With the increasing development and utilization of new energy sources, microgrid power supply systems are widely applied in industrial parks, remote areas, border outposts, and other scenarios. To ensure optimal operation of energy storage batteries, a battery management system (BMS) is essential for state monitoring and management, thereby enhancing energy storage efficiency and ensuring safe and stable operation. In microgrid energy storage, batteries often cannot be fully charged or discharged, and the system demands high energy utilization rates and reliability standards. Consequently, BMS designed for electric vehicles are not suitable for microgrid energy storage applications. Current battery energy storage system implementations often face shortcomings, such as insufficient accuracy in state of charge (SOC) estimation, which reduces energy storage utilization, and energy-wasting passive equalization methods with low efficiency. Therefore, I designed an active equalization-based battery energy storage system for microgrids, employing a master-slave architecture and modular design to achieve efficient management and energy utilization.

The battery energy storage system is critical for microgrid stability, as it manages the charging and discharging cycles, monitors health parameters, and ensures safety. My design focuses on a high-precision, reliable BMS that can handle the unique demands of microgrid environments, where fluctuations in renewable energy sources like solar and wind require robust energy buffering. The core of this battery energy storage system lies in its ability to accurately estimate SOC and perform active equalization, addressing inconsistencies in series-connected battery cells. This approach not only prolongs battery life but also maximizes the usable capacity of the battery energy storage system, making it more cost-effective and sustainable for long-term deployment.

