Introduction

Photovoltaic panels are the cornerstone of solar energy systems, converting sunlight into electricity to provide a sustainable energy source. Among the various types of photovoltaic panels, monocrystalline and polycrystalline panels are the most widely used in residential and commercial installations. This article provides a comprehensive comparative analysis of these two types of solar panels, examining their efficiency, cost, durability, and applications.

Monocrystalline Photovoltaic Panels

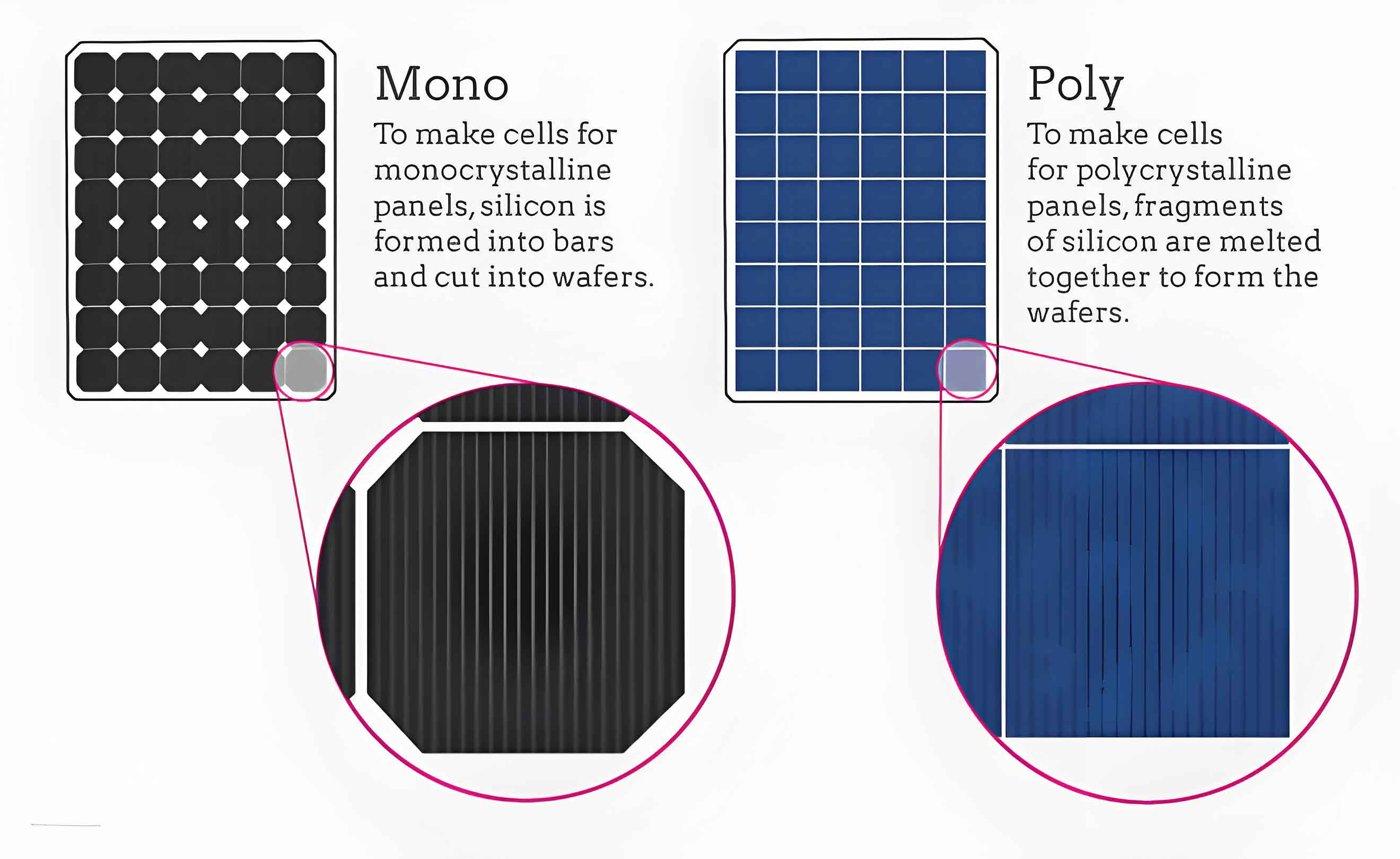

Monocrystalline photovoltaic panels are made from single-crystal silicon, which gives them their name and distinct appearance. The manufacturing process involves slicing wafers from a single, continuous crystal structure, resulting in a high-purity silicon cell.

