With the large-scale application of embedded systems such as microcontrollers, ARM, DSP, etc. in aviation equipment, it provides support for the rapid development of our military equipment and is conducive to improving the combat effectiveness of the troops. However, due to environmental limitations, some embedded systems do not have the ability to carry large capacity power supplies. Therefore, researching a power supply device for a universal embedded system has become a new topic.

Lithium batteries are a type of battery that uses lithium metal or lithium alloy as the negative electrode material and non-aqueous electrolyte solutions. The earliest lithium batteries emerged from the great inventor Edison.

Due to the highly reactive chemical properties of lithium metal, the processing, storage, and use of lithium metal have very high environmental requirements. So, lithium batteries have not been applied for a long time. With the development of microelectronics technology in the 20th century, the number of miniaturized devices is increasing, which has put forward high requirements for power supplies. Lithium batteries have entered a large-scale practical stage. It was first applied in cardiac pacemakers. Due to the extremely low self discharge rate of lithium batteries, the discharge voltage is gentle. Making it possible for pacemakers to be implanted in the human body for long-term use. In 1992, Sony successfully developed lithium-ion batteries. Its practicality greatly reduces the weight and volume of portable electronic devices such as mobile phones and laptops. The usage time is greatly extended. Due to the absence of heavy metal chromium in lithium-ion batteries, compared to nickel chromium batteries, it greatly reduces environmental pollution. Lithium batteries generally have a nominal voltage higher than 3.0 volts, making them more suitable as integrated circuit power supplies. Manganese dioxide batteries are widely used in computers, calculators, cameras, and watches.

At present, the largest capacity lithium battery (dry battery) on the market is about 6800mAh, with a charging voltage of 4.2V and a discharge voltage of 3.7V. When the battery voltage is below 2.7V, it needs to be recharged. This article takes this type of lithium battery as an example to develop a universal portable power supply for embedded systems in aviation equipment.

1. Performance indicators

In embedded systems, 51 microcontrollers have two types of power supply voltages: 5V and 3.3V. The power supply voltage of ARM, DSP and other chips is generally 3.3V. Therefore, this power supply system can provide two types of power supply: 3.3V and 5V.

Due to the rapid popularization of USB technology, a small micro USB port is used as the charging interface for the power interface. This interface can be charged directly through the USB bus or through a USB power supply.

