With the development of society and economy, there are more and more political conferences and large-scale activities. Given the increasing normalization of electricity protection work, uninterrupted power supply has become a basic requirement for electricity protection. In addition, power system failures are sudden, such as natural disasters, equipment accidents, equipment aging, and personnel operation errors.

Therefore, the research on mobile emergency power supply technology based on new energy energy storage and power supply is to use new energy emergency power supply vehicles in conjunction with diesel generator sets to provide power in the event of a power outage that cannot be restored in a short period of time. This can achieve seamless connection of zero switching time in power supply, thereby ensuring that the operating equipment is switched from mains power supply to emergency power supply, and ensuring uninterrupted operation of the equipment, Reduce the impact of power outages on production, daily life, or various activities to zero.

The operation of new energy emergency power supply vehicles in the field or without mains power input will consume the energy stored by the energy storage emergency power supply, reducing the emergency response capacity for sudden accidents. Therefore, it is urgent to develop a clean, renewable, and stable auxiliary power supply system.

1.Design of solar photovoltaic power supply system

The design of solar photovoltaic power supply systems is divided into software design and hardware design, and software design precedes hardware design. The software design includes: calculation of load electricity consumption, calculation of solar cell array radiation, calculation of solar cell and battery usage, optimization design of mutual matching between the two, calculation of solar cell array installation angle, prediction of system operation status, and analysis of system economic benefits. Hardware design includes: selection of load and necessary design, selection of solar cells and batteries, design of solar cell brackets, selection and design of inverters, selection and design of control and measurement systems. For large-scale solar cell power generation systems, there is also a need for square field design, lightning protection and grounding design, distribution system design, and selection and design of auxiliary or backup power sources. Software design, which involves complex radiation, installation inclination, and system optimization design calculations, is generally completed by computers; In cases where the requirements are not too strict, estimation methods can also be adopted.

