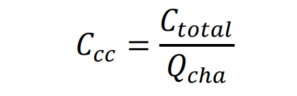

The cost of energy storage per kilowatt hour is an important indicator for measuring the economic effectiveness of energy storage systems. It is obtained by dividing the total cost of energy storage systems by the total energy stored during the heat storage process, and is calculated as follows:

Among them, 𝐶𝑐𝑐 is the energy storage cost per kilowatt hour, $/kWh; 𝐶𝑡 total is the total cost of the energy storage system, $; 𝑄𝑐ℎ𝑎 is the energy stored in the energy storage system during the heat storage process, in kWh.

Based on the proposed cost model, the total cost of each energy storage system was calculated. Then, based on the energy storage process, the unit energy storage cost of each system can be obtained.

1. Calculation of Energy Storage Costs for Different Energy Storage Systems

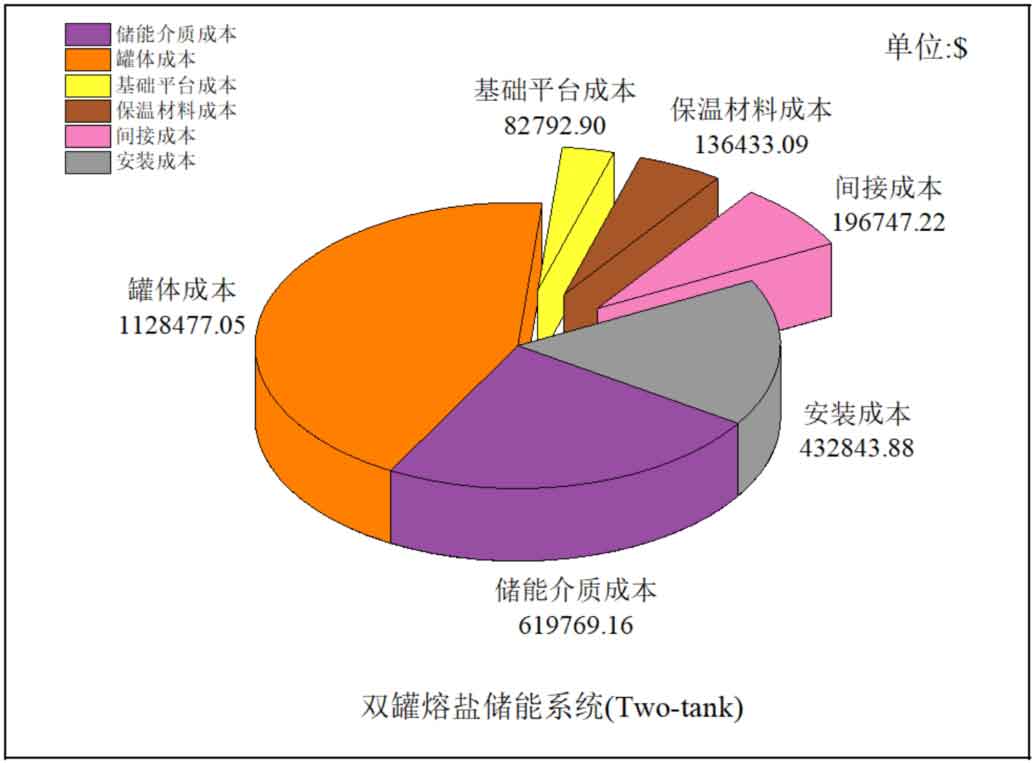

(1) Calculation of Energy Storage Cost for Two tank Molten Salt Energy Storage System

Figure 1 shows the cost breakdown of each part of the dual tank molten salt energy storage system. The total cost of the system is $2597063.31, and the energy storage cost per kilowatt hour is $26.40 per kWh, which is close to the $26.22 per kWh value reported by the National Renewable Energy Laboratory (NREL) in the United States, demonstrating the reliability of the cost analysis. From the graph, it can be seen that in the dual tank energy storage system, the proportion of tank cost is relatively high, accounting for 43.5%. Next is the cost of energy storage media, accounting for 23.9%.

In a dual tank system, the utilization efficiency of the tank body is relatively low. When one tank body is in operation, the other is basically in a stopped state, resulting in a large proportion of tank body and related costs, and a relatively high unit energy storage cost.

