has reached 13.1GW, accounting for over 90%. Similar to the global energy storage structure, China’s lithium-ion battery energy storage is also rapidly developing. In 2020, the newly added scale of electrochemical energy storage reached 1.56GW, a year-on-year increase of 145%. Among them, the newly added scale of lithium battery energy storage was 1.5GW, accounting for nearly 98%, a year-on-year increase of 146%. Figure 1 shows the cumulative installed capacity classification proportion of energy storage in China as of the end of 2020.

Safety is crucial for battery energy storage systems. During operation, lithium-ion batteries continuously charge and discharge, and due to electrochemical reactions, a large amount of heat is inevitably generated inside. If the heat is not dissipated in a timely manner, the temperature of lithium-ion batteries will continue to rise, which will seriously affect the battery’s service life and performance, and even cause thermal runaway and explosion. Compared to power batteries used in electric vehicles, battery energy storage systems aggregate a larger number of batteries, typically reaching the megawatt or hundred megawatt level; The operating conditions are more complex, sometimes charging and sometimes discharging, sometimes high magnification and sometimes low magnification; The requirement for service life is higher. Generally, power batteries require a cycling frequency of 1000-2000 times, while energy storage batteries require a cycling frequency of over 3500 times. Therefore, a reasonable and efficient battery thermal management system is crucial for ensuring the safe, efficient, and long-term operation of battery energy storage systems.

1. Overview of battery thermal management system

Battery thermal management controls the battery temperature within a certain range through reasonable design based on the impact of temperature on battery characteristics, combined with the battery heat generation mechanism. When the battery temperature is low, the diffusion ability of active substances inside the lithium battery decreases, and the charge transfer impedance increases, leading to an increase in the internal resistance of the battery. The viscosity of the electrolyte increases in a low-temperature environment, and the speed of ion transfer slows down, resulting in mismatched electron migration rates in external circuits, leading to severe polarization and reduced battery capacity. In addition, when charged at low temperatures, the negative electrode is prone to lithium precipitation, forming lithium dendrites on the surface, leading to battery failure. When the battery temperature is high, the internal side reaction speed accelerates, leading to corrosion of the anode plate, causing irreversible attenuation of capacity, and shortening the battery life. If the temperature continues to rise, materials such as battery electrodes, SEI films, and electrolytes will decompose, leading to thermal runaway, accompanied by fires and explosions.

Researchers have found that the optimal operating temperature range for lithium-ion batteries is between 20 ℃ and 40 ℃. Within the range of 30 ℃ to 40 ℃, the lifespan of lithium batteries decreases by about 2 months for every 1 ℃ increase. The battery thermal management system not only needs to control the battery within the optimal temperature range, but also ensures the temperature uniformity of the battery pack. Uneven temperature distribution can lead to uneven distribution of charge states in individual batteries, accelerating battery deterioration. According to different cooling media, battery thermal management can be divided into air cooling, liquid cooling, phase change material cooling, and heat pipe cooling.

(1) Air cooling

Air cooling, as the name suggests, uses air as a medium to cool batteries. According to whether there is external drive, it can be divided into natural convection and forced convection. Air cooling systems are widely used due to their advantages such as low cost and simple structure. However, the specific heat capacity of air is low, making it difficult to meet the cooling needs in some scenarios where batteries generate high heat.

(2) Liquid cooling

Liquid cooling can be divided into indirect cooling and immersion liquid cooling based on whether the heat exchange fluid directly contacts the surface of the battery. Compared to air, liquids have a larger specific heat capacity and thermal conductivity, carry more heat away, have better cooling effects, and have a more compact structure. However, the structure of the liquid cooling system is complex, and maintenance is difficult, resulting in potential leakage hazards.

(3) Phase change material cooling

Phase change materials can change their physical state within a certain temperature range, and cooling of phase change materials is the use of their endothermic or exothermic properties to store or release energy when the physical state changes. The heat released during battery operation is absorbed by phase change materials, which release heat to heat the battery at low temperatures. However, phase change materials can only absorb heat and cannot dissipate heat, so additional equipment is required, which inevitably increases space occupation.

