1. String solar inverter

String solar inverters are based on the concept of modularization, which involves inputting each photovoltaic string in a photovoltaic array into a designated solar inverter. Multiple solar strings and inverters are modularized and combined together. All solar inverters are connected in parallel at the AC output end. String solar inverters are used in ground power plants and have advantages such as high power generation, high reliability, high safety, and easy installation and maintenance.

Currently, many large photovoltaic power plants use string solar inverters. The main advantage is that it is not affected by the performance differences and local shading of photovoltaic cell modules between strings, and can handle photovoltaic modules with different orientations and models. It can also avoid huge power loss caused by shadows on some photovoltaic modules, and improve the overall power generation of the power generation system.

| Maximum power on DC side | 53.5kW |

| Output rated power | 47.5kW |

| Maximum AC current | 60.8A |

| Maximum conversion efficiency | 99% |

| *Efficiency in China | 98.5% |

| Input DC side voltage range | 200Vdc~1100Vdc |

| Maximum Power Tracking (MPP) range | 200Vdc~1000Vdc |

| Maximum DC input current (per circuit) | 22A |

| AC output voltage range | 500V |

| Output frequency range | 50Hz |

| Required grid form | TT, TN-S system |

| Standby power consumption/night power consumption | < 1W |

| Total harmonic distortion rate of output current | <3% (at rated power) |

| Power factor | > 0 ninety-eight |

| Automatic operation conditions | When the DC input and power grid meet the requirements, the inverter will automatically operate |

| Isolation transformer (with/without) | without |

| AC/DC surge protection (with/without) | with |

| Input reverse protection (with/without) | with |

| Other protections (please specify) | Short circuit protection, island effect protection, input reverse connection protection, overcurrent protection, etc |

| Working environment temperature range | -35 ℃~+60 ℃ |

| Relative humidity | 0-100%, non condensing |

| Maximum altitude for full power operation | ≤ 4000m (over 3000m requires derating) |

| Protection type/level | IP65 (outdoor) |

| Heat dissipation method | Self cooling |

| Weight | 55kg |

| Mechanical dimensions (width × High × Deep) | 930 × 550 × 270mm |

As the operation time of the power station increases, due to factors such as component mismatch, attenuation, and virtual connection, individual differences in components continue to increase. The advantages of refined management of components become more apparent, and the power generation of series solar inverters will be more significantly improved. The main technical parameters of the series 50kW solar inverter are shown in Table 1.

2. Centralized solar inverter

Centralized inverter technology involves several parallel photovoltaic modules connected in series and parallel to the DC input of the same centralized solar inverter. Generally, three-phase IGBT power modules are used for high power, while field-effect transistors are used for low power. At the same time, DSP controllers are used to improve the quality of the generated electricity, making it very close to sine wave current. The biggest characteristic is the high power and low cost of the system. The disadvantage is that the power generation reliability of the entire photovoltaic system is greatly affected by the poor working status of a certain photovoltaic unit group. The latest research direction is to use space vector modulation control and develop topology connections for solar inverters to achieve high efficiency under partial load conditions.

