Hainan is an area with high temperature, humidity, and salt, and grains are prone to aging during storage. Usually, rice is stored in the area for 2 years, and all quality indicators reach the level of “mild unsuitable for storage”. Numerous studies have shown that low-temperature grain storage can effectively delay the aging of rice and extend its storage period. However, the equipment used for low-temperature grain storage, such as grain coolers and air conditioning units, consumes a lot of electricity and has high storage costs, which greatly limits the promotion and application of low-temperature grain storage in the Hainan region.

In recent years, with the rapid development of solar photovoltaic power generation technology and strong advocacy and support from government departments, rooftop photovoltaic grid connected power generation systems have been widely used to provide daily lighting, air conditioning, and other services for residential buildings. The location of the granary is generally relatively open, with no shading on the roof and a large area, making it a powerful place to use solar photovoltaic power generation. Therefore, some experts and scholars have also conducted research on using solar photovoltaic power generation to provide power for grain cooling machines, air conditioning units, etc. to achieve low-temperature grain storage. Zhang Minping installed a 1600m2 photovoltaic power plant with a total installed power of 155kW on the top of a grain depot in Shanghai, achieving a summer power generation of 47.4kW · h and a winter power generation of 42.7kW · h. Huang Zhijia and others established a photovoltaic rooftop power generation system with a total DC power of 162kW in the Anhui National Grain Reserve, with an annual power generation capacity of 166.3MW · h. Huang Zhijun and others have achieved an annual solar photovoltaic power generation of 40000 kW · h by laying 556.2 m ^ 2 of solar photovoltaic ceramic tiles on the roof of grain warehouses.

Hainan is located on the northern edge of the tropics, with an annual light intensity of 1750-2650 hours and a light intensity of 50-60%. It has sufficient light and temperature, and has a high utilization rate of solar energy. However, the research on utilizing solar photovoltaic power generation technology to implement low-temperature grain storage in the Hainan region is still blank. Therefore, this article takes a certain warehouse in Hainan region as an example to design and install a rooftop photovoltaic power generation system for grain storage, and analyzes its application effect in low-temperature grain storage, in order to provide reference for the promotion and application of solar photovoltaic power generation technology in low-temperature grain storage in Hainan region.

1. Basic conditions of the reservoir area and design requirements for photovoltaic power generation system

1.1 Basic conditions of the reservoir area

The warehouse is a bungalow warehouse with a width of 9m and a length of 42m. The grain loading line is 6m high and has a flat roof without insulation measures. The roof area is 378m2. During the experiment, the warehouse was divided into two compartments, with one compartment measuring 9m × 30m, the other warehouse is 9m × 12m. Select 9m × The 30m warehouse is a testing warehouse, with solar photovoltaic power generation modules installed on its roof. 9m × A 12m warehouse will not be processed.

There are no large buildings around the warehouse, and there is no shading on the roof. According to the website of NASA in the United States, the peak sunshine hours in the reservoir area are 4.44 hours, indicating a huge potential for solar photovoltaic power generation.

1.2 Design requirements

According to the characteristics of high temperature, average annual temperature, and frequent typhoons in Hainan, this photovoltaic power generation system should meet the following requirements: firstly, photovoltaic power generation can maintain a relatively constant level throughout the year and provide stable power supply for air conditioning units throughout the year; Secondly, when installing photovoltaic modules, full consideration should be given to the impact of typhoons on the modules to prevent them from being blown down by typhoons.

2. Design of photovoltaic power generation system

2.1 Scale and operation mode of photovoltaic power generation system

This photovoltaic power generation system is installed on the roof of the experimental warehouse, with a total installation area of battery modules less than 270m ^ 2, and a total designed installed capacity of around 30kWp. The system has a small installed capacity and is mainly used to supply power to air conditioning units. In addition, the grid connection procedures are relatively complicated, so the system adopts an off grid photovoltaic power generation system.

2.2 Selection of solar cell components

At present, the commonly used types of batteries in China include monocrystalline silicon batteries, polycrystalline silicon batteries, and amorphous silicon batteries. Single crystal silicon batteries have stable performance and a photoelectric conversion rate of around 15%, but their prices are slightly higher, making them suitable for areas with more rain and relatively less sunlight. The photoelectric conversion rate of polycrystalline silicon batteries is about 12%, slightly lower than that of monocrystalline silicon batteries. However, their manufacturing materials are simple, production costs are low, and they are more suitable for areas with abundant solar energy. The manufacturing method of amorphous silicon solar cells is completely different from the above two methods. The silicon material consumption is very small, and the cells can be made very thin, with low requirements for solar lighting conditions, but their photoelectric conversion rate is only about 10%. This system uses the YL135P-17b polycrystalline silicon battery module from Yingli Company. The parameters of the battery module are shown in Table 1.