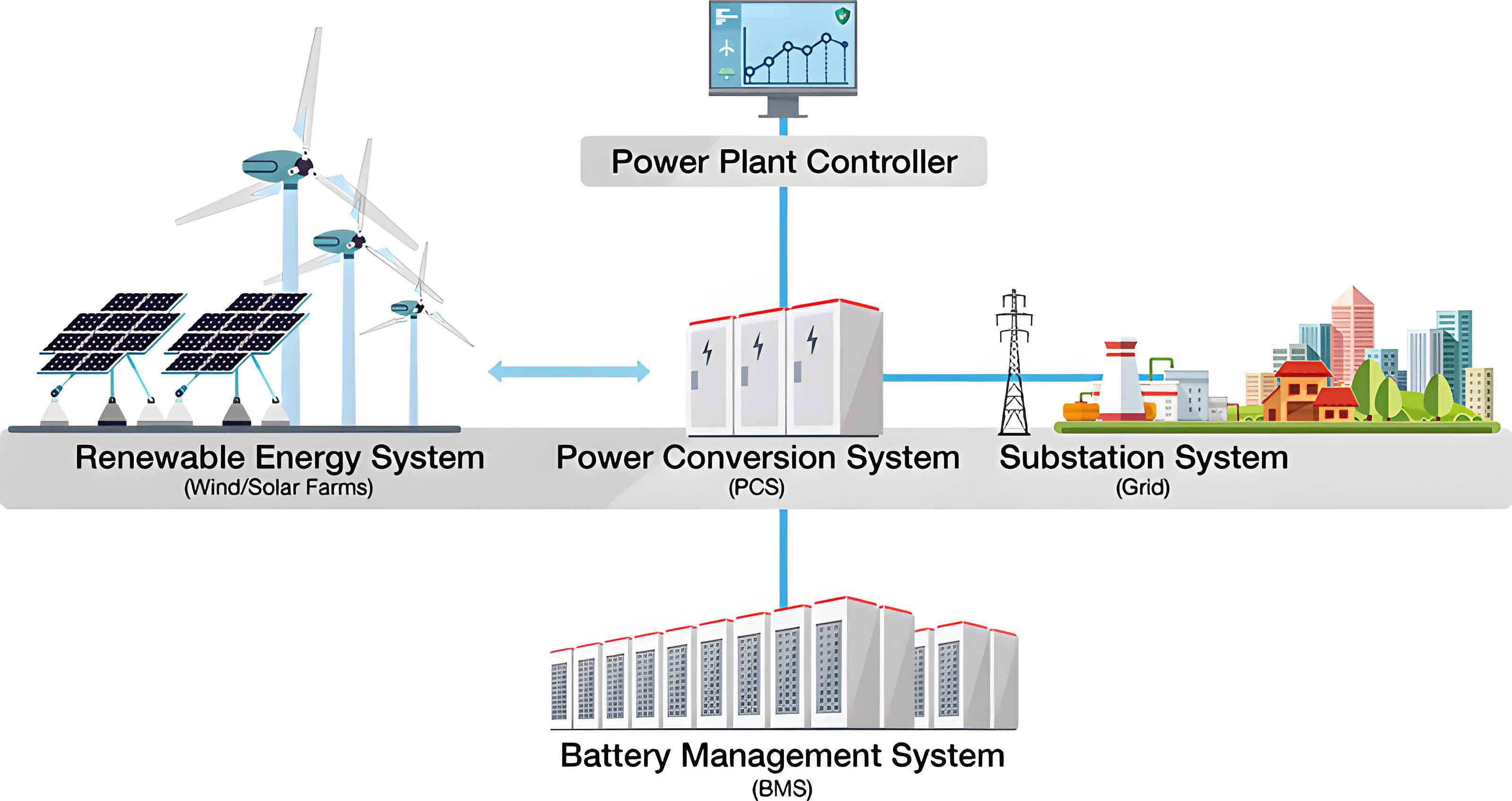

The overall design of the battery energy storage system adopts a master-slave architecture, which enhances scalability and reliability. The master control module, centered on a TMS320F2812 digital signal processor (DSP), handles data processing, SOC estimation, and system-level decisions. The slave control modules, based on LTC6811 integrated circuits, manage individual battery cells by collecting voltage, temperature, and current data, and implementing active equalization. This hierarchical structure allows for efficient management of large battery packs, as multiple LTC6811 devices can be daisy-chained to monitor hundreds of cells. Communication between modules is achieved via SPI serial interface, ensuring fast and reliable data transfer, while CAN bus facilitates interaction with external systems like the energy management system (EMS) and power conversion system (PCS). The battery energy storage system thus serves as a intelligent node in the microgrid, providing real-time insights into battery status and enabling proactive management.

In this battery energy storage system, the hardware design is foundational to its performance. I selected the TMS320F2812 DSP as the master controller due to its high computational power, with a clock frequency of 150 MHz and extensive peripherals including 12-bit ADC channels, SPI, and CAN interfaces. Its 128 kB FLASH and 18 kB RAM support complex algorithms for SOC estimation and equalization control. The minimal system includes reset circuits, crystal oscillators, and filtering circuits to ensure stable operation in harsh environments. For the slave modules, the LTC6811 chip is ideal for voltage monitoring and active equalization, capable of measuring up to 12 series-connected cells with high accuracy. Its built-in ADC eliminates the need for external converters, and the isoSPI interface allows for isolated communication, enhancing noise immunity. The hardware components are summarized in Table 1.

| Component | Model/Specification | Function |

|---|---|---|

| Master Controller | TMS320F2812 DSP | Data processing, SOC estimation, system control |

| Slave Controller | LTC6811 IC | Voltage/temperature acquisition, active equalization |

| Voltage Measurement | RC filter (100 Ω, 10 μF) | Noise reduction for accurate voltage reading |

| Active Equalization Switch | IRF2807 MOSFET | High-current switching for energy transfer |

| Temperature Sensor | DS18B20 | Digital temperature sensing with ±1°C accuracy |

| Current Sensor | CHB-200SF Hall Effect | Closed-loop current measurement |

| Power Supply | LT3990, WRB1205S, XC6209 | Voltage conversion from battery pack to 3.3V/5V/12V |