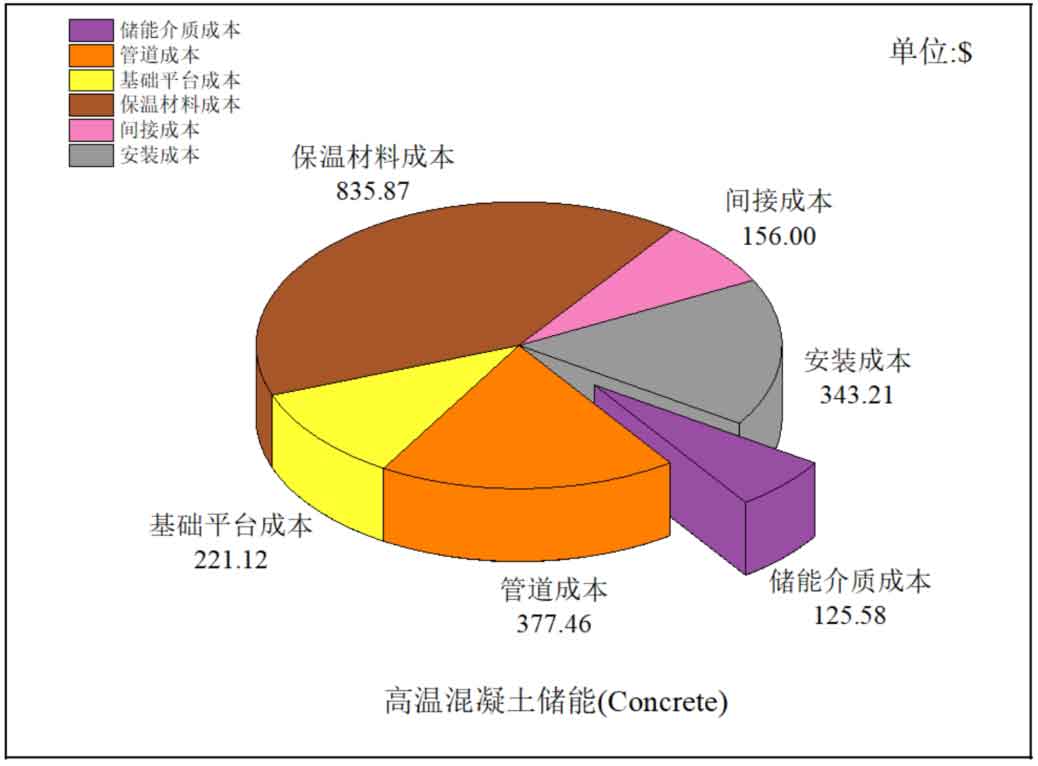

(2) Calculation of Energy Storage Cost for High Temperature Concrete Energy Storage System

Figure 2 shows the cost breakdown of each part of the concrete sensible heat energy storage system. The cost calculation of this system is based on a concrete model, with a total system cost of $2059.24 and a storage cost of $20.79 per kilowatt hour. From the perspective of cost proportions, insulation materials have the highest proportion, with a percentage of 40.6%. This is because the unit cost of insulation materials is much higher than that of other materials. Next is the cost of stainless steel pipes and fins, accounting for 18.3%. Due to its relatively low price, the proportion of concrete energy storage media in the total system cost is the smallest, only 6.1%. Because concrete energy storage systems use air as the heat transfer fluid, this cost is reduced compared to other systems.

(3) Calculation of energy storage cost for a single phase change packed bed energy storage system