| Component model | Peak power/Pmax | Power tolerance/ Δ Pmax | Peak power voltage/Vmpp | Peak power current/Impp | Open circuit voltage/Vcc | Short circuit current/Isc | Size/mm |

| yge YL135P-17b | 135 | +/-5 | 17.6 | 7.67 | 22.3 | 8.2 | 1470X680 |

2.3 Preliminary selection of solar off grid inverters

When selecting an off grid inverter, full consideration should be given to its reliability, efficiency, and the function of protecting the battery from over discharge. Considering the high summer temperatures and frequent typhoons in Hainan, the off grid inverters used in this area should have strong heat dissipation and resistance to adverse environments. Small inverters have high power generation efficiency, flexible system configuration, strong heat dissipation ability, and convenient fault maintenance. After detailed investigation and comparison from multiple parties, the Hefei Sunshine brand off grid inverter SN1105KSD1 was initially selected for this system, as shown in Table 2.

| Project | Technical parameter name | Specific parameters |

| DC input | Input rated voltage/V | DC110 |

| DC input | Input rated current/A | 51 |

| DC input | Allowable input voltage range/V | 99~150 |

| AC output | Rated capacity/kVA | 5 |

| AC output | Rated output power/kW | 4 |

| AC output | Output rated voltage and frequency | AC220V, 50Hz |

| AC output | Output rated current/A | 22.7 |

| AC output | Power factor | 0.8 |

| AC output | Protection level | IP20 |

2.4 Determination of solar cell module matrix

The off grid inverter allows an input voltage range of 99~150V, and the peak power voltage of the battery module is 17.6V. Therefore, the maximum number of modules in series is 8. The open circuit voltage of the battery module is 22.3V. When the number of series components is 7, the maximum voltage of the series components has reached 156.1V, exceeding the maximum allowable input voltage of 150V for the off grid inverter. Therefore, for better protection of the equipment, 6 series components are selected. At this time, the input voltage of the off grid inverter is 105.6V, and the maximum input voltage is 133.8V.

The rated input current of the off grid inverter is 51A, and the peak power current of the battery module is 7.67A. Therefore, the maximum number of modules in parallel is 6. The open circuit current of the battery module is 8.2A, and after parallel connection of the modules, the maximum input current of the off grid inverter is 49.2A < 51A. Therefore, it is feasible to connect six battery modules in parallel.

Based on the above analysis, the number of components in the solar cell array in series is 6, and the parallel circuit is 6 groups. The area of a square matrix is: 36 × 1.47 × 0.68=35.98m2, the total number of squares in this system is: roof area × 0.85/35.98=6 (the area occupied by the line and maintenance is 15% of the roof area). The total number of solar modules is 216, and the total DC output power is 29160W.

2.5 Determination of Azimuth and Tilt Angles of Solar Cell Module Arrays

The azimuth angle of the solar cell module array is the angle between the vertical plane of the array and the south direction (set as a negative angle towards the east and a positive angle towards the west). In general, when the square array faces due south (i.e. the angle between the vertical plane of the square array and due south is 0 °), the solar cell’s power generation is the maximum. Ge Qiang et al. found that the power generation of the battery panel at the 0 ° azimuth angle increased by 12.63% compared to the 90 ° azimuth angle. The tilt angle is the angle between the plane of the solar cell array and the horizontal ground. The optimal tilt angle is the maximum tilt angle during the year when the solar cell has the highest annual power generation. It is generally related to the local latitude, and the higher the latitude, the larger the corresponding tilt angle. Due to the relatively low latitude and abundant sunlight in the Hainan region, but occasional typhoons, combined with the above factors, the stability of the solar cell components in this system is mainly considered, so it is decided to adopt a flat layout.

2.6 Off grid photovoltaic electrical design

Each solar cell array uses a DC lightning protection combiner box to combine six small currents in parallel in the array into one large current. There are a total of 6 DC lightning protection combiner boxes in 6 square arrays. The output end of each combiner box is connected to the input end of an off grid inverter, which facilitates the off grid inverter to convert the connected high-voltage DC into 220V AC. 6 DC lightning protection combiner boxes, a total of 6 off grid inverters. All six off grid inverters are connected to one AC distribution box, which serves as a centralized interface for providing electrical energy to the load.

2.7 Design of monitoring management system, security measures, etc

This system adopts RS485 communication mode to send the collected parameters such as inverter working parameters and environmental meteorological parameters from the power generation system to the monitoring host. Automatic closed-loop control operation can be achieved through configuration logic, as well as manual control. In terms of security measures, the system is equipped with a series of functions such as automatic detection, automatic alarm, and automatic control. At the same time, the roof of the warehouse, distribution boxes, inverters, etc. are all equipped with lightning protection devices, so the equipment has good protection.