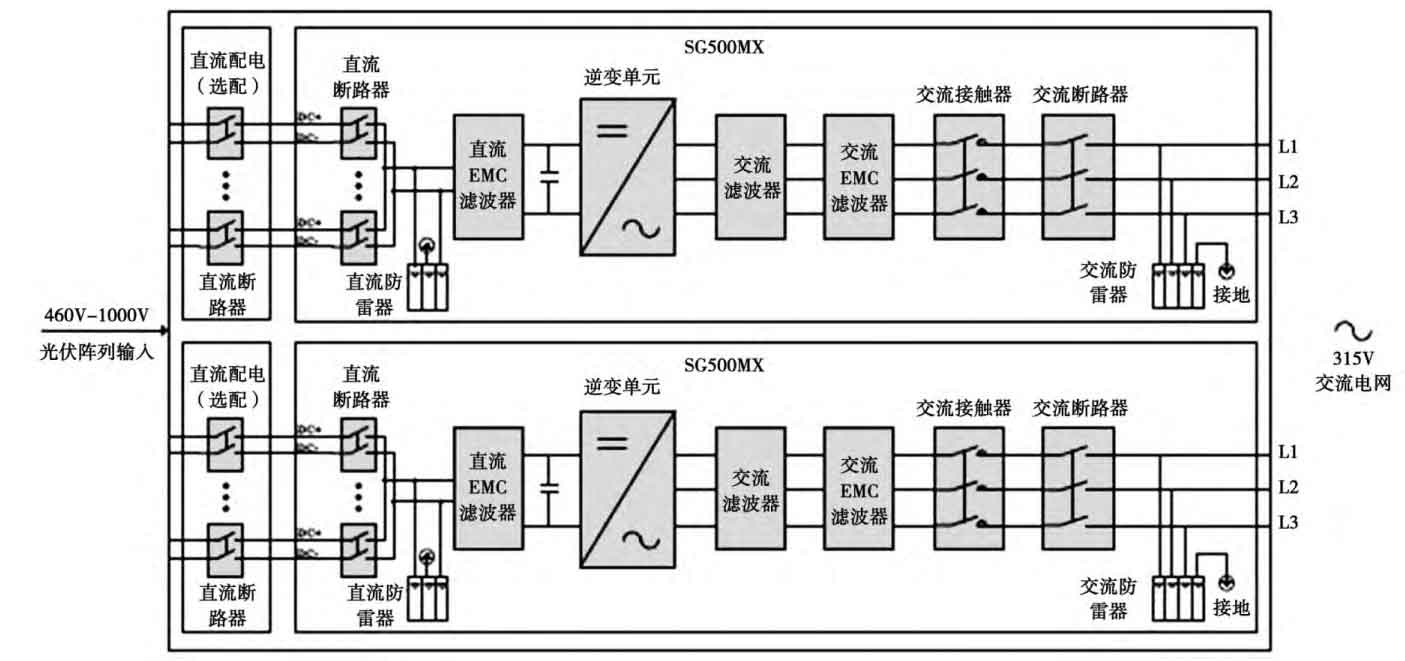

In large photovoltaic grid connected power stations both domestically and internationally, solar inverters of 250kW or above are generally used. The power levels are generally divided into 250kW, 500kW, 630kW, and 1MW. At present, domestic photovoltaic power plants often arrange photovoltaic sub arrays with a capacity of 1MWp, and plan to choose a 1000kW grid connected solar inverter with high conversion efficiency without isolation transformer.

The technical parameters and indicators of the relevant products are as follows:

The grid connected inverter power supply converts the DC voltage output by the photovoltaic array into high-frequency three-phase chopping voltage through a three-phase bridge converter, and filters it into a sine wave voltage. Then, it is boosted by a three-phase isolation transformer and integrated into the power grid. In order to generate maximum power for the photovoltaic array, an advanced MPPT (Maximum Power Point Tracking) algorithm is used on the DC side.

| Maximum power on DC side | 1120kW |

| Output rated power | 1000kW |

| Maximum AC current | 2016A |

| Maximum conversion efficiency | 98.7% |

| *European efficiency | 98.5% |

| Input DC side voltage range | 460Vdc~1000Vdc |

| Maximum Power Tracking (MPP) range | 460Vdc~850Vdc |

| Maximum DC input current | 2440A |

| AC output voltage range | 315V |

| Output frequency range | 50Hz |

| Required grid form | TT, TN-S system |

| Standby power consumption/night power consumption | <100W |

| Total harmonic distortion rate of output current | <3% (at rated power) |

| Power factor | > 0.99 |

| Automatic operation conditions | When the DC input and power grid meet the requirements, the inverter will automatically operate |

