As a key technology supporting the development of smart grids and energy transformation, energy storage has received widespread attention. Among them, battery energy storage represented by lithium-ion batteries has become one of the preferred storage carriers for large-scale energy storage. However, with the gradual increase in the scale of battery energy storage applications, many problems and risks in terms of quality and safety have been exposed. The battery energy storage system, as a complete electrical equipment product, is not yet mature, and there is uncertainty in the overall safety and quality status of energy storage power stations, resulting in low utilization rates of a large number of existing energy storage power stations. Due to the immaturity and continuous iterative development process of the entire equipment product, it is particularly important to conduct comprehensive performance evaluation around the core component of lithium-ion batteries for energy storage, in order to improve the application level of lithium-ion battery energy storage power stations at the current stage, guided by safe and high-quality applications. This article mainly reviews the latest progress of domestic standards related to energy storage lithium-ion batteries, provides a detailed analysis of the important content of the core standard for lithium-ion battery energy storage and its role in industry development, and introduces in detail the overall solution for the full-process testing and evaluation of lithium-ion battery energy storage.

1. Latest Progress of Standards Related to Energy Storage Lithium-ion Batteries

China began to compile standards related to power energy storage in 2013. At present, a series of national (industry) standards have been issued and implemented for the main equipment and systems of lithium-ion battery energy storage power stations, which specify the technical requirements and inspection requirements for quality and safety in detail and can basically meet the needs of quality control of energy storage equipment at this stage. These standards mainly include “Basic Terminology for Power Energy Storage” (DL/T 2528), “Lithium-ion Batteries for Power Energy Storage” (GB/T 36276), “Battery Management System for Power Energy Storage” (GB/T 34131), “Technical Specification for Power Conversion System of Electrochemical Energy Storage System” (GB/T 34120), “Testing Procedures for Power Conversion System” (GB/T 34133), etc. Among them, “Basic Terminology for Power Energy Storage” (DL/T 2528), as the terminology industry standard that currently best fits the actual application situation of domestic energy storage, clarifies the definitions of many key terms in actual applications, such as the rated power, rated energy, and safety performance of energy storage, which are the guaranteed values that must be met throughout the life cycle. This provides a basis for the update of relevant content in energy storage equipment and test standards. Based on the fact that the corresponding energy storage battery system is still in the process of supplementary and improvement as a whole product standard, the system-level product standard represented by the national standard “Technical Specification for Prefabricated Cabin Lithium-ion Battery Energy Storage System” is being compiled. The new progress of the current lithium-ion battery energy storage standards is shown in Table 1.

Table 1 Progress of Energy Storage Standards for Lithium Ion Batteries

| No. | Standard Name | Standard Type | Standard Number | Status |

|---|---|---|---|---|

| 1 | Basic Terminology for Power Energy Storage | Industry Standard | DL/T2528 – 2022 | Issued |

| 2 | Lithium-ion Batteries for Power Energy Storage | National Standard | GB/T 36276 | Revised and submitted for approval |

| 3 | Battery Management System for Power Energy Storage | National Standard | GB/T 34131 – 2023 | Issued |

| 4 | Technical Specification for Power Conversion System of Electrochemical Energy Storage System | National Standard | GB/T 34120 | Under Revision |

| 5 | Testing Procedures for Power Conversion System | National Standard | GB/T34133 | Under Revision |

| 6 | Technical Regulations for the Connection of Electrochemical Energy Storage Power Station to the Power Grid | National Standard | GB/T36547 | Under Revision |

| 7 | Testing Specifications for the Connection of Electrochemical Energy Storage Power Station to the Power Grid | National Standard | GB/T 36548 | Under Revision |

| 8 | Technical Specification for Prefabricated Cabin Lithium-ion Battery Energy Storage System | National Standard | In Preparation |