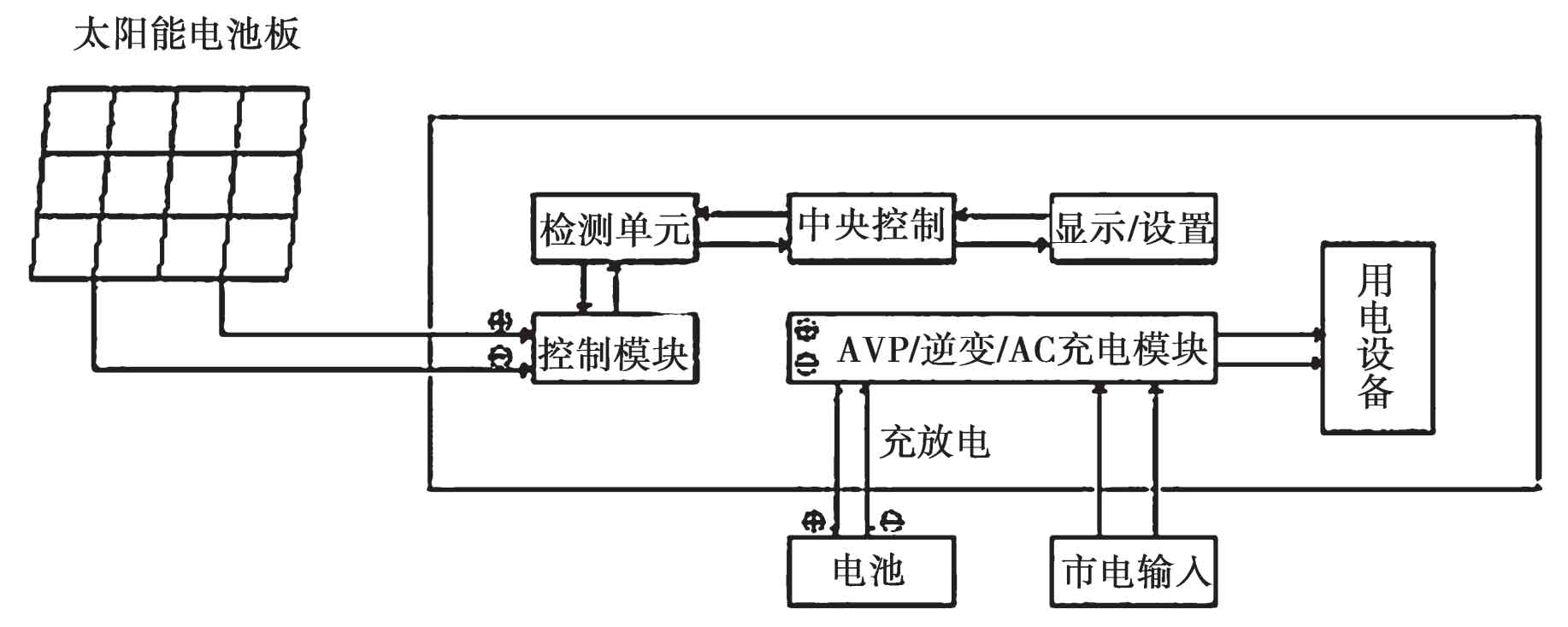

The solar panel power generation system is composed of solar panels, inverter controllers, batteries, etc. The system can set the charging mode according to the usage environment, complementary output of mains power priority or inverter priority mode, timed inverter mode and timed mains power mode, timed switch sleep mode, and other functions to provide power for equipment such as air conditioning, fans, lighting, cable reels, etc. in the vehicle compartment, as shown in Figure 1.

1.1 Selection of solar panels

1.1.1 Semi flexible solar panels

The semi flexible solar panel is shown in Figure 2.

The technical parameters of semi flexible solar panels are shown in Table 1.

| Indicators | Unit | Parameter |

| Peak power | Wp | 100 |

| Open circuit voltage (Voc) | V | 21.6 |

| Short circuit current (Isc) | A | 6.1 |

| Working voltage (Vmppt) | V | 18 |

| Working current (Imppt) | A | 5.7 |

| Dimensions | Mm | 1040×530 |

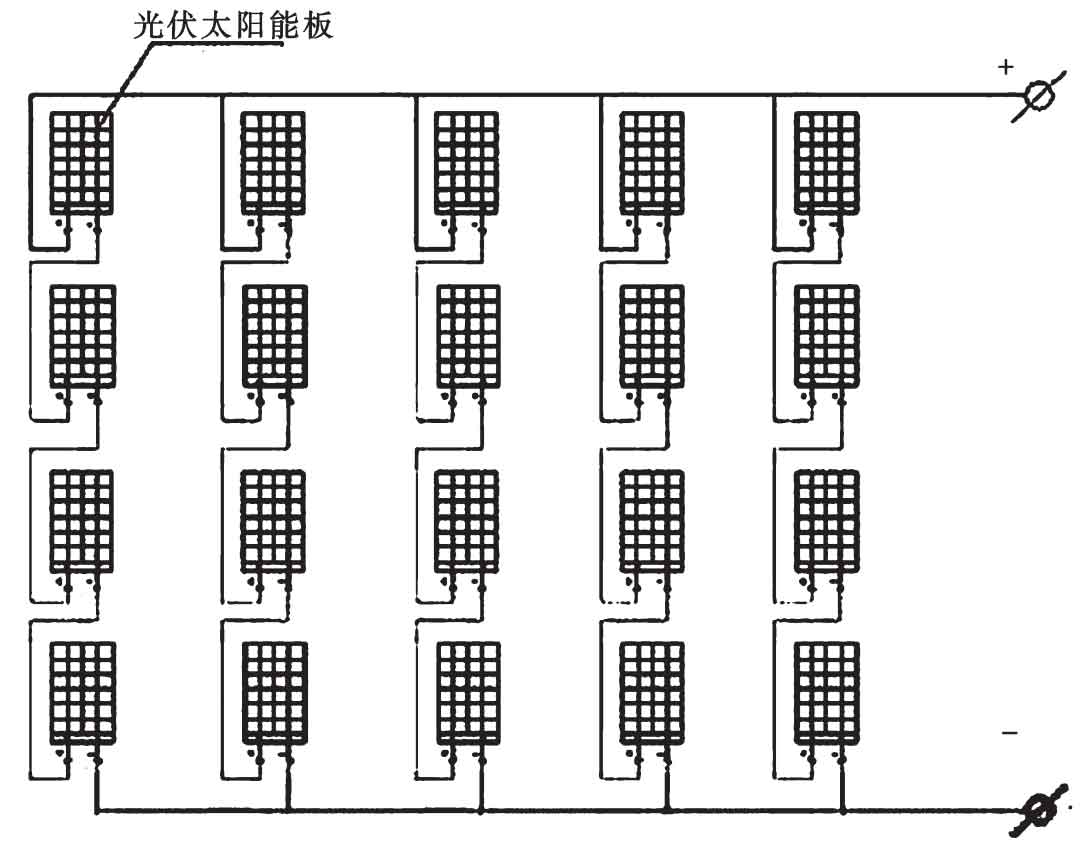

The roof of the carriage adopts 20 solar panels, which are composed of 4 series and 5 parallel solar panel components, as shown in Figure 3.