2. System composition

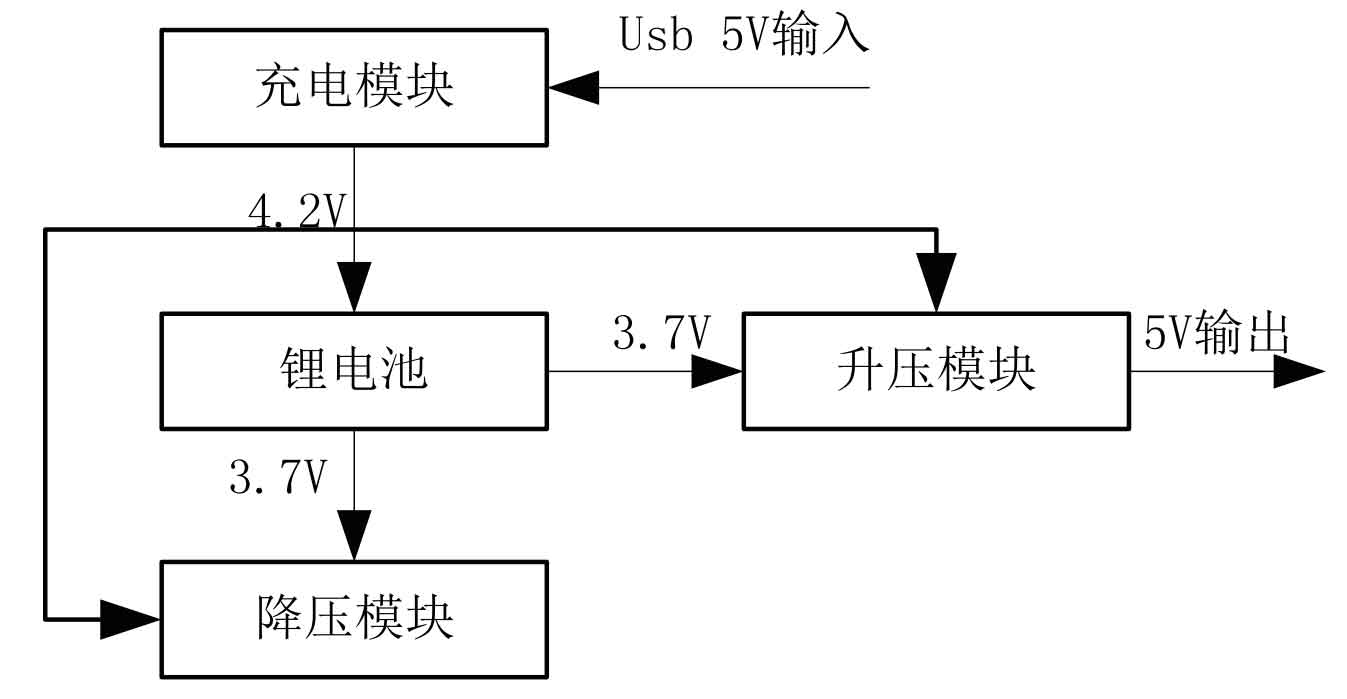

The system mainly consists of three parts: charging module, step-down module, and step-up module. The composition diagram is shown in Figure 1:

From Figure 1, it can be seen that when the 5V power supply passes through the micro USB port, it enters the lithium battery charging module and converts to a voltage of 4.2V to charge the lithium battery. When there is a 5V power supply input, the power supply voltage of the step-down module and step-up module is 4.2V. Otherwise, it is powered by a lithium battery with a supply voltage of 3.7V.

The function of the boost module is to increase the voltage to 5V output, providing power to modules such as microcontrollers.

The function of the voltage reduction module is to output a voltage of 3.3V to supply power to chips such as microcontrollers, DSP, ARM, etc.

Through the above three modules, the functions in the technical indicators can be achieved.

3. Hardware implementation

Below are the three modules in the block diagram, explaining the specific hardware implementation circuit of the system.

