The coal mine power supply system plays a crucial and important role in coal mine safety production, and the reliability of the coal mine power supply system directly affects the normal and safe operation of coal mine electromechanical equipment. Once there is a problem with the power supply system, the ventilation system, drainage system, and other loads cannot operate, which may lead to accidents such as gas explosions and well flooding, causing major accidents that endanger public safety and causing serious social impacts.

Although the design specifications for coal mine power supply systems clearly require mines with large capacity Class I loads to use dual power supply, the commonly used dual power supply method in coal mine power supply systems cannot fully meet the strict requirements for safe production and reliable power supply. Therefore, adding an independent third power source – a large capacity emergency power source – has become an inevitable choice to improve the reliability of coal mine power supply and ensure coal mine safety production.

The large capacity emergency power supply system for coal mines based on energy storage batteries has great potential for demand and high technical barriers, making it a revolutionary technology for coal mine power supply and production safety. At present, domestic enterprises have passed inspection and testing, and the explosion-proof power supply systems that have obtained coal safety certification are all small energy storage systems, which are generally used in mining vehicles, monorail cranes, and other occasions. There is no relevant emergency energy storage power supply product for large capacity Class I loads such as ventilation systems.

1. Main technical requirements

The emergency energy storage power supply system for coal mine excavation working face is mainly used in the ventilation system of tunnels and working faces. In the event of a power outage of the main and backup power sources, the emergency energy storage power supply is activated to supply power to the ventilation fan. Require energy storage batteries to have high safety, explosion-proof performance, coal mine safety certification, and be able to continuously supply power to fans for more than 2 hours. The inverter system has high reliability and a switching time of less than 20 ms. The emergency energy storage power supply system has monitoring and alarm feedback functions for residual power, battery pack voltage, temperature, and other information, and can meet the overload current (maximum 3.5 times the rated current) for direct starting of ventilation fans.

The main technical requirements for the emergency energy storage power supply system are: rated voltage 660 V, rated power of the fan 2 × 30 kW, fan overload rate 100%, inverter rated power 110 kW, power outage switching time less than 20 ms, ambient temperature 0-40 ℃. The main reference standards and protocols include GB 3836-2010 Electrical Equipment for Explosive Gas Environments MT 209-1990 General Technical Requirements for Electrical and Electronic Products for Communication, Detection, and Control in Coal Mines MT/T 408-1995 DC Stabilized Power Supply for Coal Mines.

2. Overall System Plan

2.1 Basic structure and function

The emergency energy storage power supply system consists of energy storage battery packs, inverters, chargers, and control systems.

