The optimal configuration of energy storage capacity is generally based on comprehensive consideration of factors such as energy storage system costs, high and low power conversion costs, civil construction costs, operation and maintenance costs, and types of power station batteries, with the aim of improving system operation stability, safety, and economy, in order to seek the optimal energy storage capacity configuration plan. If the configuration capacity of energy storage equipment is too large, it will cause some batteries to be idle and wasted, which is not conducive to economic efficiency; If the capacity of energy storage configuration is too small, it will pose a hidden danger to the stability and safety of system operation. Therefore, a reasonable configuration of energy storage capacity needs to meet the following requirements:

1) On the basis of completing tasks such as peak shaving and frequency regulation of energy storage power stations, meet the requirements of power grid dispatching and operation.

2) The configured capacity should meet the economic needs of the power grid as much as possible, ensuring that the optimization operation task of the power grid is completed at a lower cost.

1. Full life cycle cost of energy storage power plants

The full lifecycle cost of energy storage power plants can be divided into installation cost and operation cost. Among them, installation cost refers to the various investment costs required for building energy storage stations; Operating costs refer to the costs incurred during the daily operation of energy storage power plants, including operating and maintenance costs, residual value of power plants, and additional costs.

(1) Cost of energy storage system

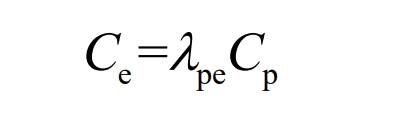

The cost of energy storage systems consists of material costs and battery manufacturing costs. Due to the energy and power characteristics of energy storage systems, the energy cost Ce (ten thousand yuan/(MWh)) and the power cost Cp (ten thousand yuan/(MWh)) of energy storage systems are used to evaluate the cost of energy storage systems in different scenarios.

| Type of energy storage | Energy type | System energy cost Ce | System power cost Cp |

| Pumped storage energy | Capacity type | 120-170 | 550-700 |

| All vanadium flow battery | Capacity type | 350-420 | 800-1500 |

| Lithium iron phosphate battery | Energy type | 150~230 | 180~300 |

| Lithium titanate battery | Energy type | 200-240 | 400-600 |

| Supercapacitor | Power type | 60000~80000 | 1000~1500 |

Table 1 shows the system energy costs and system power costs of several typical energy storage technologies, among which pumped storage power plants, lead-acid batteries, and lithium iron phosphate batteries are relatively mature types of energy storage technologies that can already be commercialized. Based on various research data, it can be concluded that the investment cost of pumped storage power plants in the current period is 6 to 6.4 billion yuan/GW. Secondly, the system energy cost of pumped storage power plants is about 1.2 to 1.7 million yuan/MWh, and the system power cost of pumped storage power plants is about 5.5 to 7 million yuan/MWh. However, due to the high site selection requirements of pumped storage power plants, the system cost of future pumped storage power plants will rise to a certain extent. Due to its short cycle life and increased environmental requirements and recycling control pressure, lead-acid batteries have little room for future cost reduction and are difficult to achieve higher profits. As the lithium iron phosphate battery with the most commercial application scenarios at present, its system energy cost is 1.5~2.3 million yuan/MWh, and the system power cost is 1.8~3 million yuan/MWh. With the development of technology and innovation in low-cost battery structures, there is still room for further cost reduction in the future. Supercapacitors belong to power based energy storage technology systems with a duration ranging from seconds to minutes. If the energy storage time is to be no less than 15 minutes, the system power cost will need 10 to 15 million yuan/MWh, which is relatively high. Lithium titanate batteries, as a relatively mature and typical power type energy storage technology, currently have a system power cost of approximately 2-3 million yuan/MWh. In the future, with the advancement of battery material technology, there is some room for cost reduction.

(2) Power conversion cost

The cost of power conversion is specifically expressed as the ratio of rated energy storage power to rated capacity. At present, the cost of power converters for most electrochemical energy storage systems is approximately 500000 to 800000 yuan/MWh.

In the equation, λ PE is the rated power of energy storage divided by the rated capacity of energy storage, Ce and Cp are the system energy cost (10000 yuan/MWh) and the system power cost (10000 yuan/MWh) respectively.

(3) Construction cost

The construction cost of energy storage power stations includes the construction, design and planning costs of energy storage stations, which are approximately 3% to 10% of the cost of energy storage systems. The mathematical expression for this is as follows:

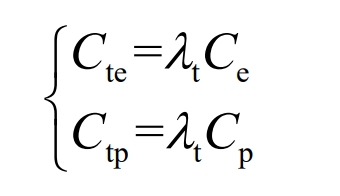

In the formula, Cte and Ctp respectively represent the construction costs of energy storage capacity and energy storage power system scenarios; λ T represents the ratio of energy storage construction cost to energy storage system cost.

