With the rapid advancement of photovoltaic technology and decreasing costs, solar power systems have gained widespread acceptance as a reliable green energy solution. In my experience, designing and implementing a small-scale roof off-grid solar system for industrial applications has proven both feasible and beneficial, particularly in urban settings where land is scarce. This off-grid solar system was specifically engineered to power LED lighting in a factory, demonstrating how standalone systems can provide consistent electricity without grid dependency. The project underscores the practicality of off-grid solar systems for localized energy needs, and in this article, I will detail the entire process from initial design to operational analysis, incorporating key calculations, tables, and practical insights.

The core objective of this off-grid solar system was to supply approximately 1000 W of LED lighting for 6 hours daily, with the ability to function autonomously for up to 3 days during cloudy weather. Located in a region similar to Shanghai, the system had to account for variable solar insolation and structural constraints of a typical industrial roof. As an engineer, I focused on optimizing each component—solar panels, batteries, charge controllers, and inverters—to ensure efficiency and reliability. The off-grid solar system design prioritizes energy independence, making it ideal for scenarios where grid connection is impractical or undesirable. Below, I elaborate on the system’s principles, electrical and structural design, installation techniques, and performance evaluation, all from a first-hand perspective.

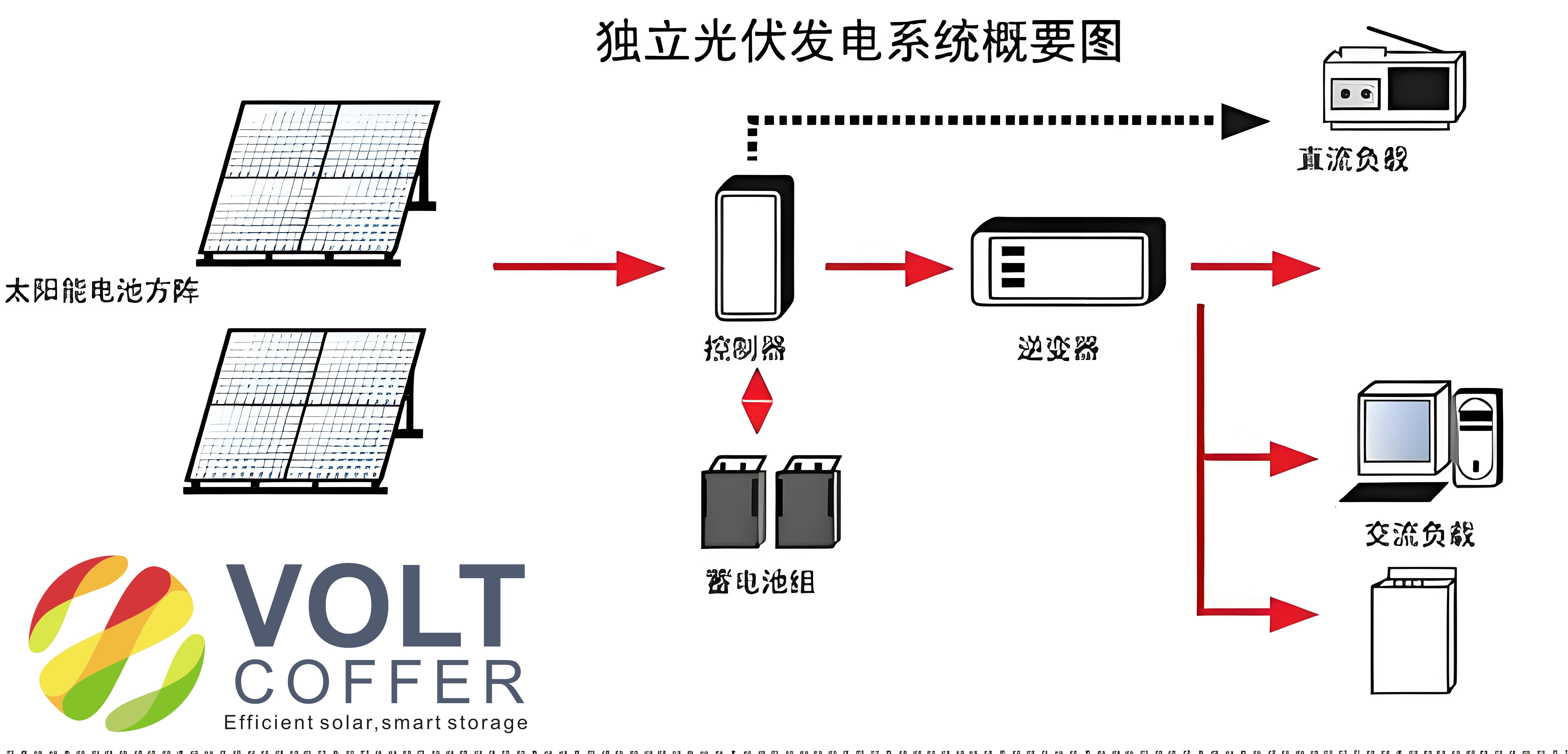

The fundamental principle of this off-grid solar system revolves around converting solar energy into usable AC power through a series of coordinated components. Solar panels generate DC electricity, which is consolidated in a combiner box with lightning protection before being regulated by a charge controller to charge the battery bank. Simultaneously, the stored DC energy is inverted to 220V AC by an off-grid inverter, powering the LED lights. This setup ensures that the off-grid solar system operates independently, leveraging battery storage to bridge gaps in solar generation. The system’s autonomy is critical for uninterrupted operation, especially in areas prone to frequent power outages or limited grid access.