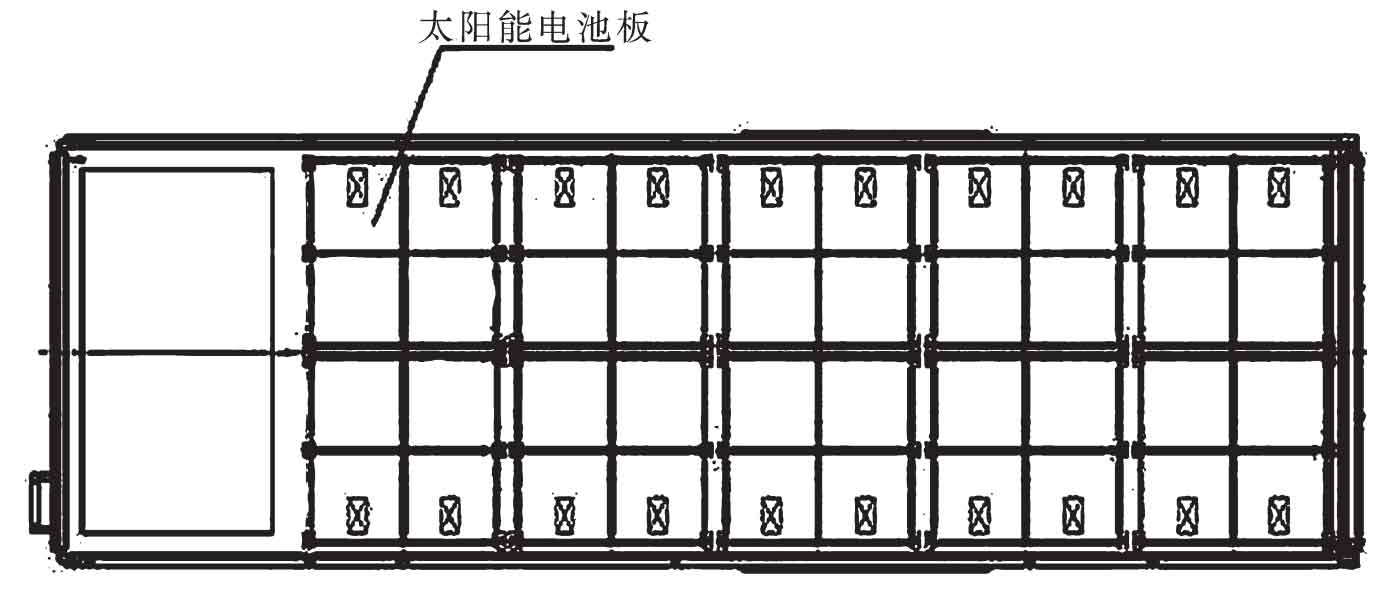

The distribution of solar panels on the roof of the carriage is shown in Figure 4.

Characteristics of solar panels: ① able to provide sufficient mechanical strength to withstand the stress generated by impacts, vibrations, etc. during driving, installation, and use of solar cell components, and to withstand the impact of hail; ② Has good sealing performance, can prevent wind, water, and isolate corrosion of solar cells under atmospheric conditions; ③ Having good electrical insulation performance; ④ Strong resistance to ultraviolet radiation; ⑤ The working voltage and output power are designed according to different requirements to meet different voltage, current, and power output requirements; ⑥ Low efficiency loss caused by series and parallel combination of solar panels; ⑦ The connection between solar panels is reliable.

1.1.2 Installation method of semi flexible solar panels

Step 1: Install the solar panel carriage ceiling bracket. According to the size of the solar panel, install a solar panel fixing bracket and substrate on the roof of the carriage.

Step 2: Paste. ① Use high-temperature resistant and strong adhesive 3M double-sided foam adhesive to stick to the back of the solar panel, and then stick it to the position to be installed on the top of the carriage Paste with special sealing silica gel for solar energy (high temperature resistance, aging resistance, and firm adhesion).

Step 3: Route the wires. Install solar panels on the roof of the carriage and connect them to each other, and introduce the bus into the car.

Step 4: Connect the electrical equipment. Connect the wiring of the electrical equipment to the load port on the inverter controller.