The voltage acquisition circuit is designed around the LTC6811, with each cell connected through an RC filter to mitigate high-frequency noise. The filter components, a 100 Ω resistor and 10 μF capacitor, reduce voltage ripple and improve measurement accuracy. Additionally, Zener diodes are placed across cell terminals for surge protection. For active equalization, I implemented a modified Buck-Boost topology controlled by the LTC6811’s GPIO pins. The circuit uses IRF2807 MOSFETs for switching, with low forward-drop Schottky diodes (IN5822) to minimize losses. To address parasitic inductance in long wires, 22 μF ceramic capacitors are added at battery interfaces, enhancing energy transfer efficiency. This equalization method allows energy to be shuffled between cells based on SOC, reducing imbalances and improving the overall performance of the battery energy storage system.

Current and temperature acquisition are integrated into the LTC6811 framework. The DS18B20 temperature sensor connects to an I/O pin via a single-wire interface, with a pull-up resistor to 3.3V. Its digital output simplifies data reading, and multiple sensors can be networked for comprehensive thermal monitoring. For current sensing, the CHB-200SF Hall sensor converts primary current to a voltage signal through a precision resistor. The signal is then conditioned with operational amplifiers to fit the LTC6811’s input range, enabling synchronized voltage and current sampling. This integrated approach ensures that all critical parameters are captured simultaneously, supporting accurate SOC estimation. The power supply module derives energy directly from the battery pack, using LT3990 to step down voltage to 12V, followed by isolated converters to produce 5V and 3.3V rails. This design eliminates external power sources, making the battery energy storage system self-sufficient and reliable.

The software development for this battery energy storage system was conducted in the Code Warrior environment, focusing on the TMS320F2812 DSP. The program flow begins with system initialization, configuring clocks, I/O ports, and communication interfaces. Data acquisition subroutines then collect voltage, current, and temperature readings from the LTC6811 via SPI. These raw values are filtered and converted using the ADC modules before being processed. A key aspect is SOC estimation, which employs an unscented Kalman filter (UKF) algorithm for high precision. The UKF models the battery dynamics with state-space equations, accounting for nonlinearities in the battery energy storage system. The state vector includes SOC, and the process is defined as:

$$ x_k = f(x_{k-1}, u_k) + w_k $$

$$ y_k = h(x_k, u_k) + v_k $$

where \( x_k \) is the state, \( u_k \) is the input current, \( y_k \) is the measured voltage, and \( w_k \), \( v_k \) are process and measurement noises. The UKF predicts and updates SOC using sigma points, providing robust estimates even under varying load conditions. This method significantly enhances the accuracy of the battery energy storage system compared to traditional coulomb counting or extended Kalman filters.

Simultaneously, safety protection subroutines monitor for overvoltage, undervoltage, overcurrent, and overtemperature conditions. If any threshold is exceeded, the DSP issues protection commands and alerts via CAN bus. The active equalization subroutine uses SOC as the control variable; when cell disparities exceed a set limit (e.g., 1%), the DSP generates PWM signals to drive the Buck-Boost equalization circuits. This ensures that energy is transferred from higher-SOC cells to lower-SOC ones, maintaining balance across the battery pack. Communication with external devices like EMS and PCS is handled through CAN messages, transmitting real-time data and receiving control instructions. This software architecture makes the battery energy storage system adaptive and intelligent, capable of responding dynamically to microgrid demands.