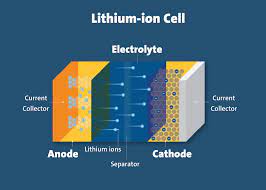

From the perspective of the structural hierarchy of battery energy storage, battery cells are connected in series and parallel to form battery modules, battery modules are connected in series and parallel to form battery clusters, battery clusters are connected in parallel to form battery energy storage systems, and battery energy storage systems are connected in parallel to form battery energy storage power stations. Each level plays a different role and function, and it is an organic whole that is indispensable. Strict inspection at each level to ensure that the working parameters and performance indicators of the battery comply with the correct logical transmission is the key to ensuring that the battery energy storage system meets the relevant standard requirements and fundamentally improving the overall quality and safety of the battery energy storage power station. At the present stage, the quality inspection of the energy storage battery system is mainly carried out around the core components of the system, such as battery cells, battery modules, battery clusters, power conversion systems, and battery management systems. According to relevant standards, the boundaries and operating parameters that can reflect the quality and safety of the battery system are determined from the source. After the completion of the system-level product standard, the effect of efficient and controllable safe application of the battery through system design and integration is confirmed from the perspective of the whole machine inspection of the system, realizing the closed-loop of the quality and safety inspection of the core equipment and system of energy storage.

2. Analysis of the Core Standard for Lithium-ion Battery Energy Storage

As the core component of the battery energy storage system, the performance level of the battery is the cornerstone of the overall quality and safety of the battery energy storage power station. The national standard “Lithium-ion Batteries for Power Energy Storage” (GB/T 36276 – 2018), issued in June 2018, has distinct characteristics of energy storage applications compared with other industry standards such as power batteries. It clarifies the technical requirements for the comprehensive performance of lithium-ion batteries from the perspective of the actual application needs of power energy storage and plays a key role in ensuring the quality and safety of energy storage applications. With the rapid development of the lithium-ion battery energy storage market and the rapid iteration of technical levels and application requirements, the standard began to be revised in early 2022, further proposing the technical requirements for energy storage batteries that match the actual operating conditions of power energy storage, which is of great significance for improving the standardization and normalization level of battery energy storage equipment before operation, improving the operational reliability of energy storage power stations, and reducing the safety risks of energy storage power stations.

2.1 Standard Content

The “Lithium-ion Batteries for Power Energy Storage” (GB/T 36276) decomposes the overall quality and safety requirements of power equipment in the power system to the core component of energy storage batteries, focusing on the key working parameters and the correct logical relationship of performance transmission from the levels of battery cells, battery modules to battery clusters, and puts forward clear requirements for each level of the battery.

In terms of electrical performance, it specifies the initial charge and discharge performance requirements of battery cells, battery modules, and battery clusters, the power characteristics, rate charge and discharge performance, energy retention and energy recovery capabilities of battery cells and battery modules, etc., to fundamentally guarantee the overall performance of the battery energy storage power station; in terms of environmental adaptability, it specifies the high-temperature adaptability and low-temperature adaptability requirements of battery cells and battery modules, and the initial charge and discharge performance requirements of battery cells at high altitudes, to ensure the adaptability of the battery under different environmental conditions; in terms of durability, it specifies the storage performance and cycle performance requirements of battery cells and battery modules, and for the first time proposes the cycle performance technical requirements and test methods related to the rated power, rated energy, and cycle times to ensure that the battery can meet the cycle performance indicators throughout the life cycle. In terms of safety performance, it specifies the requirements for the electrical safety performance, mechanical safety performance, environmental safety performance, thermal safety performance, and safety protection functions of lithium-ion batteries for power energy storage, to fundamentally guarantee the overall quality and safety of the battery energy storage power station. To verify the consistency between the key performance of the products actually used in the project and the corresponding type-tested products, and to ensure the realization of various functions and performance indicators of the battery energy storage system, the sampling inspection rules are specified.

2.2 Standard Function

This standard provides a unified standardized tool for the quality control of batteries in engineering applications, and solves several major problems and pain points faced by energy storage batteries as a new power system component in the early stage of application.