(4) Operation and maintenance costs

The operation and maintenance cost of energy storage power stations refers to the fuel cost, equipment maintenance and upkeep cost, component replacement cost, labor cost, and depreciation cost of scrapped components invested in daily operation after the construction of the energy storage station is completed and put into operation. According to research, pumped storage power plants have the highest operating and maintenance costs compared to other electrochemical energy storage technologies, with an average annual operating and maintenance cost of approximately 70 to 80 million yuan/GW. Capacity based energy storage power stations and energy based energy storage power stations, due to their relative safety and stability, generally adopt remote monitoring and regular inspections for maintenance and repair; Due to its short charging and discharging time, high power, relatively complex operating conditions, and linkage with thermal power plants, power type battery energy storage power stations generally arrange personnel to be on duty 24 hours a day. In power type energy storage technology, employee salary income accounts for a large proportion of operation and maintenance costs. The replacement cycle of liquid flow batteries is around 3-6 years, while other types of energy storage power stations replace a small amount of batteries annually or utilize new and old batteries in a cascade manner. In addition, due to the temperature and environmental requirements during the operation of electrochemical energy storage stations, it is necessary to replace the components of the air conditioning and constant temperature system every three years, such as the replacement of fan blades and dust removal filter screens. Overall, the operation and maintenance cost accounts for approximately 1% to 10% of the system cost, which is related to the type of battery. The expression is:

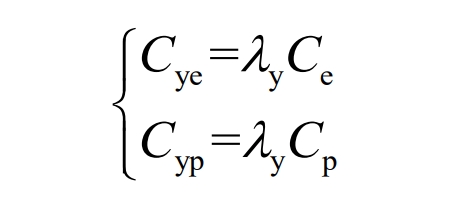

In the formula, Cte and Ctp respectively represent the construction costs of energy storage capacity and energy storage power system scenarios; λ T represents the ratio of energy storage construction cost to energy storage system cost.

(5) Residual value of power station

The residual value of an electrochemical energy storage power station refers to the remaining value after deducting the processing cost after the service life of the station has passed. At present, it seems that the recycling value of lead-acid batteries and all vanadium flow batteries is relatively high, accounting for about 20% to 40% of the system cost. In the battery pack of ternary lithium batteries, the electrode material contains metal elements such as cobalt and nickel, which is relatively expensive and has a recycling value of about 10% to 18%. However, lithium iron phosphate batteries have low recycling value due to the absence of precious metals in the material.

In addition, after the end of the service life of the electrochemical energy storage station, the battery components are scrapped due to their low lifespan, but their power conversion devices still have utilization value. Therefore, the residual value of the energy storage station is between 3% and 40%, which depends on the type of energy storage technology.

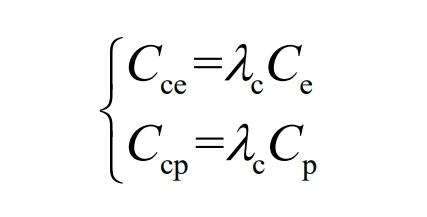

In the formula, Cce and Ccp respectively represent the residual values of capacity based energy storage stations and power based energy storage stations, λ C represents the ratio of residual value of energy storage power plants to the cost of energy storage systems.

(6) Additional costs

The additional cost of energy storage power stations refers to other costs in addition to the aforementioned costs. This includes additional fees such as bank loan interest, document processing fees, admission testing fees, and various project management fees. At present, there is a lack of standardized and standardized unified evaluation standards for this cost. Through research and data calculation, the ratio of additional cost to energy storage system cost is about 10% to 20%. In the future, as energy storage power station projects gradually become standardized and standardized, with unified evaluation indicators, this cost will be significantly reduced.

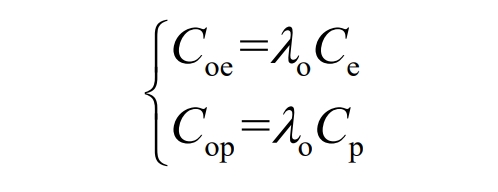

In the formula, Coe and Cop represent the additional costs of capacity based energy storage stations and power based energy storage stations, respectively, λ O represents the ratio of the additional cost of energy storage power plants to the cost of energy storage systems.