In the electrical design phase, I began by calculating the daily energy requirement of the load. For a 1000 W LED load operating 6 hours daily, the energy consumption is:

$$ E_{\text{load}} = P_{\text{load}} \times t = 1000 \, \text{W} \times 6 \, \text{h} = 6000 \, \text{Wh} $$

To account for system losses and ensure reliability during 3 days of autonomy, the battery capacity was determined using the formula:

$$ C_{\text{battery}} = \frac{E_{\text{load}} \times D}{\eta_{\text{system}} \times V_{\text{system}} \times \text{DOD}} $$

where \( D = 3 \) days (autonomy), \( \eta_{\text{system}} = 0.70 \) (system efficiency), \( V_{\text{system}} = 48 \, \text{V} \) (system voltage), and DOD = 0.5 (depth of discharge for lead-acid batteries). Plugging in the values:

$$ C_{\text{battery}} = \frac{6000 \times 3}{0.70 \times 48 \times 0.5} \approx 1071 \, \text{Ah} $$

For practicality and safety margins, I selected a 48V 500Ah battery bank composed of 24 individual 2V 500Ah gel batteries, which provides a balance between cost and performance. The solar array size was then calculated based on peak sun hours (PSH) in the region, approximately 3.5 hours for Shanghai:

$$ P_{\text{array}} = \frac{E_{\text{load}}}{\eta_{\text{system}} \times \text{PSH}} = \frac{6000}{0.70 \times 3.5} \approx 2449 \, \text{Wp} $$

To accommodate losses and potential expansion, I opted for 16 monocrystalline solar panels rated at 190 Wp each, resulting in a total capacity of 3040 Wp. The panels were configured in 2 series strings of 8 panels each, with an open-circuit voltage of 85–95 V and a operating voltage around 75 V, ensuring compatibility with the 48V system. The charge controller, a 48V 60A maximum power point tracking (MPPT) unit, enhances energy harvest by optimizing the panel output, while a 2 kVA off-grid inverter converts DC to AC for the loads. Key electrical parameters are summarized in the tables below.