(1) It solves the problem of the disconnection between the battery specification labeling and its calibration test conditions and the actual application. This standard labels the technical specifications of the battery according to the energy (W/Wh) actually operated by the power system, changing the traditional labeling method of current/capacity (A/Ah), and unifies the requirements for the rules of battery coding, specifying that the lithium-ion batteries used for power energy storage need to indicate the nominal voltage, rated charge and discharge power, rated charge and discharge energy, and other most critical specification parameter information. At the same time, this standard calibrates the key electrical performance indicators such as energy, efficiency, and life based on the actual operating rated power conditions, and uses this as the basic prerequisite for the evaluation of safety performance, avoiding the disconnection between the technical standard requirements and their test and evaluation conditions and the actual application conditions.

(2) It solves the problem of unclear setting of key working parameters. This standard clarifies that the limit settings of the voltage, temperature, current, and other key working parameters during the actual operation of the battery should be consistent with the set values in the type test, and should be unique, to avoid the inconsistency between the actual supplied products and the products during testing in terms of operating conditions and performance. It ensures that the battery working parameters and performance are transmitted step by step in different levels of battery cells, battery modules, and battery clusters and comply with the correct logical relationship. The principles for setting battery operating parameters are shown in Table 2.

Table 2 Principles for setting battery operating parameters

| Battery Level | Type of Operating Parameter | Operating Parameter Requirements |

|---|---|---|

| Battery Cell | Consistent with the battery cell specification parameter table | |

| Voltage Limit | Charge Voltage First Alarm Value > Charge Voltage Second Alarm Value > Charge Voltage Third Alarm Value > Charge Cut-off Voltage | |

| Discharge Voltage First Alarm Value < Discharge Voltage Second Alarm Value < Discharge Voltage Third Alarm Value < Discharge Cut-off Voltage | ||

| Temperature Limit | High Temperature First Alarm Temperature > High Temperature Second Alarm Temperature > High Temperature Third Alarm Temperature > High Temperature Cut-off Temperature | |

| Low Temperature First Alarm Temperature < Low Temperature Second Alarm Temperature < Low Temperature Third Alarm Temperature < Low Temperature Cut-off Temperature | ||

| Battery Module | Consistent with the battery module specification parameter table | |

| Rated Charge and Discharge Power | ≤ Rated Charge and Discharge Power in the Battery Cell Type Test Report × Number of Battery Cells in the Battery Module | |

| Rated Charge and Discharge Energy | ≤ Rated Charge and Discharge Energy in the Battery Cell Type Test Report × Number of Battery Cells in the Battery Module | |

| Voltage Limit | Charge Voltage Limit < Charge Voltage Limit of the Battery Cell × Number of Battery Cells Connected in Series in the Battery Module | |

| Discharge Voltage Limit > Discharge Voltage Limit of the Battery Cell × Number of Battery Cells Connected in Series in the Battery Module | ||

| Charge Voltage First Alarm Value > Charge Voltage Second Alarm Value > Charge Voltage Third Alarm Value > Charge Cut-off Voltage | ||

| Discharge Voltage First Alarm Value < Discharge Voltage Second Alarm Value < Discharge Voltage Third Alarm Value < Discharge Cut-off Voltage | ||

| Battery Cell Operating Parameter | Consistent with the battery cell specification parameter table | |

| Battery Cluster | Consistent with the battery cluster specification parameter table | |

| Rated Charge and Discharge Power | ≤ Rated Charge and Discharge Power in the Battery Module Type Test Report × Number of Battery Modules in the Battery Cluster | |

| Rated Charge and Discharge Energy | ≤ Rated Charge and Discharge Energy in the Battery Module Type Test Report × Number of Battery Modules in the Battery Cluster | |

| Voltage Limit | Charge Voltage Limit < Charge Voltage Limit of the Battery Module × Number of Battery Modules Connected in Series in the Battery | |

| Discharge Voltage Limit > Discharge Voltage Limit of the Battery Module × Number of Battery Modules Connected in Series in the Battery | ||