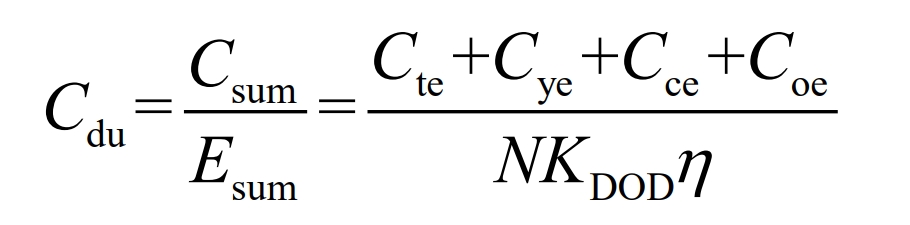

2.Energy storage system kWh cost

The cost of electricity per kilowatt hour, also known as Levelized Cost of Energy (LCOE), is the energy storage cost calculated by equalizing the cost of energy storage stations throughout their entire lifecycle with their total electricity generation. The calculation method is the total investment in energy storage power plants/the total power generation of energy storage power plants. The calculation of kilowatt hour electricity cost has important guiding significance for the allocation of energy storage capacity and the economic evaluation of energy storage technology. The calculation expression is as follows:

In the formula, Cdu is the cost of kilowatt hours of electricity; Csum is the total cost of the energy storage system; Esum is the total power generation throughout the entire life cycle of the energy storage plant; N is the cyclic service life (years); KDOD is the discharge depth (%); η Is the system energy efficiency (%); Å represents the battery capacity retention rate when the energy storage system is retired.

The calculation parameters and cost of several types of energy storage technologies are shown in Table 1.