(4) Heat pipe cooling

The working fluid is heated and vaporized in the evaporation section, absorbing heat and becoming steam. Under the pressure difference, it flows towards the condensation section, releasing latent heat and becoming a liquid. Under the capillary force, it flows back to the evaporation section to complete the cycle. Heat pipe cooling has high thermal conductivity, fast response, and good temperature uniformity due to the phase change of its working fluid. However, the high cooling cost of heat pipes and their reliance on gravity limit their usage scenarios, and there are currently few practical applications.

Currently, air cooling is mostly used in practical applications for battery energy storage systems. On the one hand, air cooling has a simple structure, low cost, and convenient maintenance; On the other hand, battery energy storage systems have more relaxed requirements for space and energy density compared to electric vehicles, and can reduce battery heat production by increasing the number of batteries to reduce the charging and discharging rate.

2. Current research status of wind cooling and heat management at home and abroad

At present, the thermal management of air-cooled batteries can be divided into four levels according to scale: individual battery level, battery pack level, battery cabinet level, and full size container/room level.

For single cell batteries, research mostly focuses on analyzing the mechanism of battery heat generation, combining theory with experiments to construct a battery heat generation model, and predicting temperature changes in battery charging and discharging behaviors. Wuhan University of Science and Technology student Che Du Lan and others conducted simulation on stacked lithium batteries, simplifying them into three parts: the battery cell, positive pole, and negative pole. They analyzed the heat generation behavior of the battery under different discharge rates and environmental temperatures. The results indicate that as the discharge rate increases, the battery temperature increases, the temperature rise rate also increases, and the temperature distribution becomes more uneven. When discharging at the same rate, the temperature rise of the battery increases as the ambient temperature decreases. Dong Hyup Jeon and others from Seoul University in South Korea conducted simulation research on a cylindrical 18650 battery, analyzing the internal temperature distribution of the battery under different discharge rates and State of Charge (SOC) conditions. The results show that under high rate discharge, the heat of the battery mainly comes from Joule heat. When the battery is discharged at 5C, Joule heat accounts for 62.8%, while when the battery is discharged at 0.5C, Joule heat only accounts for 12.8%.

At present, most research on air cooling and heat management is focused on battery packs, mainly focusing on optimizing flow channel layout, flow control strategies, and inlet and outlet positions. Fan et al. studied the effects of different battery spacing and inlet flow rates on the temperature distribution of battery packs through CFD simulation analysis. The results show that as the inlet flow rate increases, the maximum temperature of the battery pack decreases; The larger the battery spacing, the more uniform the temperature distribution. Chen’s research team conducted optimization research on the battery gap for parallel prism battery packs. Under the same energy density, the maximum temperature of the optimized structure can be reduced by 4 ℃ and the maximum temperature difference can be reduced by 25%. Wang et al. used CFD to study the effect of cylindrical battery layout on the temperature of the battery pack, and concluded that 5 × The 5-cubic structure layout can achieve the best balance between cooling efficiency and space utilization. Lu et al. conducted research on the arrangement of staggered cylindrical batteries. The conclusion shows that the cooling channel diameter is 1mm, and the optimal channel position is at the top of the battery pack.