| Charge Voltage First Alarm Value > Charge Voltage Second Alarm Value > Charge Voltage Third Alarm Value > Charge Cut-off Voltage | ||

| Discharge Voltage First Alarm Value < Discharge Voltage Second Alarm Value < Discharge Voltage Third Alarm Value < Discharge Cut-off Voltage | ||

| Current Limit | Charge Current First Alarm Value > Charge Current Second Alarm Value > Charge Current Third Alarm Value > Charge Current Cut-off Value | |

| Discharge Current First Alarm Value > Discharge Current Second Alarm Value > Discharge Current Third Alarm Value > Discharge Current Cut-off Value | ||

| Battery Module Voltage Range Limit | Battery Cluster Charge Battery Module Voltage Range First Alarm Value > Battery Cluster Charge Battery Module Voltage Range Second Alarm Value > Battery Cluster Charge Battery Module Voltage Range Third Alarm Value > Battery Cluster Charge Battery Module Voltage Range Cut-off Value | |

| Battery Cluster Discharge Battery Module Voltage Range First Alarm Value > Battery Cluster Discharge Battery Module Voltage Range Second Alarm Value > Battery Cluster Discharge Battery Module Voltage Range Third Alarm Value > Battery Cluster Discharge Battery Module Voltage Range Cut-off Value | ||

| Battery Cluster Charge Battery Cell Voltage Range First Alarm Value > Battery Cluster Charge Battery Cell Voltage Range Second Alarm Value > Battery Cluster Charge Battery Cell Voltage Range Third Alarm Value > Battery Cluster Charge Battery Cell Voltage Range Cut-off Value | ||

| Battery Cell Temperature Range Limit | Battery Cluster Charge Battery Cell Temperature Range First Alarm Value > Battery Cluster Charge Battery Cell Temperature Range Second Alarm Value > Battery Cluster Charge Battery Cell Temperature Range Third Alarm Value > Battery Cluster Charge Battery Cell Temperature Range Cut-off Value | |

| Battery Cluster Discharge Battery Cell Temperature Range First Alarm Value > Battery Cluster Discharge Battery Cell Temperature Range Second Alarm Value > Battery Cluster Discharge Battery Cell Temperature Range Third Alarm Value > Battery Cluster Discharge Battery Cell Temperature Range Cut-off Value | ||

| Insulation Resistance Limit | Battery Cluster First Alarm Insulation Resistance < Battery Third Alarm Insulation Resistance | |

| Battery Module Operating Parameter | Consistent with the battery module specification parameter table | |

| Battery Cell Operating Parameter | Consistent with the battery cell specification parameter table |

(3) It solves the problem of unified evaluation of cycle life. Evaluated under the most stringent full charge and discharge conditions, for the first time, the rated power, rated energy, and nominal cycle times are correlated, and the life expectancy under shallow charge and shallow discharge conditions can be downward compatible. The cycle performance requirements at the battery cell and battery module levels are used as the unified evaluation standard for battery life, meeting the expectations for system life, and to a certain extent, constraining the current problem of blindly claiming the number of cycles. At the same time, the requirement for the thermal runaway performance of the battery cell after cycling is added, and the enhancement of safety performance, which is the guaranteed value that must be met throughout the life cycle, guides battery manufacturers to continuously progress in battery safety design and production process control.

(4) It clarifies the sampling inspection rules for energy storage batteries, providing a standard basis for carrying out the arrival sampling inspection of energy storage batteries, which is of great significance for improving the reliability of energy storage power stations and reducing the safety risks of energy storage power stations.

