According to the economic analysis of different energy storage systems, it can be seen that the cost of energy storage media, packaging cost of phase change materials, and tank cost are important variables that affect the cost of energy storage systems in different systems. Based on the unit energy storage system cost, select the above variables for sensitivity analysis of key factors. The sensitivity range is set to -20%~20%. Based on sensitivity analysis, the ranking of the impact of different influencing variables on the cost of unit energy storage system can be obtained.

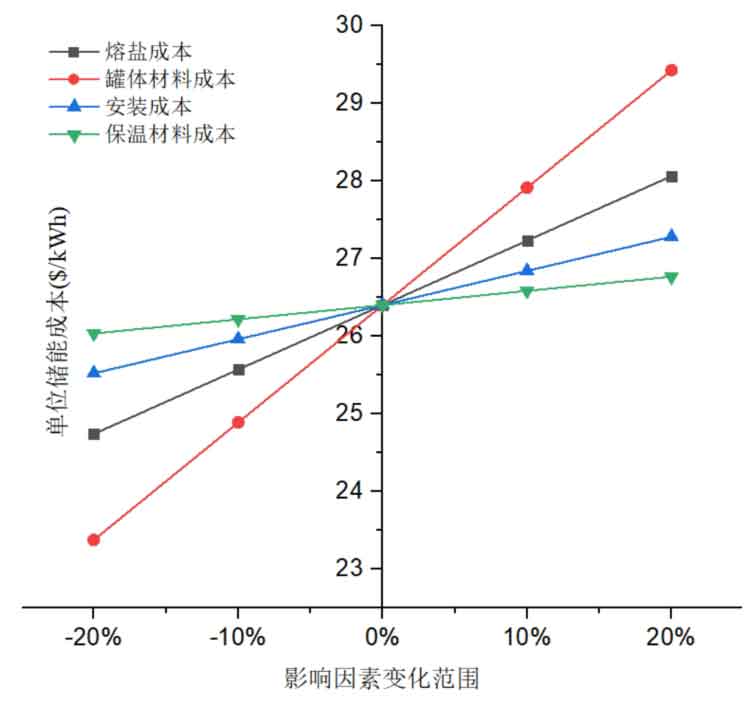

(1) Dual tank molten salt energy storage system

Figure 1 shows the sensitivity analysis of the unit energy storage system cost for a dual tank molten salt system. From the graph, it can be seen that the cost of tank material is the most sensitive parameter, followed by the cost of molten salt fluid. The sensitivity of the impact of installation cost and insulation material cost on the unit energy storage system cost is relatively small. If the material cost of the tank is reduced by 20%, the unit energy storage system cost of the dual tank molten salt system will decrease by 11.5% compared to the baseline situation, to 23.37 $/kWh. For molten salt fluids, if the cost is reduced by 20%, the unit energy storage system cost of the system will be reduced by 6.3%, to 24.74 $/kWh. Due to the high proportion of tank cost in the total cost of a dual tank energy storage system, the reduction of tank material cost has the most significant effect on reducing the cost of the energy storage system.