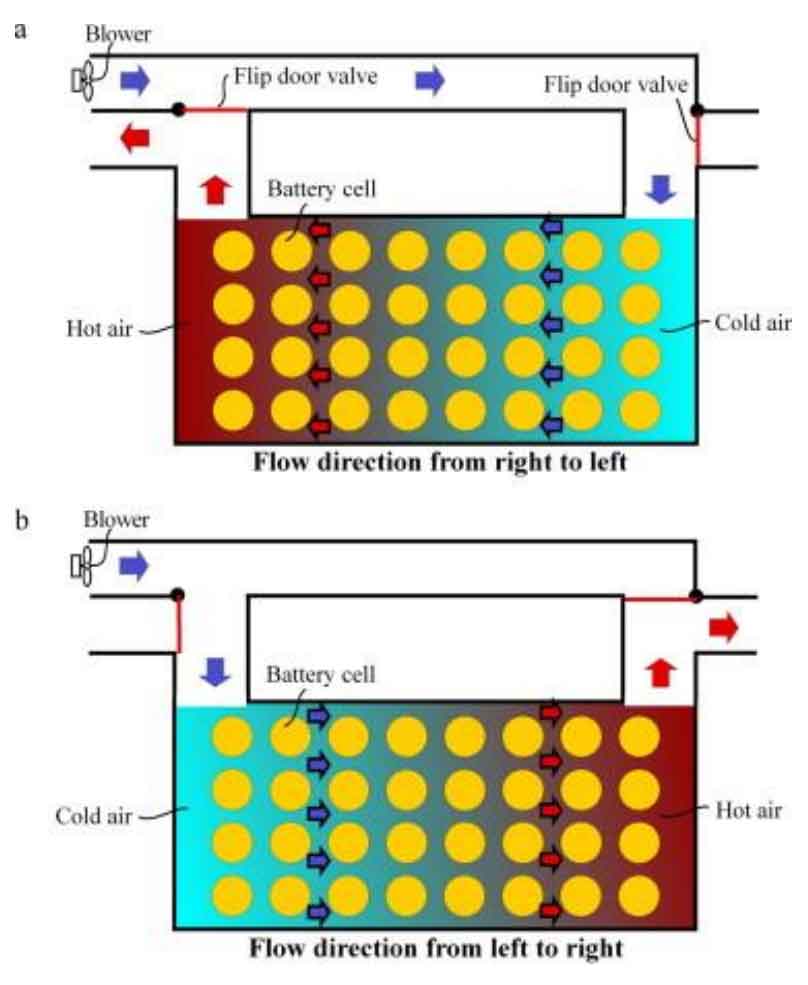

Mahamud et al. proposed for the first time a method of controlling the direction of cold air flow to repeatedly change to improve the operating environment of the battery pack, with the specific structure shown in Figure 2. The results show that compared to unidirectional flow, this air flow method can reduce the maximum temperature difference of the battery pack by 4 ℃ and the maximum temperature by 1.5 ℃. Wang et al. used reciprocating air for cooling the battery pack and found that temperature uniformity was significantly improved during non periodic cycles, with a maximum temperature difference reduction of 49.5% and 25.5%, respectively, compared to forward airflow and periodic conditions. He et al. developed a reduced order model to describe the thermal behavior of battery packs and proposed a control strategy to optimize reciprocating flow. After optimization, the air flow rate was reduced and the cooling performance was significantly improved.