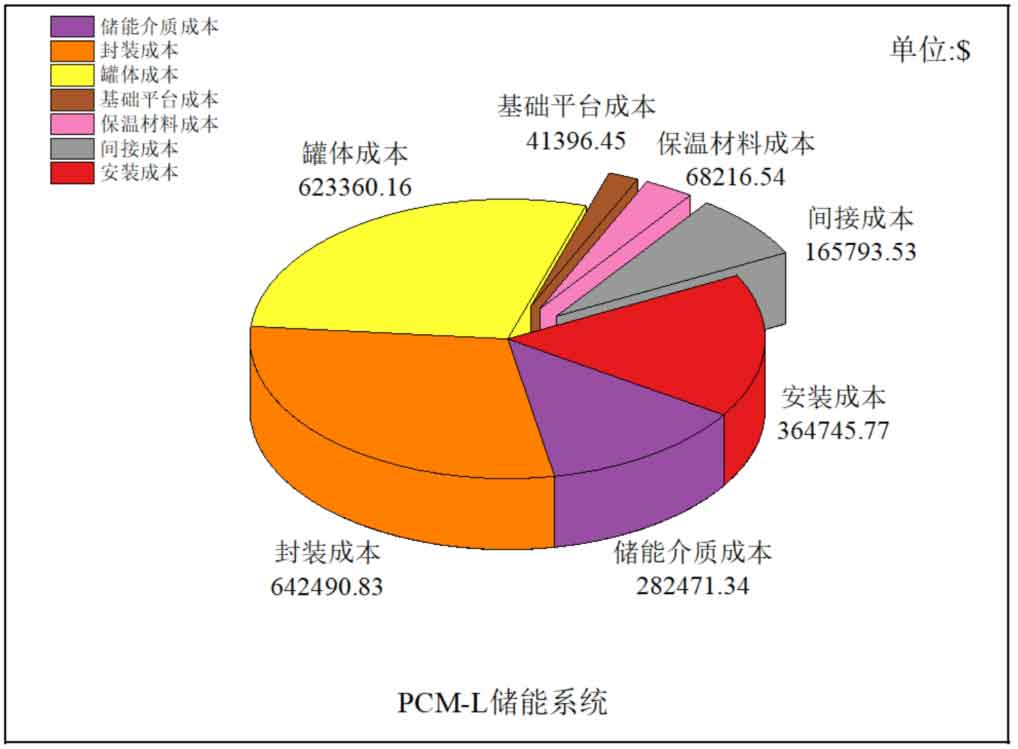

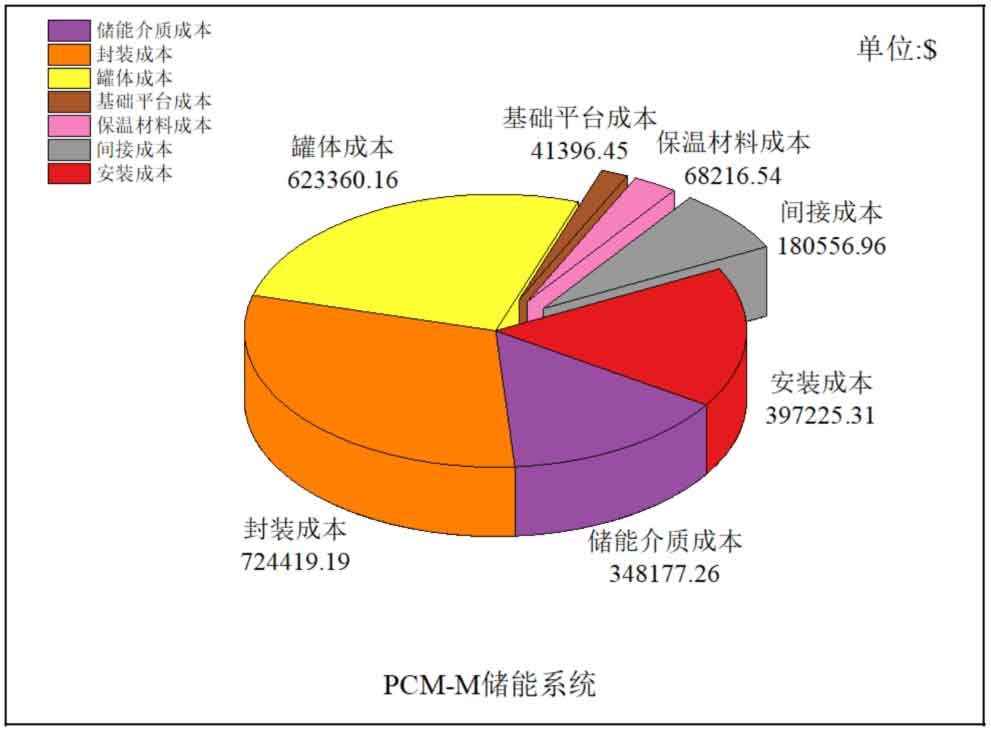

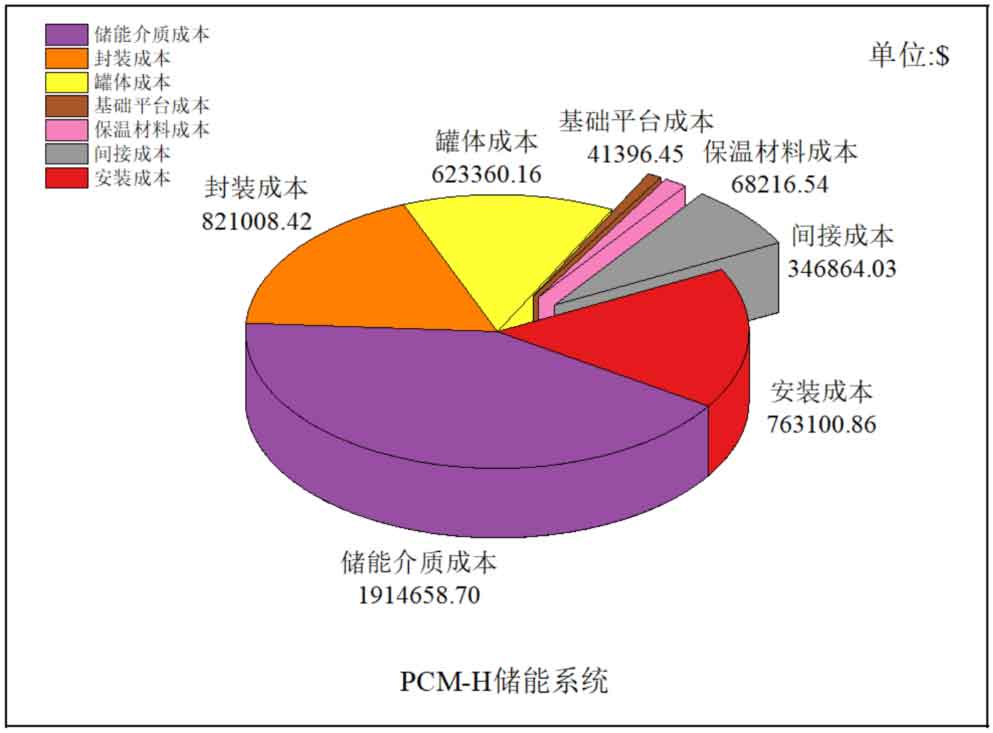

Figure 3 shows the cost breakdown of each part of a single phase change packed bed energy storage system. There are three situations here, mainly using phase change materials with low temperature, medium temperature, and high temperature as energy storage media. The cost composition of the three energy storage systems is basically the same, but due to different energy storage media, there are differences in the total cost and energy storage of the system, and the unit energy storage cost is also different. From the perspective of total cost, as the phase transition temperature increases, the total cost of energy storage systems increases. The total cost of the low-temperature phase change packed bed energy storage system (PCM-L) is the smallest, with a size of 2188474.63 $. The total cost of the high-temperature phase change packed bed energy storage system (PCM-H) is the largest, with a size of 4578605.16 $. The total cost of the medium temperature phase change packed bed energy storage system (PCM-M) is between the two, with a size of 2383351.88 $.

From the perspective of the cost composition of each energy storage system, the cost of energy storage media, packaging cost, and tank cost are important components. Except for high-temperature energy storage systems, the packaging cost of the other two energy storage systems accounts for the largest proportion. As the phase change temperature increases, the packaging cost of phase change materials increases. As the phase change temperature increases, the density of the phase change material increases. When the tank volume remains constant, the mass of the phase change material increases, resulting in an increase in packaging costs as the mass increases. From the proportion of packaging cost of phase change materials to total cost, the packaging costs in PCM-L, PCM-M, and PCM-H systems account for 29.4%, 30.4%, and 17.9%, respectively.

In the three energy storage systems of PCM-L, PCM-M, and PCM-H, the proportion of tank cost to total cost is 28.5%, 26.2%, and 13.6%, respectively. Because the tank body is made of stainless steel material, the cost of stainless steel is relatively high, resulting in a higher cost for the tank body. In addition, compared to the dual tank molten salt energy storage system, the design of the phase-change packed bed energy storage system should also consider the ratchet effect that exists in long-term use [150], and it is necessary to increase the thickness of the tank body. This will increase the amount of stainless steel material used, which will also lead to increased costs. The installation cost of energy storage systems is calculated based on 20% of the total material cost and indirect cost, so the installation cost is relatively high. Among the three systems, the installation cost accounts for about 16.7% of the total cost.