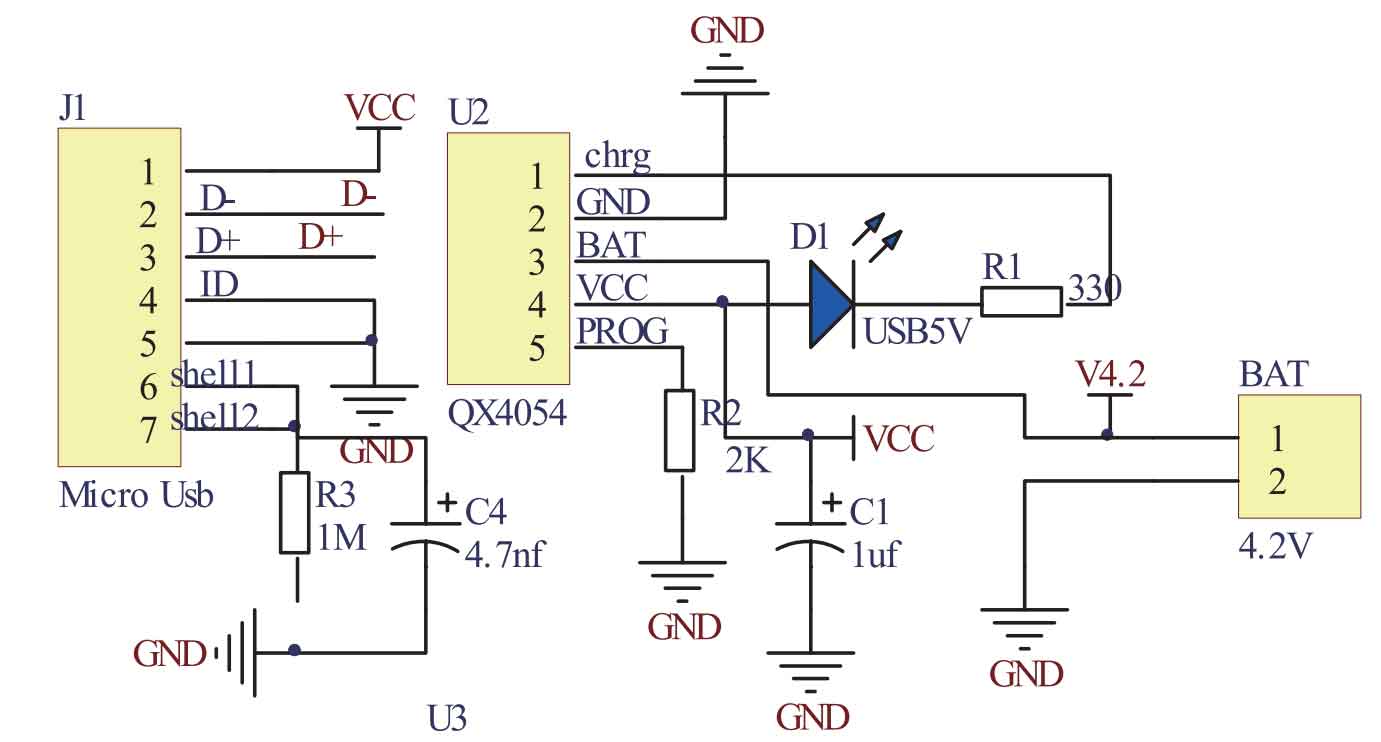

3.1 Charging module

The charging module adopts QX4054 chip. This chip is a complete single cell lithium-ion battery constant current and constant voltage linear charging IC. It adopts a very small SOT-23-5 package, requiring only a few external components, making it truly suitable for portable product applications. Moreover, QX4054 is specifically designed for USB power supply characteristics. Meanwhile, QX4054 can also serve as an independent linear lithium-ion battery charger. Its charging current is programmable, up to 800mA. The specific implementation circuit is shown in Figure 2:

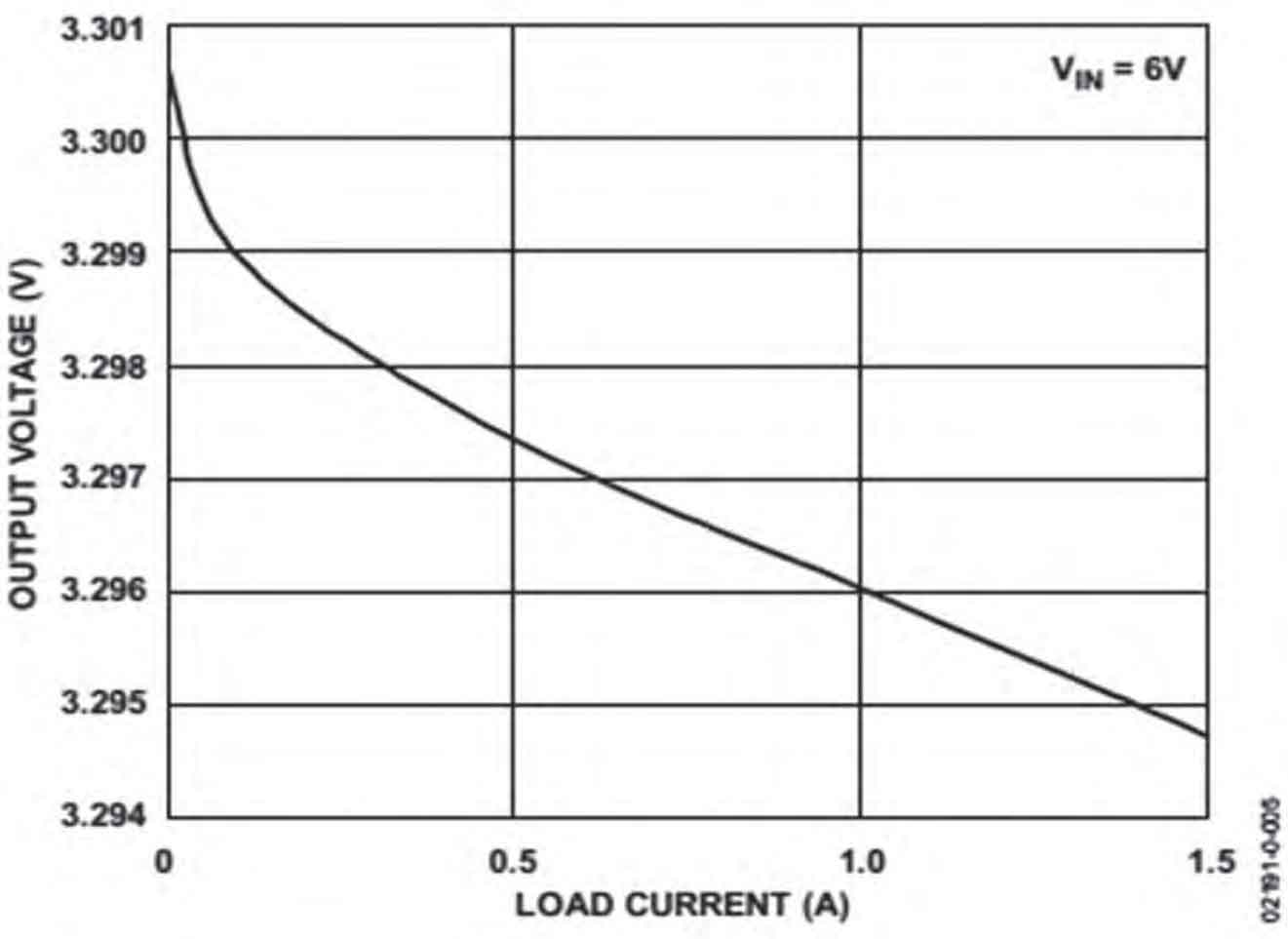

The prog pin of pin 5 can program the charging current, and the level on this pin is defined as 1V. The size of the set charging current in all working states can be calculated using the following equation:

We used a 2K Ω resistor here, and from the above equation, it can be seen that the charging current is 500mA.

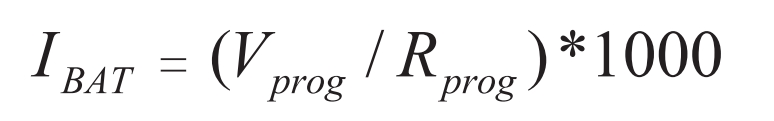

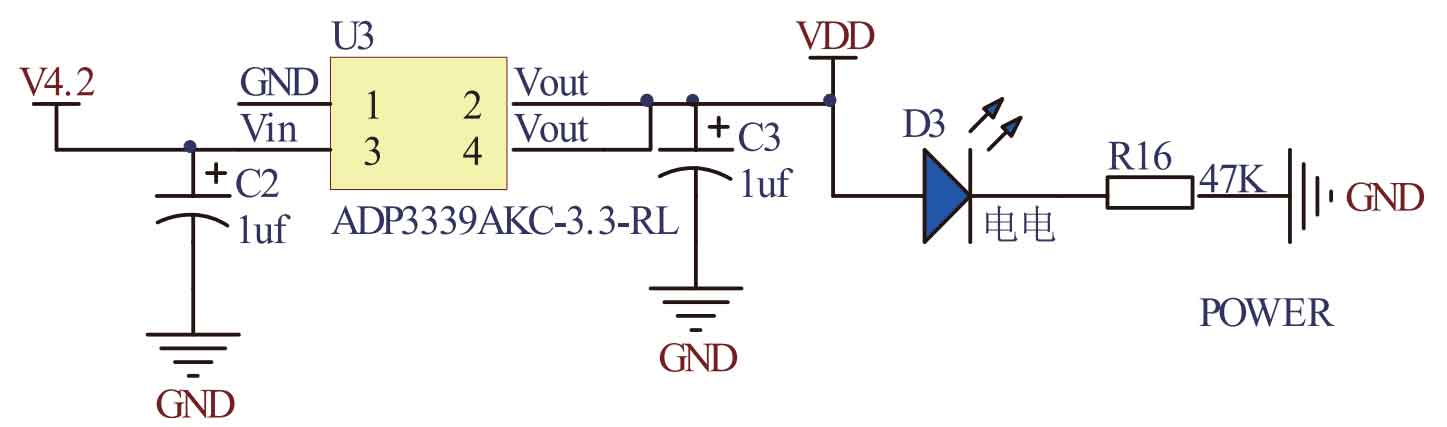

3.2 Voltage reduction module

The voltage reduction module adopts ADI’s ADP3339AKC-3.3-RL chip. The chip has a three terminal adjustable or fixed voltage of 3.3V and an output current of 1A. Adopting SOT23-3 packaging. The relationship between its output voltage amplitude and current is shown in Figure 3: The specific circuit diagram of the step-down module is shown in Figure 4:

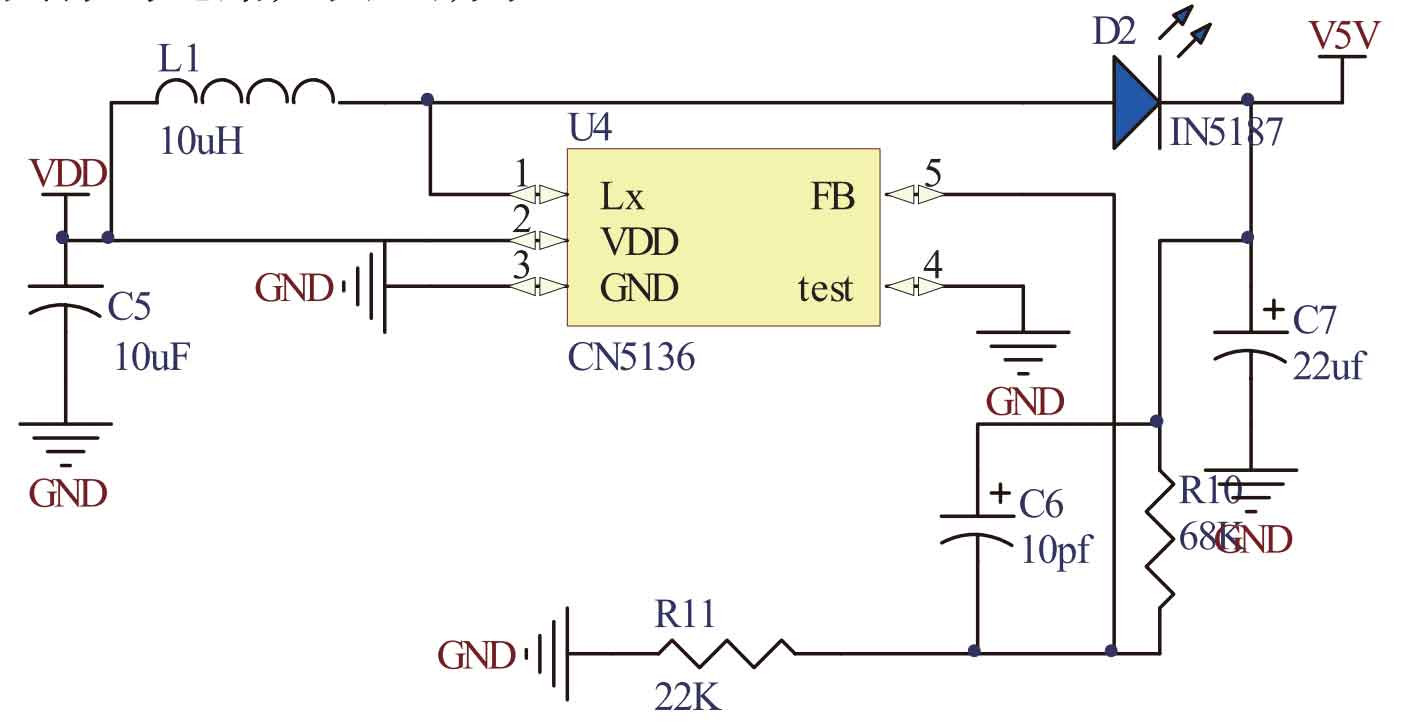

3.3 Booster module

The boost module adopts the CN5136 module from Shanghai Ruyun Company, which is an efficient pulse frequency modulation (PFM) DC-DC converter with a maximum output current capacity of 500mA. The output voltage of CN5136 can be set through an external resistor. The high-precision voltage reference source on the chip ensures the accuracy of the output voltage and low temperature drift. The working voltage range of CN5136 is from 2.7V to 6V, which is very suitable for applications powered by lithium batteries and three nickel hydrogen batteries. CN5136 adopts a 5-pin SOT23 package. The specific circuit is shown in Figure 5:

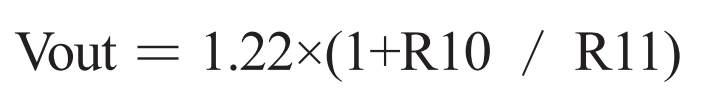

The output voltage value is determined by the ratio of R10 and R11 resistors connected to the FB pin, and the specific calculation formula is:

Among them, R10 takes a value of 68K and R11 takes a value of 22K. After calculation with formula 2, the final result is 5V.

4. Summary

The article introduces a design method for a lithium-ion battery based power system, which uses a micro USB port for charging and can provide 5V and 3.3V voltages, meeting the power supply needs of most embedded systems. The circuit adopts a universal design concept, which has the advantages of small size and low cost, and can be widely applied in various situations where embedded instruments and meters are used.