| Component | Specification | Quantity |

|---|---|---|

| Solar Panel | 190 Wp monocrystalline | 16 |

| Combiner Box | 8-input with lightning protection | 1 |

| Charge Controller | 48V, 60A MPPT | 1 |

| Off-grid Inverter | 220V, 2 kVA | 1 |

| Battery | 2V, 500Ah gel VRLA | 24 |

| Energy Meter | Single-phase pulse type | 1 |

| Parameter | Value |

|---|---|

| Installed Capacity | 3.04 kWp |

| Location | Shanghai area equivalent |

| Load Requirement | 1000 W LED for 6 hours daily |

| System Efficiency | >70% |

| Autonomy Days | 3 days |

| Array Tilt and Orientation | 35° south-facing |

| Battery Bank Voltage | 48 V |

| Battery Capacity | 500 Ah |

The structural design of the off-grid solar system was tailored to the factory’s彩钢板 roof, which had an east-west gable configuration. To maximize energy yield, I oriented the solar panels at a 35° tilt facing true south, as determined by solar radiation models. The mounting structure utilized aluminum rails and stainless steel fasteners to resist corrosion, with panel clamps ensuring secure attachment. A critical consideration was maintaining a minimum 100 mm clearance between the panel edges and the roof surface to facilitate water drainage and reduce debris accumulation. For wind resilience, the支架 was anchored to the roof’s load-bearing steel tracks using galvanized brackets and bolts, supplemented by waterproof seals at penetration points to prevent leaks. This approach not only enhanced durability but also complied with local building codes, making the off-grid solar system both efficient and structurally sound.

During installation, I adhered to a meticulous施工 plan that emphasized safety and precision. The process began with site assessment and measurement, followed by assembly of the mounting structure. Panels were then mounted using aluminum clamps, and wiring was routed along the rails, secured with zip ties, and protected by PVC conduits in exposed areas to mitigate environmental wear. All electrical connections were labeled to prevent polarity errors, and the system was grounded for lightning protection. Waterproofing measures, such as silicone sealant around bolt holes, were applied to preserve roof integrity. This hands-on phase highlighted the importance of quality craftsmanship in ensuring the long-term reliability of an off-grid solar system, particularly in harsh weather conditions.

To evaluate the off-grid solar system’s performance, I monitored key metrics over several months, including daily energy generation, consumption, and battery state of charge. Data from August revealed consistent operation, with generation exceeding consumption on sunny days, leading to full battery recharge, and deficits on cloudy days necessitating battery discharge. The system efficiency was calculated periodically using:

$$ \eta_{\text{system}} = \frac{E_{\text{output}}}{E_{\text{input}}} \times 100\% $$

where \( E_{\text{output}} \) is the energy delivered to the load and \( E_{\text{input}} \) is the solar energy incident on the panels. Average efficiency ranged between 70-75%, aligning with design expectations. The battery performance was also assessed through voltage and capacity measurements, confirming that the off-grid solar system could sustain the load during autonomy periods without significant degradation. This real-world analysis underscores the viability of such systems for similar applications, providing a template for future projects.

In reflection, this small-scale roof off-grid solar system project exemplifies the potential of decentralized energy solutions. The design and implementation process taught me valuable lessons in component selection, such as the trade-offs between battery capacity and cost, and the benefits of MPPT technology in improving energy harvest. Despite the higher initial investment compared to grid-tied systems, the off-grid solar system offers unparalleled independence, making it suitable for remote locations or as a backup power source. As technology evolves and costs decline, I anticipate that off-grid solar systems will become more accessible, empowering individuals and businesses to adopt sustainable energy practices. This experience reaffirms the importance of holistic planning—from electrical calculations to structural integration—in achieving a successful off-grid solar system deployment.

Looking ahead, I plan to explore advancements in battery technologies, such as lithium-ion options, which could enhance the efficiency and lifespan of future off-grid solar systems. Additionally, integrating smart monitoring systems could provide real-time data for optimized performance. The lessons from this project can be scaled to larger installations or adapted for residential use, further promoting the adoption of off-grid solar systems worldwide. Ultimately, the journey of designing and operating this system has deepened my appreciation for renewable energy’s role in addressing global energy challenges, and I am committed to continuing this work in future endeavors.