Step 5: Connect the battery. Connect the battery inside the carriage to the battery port on the inverter controller.

Step 6: Connect the inverter controller. Connect the positive and negative poles of the solar panel to the photovoltaic positive and negative ports of the inverter controller.

1.2 Selection of inverter controller

1.2.1 Composition of electrical load inside the carriage

Fan: 250W; Lighting: 40W; Reel motor: 1500W; Total maximum power: 1790W.

1.2.2 Selection of controllers

The function of the controller is to protect the charging and discharging of the battery and keep the solar panel in the optimal working state. The current specification of the controller (select a 40A controller) I>P negative/battery voltage/inverter efficiency=1790/48/0.9=41.4, and the output power of the inverter must be greater than the maximum power of the load (select an inverter with an output power of 5000W).

1.2.3 Selection of batteries

Calculation of daily electricity consumption of the load: The cable reel motor works for 0.2 hours, 0.2 × 1500=300Wh; Fan working for 8 hours, 8 × 250=2000Wh; Lighting work for 8 hours, 8 × 40=320Wh; A total of 2620Wh.

Select a standard 12V battery with a capacity of C=W (daily energy consumption)/(voltage × Battery discharge efficiency × Battery discharge depth)=2620/(12 × zero point nine × 0.8)=303.24Ah, combined with solar charging supplement, select a 200Ah/12V battery, consisting of 4 series connected battery packs.

1.2.4 Selection of solar panels

Query the local peak sunshine hours, calculate the sunshine hours in Guiyang City in China at 2.84, and the peak power of solar panels Wp=daily electricity consumption/(peak sunshine hours) × Charging utilization rate × Transmission loss rate × Storage discharge loss rate)=2620/(2.84 × zero point nine × zero point nine × 0.9)=1265W.

Therefore, the roof of the carriage adopts 20 solar panels, which are composed of 4 series and 5 parallel solar panel components, with a peak power of 2000W>1265W, meeting the requirements.

1.3 Functions of inverter controller

1.3.1 Charging function

There are two charging modes. ① PV charging, mains not charging: When both PV and mains are connected, only PV is charging when there is sunlight; ② PV and mains charging simultaneously: When both PV and mains are connected, AC is charging the battery, and if there is sunlight, PV is also charging.

1.3.2 City power complementary function

There are two complementary modes as follows.

AC First mains power priority, inverter backup UPS function mode: When both the battery and mains power are connected, priority is given to using mains power to supply the load. When the mains power is cut off, it automatically switches to battery inverter power supply. The steps are as follows: ① When there is mains power, it is directly output after AVR voltage stabilization and simultaneously charges the battery; ② After a sudden power outage, the system automatically switches to inverter power supply within 5ms to ensure uninterrupted output; ③ When the mains power is restored, the system automatically switches to mains power and charges the battery.

DC First inverter priority, mains backup UPS function mode: When both the battery and the mains are connected, the DC power of the battery is prioritized to be converted into AC power to supply the load. When the battery capacity is insufficient, it automatically switches to mains power supply. The steps are as follows: ① When the battery is charged, directly invert to supply power to the load; ② When the battery runs out of power, it automatically switches to mains power supply within 5ms; ③ After the battery is fully charged (such as solar or wind energy controllers charging the battery), it automatically switches to inverter power supply.

1.3.3 Timing function

Timing switch normal mode and sleep mode: You can set a specific time to turn on normal output, and set a specific time to turn off AC output and enter sleep mode. Switching mode between inverter and mains power: You can set a specific time to start using inverter output for power supply, and you can set a specific time to use mains power supply, suitable for segmented charging places.

1.3.4 Record Query Function

Fault mode query: can query product fault record information; Discharge time query: You can query the last time the battery was powered.

2. Conclusion

The application of solar panels for energy storage and power generation has a very leading approach and approach. Due to its close proximity to practical needs, the overall plan design is reasonable and can meet the needs of distribution network operations. Installing a solar auxiliary system on the energy storage emergency power supply can effectively ensure that its energy storage is not lost during field applications. The solar energy storage emergency power supply vehicle utilizes solar energy and colloidal batteries to achieve energy storage, and works with diesel generators to achieve zero switching time to ensure power supply. It has significant military significance for the maintenance of power supply for unmanned, non electric desert and island garrisons, and for consolidating national defense construction. It is also of great significance for energy conservation and emission reduction, and for promoting the innovative application of solar energy in automobiles and electrical equipment.