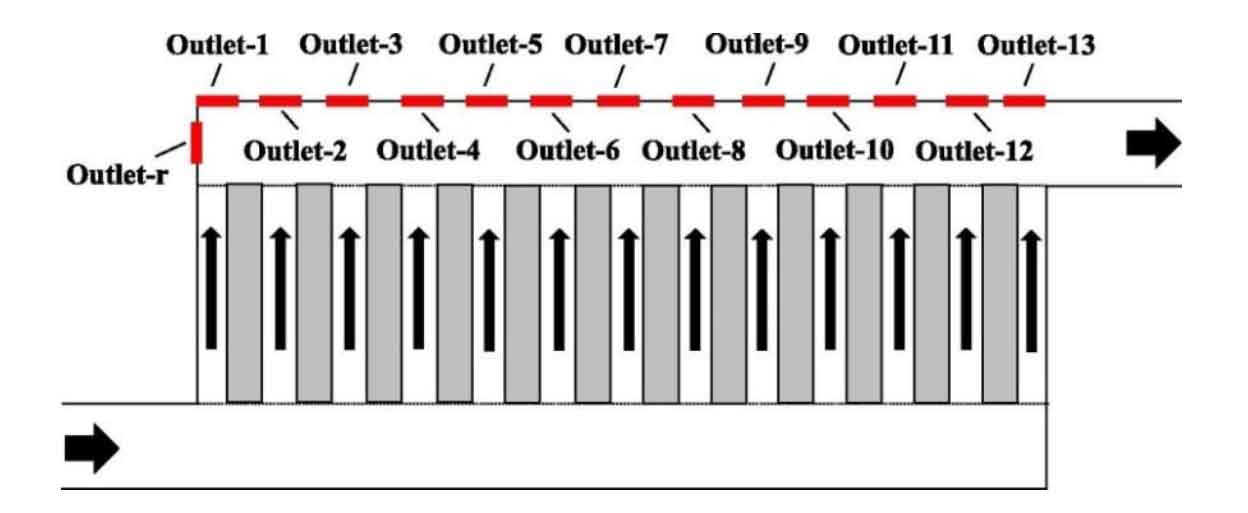

Wang Tianbo et al. studied the influence of the direction and position of the inlet and outlet on the heat dissipation effect of the battery pack, and the results showed that the lateral ventilation method had the best heat dissipation effect. Hwang et al. and Wang et al. investigated the effect of inlet and outlet positions on the thermal management cooling performance of batteries. The results indicate that the position of the ventilation opening has a significant impact on the heat dissipation effect. Chen et al. used numerical methods to study the effect of different inlet and outlet arrangements on heat dissipation performance. The results indicate that the heat dissipation performance of using a symmetrical structure arrangement is better than that of an asymmetric arrangement. Compared with the asymmetric structure, the improved model reduces the maximum temperature by 43% and reduces energy consumption by at least 33% under different intake flow rates. Hong et al. studied the effect of secondary ventilation openings on the cooling and heating performance of forced convection air, and the specific structural diagram is shown in Figure 3. They suggest setting the second outlet above the highest temperature battery in the battery pack, and the position of the second outlet close to the outlet can improve the temperature uniformity of the battery pack.