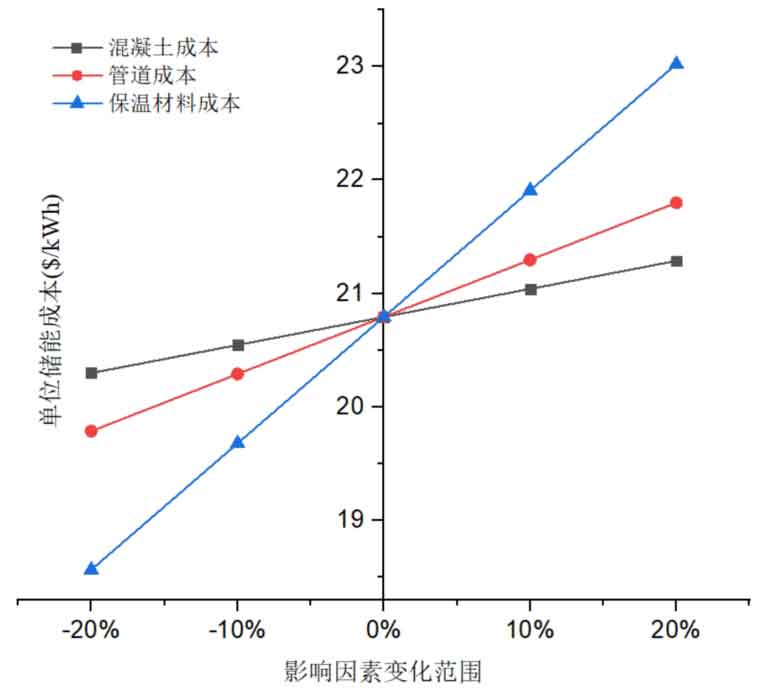

(2) High temperature concrete energy storage system

Figure 2 shows the sensitivity analysis of the unit energy storage system cost for high-temperature concrete systems. From the perspective of sensitivity, they are insulation material cost, pipeline cost, and concrete cost in order. Due to the relatively high price of insulation materials, the unit energy storage system cost is most affected by them. When the cost of insulation materials is reduced by 20%, the unit energy storage system cost of the concrete system decreases by 10.7%, to 18.57 $/kWh. The cost of concrete has a relatively small impact on the energy storage cost of the system. As the cost of concrete increases by 20%, the unit energy storage system cost of the system only increases by 2.4%. This also indicates from another perspective that concrete, as a sensible thermal energy storage material, has good cost advantages and has the possibility of large-scale application in solar thermal power plants. The cost of heat transfer pipelines is also relatively high, which has a significant impact on the unit energy storage system cost of the system. When the pipeline cost increases by 20%, the unit energy storage system cost of the system increases by 4.9% relative to the baseline situation.

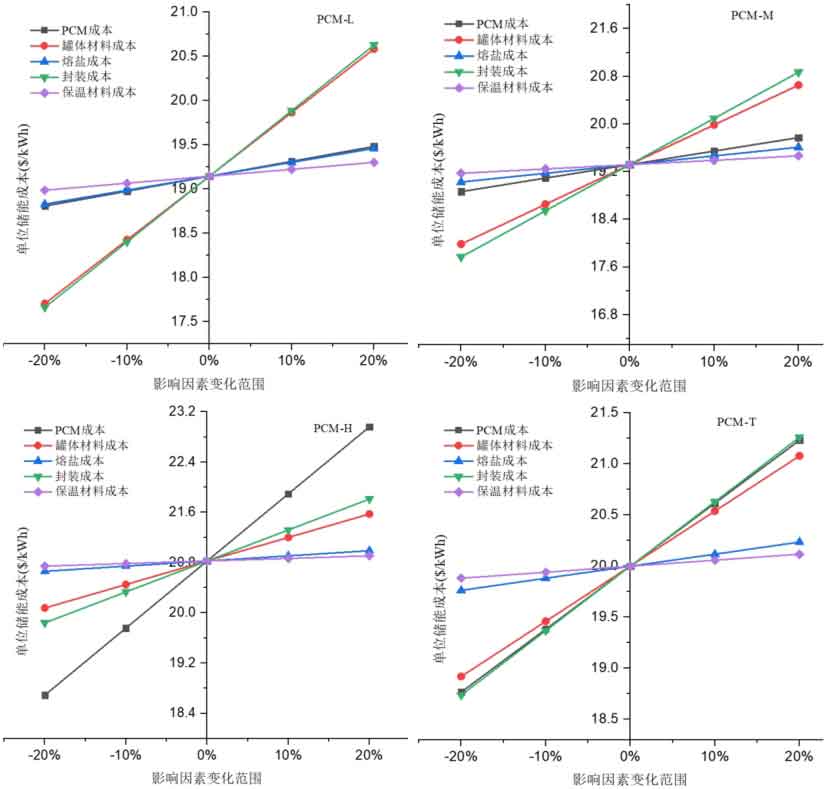

(3) Phase change packed bed energy storage system

Figure 3 shows the sensitivity analysis of unit energy storage cost for phase change packed bed energy storage systems. From the graph, it can be seen that for low-temperature and medium temperature phase change packed bed energy storage systems, the most important factor affecting their unit energy storage cost is packaging cost, followed by tank cost, phase change material cost, molten salt cost, and insulation material cost. For high-temperature phase change energy storage systems, due to the high cost of phase change materials, the cost of energy storage media is the most important factor affecting the unit energy storage system cost. For a three-layer phase change energy storage system, the packaging cost of phase change materials has the greatest impact on the unit energy storage system cost, followed by the cost of phase change materials, and the difference in importance between the two is relatively small. The order of influence of other factors is the cost of tank materials, the cost of molten salt, and the cost of insulation materials.