3.Overall Solution for the Full-process Testing and Evaluation of Lithium-ion Battery Energy Storage

The safety and quality of energy storage power stations are inseparable. The current situation of widespread concerns about the safety hazards and quality problems of battery energy storage power stations is mainly reflected in the fact that the key technical indicators such as the actual available energy, actual service life, system energy efficiency, and continuous operation safety and reliability cannot reach the promised values. Ultimately, it is because the quality status of the main equipment and systems of the energy storage power station cannot be confirmed, and the performance indicators are ambiguous. If the design, manufacturing technology level, initial quality, or abnormal quality attenuation within the warranty period of the core equipment such as energy storage batteries do not meet the safety technical requirements of the standard, the safety risks and hidden dangers during the operation of the electrochemical energy storage power station will be extremely high. Therefore, the inspection of the quality and safety of lithium-ion battery energy storage equipment should run through all links of the energy storage application and cover different levels of equipment or system forms according to the corresponding standards, and be interconnected to form a closed loop, so as to fundamentally improve the operational reliability of the energy storage power station and reduce the safety risks of the energy storage power station.

Starting from the actual needs of power energy storage applications, combined with the profound research and accumulation of battery energy storage characteristic evaluation and detection technology, China Electric Power Research Institute has proposed an overall solution for the full-process testing and evaluation of battery energy storage, covering type testing, level evaluation, arrival sampling, grid connection testing, and operation assessment testing. Specifically, it is divided into three major processes: before, during, and after. Before includes type testing and level evaluation, which are used to test whether the equipment manufacturing enterprise has the ability and technical level to mass-produce products that meet the standard technical requirements; during includes arrival sampling and grid connection testing, which are used to test the consistency between the actual supplied batch of products and the type-tested products in terms of key performance, as well as the consistency between the actual operating parameters of the battery and the detection parameters; after includes operation assessment, which is used to test the attenuation of the charge and discharge energy and efficiency of the battery energy storage system during operation. Through this solution, closed-loop management of the entire chain and all links of the grid-side, power supply-side, and user-side energy storage equipment involved in the operation of the power grid can be achieved, guiding the energy storage industry towards a standardized, healthy, and sustainable development path of strictly implementing energy storage standards.

3.1 Type Testing

Type testing is to test the ability of the manufacturing enterprise to research, develop, design, and manufacture products that meet the standard technical requirements. Passing the type testing is the basic prerequisite and bottom-line requirement for the product to enter the market. The objects of type testing mainly include battery cells, battery modules, battery clusters, battery management systems, and power conversion systems. Type testing can provide users with comprehensive and accurate data support, and provide the only credible standardized technical information for battery technology selection and equipment procurement evaluation, solving the pain points of insufficient effective information and information asymmetry in the application process of energy storage batteries. The standard basis for the type testing of energy storage batteries is “Lithium-ion Batteries for Power Energy Storage” (GB/T 36276), the standard basis for the type testing of battery management systems is “Battery Management System for Power Energy Storage System.

3.2 Level Evaluation

Product performance level evaluation is based on the passing of the national standard type testing, combined with the form of product sampling inspection on the manufacturer’s production line. Through the research and analysis of a large number of type testing data of energy storage batteries, the key performance and technical indicators of energy storage batteries are identified, and the quality and safety technical level of battery products is displayed and identified in all aspects in the form of performance level division combined with detailed performance data. It directly reflects the distinction of the technical level of energy storage battery products in different dimensions. The objects of level evaluation mainly include battery cells, battery modules, battery clusters, battery management systems, power conversion systems, and battery energy storage systems. Product performance level evaluation provides a more convenient technical tool to fundamentally solve the pain points of insufficient effective information, information asymmetry, and technical comparison and screening difficulties during the application of energy storage batteries, guides the technological upgrading and transformation of energy storage batteries, and promotes the healthy and sustainable development of the battery energy storage industry.

3.3 Arrival Sampling

Arrival sampling is to prevent the products of the actual supplied batch with poor quality control from entering the energy storage engineering site, and it is the most critical link in the safety management of electrochemical energy storage power stations. The objects of sampling inspection mainly target the core component products of the energy storage battery and its management system that can directly affect the safe operation of the electrochemical energy storage power station, including battery cells, battery modules, and battery management systems.

