Solar photovoltaic power generation has significant energy and environmental benefits, and is one of the highest-quality green energy sources. It is a new energy source that the country vigorously promotes.Steel companies have a large number of factory buildings, and using their roofs to install photovoltaic power generation equipment can generate electricity that can be consumed locally by the enterprise, which plays a positive role in promoting energy conservation and emission reduction and achieving carbon neutrality.In recent years, Baowu Group Zhongnan Iron and Steel Guangdong Zhongnan Iron and Steel Co., Ltd. (hereinafter referred to as “Zhongnan Shares”) has used its own factory roofs to build a phase-I photovoltaic power generation project, which has achieved good energy conservation and environmental protection effects.

1. Photovoltaic power generation principle

Photovoltaic power generation refers to the power generation method that directly converts solar radiation into electrical energy. Photovoltaic power generation is the mainstream of solar power generation today, so now people often refer to solar power generation as photovoltaic power generation.

Photovoltaic cells are semiconductor devices with light and electricity conversion characteristics that directly convert solar radiation energy into direct current electricity. They are the most basic unit of photovoltaic power generation.The unique electrical characteristics of photovoltaic cells are achieved by doping certain elements (such as phosphorus or boron) into crystalline silicon, which creates a permanent imbalance in the molecular charge of the material, forming a semiconductor material with special electrical properties.Under sunlight illumination, free charges can be generated in semiconductors with special electrical properties. These free charges move and accumulate in a directional manner, generating electrical energy when they are closed at both ends. This phenomenon is known as the “photo-voltaic effect”, or simply the “photovoltaic effect”.

The photovoltaic power generation system consists of a photovoltaic array (made up of strings and parallel strings of photovoltaic modules), a controller, a battery pack, a DC/AC inverter, etc. The core component of the photovoltaic power generation system is the photovoltaic module, which is made up of strings and parallel strings of photovoltaic cells and encapsulated. It converts the solar energy directly into electrical energy.The photovoltaic module generates DC power, which can be directly used or converted into AC power by an inverter.In addition, energy storage devices such as batteries can be used to store electrical energy, which can be released at any time as needed.

2. Application condition analysis

Factories in the industrial sector usually have large roof areas, which are open and flat, making them suitable for installing photovoltaic arrays.At the same time, due to the high power load of factories, distributed photovoltaic grid-connected systems can locally consume the generated electricity, offsetting some of the electricity purchased online and saving electricity costs.An important factor affecting photovoltaic power generation is whether the local solar energy resources meet the requirements of new projects. The following is an analysis of the application resources of the solar energy project of Zhongnan Co., Ltd.