For energy storage media, its cost is related to the density, latent heat value, and other thermal properties of the material itself. The density of high-temperature phase change materials is generally high, and the unit mass cost is also relatively high. Due to the relatively high price of phase change materials in high-temperature phase change energy storage systems, the cost of energy storage media accounts for the largest proportion of the total cost, accounting for 41.8%. In PCM-L and PCM-M energy storage systems, the cost of energy storage media accounts for 12.9% and 14.6% of the total cost, respectively. The indirect cost of energy storage systems accounts for approximately 7.6% of the total cost.

From the perspective of unit energy storage cost, the unit energy storage costs of PCM-L, PCM-M, and PCM-H systems are 19.14 $/kWh, 19.32 $/kWh, and 20.83 $/kWh, respectively. As the phase transition temperature increases, the total cost of the energy storage system increases, and the energy storage capacity of the system also increases. The density, specific heat, and latent heat of high-temperature phase change materials are relatively large, thus storing more energy within the operating temperature range. From the perspective of unit energy density, the PCM-H system has the highest unit energy density of 459.01 kWh/m3, which is 48.0% and 43.9% higher than the PCM-L system and PCM-M system, respectively. This means that the PCM-L system and PCM-M system require larger tank volumes to store the same amount of heat.

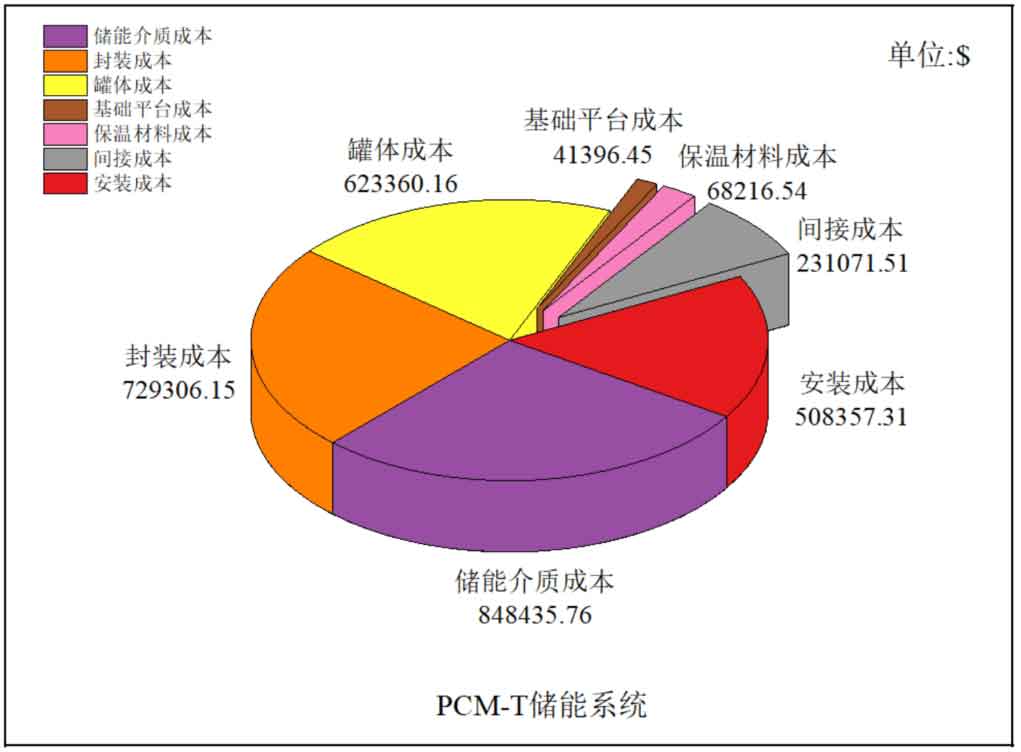

(4) Calculation of energy storage cost for a three-layer phase-change packed bed energy storage system (PCM-T)

Compared with a single phase change material energy storage system, a cascaded phase change energy storage system can more efficiently utilize the heat of the heat transfer fluid and improve the heat transfer rate of the system. At the same time, in order to achieve a relatively balanced level between system energy storage and unit energy storage cost, a three-layer phase change energy storage form is used. The cost composition of each part of the PCM-T energy storage system is shown in Figure 4. The total cost and unit energy storage cost of the PCM-T system are lower than those of the PCM-H system, but higher than those of the PCM-L and PCM-M systems. Compared to the PCM-H system, due to the reduction of high-temperature phase change materials, the proportion of energy storage medium cost is reduced, and the total cost is also reduced. The total cost of the PCM-T system is $3050143.89, and the unit energy storage cost is $20.00 per kWh. Like high-temperature phase change energy storage systems, the cost of energy storage media accounts for the largest proportion, at 27.8%. Next is the packaging cost of phase change materials, accounting for 23.9%, and the tank cost accounting for 20.4%.