| Automatic restart time after power outage | 5 minutes (adjustable time) |

| Isolation transformer (with/without) | without |

| Ground point fault detection (with/without) | with |

| Overload protection (with/without) | with |

| Overvoltage protection (with/without) | with |

| Other protections (please specify) | Short circuit protection, island effect protection, overheating protection, overload protection, etc |

| Working environment temperature range | -35 ℃~+50 ℃ |

| Relative humidity | 0-95%, non condensing |

| Maximum altitude for full power operation | ≤ 6000m (if exceeding 3000m, it needs to be derated for use) |

| Protection type/level | IP65 (outdoor) |

| Heat dissipation method | Air-cooled |

| Weight | 4200kg |

| Mechanical dimensions (width × High × Deep) | 2538 × 2470 × 2050mm |

3. Comparison of two forms of solar inverters

When centralized solar inverters are used in photovoltaic power plants, the system mainly includes photovoltaic modules, DC cables, DC combiner boxes, inverters, AC cables, and step-up transformers; When using a string inverter, the system includes components, DC cables, inverters, AC cables, AC combiner boxes, and step-up transformers. The series solar inverter reduces the DC cable from the combiner box to the solar inverter compared to the centralized one.

The comparison of two forms of solar inverter technology is shown in Table 3.

| Project | String scheme | Centralized solution | Conclusion |

| System power | 1MW sub array with 100 MPPT channels | 1MW sub array with only 2 MPPT channels | String dominant |

| General layout and construction | 1MW sub array only requires one boost transformer and its foundation | For each 1MW sub array, one set of containerized inverter, step-up transformer, and their foundation are required | String dominant |

| Design | Inverter replaces combiner box, with simple structure and design scheme | Adopting conventional and mature design schemes, the design scheme is simple | Same |

| Procurement | Currently, relevant applications are gradually being carried out in China | Inverters and related equipment are relatively mature, and are widely used in China and the United States | Centralized dominance |

| Operations and Maintenance | The string inverter is basically maintenance-free design, which can accurately locate the faults of each photovoltaic string and save fault location time | Professional engineers are required for maintenance, and regular dust cleaning and dust net maintenance are required | String dominant |

| Safety and reliability | The failure of a single series inverter has little impact on the power station, and only affects 5% of the power generation for a 1MWp square array | 100% impact on power generation when a single 1000kW inverter in a 1MWp square array malfunctions | String dominant |

| System loss | Inverter installed outdoors, without heat dissipation and power consumption, with low losses for conventional dual winding transformers | The containerized inverter has an extremely wide thermal design margin and operates without derating when the outdoor temperature reaches 55 ℃. However, the losses of the split transformer are slightly higher than those of the double winding transformer | String dominant |

| Economy | The price of string inverters is relatively high | Centralized inverters are cheap | Centralized dominance |

The string solar inverter not only brings high power generation during the 25 year life cycle of the power plant, but also effectively solves the long-term problems of after-sales delivery and operation and maintenance of photovoltaic power plants. The string solar inverter scheme has obvious advantages in both initial construction and later operation and maintenance.

But currently, the initial cost of string solar inverters is slightly higher, and from the economic perspective of initial investment, string solar inverters are slightly inferior to centralized solar inverters.

4. Conclusion

The series solar inverter scheme has obvious advantages in terms of easy construction, simple maintenance in the later stage, high overall power generation, and high electric field revenue in the later stage. But currently, the cost of string solar inverters is slightly higher, and the initial investment is greater than the centralized solar inverter scheme. Therefore, considering the economy of initial investment, it is advisable to choose a centralized solar inverter scheme; In addition, if the project construction site is relatively flat, there are no obvious obstacles around it, and the component layout is highly uniform, it is also advisable to choose a centralized solar inverter. String solar inverters are more suitable for photovoltaic projects with high initial investment, greater emphasis on later stage profits, and irregular construction locations.