2.1 Solar energy resources in Shaoguan

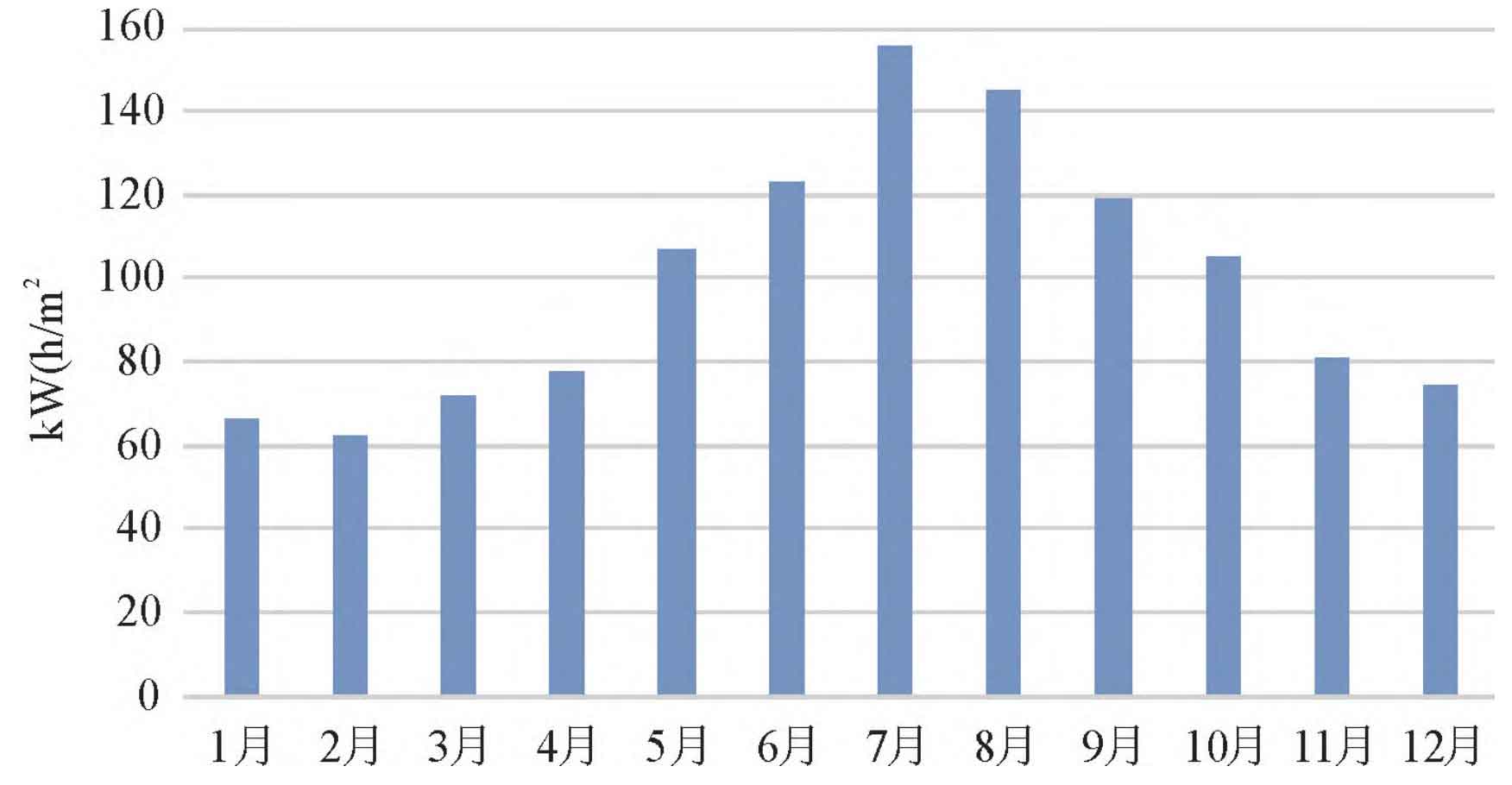

Zhongnan Co., Ltd. is located in Shaoguan City, Guangdong Province, in the northern part of Guangdong Province, bordering Hunan Province to the north, Jiangxi Province to the east, and Heyuan, Huizhou, Guangzhou, Qingyuan and other cities in Guangdong Province to the southeast, south and west.It is located between 23°53′N and 25°31′N and between 112°53′E and 114°45′E.Shaoguan City is located in the south of the Nanling Mountain Mountains. The terrain is mainly mountainous and hilly. Valley basins are distributed in Shaoguan City, with plains and platforms accounting for about 20% of the total area.Shaoguan belongs to the mid-subtropical humid monsoon climate zone, with a pleasant climate.The characteristics of the four seasons are continuous rainy days in spring, less precipitation in autumn, cold in winter, and hot in summer.The annual average temperature is 18.8 to 21.The average temperature in the coldest month (January) is 8-11℃, and the average temperature in the hottest month (July) is 28-29℃. The temperature increases from north to south in winter, and the temperature is similar in summer.The solar radiation with an average daily temperature above 10℃ accounts for 90% of the total annual radiation. The solar radiation in a recent year is shown in Table 1 and Figure 1.

| Month | Average temperature/℃ | Total horizontal irradiation kWh/m ^ 2/mth | Total horizontal irradiation MJ/m ^ 2/mth | Average wind speed/m · s ^ -1 |