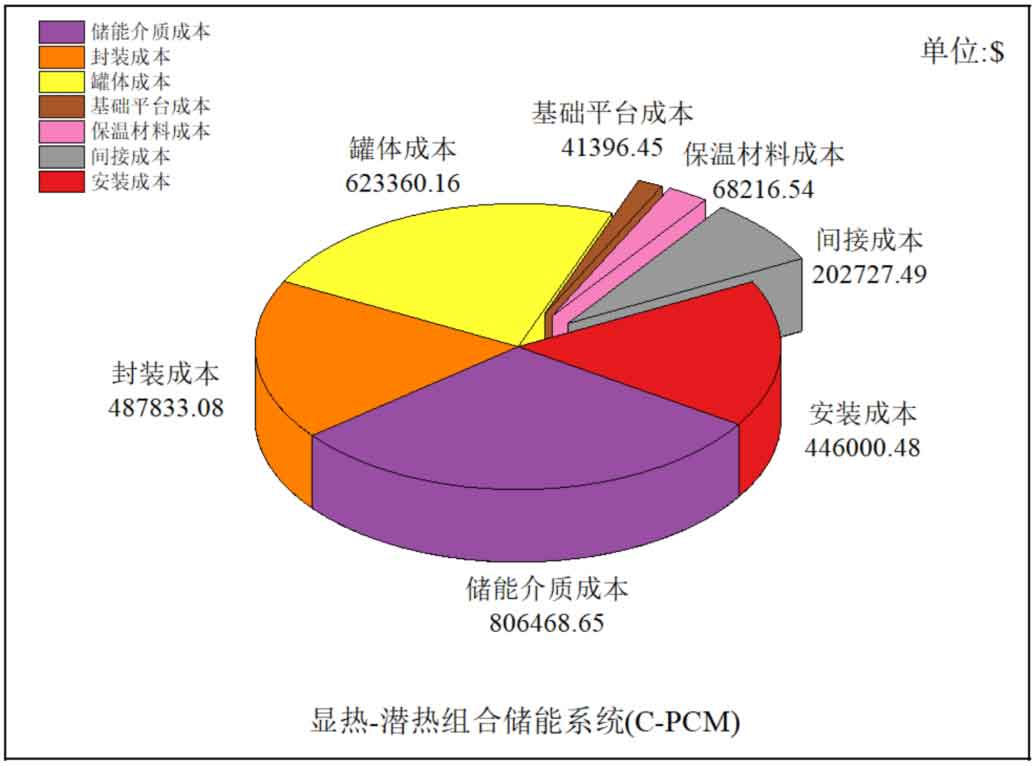

(5) Calculation of energy storage cost for a combined sensible and latent heat packed bed energy storage system (C-PCM)

From the cost calculation results of the phase change packed bed energy storage system, it can be seen that the cost of phase change materials and packaging costs account for a relatively large proportion. In order to reduce the cost of energy storage systems and increase energy storage rates, it is considered to use concrete instead of phase change materials in the middle of the tank body. Concrete has a lower price and a higher thermal conductivity than phase change materials, resulting in faster heat transfer. Figure 5 shows the cost results of the sensible latent heat combined packed bed energy storage system. From the graph, it can be seen that although the cost of related phase change materials has been reduced, the cost of energy storage media still accounts for the largest proportion, at 30.1%. Next is the cost of the tank, accounting for 23.3%. Compared to the PCM-T system, the packaging cost has decreased to 18.2%. From the perspective of unit energy storage cost, the unit energy storage cost of the C-PCM system is 19.17 $/kWh, which is 4.2% less than that of the PCM-T system. Due to the fact that concrete is a sensible thermal energy storage material, the energy density per unit volume is lower than that of phase change materials, resulting in a decrease in system energy storage. When both total cost and energy storage are reduced, the unit energy storage cost of the system is reduced.

