With the continuous development and utilization of new energy, solar cells have attracted great attention as a new type of energy. On the one hand, they are pollution-free, and on the other hand, they are inexhaustible. Solar street lights are a type of lighting tool based on solar cells, which work by utilizing the photovoltaic effect of solar cells. As a new type of lighting tool, solar street lights have a relatively short development time, especially in terms of mechanical finite element analysis, which is scarce. Using ABAQUS finite element analysis software, stress analysis is carried out to identify some of the reasons for the failure of street lights, thereby ensuring that their structure is safer and more reliable, and reducing the frequency of daily maintenance.

1. Finite element analysis of street lamp poles

1.1 Establishment of finite element model

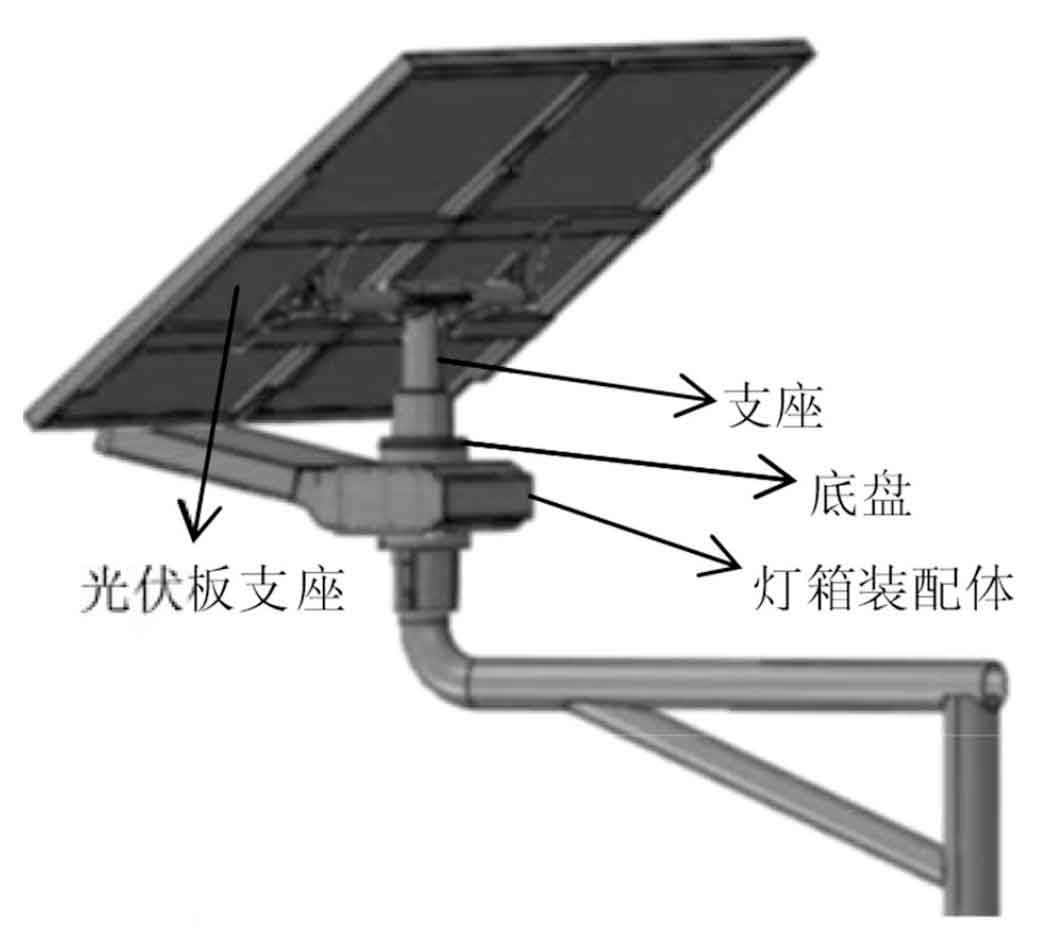

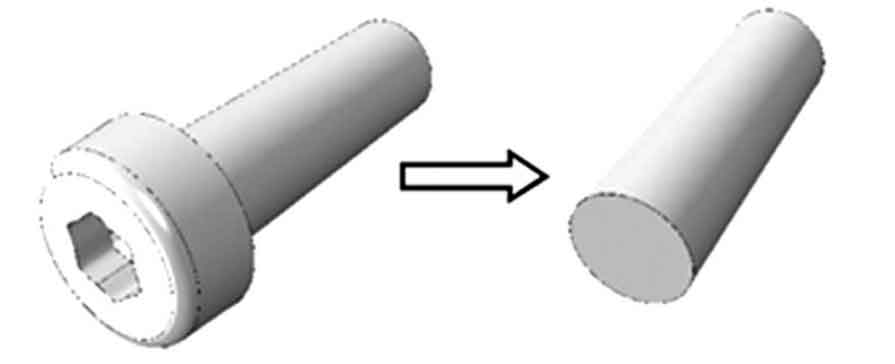

The solar street light is composed of a foundation, flange, bolt, lamp pole, lamp head, solar bracket, battery panel, and battery panel bracket. After establishing a street lamp model using SolidWorks software, import it into ABAQUS finite element software for analysis. The specific model is shown in Figure 1, which further simplifies the structure of some parts, as shown in Figure 2.