| January | 10.4 | 66.27 | 238.57 | 3.1 |

| February | 13.4 | 62.27 | 224.17 | 3.1 |

| March | 16.4 | 72.27 | 260.17 | 3.3 |

| April | 21.1 | 77.27 | 278.17 | 3.2 |

| May | 25.2 | 107.27 | 386.17 | 3.2 |

| June | 27.4 | 123.27 | 443.77 | 3.1 |

| July | 29.2 | 155.27 | 558.97 | 3.0 |

| August | 28.7 | 145.27 | 522.97 | 3.4 |

| September | 26.5 | 119.27 | 429.37 | 3.3 |

| October | 22.8 | 105.27 | 378.97 | 2.9 |

| November | 16.9 | 81.27 | 292.57 | 2.7 |

| December | 12 | 74.27 | 267.37 | 2.9 |

| Annual | 20.8 | 1189.24 | 4281.26 | 3.1 |

From Figure 1, we can see the trend of total radiation change from month to month.It gradually increases from February, reaching the highest level (155.27 kWh/m2) in July, and slightly decreases in September and October, but still remains at a high level. The total radiation is most abundant from May to October, and then gradually decreases until February, when it reaches the lowest level of the year (62.27 kWh/m2).

According to the data of the annual radiation measured by NASA for many years, the total annual solar radiation at the location of the project is 4281.26MJ/m2.According to the “Solar Energy Resource Assessment Method” (QX/T89-2008), the solar energy resource abundance is evaluated based on the annual total solar radiation. After analysis, the annual sunshine duration is 1473-1925 hours.The solar energy resources in this area belong to the relatively abundant zone, and the solar radiation level is III, which is suitable for the construction of photovoltaic power generation projects.

2.2 Utilizable Resources of Roof Photovoltaic

After years of construction and development, Zhongnan has a large number of factories. After on-site research, it has selected the steel rolling area with better air environment and some office areas as the site for the photovoltaic power station.The resources available for this phase of the photovoltaic project include 415,600 square meters of color steel tile roofs and concrete roofs of the factories, of which the color steel tile roof area is about 402,700 square meters and the concrete roof area is about 12,900 square meters.

