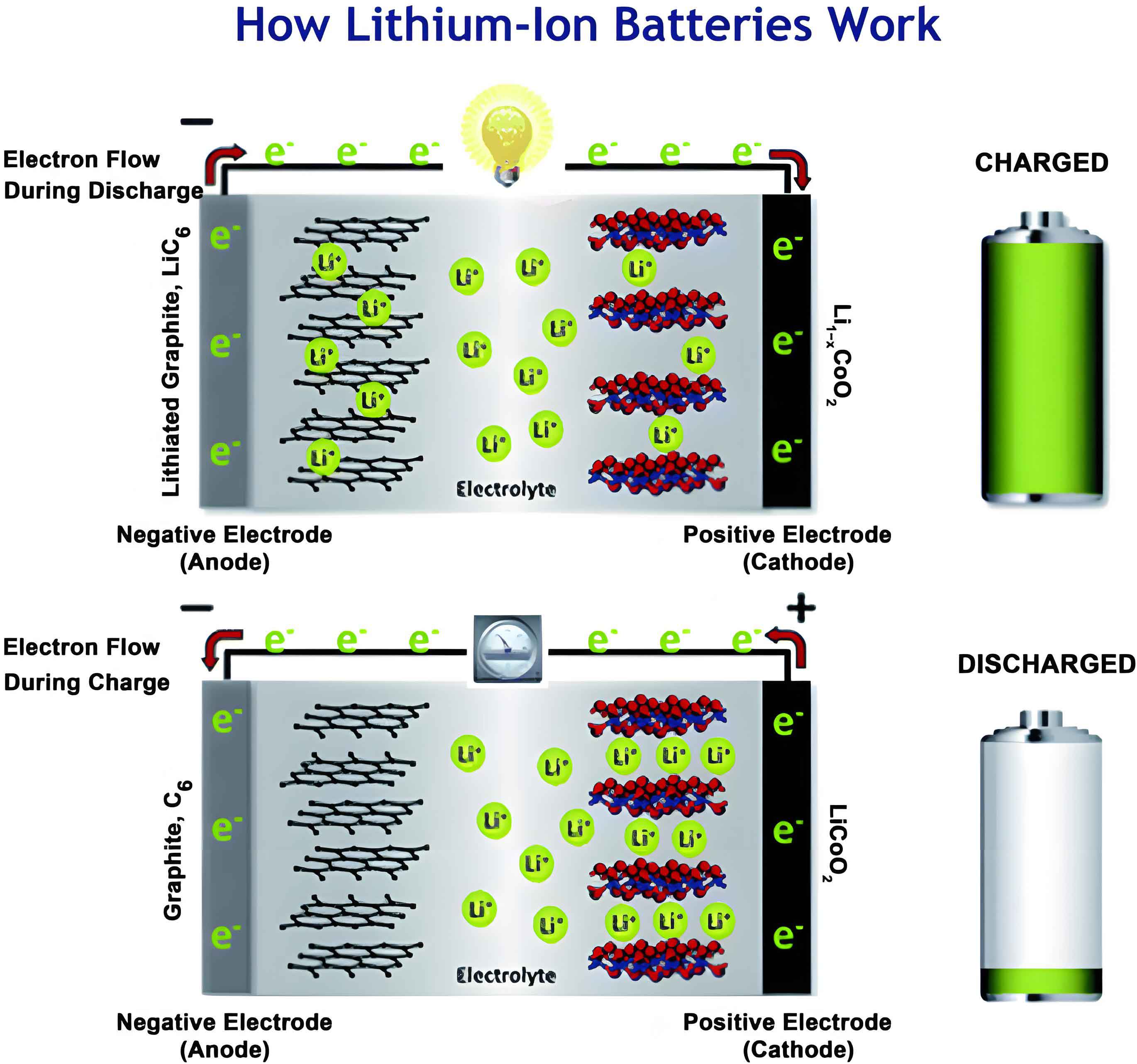

The relentless pursuit of higher energy density, superior power density, and extended cycle life for lithium-ion batteries represents a cornerstone of modern energy research. As the dominant power source for portable electronics and electric vehicles, the performance limits of conventional electrode materials are being approached. This reality necessitates a paradigm shift towards novel materials with inherent structural advantages. Among the plethora of candidates, Metal-Organic Frameworks (MOFs) have emerged as a particularly promising class of materials for next-generation lithium-ion battery anodes. Their defining characteristics—exceptional porosity, tunable chemical composition, and diverse architectural possibilities—offer a unique platform to address critical challenges such as ionic transport kinetics, structural stability during lithiation, and overall electrochemical activity.