To validate the battery energy storage system, I conducted experiments on a 12-cell series-connected battery pack. The tests focused on measurement accuracy and equalization effectiveness. For voltage accuracy, comparisons were made between BMS readings and a Fluke 175C digital multimeter, with results shown in Table 2. The BMS demonstrated errors within ±5 mV, meeting design specifications. Temperature accuracy was evaluated using a thermal chamber, with errors within ±1°C across a range from -10°C to 50°C, as summarized in Table 3.

| Cell Number | BMS Reading (V) | Multimeter Reading (V) | Error (mV) |

|---|---|---|---|

| 1 | 3.245 | 3.249 | +4 |

| 2 | 3.252 | 3.254 | +2 |

| 3 | 3.201 | 3.200 | -1 |

| 4 | 3.250 | 3.247 | -3 |

| 5 | 3.184 | 3.186 | +2 |

| 6 | 3.215 | 3.218 | +3 |

| 7 | 3.226 | 3.223 | -3 |

| 8 | 3.237 | 3.241 | +4 |

| 9 | 3.268 | 3.266 | -2 |

| 10 | 3.216 | 3.218 | +2 |

| 11 | 3.221 | 3.218 | -3 |

| 12 | 3.239 | 3.244 | +5 |

| Thermal Chamber Temperature (°C) | BMS Reading (°C) | Error (°C) |

|---|---|---|

| -10 | -10.5 | -0.5 |

| 0 | -0.2 | -0.2 |

| 10 | 9.7 | -0.3 |

| 20 | 20.1 | +0.1 |

| 30 | 29.8 | -0.2 |

| 40 | 40.6 | +0.6 |

| 50 | 50.8 | +0.8 |

For equalization testing, two battery groups were prepared with identical initial SOC profiles but internal disparities up to 6%. One group utilized the active equalization circuit, while the other operated without it. Both groups underwent constant-current discharge via an electronic load, with SOC recorded every 3 minutes over 30 minutes. The results, presented in Table 4, show that the equalized group reduced SOC differences to within 1%, whereas the unequalized group saw disparities grow to 6.09%. This highlights the effectiveness of the active equalization in maintaining consistency, crucial for the longevity and efficiency of the battery energy storage system.

| Cell Number | Initial SOC (%) | Equalized Group Final SOC (%) | Non-Equalized Group Final SOC (%) |

|---|---|---|---|

| 1 | 74 | 68.85 | 70.52 |

| 2 | 76 | 68.92 | 71.23 |

| 3 | 73 | 68.57 | 68.85 |

| 4 | 75 | 68.75 | 70.21 |

| 5 | 72 | 68.34 | 67.95 |

| 6 | 70 | 68.05 | 65.14 |

The experimental validation confirms that this battery energy storage system design meets the stringent requirements of microgrid applications. The high-precision data acquisition, with voltage errors within ±5 mV and temperature errors within ±1°C, ensures reliable monitoring. The active equalization, driven by SOC-based algorithms, effectively mitigates cell imbalances, keeping SOC differences below 1%. This enhances the overall energy utilization and safety of the battery energy storage system. Moreover, the modular hardware and scalable software allow for adaptation to larger battery packs, making it suitable for diverse microgrid settings. The integration of advanced techniques like UKF for SOC estimation represents a significant improvement over traditional BMS, addressing common pitfalls in battery energy storage system implementations.

In conclusion, the battery energy storage system I designed for microgrids demonstrates a robust and efficient approach to battery management. By leveraging a master-slave architecture with TMS320F2812 and LTC6811 components, it achieves precise state monitoring, accurate SOC estimation, and effective active equalization. The system’s performance, validated through rigorous testing, shows that it can significantly improve the reliability and longevity of energy storage batteries in microgrid environments. Future work could focus on enhancing communication protocols for larger-scale deployments or integrating machine learning algorithms for predictive maintenance. This battery energy storage system serves as a foundational technology for advancing renewable energy integration, contributing to more resilient and sustainable power networks.

The design principles outlined here emphasize the importance of accuracy and efficiency in battery energy storage system development. As microgrids continue to evolve, the demand for intelligent BMS will grow, and this work provides a scalable framework. The use of formulas like the UKF state-space model and detailed hardware tables ensures transparency and reproducibility. Ultimately, this battery energy storage system not only addresses current challenges but also paves the way for next-generation energy storage solutions, where smart management is key to unlocking the full potential of renewable sources.