3. System design and selection

3.1 Overall System Structure

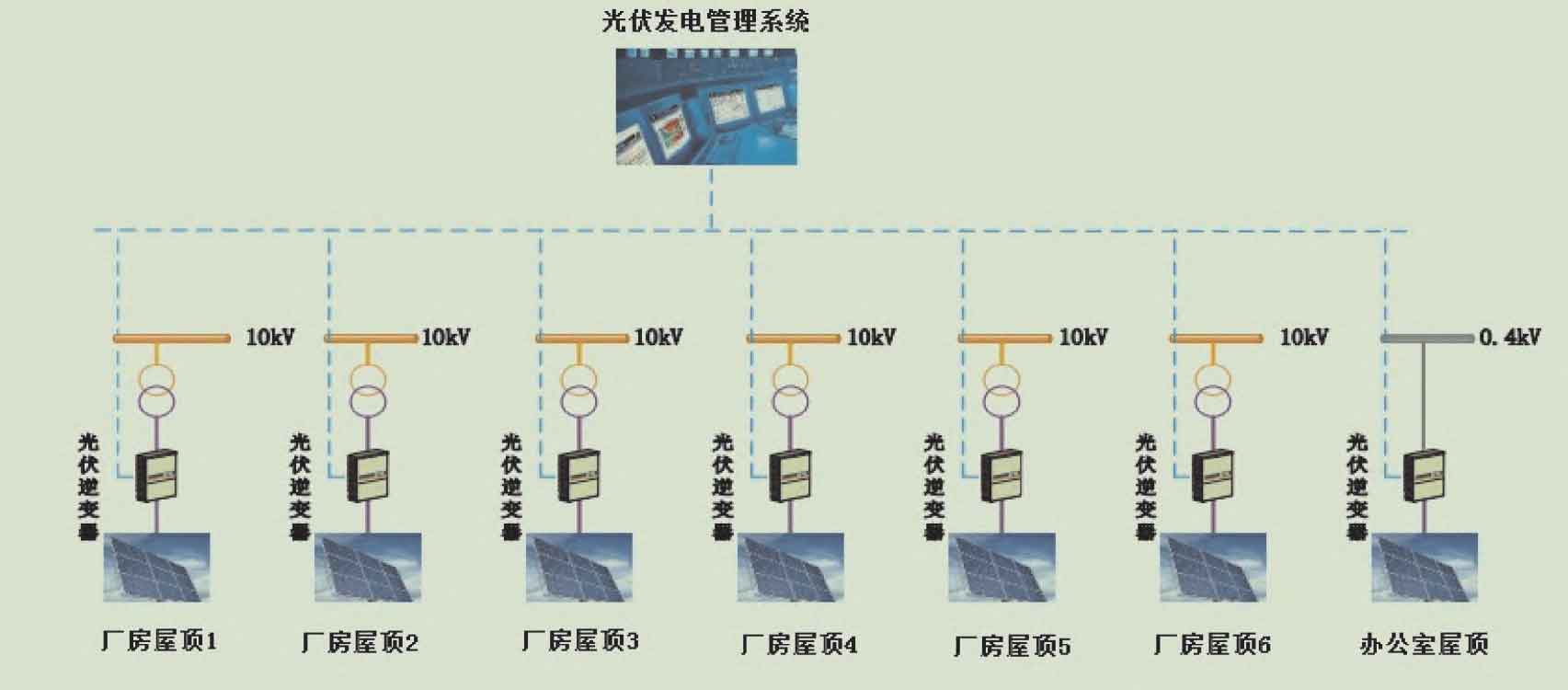

The roof photovoltaic power generation in this project is based on the principle of “self-generating and self-consuming, installing as much as possible”, maximizing the use of roof resources, and fully self-consuming.Using the roofs of six factory buildings in the steel rolling area to install photovoltaic power generation panels, setting up a 10 kV photovoltaic power distribution system on site, and connecting it to the corresponding 10 kV system;the remaining office 0.4 kV roof photovoltaic system is connected to the nearest 0.4 kV power distribution system. The system configuration is shown in Figure 2.

The total installed capacity of photovoltaic power generation in this project is about 25.68MWp, using high-efficiency monocrystalline silicon 455Wp photovoltaic modules, and adopting 225kW, 50kW, and 60kW string inverters, which are connected to the nearest 10kV or 0.4kV power distribution system in the plant.The buildings selected for the project are all already built, and the roofs are mainly made of color steel tile structure and concrete structure. In order to make full use of the roof resources, the color steel tile roofs are installed in a fixed and flat manner, while the concrete roofs are installed at the optimal inclination angle.

3.2 Selection of Photovoltaic Modules

The basic principle of selecting photovoltaic modules: On the premise of high product technology maturity and reliable operation, combined with the natural environment, construction conditions, and transportation conditions around the power station, the leading photovoltaic module types in the industry are selected.Then, based on the solar energy resources and the selected photovoltaic module types of the power station, the photovoltaic modules with the best comprehensive indicators are finally selected.

| Comparison item | Monocrystalline silicon | Polycrystalline silicon | Compare Results |

| Technical maturity | Mature technology and stable performance | Mature technology and stable performance | Both have mature technology and stable performance |

| Mechanical properties | Manufacturing process: The fragmentation rate of single crystal batteries is usually around 0.8%; Transportation process: Good resistance to damage, less prone to breakage and hidden cracks; Usage: Long term alternation of high and low temperatures may result in minimal cracking. | Manufacturing process: The fragmentation rate of polycrystalline batteries is generally greater than 2%; Transportation: Due to natural structural differences, the resistance to damage is not as good as that of single crystals; Usage: Long term alternating high and low temperatures may result in higher cracking rates than single crystals. | Single crystal is a complete lattice arrangement, while polycrystalline is a combination of multiple small single crystals. The maximum bending displacement of polycrystalline silicon is 1/4 lower than that of monocrystalline silicon, and the mechanical properties of single crystals are better, less prone to cracking, and better able to ensure output power. |

| Photoelectric conversion efficiency | 19%~21% | 16.5% to 18.6% | The conversion efficiency of single crystals is generally about 3% higher than that of polycrystals. |

| Maximum power of a single board | About 450W | About 400W | Due to the limitations of battery cell technology, the power per unit area of polycrystalline materials has reached the bottleneck, while the power of single crystals is significantly higher than that of polycrystalline materials, and there is still room for improvement. |

| 25a attenuation rate | 15.2% to 16.9% | 16.5% to 20.3% | The attenuation rate of single crystal at 25a is about 3% less than that of polycrystalline. |

| Temperature rise response | Single crystal battery materials have high purity, low internal resistance, and small temperature rise. | Polycrystalline materials have lower photoelectric conversion rates, converting more light energy into thermal energy rather than electrical energy. | At the highest light intensity, the working temperature of single crystals is 5% to 6% lower than that of polycrystals, resulting in lower power loss. |

| Weak light response | Under low light conditions, the efficiency of the battery decreases slightly. | The efficiency of the battery decreases under low light conditions. | Under low irradiance conditions, the efficiency attenuation of single crystal batteries is smaller than that of polycrystalline batteries, indicating that the weak light response of single crystal batteries is better than that of polycrystalline batteries. |