1.2 Finite element analysis of changes in lamp pole length

1.2.1 Analysis of Mises stress results

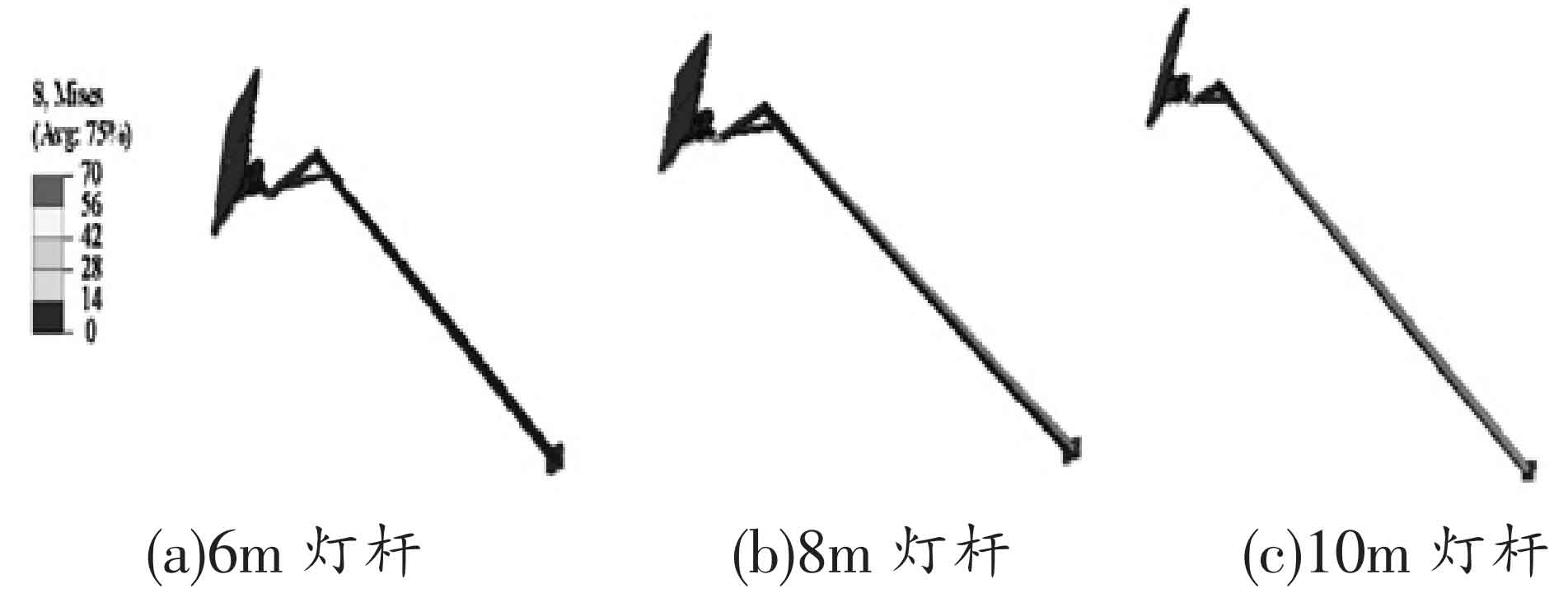

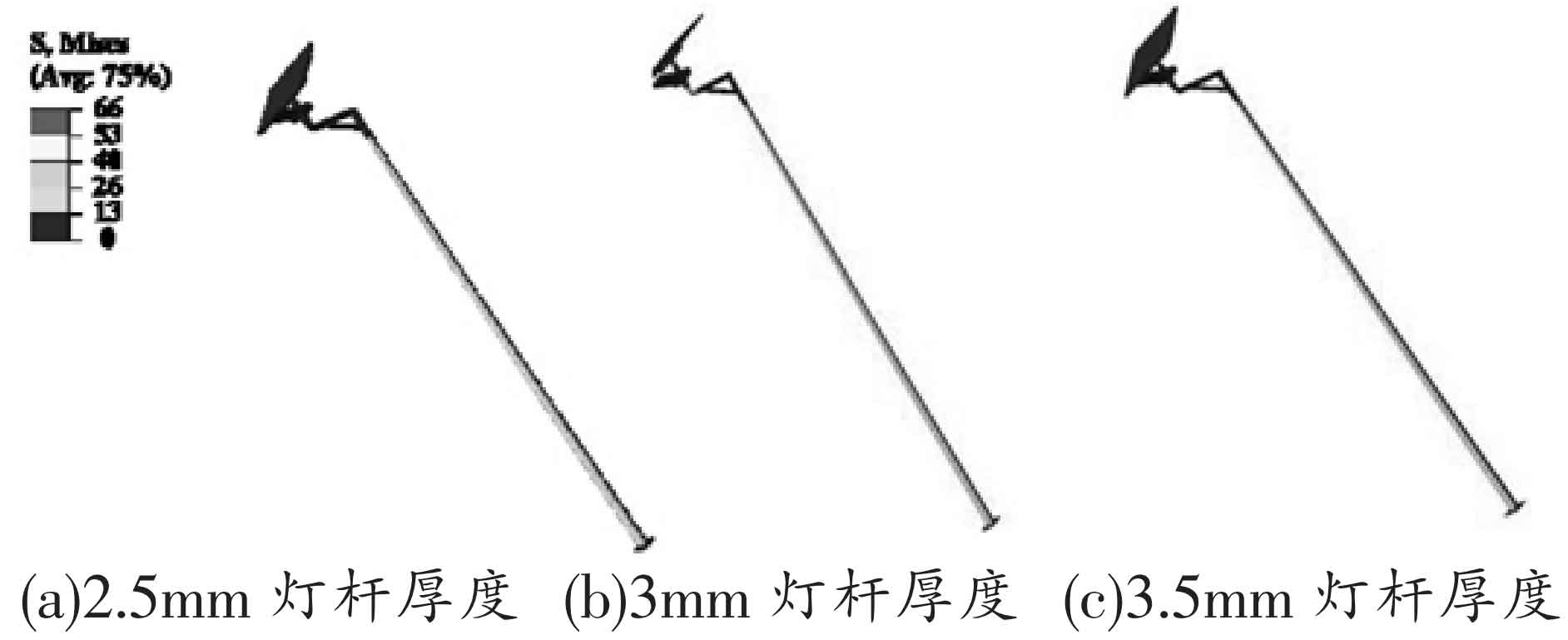

We will analyze the solar street lamp structures corresponding to three different lengths of lamp posts to explore the impact of changes in lamp post length on the strength and stiffness of solar street lamp structures. As shown in Figure 3.