For the packaging cost of phase change materials, if the packaging cost is reduced by 20%, the unit energy storage system cost of PCM-L, PCM-M, PCM-H, and PCM-T systems can be reduced by 7.7%, 8.0%, 4.8%, and 6.3%, respectively. The cost of tank materials is also one of the important factors affecting the cost of energy storage systems. In the PCM-L system, the sensitivity of the impact of tank material cost and packaging cost on the unit energy storage system cost is basically the same. If the cost of tank materials is reduced by 20%, the unit energy storage system costs of PCM-L, PCM-M, PCM-H, and PCM-T systems can be reduced by 7.5%, 6.9%, 3.6%, and 5.4%, respectively. The sensitivity of the impact of phase change material cost on the unit energy storage system cost of PCM-H system is higher than that of the other three energy storage systems. When the cost of high-temperature phase change materials is reduced by 20%, the unit energy storage system cost will be reduced by 10.3%. The cost of high-temperature phase change materials is relatively high, and the more high-temperature phase change materials are used, the greater the impact on the cost of energy storage systems. In the PCM-T system, due to the fact that the volume of high-temperature phase change materials only accounts for one-third of the tank body, the sensitivity of the cost of phase change materials to the unit energy storage system cost of the system decreases. When the cost of phase change materials is reduced by 20%, the unit energy storage system cost will be reduced by 6.2%.

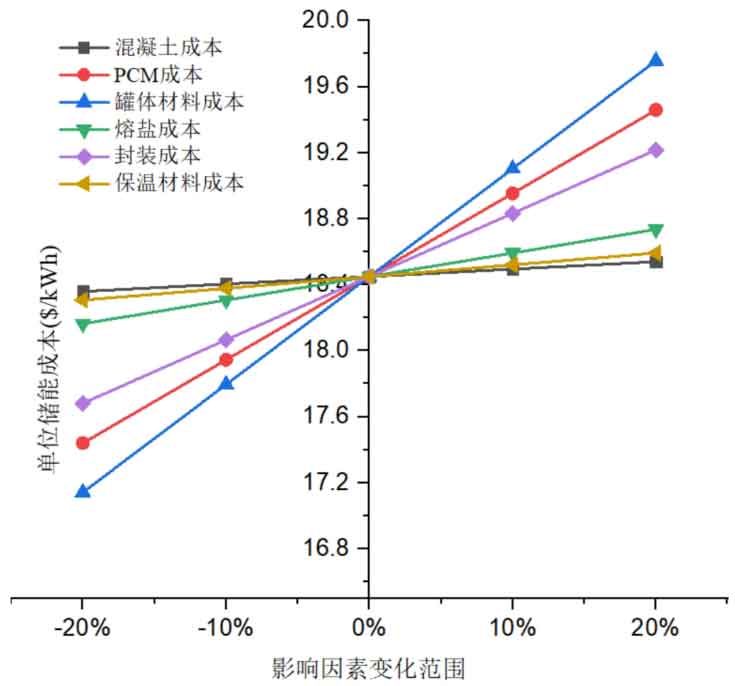

(4) Sensible latent heat combined packed bed energy storage system

Taking the sensible latent heat combined packed bed system (C-PCM) with a concrete volume fraction of 50% as an example, Figure 4 shows the cost sensitivity analysis of the unit energy storage system of the C-PCM system. From the graph, it can be seen that the unit energy storage cost of the C-X1 energy storage system is 18.45 $/kWh. The order of factors affecting the unit energy storage system cost is tank material cost, phase change material cost, phase change material packaging cost, molten salt fluid cost, insulation material cost, and concrete material cost. The cost of tank materials has become the most sensitive factor affecting the unit energy storage system cost of the system. Assuming that the cost of tank materials is reduced by 20%, the unit energy storage system cost of the system will be reduced by 7.1%. Due to the significant proportion of tank cost in the total cost of energy storage systems, using a single tank for energy storage can greatly save on tank related costs, thereby reducing the total cost of energy storage systems. Compared to traditional dual tank energy storage systems, single tank energy storage is an effective method to reduce energy storage costs.

Due to the use of phase change materials with higher energy density as energy storage media, the energy storage per unit volume of the system increases. However, the cost of high-temperature phase change materials is relatively high, and the increase in energy storage will also increase the system cost. The cost of phase change materials is the second most sensitive factor affecting the unit energy storage of the system. When the cost of phase change materials is reduced by 20%, the unit energy storage cost of the sensible latent heat combination system will be reduced by 5.5%. The cost of concrete is relatively low. Using a certain amount of concrete to replace some phase change materials may reduce energy storage, but it can also reduce system costs. The unit energy storage system cost of the sensible latent heat combined packed bed system is least sensitive to the impact of concrete cost. In the absence of significant impact on system energy storage and energy storage efficiency, concrete solid material is an optional filling material for phase change packed bed energy storage systems.