At present, the most commonly used solar cells at home and abroad are single crystal silicon and polycrystalline silicon solar cells, and the production of photovoltaic modules in China is also mainly based on single crystal silicon and polycrystalline silicon solar cells. The main technical indicators of single and polycrystalline modules are compared in Table 2.

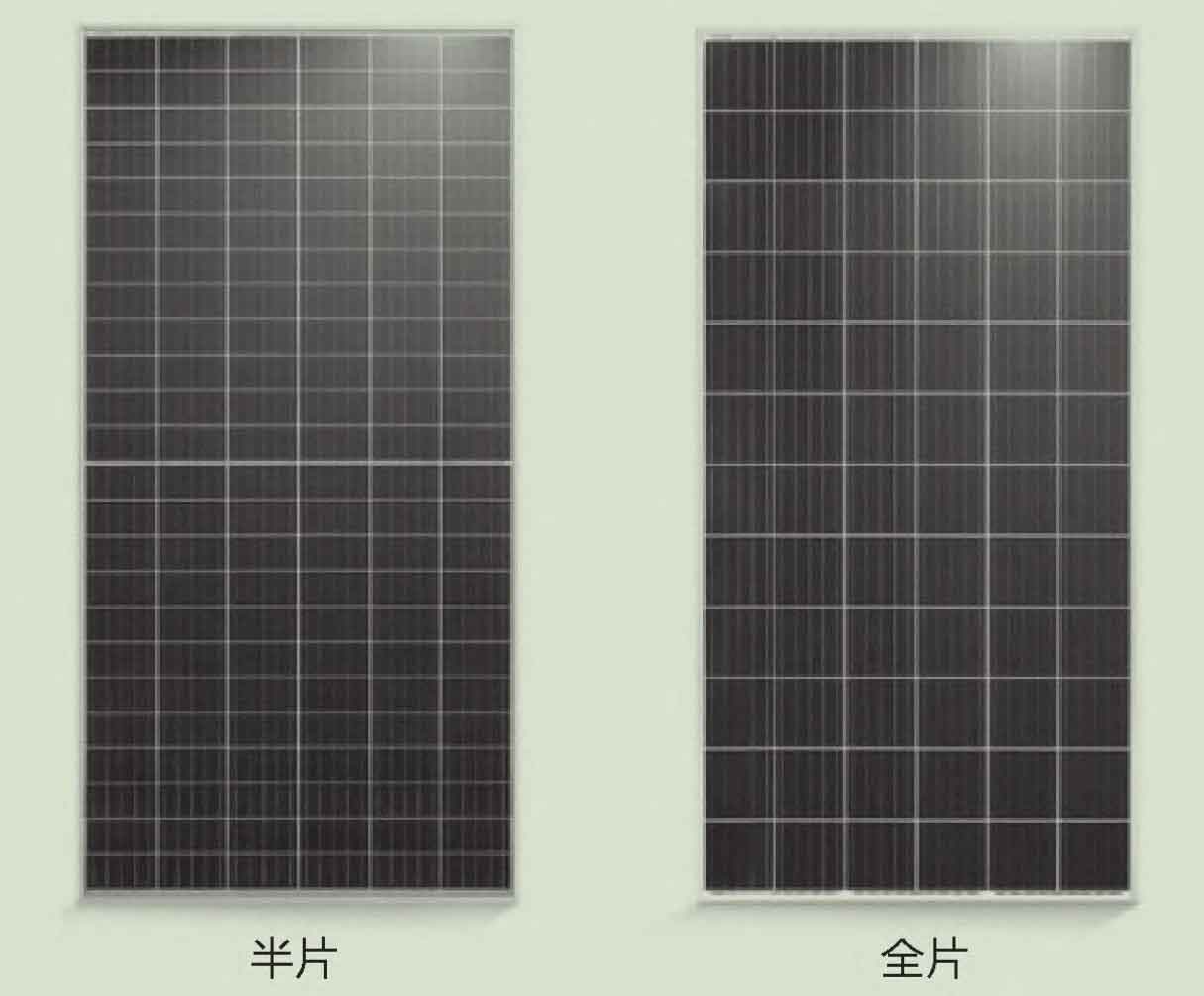

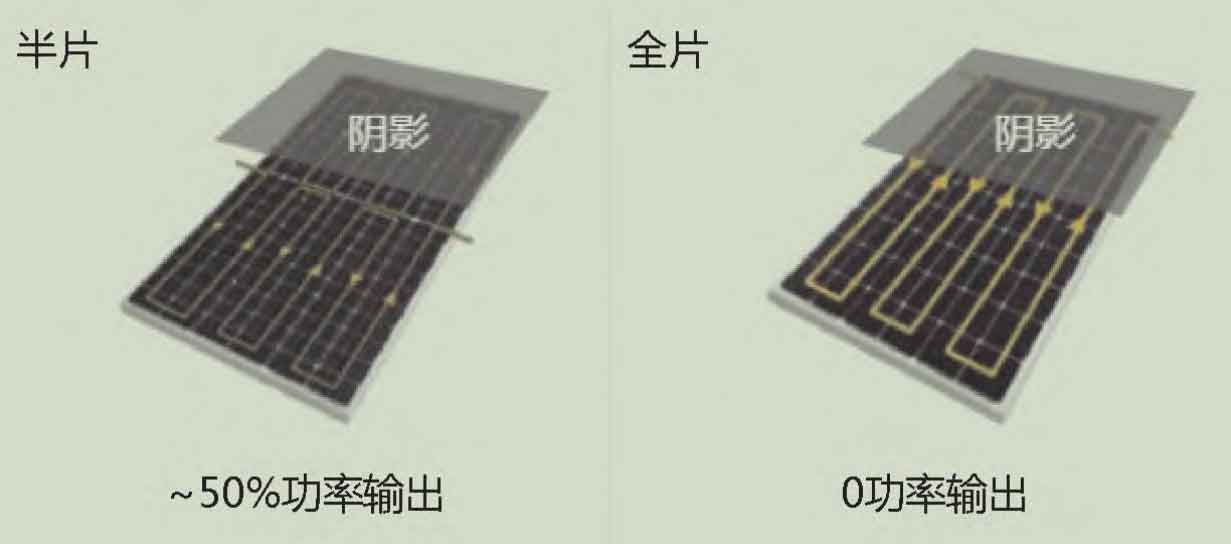

Considering the above factors, the project chooses single crystal silicon solar cells.Combined with the currently widely used high-power and high-efficiency components, the half-wafer technology is adopted, which has the advantages of improving the encapsulation power, reducing the hot spot, low operating temperature, reducing the loss of power generation when blocked, technical compatibility, strong scalability, and low cost. The cost performance is high.The comparison between half-wafer and full-wafer is shown in Figure 3 and Figure 4.

3.3 Selection of inverter

1) Classification of inverters

At present, there are mainly three inverter integration schemes for domestic photovoltaic power plants, namely centralized, string, and distributed.

Centralized means that each typical unit uses multiple DC combiner boxes to group DC power, which are then connected to large grid-connected inverters within the unit. The power is inverted into AC and input into a local booster box for boosting.However, the use of large-capacity centralized inverters within the unit results in a small number of MPPT (maximum power point tracking controllers).When factors such as different roof orientations and component efficiency degradation cause significant differences in photovoltaic module output, it will affect the overall power generation efficiency.The number of MPT tracking paths per photovoltaic unit in string inverters is much larger than that in centralized inverter solutions, making it particularly suitable for roof-mounted distributed photovoltaic and complex scenario photovoltaic projects.Moreover, string inverters are small in size, do not require specialized lifting tools for rapid installation, and can be directly fixed on photovoltaic module supports, eliminating the need for site selection and infrastructure work for centralized inverter boxes, reducing construction difficulty and ensuring construction progress.