From Figure 3, it can be seen that the photovoltaic panels, brackets, and other positions are subjected to relatively small forces. From force to knowledge, it can be known that the areas with larger forces are at the connection positions between the solar path lighting panels and brackets, as well as between the brackets and bases. The stress corresponding to a 6m lamp post at the connection position between the solar path lighting panels and brackets is 24MPa, a 8m lamp post at 42MPa, and a 10m lamp post at 65MPa, The maximum stress basically increases in an arithmetic sequence. Therefore, the maximum stress value of the structure at other lengths can be calculated.

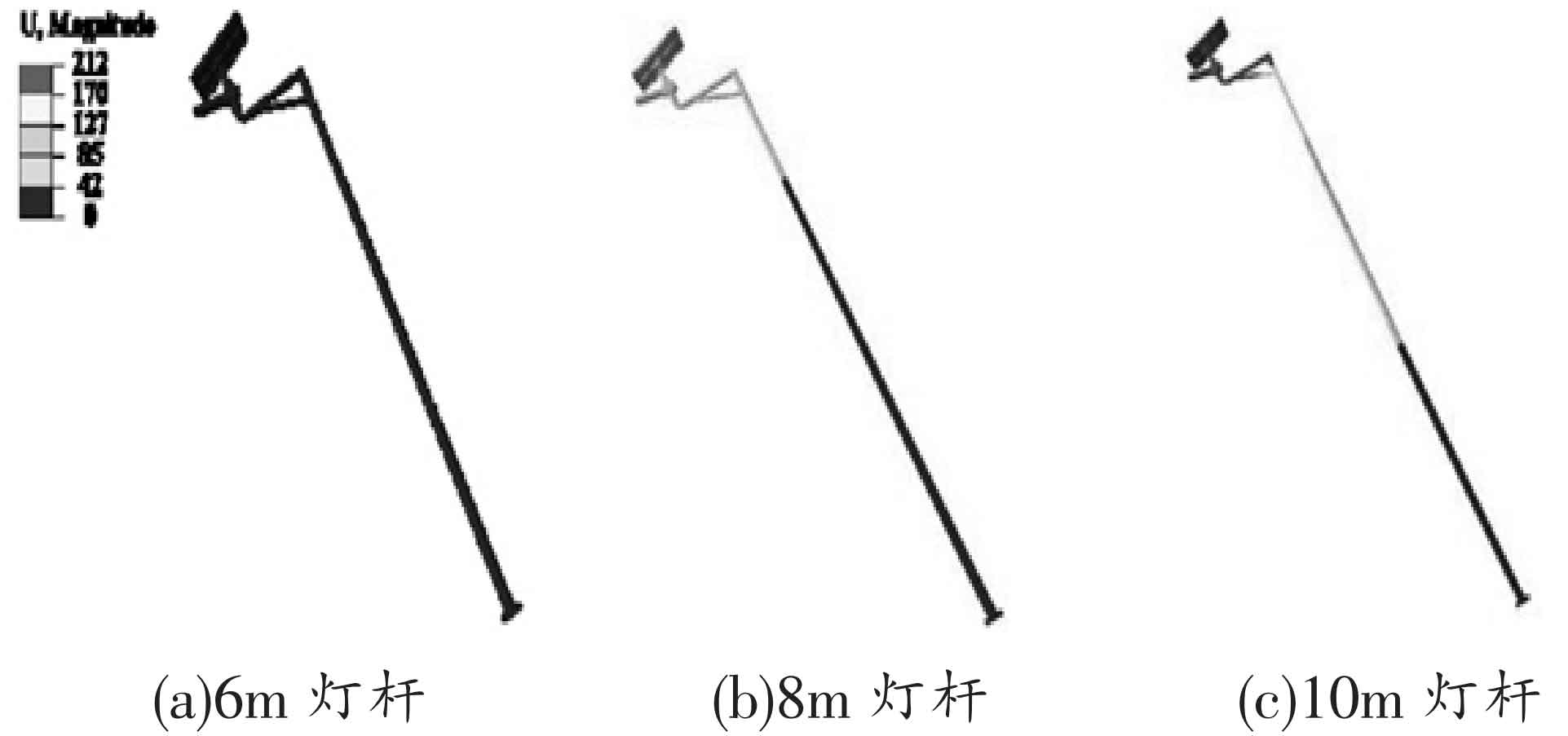

From Figure 4, it can be seen that the structure of the lamp post is similar to a cantilever beam, with the maximum deformation generated at the free end. According to theoretical mechanics knowledge, it is recommended to increase the wall thickness of the lamp post while increasing its length in order to increase the stiffness of the structure. Avoid bending of the lamp post.

1.3 Finite element analysis of changes in wall thickness of lamp posts

1.3.1 Analysis of Mises stress results

From Figure 5, it can be seen that the photovoltaic panels, brackets, and other positions are subjected to relatively small forces. Based on the above image and the knowledge of force variation learned, it can be known that the areas with greater stress are at the connection between the solar path lighting panel and the bracket, the connection between the bracket and the base, and the parts with greater stress concentration are at the connection between the base and the bolt, as well as the inner and outer sides of the upright pole. The maximum stress of the 2.5mm solar street lamp pole structure is 46MPa, the maximum stress of the 3.0mm lamp pole structure is 36MPa, and the maximum stress of the 3.5mm lamp pole structure is 33MPa. The thickness of the lamp post directly affects the size of its load-bearing area. The smaller the wall thickness of the solar street lamp post, the smaller the load-bearing area, so the stress it receives will be greater.

1.3.2 Analysis of deformation results

As shown in Figure 6, the lamp post structure is similar to a cantilever beam, with the maximum deformation generated at the free end. Similarly, the stiffness of a 3.5mm lamp post is the highest, while that of a 2.5mm lamp post is the lowest. Increasing the thickness of the lamp post can significantly reduce the deformation of the overall structure. The thicker the lamp post, the smaller the deformation of the structure.