My research focuses on harnessing the synergistic potential of bimetallic systems within the MOF architecture. Specifically, the synthesis and electrochemical evaluation of a cobalt-nickel based MOF (CoNi-MOF) as an anode material for lithium-ion batteries has revealed extraordinary performance metrics, prompting a deeper investigation into the underlying mechanisms responsible for its high capacity and remarkable rate capability. This article details the journey from material design to mechanistic understanding, employing a suite of advanced characterization techniques to unravel the complex electrochemical behavior of this material.

1. Design Rationale and Synthesis of CoNi-MOF

The selection of cobalt and nickel as the metal nodes is strategic. Both transition metals are known for their rich redox chemistry, which is fundamental for conversion-type electrode reactions in lithium-ion batteries. Furthermore, the combination of two different metals can lead to synergistic effects, potentially enhancing electronic conductivity and offering multiple redox-active sites. The organic linker, terephthalic acid (BDC), provides a rigid and conjugated structure that can contribute to the overall framework stability and may also participate in charge storage through its functional groups.

The synthesis was achieved via a straightforward solvothermal method, which typically yields materials with good crystallinity and controlled morphology. The reaction involves the self-assembly of Co2+ and Ni2+ ions with BDC linkers in a mixed solvent system (DMF/ethanol/water) at elevated temperature. The product, as confirmed by X-ray diffraction (XRD), possesses a lamellar bulk structure isostructural to known nickel-based MOFs. This layered morphology is highly desirable for electrode applications as it can facilitate electrolyte penetration and provide short diffusion paths for Li+ ions, a critical factor for achieving high-rate performance in lithium-ion batteries.

The morphology and elemental distribution were verified using electron microscopy. The material exhibits a distinct layered architecture, and energy-dispersive X-ray spectroscopy (EDS) mapping confirms the homogeneous distribution of Co, Ni, O, and C throughout the structure, indicative of a well-formed bimetallic framework.

2. Electrochemical Performance: Quantifying Excellence

The electrochemical performance of the CoNi-MOF anode was evaluated in a standard half-cell configuration against metallic lithium. The results are nothing short of impressive, positioning this material among the top-performing MOF-based anodes reported for lithium-ion batteries.

2.1 Cyclic Voltammetry and Reaction Mechanism

Initial cyclic voltammetry (CV) scans provide insight into the electrochemical reactions. The first cathodic scan shows a prominent, irreversible peak around 1.23 V, attributed to the decomposition of the electrolyte and the formation of the solid electrolyte interphase (SEI). In subsequent cycles, the CV curves become highly reproducible, featuring broad reduction peaks (lithiation) below 1.0 V and distinct oxidation peaks (delithiation) near 1.23 V and 1.50 V. The excellent overlap of curves from the 2nd cycle onward signifies high electrochemical reversibility. The redox reactions can be associated with the stepwise reduction of Co2+ and Ni2+ to their metallic states (Co0, Ni0) and the possible involvement of the organic linker, followed by their re-oxidation upon charging.

2.2 Galvanostatic Cycling and Rate Performance

The true testament to the material’s capability lies in its long-term cycling and rate performance. When cycled at a current density of 500 mA g-1 within a voltage window of 0.01-3.00 V, the CoNi-MOF anode delivers an initial discharge capacity exceeding 2000 mAh g-1. After an expected initial drop due to SEI formation, the capacity not only stabilizes but gradually increases—a phenomenon often linked to electrochemical activation and the gradual exposure of active sites. After 200 cycles, a high reversible capacity of approximately 1120 mAh g-1 is retained, which is approximately three times the theoretical capacity of commercial graphite (372 mAh g-1). The coulombic efficiency quickly rises and remains near 100% after the first few cycles.