Due to the particularity and complexity of energy storage batteries, it is necessary to ensure that the product quality of the actual supplied batch meets the requirements through actual testing, and to ensure the consistency of the physical state, electrical performance, safety performance, working parameters, and functions of the core component products such as battery cells, battery modules, and battery management systems that directly affect the safe operation of the electrochemical energy storage power station with their corresponding type-tested products. During the promised warranty period, the energy storage batteries should meet all the safety technical requirements of the standard. Since full inspection is not possible, sampling inspection is not omnipotent, but it can achieve the purpose of feeding the standard requirements back to the product’s safety design and production quality control, and greatly reducing the probability of safety risks. The sampling inspection items and inspection rules for energy storage batteries and their management systems have been clarified in the revised “Lithium-ion Batteries for Power Energy Storage” (GB/T 36276) and the issued “Battery Management System for Power Energy Storage” (GB/T 34131 – 2023).

3.4 Grid Connection Testing

According to the standards “Technical Regulations for the Connection of Electrochemical Energy Storage System to the Power Grid” (GB/T 36547) and “Testing Specifications for the Connection of Electrochemical Energy Storage System to the Power Grid” (GB/T 36548), the availability and performance reliability of the overall function of the energy storage power station need to be tested. The consistency check between the actual operating parameters of the battery in the energy storage system and the corresponding working parameters recorded in the type test report should be used as a precondition for grid connection testing to confirm the quality and safety status of the energy storage batteries at each level. On this basis, the promised indicators such as energy, efficiency, life, and safety of the energy storage power station, as well as whether the battery working parameters comply with the performance transmission from the component levels of battery cells, battery modules, and battery clusters to the energy storage system/energy storage power station, should be focused on. The overall performance of the energy storage system/energy storage power station, such as grid adaptability, power control, high and low voltage ride-through, power quality, protection function, charge and discharge response time, charge and discharge regulation time, charge and discharge conversion time, and the overall energy and efficiency of the entire station, should be tested to determine whether they can reach the standard technical requirement values and promised values according to the standard methods and the agreed working parameters of the battery and other equipment.

3.5 Operation Assessment Testing

The premise of the operation assessment testing of the battery energy storage power station is to check the consistency between the actual operating parameters of the battery during the system operation and the type test parameters. On this basis, it is necessary to check whether the key indicators such as the charge and discharge energy attenuation rate and energy efficiency of the energy storage power station meet the relevant agreements. This is a key constraint means for the supplier to actively ensure the quality and safety of the battery during the warranty period, and directly affects the integrated design and investment of the energy storage system.

4. Conclusion

This article first reviews the latest progress of standards related to energy storage lithium-ion batteries, and introduces the impact of each level of the battery energy storage system on the overall quality and safety of the battery energy storage power station. Then, for the core standard of lithium-ion battery energy storage, from the aspects of standard content and standard function, it introduces in detail the characteristics, key content, and the role of the “Lithium-ion Batteries for Power Energy Storage” (GB/T 36276) in the development of the industry and the problems it solves. Finally, it proposes an overall solution for the full-process testing and evaluation of battery energy storage, and introduces in detail the role of each link of the solution from the five aspects of type testing, level evaluation, arrival sampling, grid connection testing, and operation assessment testing. Through this solution, closed-loop management of the entire chain and all links of the grid-side, power supply-side, and user-side energy storage equipment involved in the operation of the power grid can be achieved, guiding the energy storage industry towards a standardized, healthy, and sustainable development path of strictly implementing energy storage standards.

With the expansion of the scale of battery energy storage power stations, the increase in the energy and voltage levels of the energy storage system, and the diversification of application scenarios of the energy storage system, these changes place higher requirements on the technical level and safety of the energy storage equipment. At the present stage, the standards for energy storage lithium-ion batteries mainly focus on the evaluation of the safety and quality status of the energy storage equipment before operation. There is still a lack of good solutions for the life prediction of the energy storage battery system after the energy storage power station is put into operation, and the evaluation technology for the overall safety and reliability of the energy storage battery system is still missing, which is a hot and difficult issue in the industry and also the direction for the development of the comprehensive performance evaluation of energy storage lithium-ion batteries in the future.