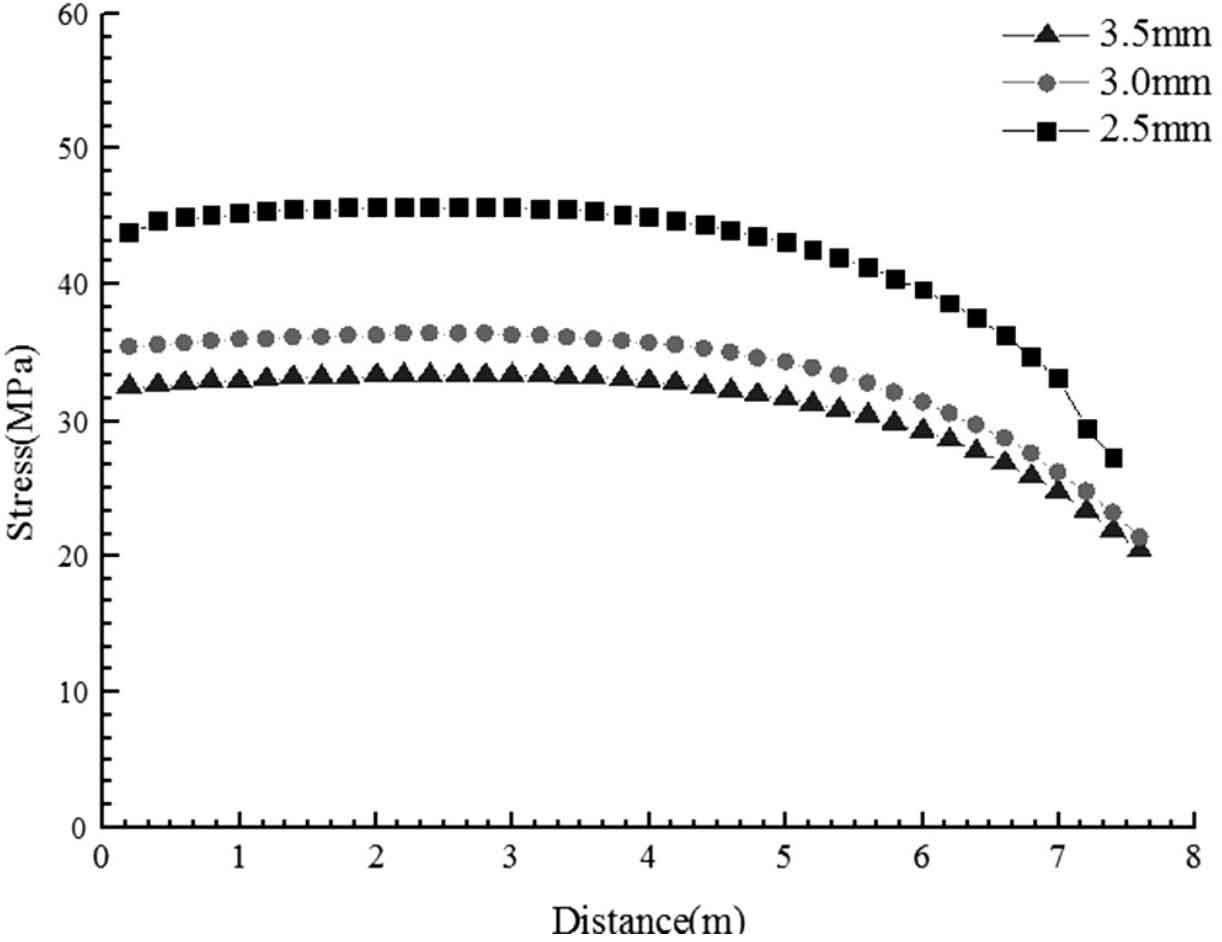

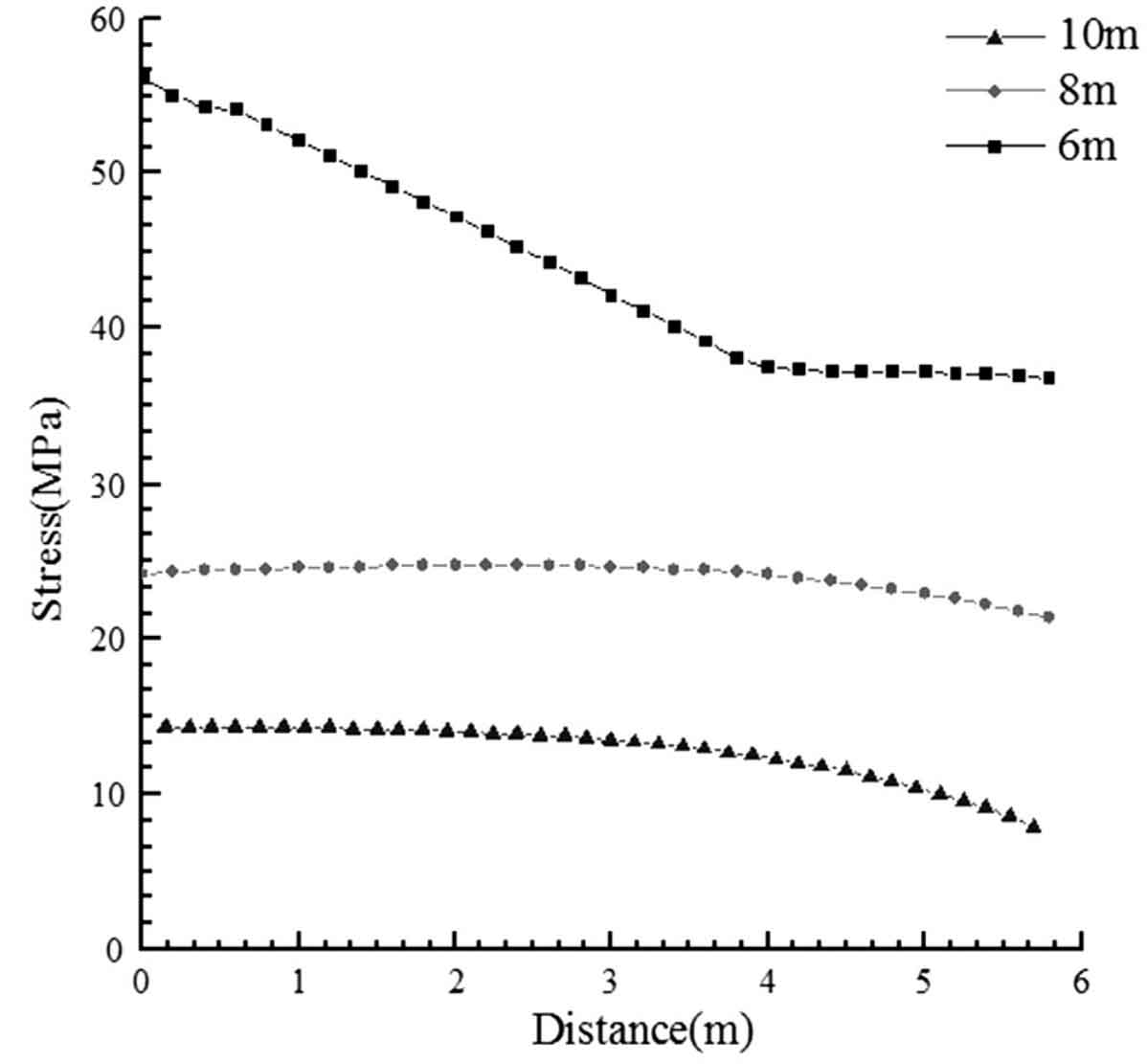

1.3.3 Origin data processing

Through the analysis of origin data, it can be seen that there are changes in stress around the base for three types of rod lengths and wall thicknesses, as shown in Figures 7 and 8.

From Figure 7, it can be seen that the stress concentration of a 10m length lamp post is significantly greater than that of 8m and 6m. As the distance from the end increases, the stress of the lamp post gradually decreases. Therefore, the design of the lamp post can adopt a structure with a thick bottom and a thin top, while ensuring structural safety and minimizing the cost of the structure.

From Figure 8, it can be seen that the lamp post with a thickness of 3.0mm is the most economical and safe. The thicker the wall of the lamp post, the better the strength, stiffness, and stability of the structure. However, while meeting the strength requirements, the smaller the wall thickness, the lower the cost of solar street lights.

2. Conclusion

This paper mainly discusses the stress situation of solar street lights under different structural parameters, and ultimately finds that:

1) From the Mises stress diagram, it can be seen that solar panels and other components are not subjected to significant stress overall. Based on the analysis results and basic mechanical knowledge, it can be concluded that a significant stress concentration is located at the bolt connection between the bracket and the base. Rod length and wall thickness are two important factors affecting the lifespan of solar street lights. The shorter the rod length and the thicker the wall thickness, the more reasonable the stress on the entire solar street light, and the safety and reliability are improved.

2) As the wall thickness of the lamp post increases, the strength, stiffness, and stability of its own structure become better. The smaller the wall thickness, the more obvious the stress concentration phenomenon. The stress concentration in the lamp post is mostly at the connection between the base and bolts, as well as the inner and outer sides of the upright pole.

3) As the length of the lamp post increases, the stiffness of its own structure decreases exponentially, and the structural stability becomes worse. The stress concentration in the lamp post is mostly concentrated at the connection between the base and bolts, as well as on the inner and outer sides of the upright pole.