Even more striking is the rate capability. The anode delivers substantial capacities at increasingly higher current densities. The relationship between capacity retention and current density can be modeled. The capacity (C) at a given current density (i) often follows a power-law decay relative to the capacity at a low reference current (C0):

$$ C(i) = C_0 \cdot i^{-k} $$

where \( k \) is the rate capability factor. A smaller \( k \) indicates better tolerance to high current. For the CoNi-MOF, the \( k \) value is remarkably low, indicating superb rate performance. The capacity recovers significantly when the current density is returned to 500 mA g-1, demonstrating excellent structural resilience.

| Current Density (mA g-1) | Discharge Capacity (mAh g-1) | Cycle Number | Key Observation |

|---|---|---|---|

| 500 | ~1120 | 200th | High reversible capacity |

| 500 | ~865 | Rate Test | Initial rate step |

| 1000 | ~510 | Rate Test | |

| 2000 | ~304 | Rate Test | |

| 3000 | ~215 | Rate Test | Good capacity at high rate |

| 5000 | ~140 | Rate Test | |

| 500 (return) | ~767 | Rate Test | Excellent capacity recovery |

2.3 Electrochemical Impedance Spectroscopy (EIS)

EIS measurements were conducted to understand the kinetics. The Nyquist plots consist of a semicircle in the high-medium frequency region (representing charge transfer resistance, Rct) and a sloping line in the low-frequency region (representing Li+ diffusion). A key finding is that both the SEI resistance (RSEI) and Rct decrease and stabilize upon cycling. This suggests the in-situ formation of a stable and highly conductive interface, which is crucial for the sustained high-rate performance of this lithium-ion battery anode. The Warburg coefficient (σ), derived from the low-frequency data, is relatively low, indicating fast solid-state Li+ diffusion within the electrode material.

3. Mechanistic Insights: Beyond Conventional Conversion

While the high capacity could be preliminarily ascribed to the conversion reaction of Co/Ni oxides and the possible contribution of the organic matrix, the extraordinary magnitude and stability demanded a more profound investigation using advanced characterization tools.

3.1 Structural Evolution and Valence Changes

Ex-situ XRD analysis of electrodes after extensive cycling revealed the complete disappearance of crystalline MOF peaks. This indicates an irreversible collapse of the long-range ordered framework during the initial lithiation process, transforming it into a composite of metallic clusters, lithium compounds, and amorphous carbonaceous species.

To probe the chemical state evolution of the redox-active metals, X-ray Absorption Spectroscopy (XAS) was employed. The X-ray Absorption Near Edge Structure (XANES) spectra at the Co K-edge and Ni K-edge provided clear evidence of reversible redox activity:

- Fully Discharged State (0.1 V): The absorption edge positions and white line intensities for both Co and Ni closely match those of Co0 and Ni0 metal foils, confirming the reduction to the metallic state.

- Fully Charged State (3.0 V): The edges shift back to higher energies, and the spectral features resemble those of Co2+ and Ni2+ reference compounds (e.g., CoO, NiO), indicating re-oxidation.

This confirms the central conversion reaction: \( \text{M}^{2+}\text{O} \) (in MOF, M=Co/Ni) + 2Li+ + 2e– \(\rightleftharpoons\) M0 + Li2O. However, the capacity contribution from this reaction alone is insufficient to explain the observed >1000 mAh g-1.

Extended X-ray Absorption Fine Structure (EXAFS) analysis quantified the local structural changes. The Fourier-transformed EXAFS spectra show the disappearance of the M-O coordination shell and the emergence of a M-M shell upon discharge, which reverses upon charge. The bond lengths extracted from EXAFS fitting further corroborate the conversion mechanism.