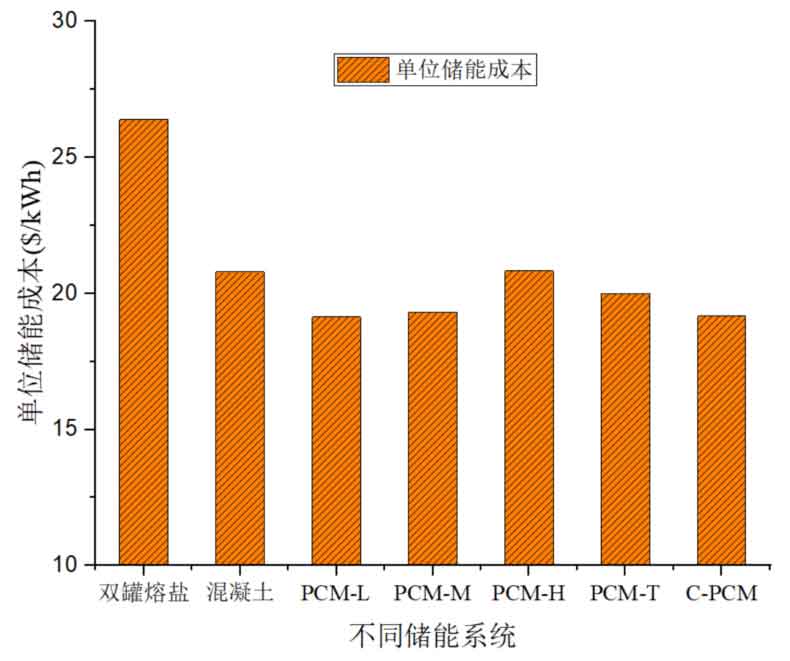

2. Comparison of Unit Energy Storage Costs for Different Energy Storage Systems

By calculating the cost of different energy storage systems mentioned above, the total cost and unit energy storage cost of each system can be obtained. Compare the unit energy storage costs of dual tank molten salt energy storage systems and different forms of packed bed energy storage systems under the same tank configuration and operating conditions. The dual tank molten salt energy storage system uses two tanks, and the cost associated with the tanks is double. The tank cost is generally higher, making the total system cost relatively high. In order to reduce the energy storage cost of the system, single tank energy storage is used instead of double tanks. At the same time, using encapsulated phase change materials to replace some molten salts can increase energy storage. Although the total system cost increases, the unit energy storage cost is reduced.

Figure 6 shows a comparison of unit energy storage costs for several different energy storage systems. Using high-temperature concrete to replace some phase change materials can reduce the total cost of the system compared to a three-layer phase change filled bed energy storage system. The unit energy storage cost of the sensible latent heat combined packed bed energy storage system (C-PCM) is relatively low, at $19.17/kWh, which is 27.4% lower than the unit energy storage cost of the dual tank molten salt energy storage system. This is mainly because the cost of the tank body in the dual tank molten salt energy storage system accounts for a relatively large proportion, and the amount of molten salt used is also relatively high. In the C-PCM system, using only one tank reduces the cost of the tank, while phase change materials and concrete partially replace molten salt, resulting in a decrease in the amount of molten salt used in the system. Although replacing some molten salt with phase change materials increases the cost of energy storage media, the energy storage of the system also increases. As a result, the unit energy storage cost of the C-PCM system is lower than that of the dual tank molten salt energy storage system. The total cost of the high-temperature phase change energy storage system (PCM-H) is the highest, mainly due to the high cost of high-temperature phase change materials, but its unit energy storage cost is still lower than that of the dual tank molten salt energy storage system.

From the graph, it can be seen that the unit energy storage cost of the dual tank molten salt energy storage system is the highest, followed by the high-temperature phase change energy storage system. When using phase change latent heat energy storage, the unit energy storage cost is reduced. Using a combination of sensible and latent heat to fill the bed energy storage system, high-temperature and low-temperature phase change materials are arranged at the top and bottom of the tank, respectively, to buffer the fluid outflow temperature. At the same time, the total cost and unit energy storage cost of the C-PCM energy storage system are relatively small, and the energy storage efficiency is also higher than that of low-temperature and medium temperature phase change energy storage systems. Therefore, it can be considered that the sensible latent heat combined energy storage system is a good alternative to the dual tank molten salt energy storage system.