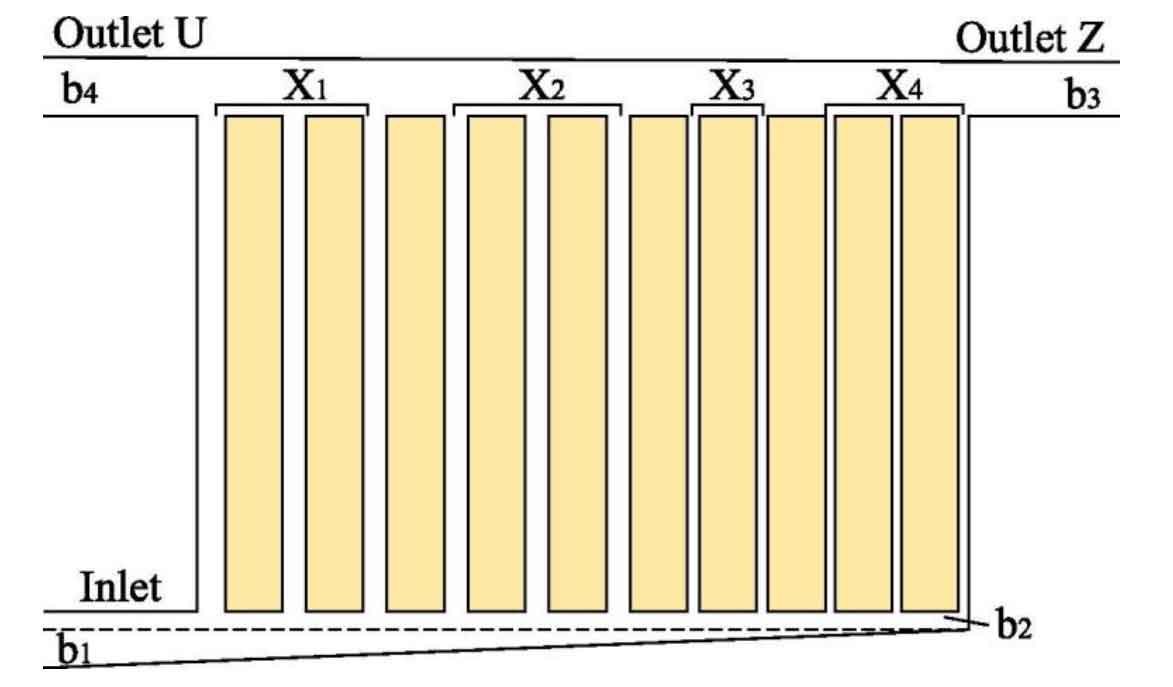

Li et al. optimized four parameters for inlet and outlet, with b1, b2, b3, and b4 used to control the angle and width of the airflow, as shown in Figure 4. They optimized the maximum temperature, temperature uniformity, and pressure drop under U-shaped, Z-shaped, and J-shaped airflow modes. Compared with the original model, the optimized design reduced the temperature rise by 35.3%, 46.6%, and 31.2%, respectively.

There is relatively little research on battery thermal management for containers, with a focus on optimizing airflow organization in large spaces. Luo Jun et al. conducted experimental research on the temperature characteristics of a container type battery energy storage system under equal power charging and discharging conditions. Wang Xiaosong et al. conducted simulation research on the air cooling and heat dissipation of container type battery energy storage system, analyzed the temperature field and flow field of the entire container, and found that there were significant differences in the temperature field and flow field between the near end of the air conditioner and the far end of the air outlet. By adding a guide plate to optimize the air duct structure, the optimized flow field and temperature field distribution are more uniform, effectively reducing the temperature difference between battery modules. Cao et al. developed an electrothermal flow coupling model for practical full-scale lithium battery energy storage systems. The internal temperature and velocity fields under different environmental temperatures were simulated and studied, and verified with the temperature measured at actual operation points.

From the above review of thermal management of air-cooled batteries, it can be seen that the research on individual batteries is the foundation, with the main purpose of constructing a battery heat generation model. Most of the research focuses on battery pack cooling. At present, research on air cooling for energy storage batteries is mostly based on large-scale container cooling, and there is little mention of battery cabinet cooling. Container cooling, on the other hand, focuses more on the airflow organization in large spaces. In simulation research, the heat generation of the battery pack is usually considered as a whole, thus ignoring the temperature difference between individual cells and the temperature difference between individual cells. Battery cabinets are widely used as part of large-scale energy storage systems and can be used separately to provide power for various scenarios. Therefore, it is of great significance to study the air cooling and heat dissipation system of battery cabinets.

Summary

This article studies the air cooling and heat dissipation system of the electrochemical energy storage system battery cabinet. Taking square lithium-ion batteries as the research object, a heat generation model of lithium-ion batteries was established through experimental and numerical simulation methods. The factors affecting the heat dissipation performance of the battery cabinet were analyzed through numerical simulation methods, and a reasonable cooling strategy was provided. The following aspects of research were mainly conducted:

(1) This article elaborates on the development background and significance of energy storage systems, introduces the advantages and current development status of electrochemical energy storage systems, and provides an overview of thermal management methods for air-cooled batteries of various scales.

(2) A detailed introduction was given to the structure, working principle, heat generation mechanism, and heat transfer characteristics of lithium-ion batteries. A battery heat generation model was established, and the thermal characteristics of lithium-ion batteries were studied through CFD simulation. The temperature distribution of lithium-ion batteries at different discharge rates was analyzed, and the accuracy of the heat generation model was verified through experiments.

(3) For single-layer battery cabinets, the effects of different discharge rates, inlet flow rates, battery gaps, inlet arrangements, and the distance between the battery pack and the wall on heat dissipation performance were studied through CFD simulation. A comprehensive analysis of different discharge rates, inlet temperatures, and battery gaps was conducted, and the critical inlet flow rate to meet the heat dissipation demand was given.

(4) For multi-layer battery cabinets, experiments were established to verify the flow field inside the cabinet, and a single air supply method was proposed. The effects of different air supply methods, inlet flow rate, number of batteries in each layer, and number of battery cabinet layers on heat dissipation performance were studied through CFD simulation. Reasonable suggestions were given for the layout of the battery cabinet.