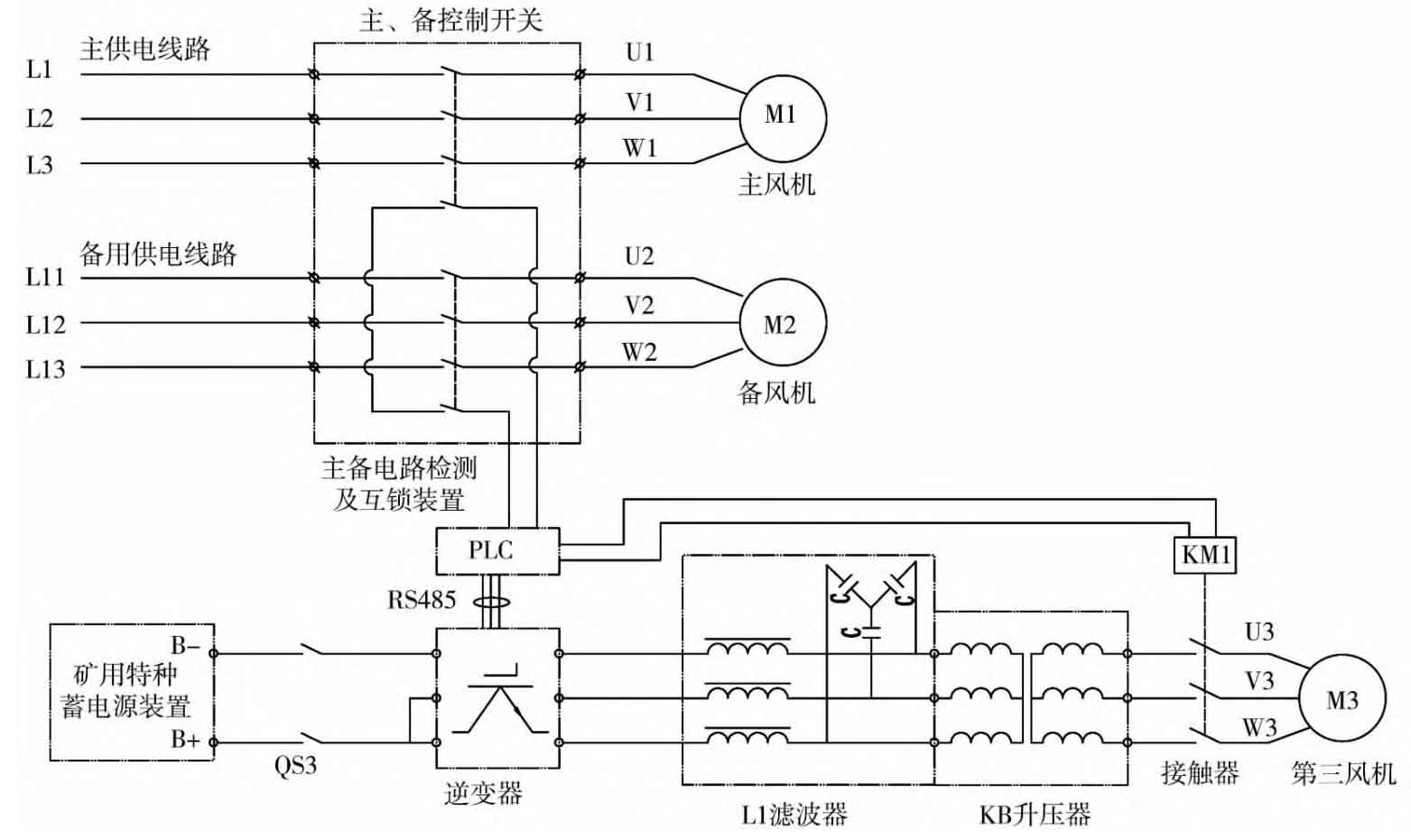

The emergency energy storage power supply system, in the hot standby state, can independently detect whether the dedicated power supply lines for the main and backup fans have abnormal power supply. The control point should be connected to the feeding switch point. When both the main and backup fans lose power, the inverter is triggered to start. After a delay of 10-20 seconds, power is output to the ventilation fan, and the third fan starts to operate; When either the main or backup fan circuit returns to normal power supply, the inverter shuts down and automatically enters standby mode. The emergency energy storage power supply system is equipped with a special power supply device, ensuring a storage capacity of 2 × The standby local ventilation fan with a load of 30 kW operates normally for about 2 hours.

2.2 System working principle

The energy storage unit adopts a special explosion-proof power supply device for coal mine lead-acid batteries, with an overall nominal voltage of 320 V and a rated capacity of 350 A · h. Using inverter technology, the DC power supply is converted into an AC 210V power supply through an IGBT module. High frequency harmonics are eliminated through a sine wave filter, and then a 660V power supply is provided to the fan through an isolated step-up transformer. The inverter is controlled by PLC and monitors the feeding switches of the main and backup fans. It has functions such as wind and electricity blocking, undervoltage protection, overvoltage, overcurrent, short circuit, and leakage blocking, achieving automatic switching of inverter start and stop. The working principle is shown in the figure.