3. Application Effect of Off grid Photovoltaic Power Generation System

3.1 System power generation

The total installed capacity of this system is 29160W. After installation, the system has been running normally for 1 year. During this period, under clear weather, the system generated an average daily DC power of 116kW · h. During the power generation process of this system, due to power losses such as off grid inverters, batteries, and system losses, the average system conversion efficiency when the system is converted to 220V and 50Hz AC power for air conditioning units is 0.65, which means that the daily solar photovoltaic system can provide 75.4kW · h of 220V and 50Hz AC power for air conditioning units.

3.2 Grain temperature changes under solar photovoltaic power supply conditions

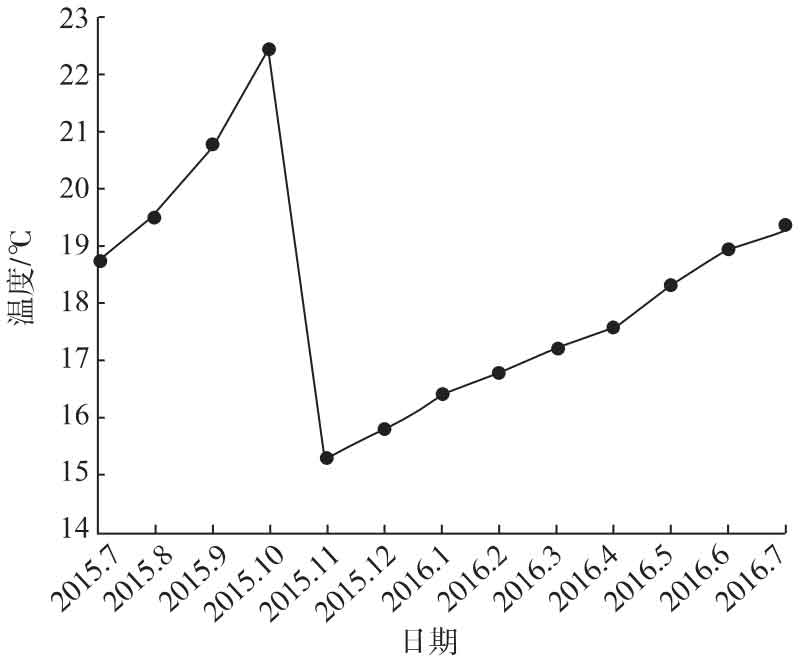

Based on the above situation, two 2-horsepower air conditioners (with a total power of 2940W) were installed in this experimental warehouse, which were turned on 24 hours a day to maintain the rice in the warehouse at a lower temperature. The daily power consumption of the air conditioning unit was 70560W · h < 75.4kW · h. Therefore, this solar photovoltaic system can maintain two 2-horsepower air conditioners to supply power to the grain depot 24 hours a day. Under the temperature control conditions of two 2-horsepower air conditioners, the average grain temperature change in the warehouse from July 2015 to July 2016 is shown in Figure. Due to the high temperature in Hainan region from June to October each year, even under the temperature control of air conditioning units, the average temperature of grain piles continues to rise. By mid October, the average temperature of grain piles is close to 23 ℃. At this point, one grain cooler is used to cool the grain pile. The grain cooling electrical and mechanical energy is provided by the external network, with a power of 64.3kW. After working for 63 hours, the average temperature of the grain pile drops to around 16 ℃. This process consumes a total of 4050.9kW · h of external network electrical energy. Then continue to turn on the air conditioning unit to maintain the grain temperature. Although the temperature of grain continues to rise during storage, as of July 2017, the average temperature of the grain pile remained below 20 ℃. Therefore, as long as the external network provides 4050.9kW · h of electricity, the electricity generated from solar photovoltaic power generation can maintain an average grain temperature below 20 ℃ for 10 months within a year in the experimental warehouse.

4. Conclusion

Hainan is a high temperature and humidity area, and grain is prone to aging during storage. Taking advantage of the long sunshine time and abundant solar energy resources in Hainan region, installing a solar photovoltaic power generation system on the roof of the reservoir area to provide electricity for the grain depot and achieve low-temperature grain storage is an effective way to solve the above problems. This article focuses on an area of 9m in the Hainan region × Taking a flat warehouse with a length of 30m and a grain loading line of 6m as an example, a solar off grid photovoltaic power generation system was installed on the roof of the warehouse. By selecting the type, scale, solar modules, and off grid inverters of photovoltaic power generation, a total DC output power of 29160W of off grid solar photovoltaic power generation system was designed and installed. At present, the system has been operating normally for one year. Under clear weather, the system generates an average daily DC power of 116kW · h and can provide electricity for two 2-horsepower air conditioners 24 hours a day. Under the above conditions, if the external network is supplemented with 4050.9kW · h of electricity annually to cool the grain cooler when the grain temperature rises, the average grain temperature in the warehouse can be maintained at 20 ℃ for 10 months within one year, which can basically achieve quasi low-temperature storage.