3.2 The Role of Amorphous Lithium Metal: A Key Discovery

The pivotal insight came from Time-of-Flight Secondary Ion Mass Spectrometry (TOF-SIMS), a highly surface-sensitive technique capable of mapping light elements like lithium. The TOF-SIMS analysis of the cycled anode yielded remarkable results:

- Elemental Mapping: Ion maps over a 100 μm × 100 μm area showed a uniform and dense distribution of Li+ ions throughout the electrode, co-localized with Co+ and Ni+ signals.

- Depth Profiling: The signal intensity for Li+ remained extraordinarily high and constant from the surface to depths exceeding 700 nm. Critically, the Li+ signal intensity was about two orders of magnitude greater than that of Co+ and Ni+.

This overwhelming abundance of lithium cannot be rationalized solely by the formation of Li2O or lithium-organic complexes from the conversion reaction. The most plausible explanation is the deposition of a significant amount of amorphous lithium metal within the porous, collapsed matrix of the electrode.

The absence of sharp Li0 peaks in XRD confirms its amorphous nature. This amorphous Li metal, uniformly dispersed and trapped within the conductive carbonaceous matrix derived from the organic linker and the metallic Co/Ni nanoclusters, is proposed as the primary source of the additional, highly reversible capacity. The governing reaction for this process can be viewed as a plating/stripping reaction within the composite matrix: \( \text{Li}^+ + e^- \rightleftharpoons \text{Li}^0 \) (amorphous, confined).

The advantages of this configuration are multifold for a lithium-ion battery anode:

| Feature | Benefit for Lithium-Ion Battery Performance |

|---|---|

| Amorphous Structure | Prevents the formation of crystalline dendrites, enhancing safety. |

| Confinement in Porous Matrix | Mitigates large volume changes associated with Li plating/stripping, improving cycle life. |

| Intimate Contact with Conductive Matrix (Metals/C) | Ensures excellent electronic conductivity, enabling high-rate capability. |

| High Li Content | Directly contributes to the very high specific capacity. |

The overall capacity (Qtotal) of the cycled CoNi-MOF anode can thus be expressed as a sum of contributions:

$$ Q_{\text{total}} = Q_{\text{conversion}} + Q_{\text{Li-metal}} + Q_{\text{capacitive}} $$

where \( Q_{\text{conversion}} \) is from the metal oxide conversion, \( Q_{\text{Li-metal}} \) is from the reversible plating/stripping of amorphous Li, and \( Q_{\text{capacitive}} \) is from surface capacitive effects on the high-surface-area amorphous carbon.

4. Conclusion and Perspective

This investigation demonstrates that a bimetallic CoNi-MOF, through a carefully designed synthesis, can be transformed into an exceptional anode material for lithium-ion batteries. Its performance—characterized by a high reversible capacity (~1120 mAh g-1), outstanding rate capability, and good cycle life—stems from a unique multi-mechanism storage process.

The initial crystalline MOF acts as a precursor that, upon electrochemical cycling, reorganizes into a multifunctional nanocomposite. This composite facilitates: (i) a reversible conversion reaction of Co/Ni species, (ii) the stable plating and stripping of amorphous lithium metal within its pores, and (iii) likely additional capacitive storage. The synergy between the metallic clusters (for conductivity), the amorphous carbon (for buffering and conductivity), and the trapped amorphous Li (for capacity) creates an ideal environment for high-performance energy storage.

This work illuminates a promising path forward for MOF-based electrode design. It moves beyond using MOFs merely as sacrificial templates for deriving porous carbons or metal oxides, instead leveraging their unique chemistry to generate electrochemically active composites in situ. Future research should focus on:

- Optimizing the MOF structure (linker choice, metal ratio, porosity) to further control the properties of the resulting composite.

- Employing in-situ/operando characterization techniques to dynamically track the phase transformation and Li metal deposition process.

- Exploring the scalability of the synthesis and electrode fabrication for practical lithium-ion battery applications.

By unraveling the complex interplay between structure, composition, and electrochemical function, this study contributes significantly to the fundamental understanding and development of advanced anode materials, pushing the boundaries of what is possible for next-generation energy storage in lithium-ion batteries.