Key Characteristics:

- High Efficiency: Monocrystalline panels are known for their high efficiency, typically ranging from 18% to 24%.

- Longevity: They offer superior longevity and performance over time, often with warranties of 25 years or more.

- Appearance: These panels have a uniform dark appearance, often black or dark blue.

Table 1: Advantages and Disadvantages of Monocrystalline Photovoltaic Panels

| Advantages | Disadvantages |

|---|---|

| High efficiency | Higher cost |

| Superior performance in low-light conditions | Complex manufacturing process |

| Long lifespan and warranties | Requires more space for installation |

| Aesthetic appeal | Higher energy payback time |

Polycrystalline Photovoltaic Panels

Polycrystalline photovoltaic panels are made from silicon crystals that are melted together. The manufacturing process is simpler and less expensive than that of monocrystalline panels, resulting in lower production costs.

Key Characteristics:

- Moderate Efficiency: Polycrystalline panels typically have efficiencies ranging from 15% to 18%.

- Cost-Effective: They are generally less expensive than monocrystalline panels due to the simpler manufacturing process.

- Appearance: These panels have a bluish hue with a less uniform appearance compared to monocrystalline panels.

Table 2: Advantages and Disadvantages of Polycrystalline Photovoltaic Panels

| Advantages | Disadvantages |

|---|---|

| Lower cost | Lower efficiency |

| Simpler manufacturing process | Slightly shorter lifespan |

| Good performance in high temperatures | Less aesthetic appeal |

| Less waste in production | Requires more space for the same output |

Comparative Analysis

To understand the strengths and weaknesses of each panel type, it is essential to compare their performance across several key metrics: efficiency, cost, durability, and applications.

1. Efficiency

Monocrystalline panels are more efficient than polycrystalline panels due to their high-purity silicon composition. They can convert a higher percentage of sunlight into electricity, making them more suitable for installations where space is limited.

List: Efficiency Comparison

- Monocrystalline: 18% to 24%

- Polycrystalline: 15% to 18%

2. Cost

Polycrystalline panels are generally less expensive than monocrystalline panels. This cost difference makes polycrystalline panels a popular choice for large-scale installations where budget constraints are significant.

List: Cost Factors

- Material costs

- Manufacturing complexity

- Installation expenses

3. Durability and Lifespan

Both monocrystalline and polycrystalline panels are durable and can last for 25 years or more. However, monocrystalline panels tend to have slightly better longevity and performance warranties.

Table 3: Durability Comparison

| Feature | Monocrystalline | Polycrystalline |

|---|---|---|

| Lifespan | 25-30 years | 20-25 years |

| Performance Warranty | 25+ years | 20-25 years |

| Resistance to Heat | Higher | Moderate |

| Degradation Rate | Lower | Slightly higher |

4. Applications

Both types of panels are used in a variety of applications, from residential rooftops to large solar farms. The choice between the two often depends on specific project requirements such as space availability, budget, and aesthetic preferences.

List: Typical Applications

- Monocrystalline: Residential rooftops, commercial buildings, areas with space constraints.

- Polycrystalline: Large solar farms, industrial installations, budget-conscious projects.

Future Trends and Developments

The solar industry is continually evolving, with advancements in both monocrystalline and polycrystalline technologies aiming to improve efficiency, reduce costs, and enhance durability. Emerging trends include the development of bifacial panels, which can capture sunlight on both sides, and the integration of new materials like perovskite to boost performance.

Future Trends:

- Bifacial Panels: These panels offer higher energy yield by capturing reflected sunlight on the rear side.

- Perovskite Integration: Combining traditional silicon with perovskite materials can significantly enhance efficiency.

- Smart Inverters: Advanced inverters that optimize energy management and storage.

Conclusion

Monocrystalline and polycrystalline photovoltaic panels each have their unique strengths and weaknesses, making them suitable for different applications and budgets. Monocrystalline panels offer higher efficiency and better performance in limited spaces, while polycrystalline panels provide a cost-effective solution for large-scale installations. As technological advancements continue to push the boundaries of solar energy, both types of panels will play crucial roles in the transition to sustainable energy solutions.

By understanding the comparative advantages of monocrystalline and polycrystalline panels, consumers and businesses can make informed decisions that best meet their energy needs and environmental goals. The ongoing innovation in solar technology promises to further enhance the efficiency, affordability, and accessibility of solar power, contributing to a cleaner and more sustainable future.