3. Main research content

3.1 Battery Selection and Battery Grouping Technology Research

Compared with other forms of energy storage, battery energy storage has higher charging and discharging efficiency, lower operation and maintenance costs, and more mature technology. Therefore, battery energy storage is the preferred choice for large capacity emergency power sources. The working characteristics of emergency power storage batteries are that the system is in a “standby” state for a long time, with a large amount of batteries, fewer deep charging and discharging times, and extremely high requirements for reliability and safety.

In the selection of energy storage battery types, lead-acid batteries have good safety and low prices, but their float charging state has a short lifespan and poor long-term backup reliability. Additionally, due to the hydrogen and oxygen evolution problems of large capacity lead-acid batteries, they require ventilation and must be charged in dedicated coal mine tunnels. Lithium iron phosphate battery energy storage unit has a cycle life of over 2000 times, a charging and discharging rate of 3-5 C, a high specific power to energy ratio, and a volume weight of about 1/3 of lead-acid batteries. Float charging does not affect battery life, and long-term backup reliability is high. However, lithium iron phosphate batteries suffer from overheating, insulation failure, and combustion problems.

As an emergency power source for underground ventilation fans, the maximum output power of the battery pack should meet the instantaneous power demand when the fan starts. The total capacity design requirement is to provide continuous power for the ventilation fan for more than 2 hours to ensure the reliability and safety of the device’s operation. At the same time, considering the economy and feasibility of energy storage devices, it is necessary to design the capacity and charge discharge control measurement of the battery pack reasonably, and try to make it work in the ideal state of “shallow charging and shallow discharging” to extend the working life of the battery pack.

3.2 Design and research of battery management system

The battery management system can collect real-time battery information, including the total voltage of the battery pack, individual battery voltage, charging and discharging current, temperature and other parameters, measure and display the remaining power, and provide a data transmission interface to complete communication with some devices and upper computers on the CAN bus.

3.3 Research on inverter system design

An inverter unit is a device that converts direct current (battery) into sine wave alternating current, consisting of an inverter bridge, control logic, and filtering circuit. The IGBT module has the characteristics of high reliability, simple driving, easy protection, no buffering circuit, and high switching frequency. Adopting an online topology structure, the inverter is always running online and ready for use at any time, achieving a switching time of 10 ms.

The output end of the inverter is equipped with an isolation transformer, which makes the power frequency equipment have good resistance to load shocks; By redistributing the load of the transformer, the ability of the power supply to carry unbalanced loads is improved; Equipped with dedicated sine wave filters, it can effectively suppress harmonic pollution and improve power factor.

3.4 System reliability analysis and optimization research

Considering the particularity of the underground environment and the high reliability and safe operation requirements of equipment, reliability analysis and optimization design of the emergency power supply system are carried out. Based on the uncertainty transfer theory, the mechanical structure of the emergency power supply system is designed with high reliability. Multiple factors are coupled to analyze their uncertainty and reveal the transmission mechanism of uncertainty. In terms of optimal design of energy storage capacity, instantaneous power and capacity constraints are considered, combined with practical requirements such as reliability and economy, to carry out optimal design of battery pack configuration and capacity. Considering time-varying factors such as battery performance degradation in the emergency power supply system, combined with the characteristics of coexistence of subjective and objective information of equipment and multiple sources of information, a dynamic reliability analysis method for emergency power supply is constructed. Establish a reliability model for emergency power supply system under multiple fault modes, analyze and optimize its reliability design, and improve the reliability, safety, and stable operation of the system under probability constraints.

4. Conclusion

The application of emergency energy storage power supply system for coal mine excavation face ventilation provides a third local ventilation device for coal mine excavation working face, realizing automatic switching, ensuring the continuity of air supply, and avoiding gas exceeding limit accidents caused by power outage and wind stoppage. The first batch of products were applied in various working faces of Jizhong Energy Fengfeng Group’s Jiulong Mine, Yangdong Mine, Xintun Mine, Xin’an Mine and other mines, which is of great significance in preventing gas exceeding limits, reducing gas accidents, and improving coal mine production safety.