Distributed inverters belong to a new technology genre, with the main feature of pre-installing MPPTs in the combiner box and adding MPPT functionality to the combiner box. It has the characteristics of both centralized power inverters and distributed MPPTs in series.Due to the increase in DC and AC voltage on the inverter side, the transmission loss of the line is reduced accordingly.The number of MPPT tracking paths per photovoltaic unit is also much larger than that of centralized inverter solutions, which can effectively increase the power generation of such photovoltaic projects in roof-top distributed photovoltaic and complex scene photovoltaic projects.However, distributed inverters are relatively expensive compared to centralized inverters, which will increase the investment in the construction of photovoltaic power plants.

2) Selection of inverter

String inverters and centralized inverters have their own advantages and disadvantages in technology, with string inverters being more widely used in distributed power stations;centralized inverters are more commonly used in large ground-based power stations or compactly distributed distributed power stations.Considering the characteristics of the project’s scattered plant buildings, long roofs, and the arrangement of roof lighting strips and ventilation towers, the plant roof will use 225 kW string inverters;the concrete roof has a small installed capacity of photovoltaic power, so 50 kW and 60 kW string inverters will be used.

3.4 Design of component series and parallel connection

Design principle of component series and parallel connection:

1) The open circuit voltage of the string should be less than the maximum system voltage of the components and less than the maximum DC input voltage of the inverter;

2) The minimum operating voltage of the string should be greater than the minimum DC input voltage of the inverter and less than the upper limit of the inverter’s MPPT voltage range;

3) When the system is started, the minimum operating voltage of the string should be greater than the starting voltage of the inverter. The light intensity requirement at startup should be as low as possible, and the operating temperature requirement should be as high as possible.

According to the Design Code for Photovoltaic Power Station (GB 50797-2012), the electrical performance parameters of each photovoltaic module in the same string of photovoltaic modules should be consistent. After calculation, the optimal working voltage after connecting 28 modules in series is close to the rated input voltage of the inverter, at which the inverter efficiency is the highest. Therefore, it is determined that the number of series-connected 455Wp single crystal silicon photovoltaic modules is 28, that is, each string consists of 28 photovoltaic modules.

4. Project operation situation

4.1 Electricity Generation

After the project is put into operation, it can generate an average of about 21 million kWh per year, which not only reduces the company’s outsourcing power consumption, but also fulfills the national task of consuming green power. The scene after the project is completed is shown in Figure 5.

4.2 Economic Benefits

The economic benefits mainly consist of power generation benefits and carbon reduction benefits, which are roughly calculated as follows.

1) Power generation benefit

Power generation benefit = power generation capacity × electricity price = 21 million kWh/a × 0.58 yuan/kWh = 12.18 million yuan/a

2) Reducing carbon emissions and reducing the benefits of outsourcing carbon

Carbon reduction of the project = external power generation × power emission factor = 21 million kWh/a × 6.379 tCO2/million kWh = 13,396 tCO2/a

Reducing the benefit of outsourcing carbon = the amount of carbon reduction in the project × the price of carbon trading = 133.96 million tCO2/a × 80 yuan/t = 1.07168 million yuan/a

4.3 Existing Problems

Due to the construction of the project in a steel enterprise, the air cleanliness is worse than that in cities or villages, and the phenomenon of dust accumulation on photovoltaic panels is common. The serious situation of dust accumulation is shown in Figure 6, which will have a negative impact on the power generation.Therefore, it is necessary to arrange maintenance personnel to regularly clean the photovoltaic panels to maintain the project’s power generation at a good level.

5. Conclusion

Carbon neutrality is a goal that our country needs to achieve in the future. Photovoltaic power generation itself does not consume fuel, does not emit any substances including greenhouse gases and other exhaust gases, does not pollute the air, and does not produce noise. Therefore, photovoltaic power generation will gradually become one of the main power generation subjects.According to statistics, installing a 1 kW photovoltaic power generation system under average sunlight conditions in China can generate 1200 kWh of electricity, reduce the use of coal (standard coal) by about 400 kg, and reduce carbon dioxide emissions by about 1 t. Photovoltaic power generation will be an important means for China to achieve carbon neutrality.Iron and steel enterprises have a large number of industrial plants. If they use their roofs to build photovoltaic power generation systems, they can not only reduce the amount of electricity purchased by the enterprise, but also contribute to the realization of carbon neutrality for the country and the enterprise. It is a technology worthy of vigorous promotion and application.