| Type | KDOD (%) | η (%) | ε (%) | N/time | Kilowatt hour cost |

| Pumped storage | 100 | 76 | 1 | 16000 | 0.21~0.25 |

| Lead acid battery | 70 | 80 | 70 | 2500~3500 | 0.61~0.82 |

| Lithium iron phosphate | 90 | 88 | 70 | 3500~5000 | 0.62~0.82 |

| Full vanadium liquid flow | 90 | 72 | 70 | 6000~8000 | 0.71~0.96 |

| Lithium ternary | 90 | 90 | 70 | 3000~3700 | 0.88~1.26 |

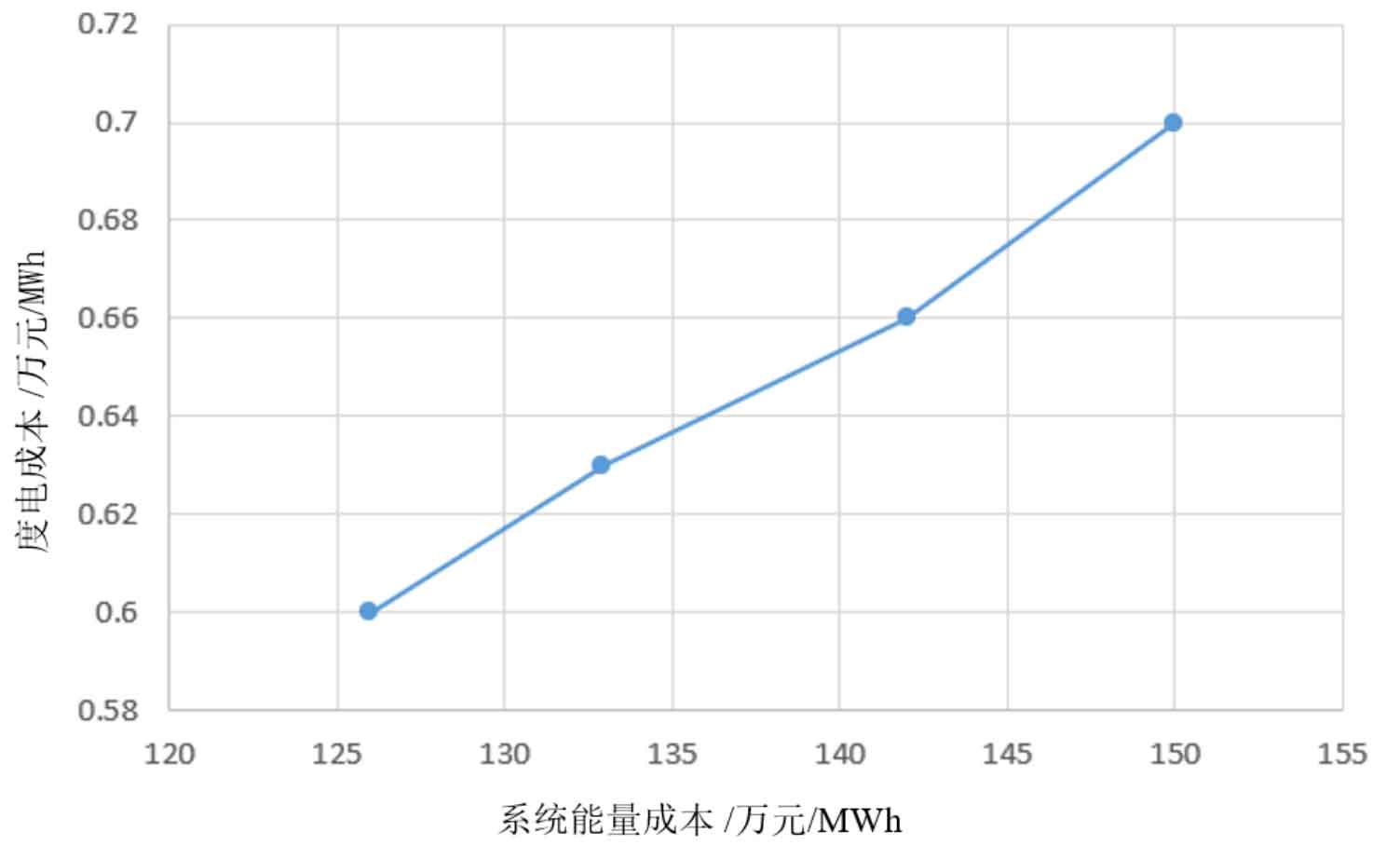

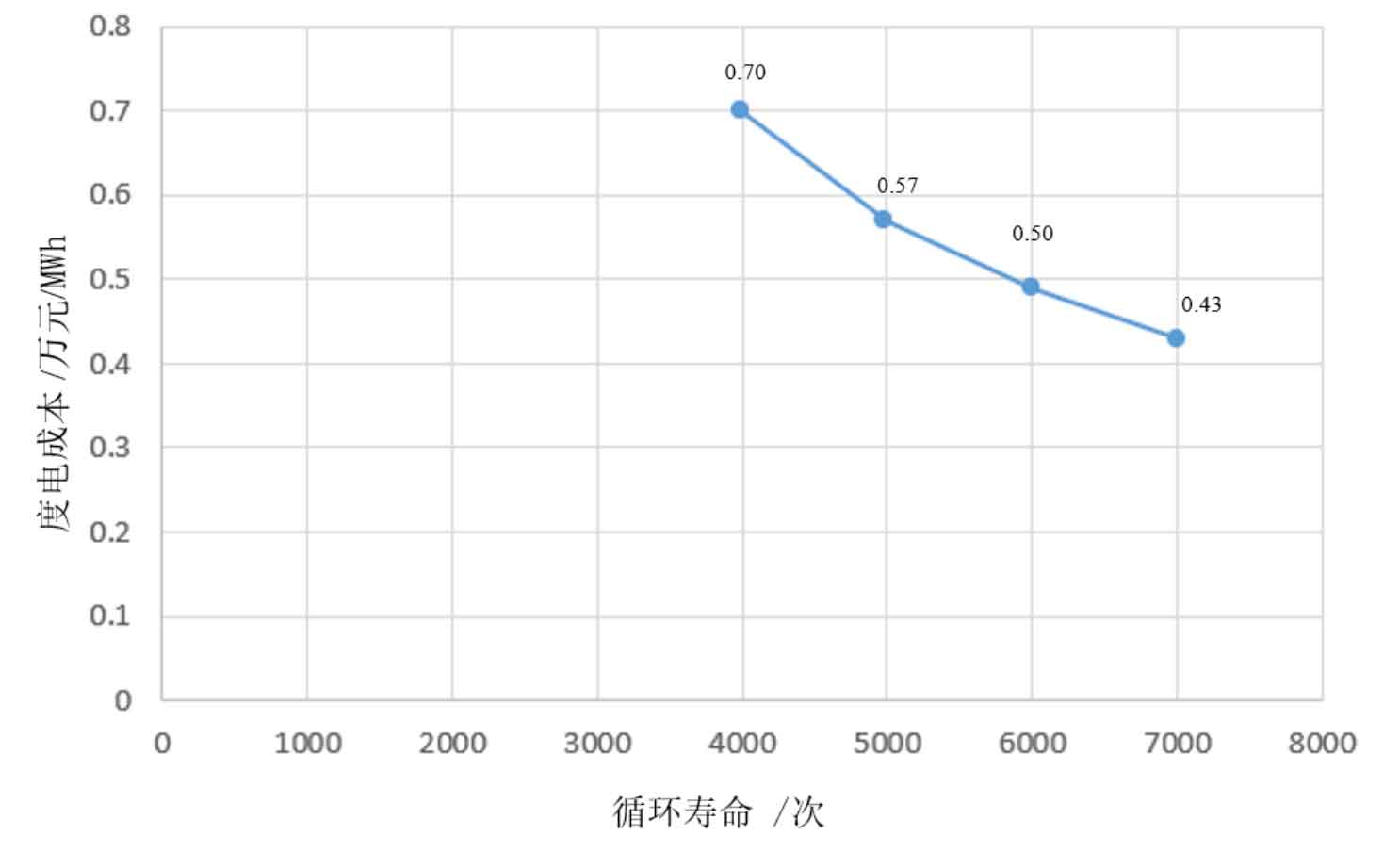

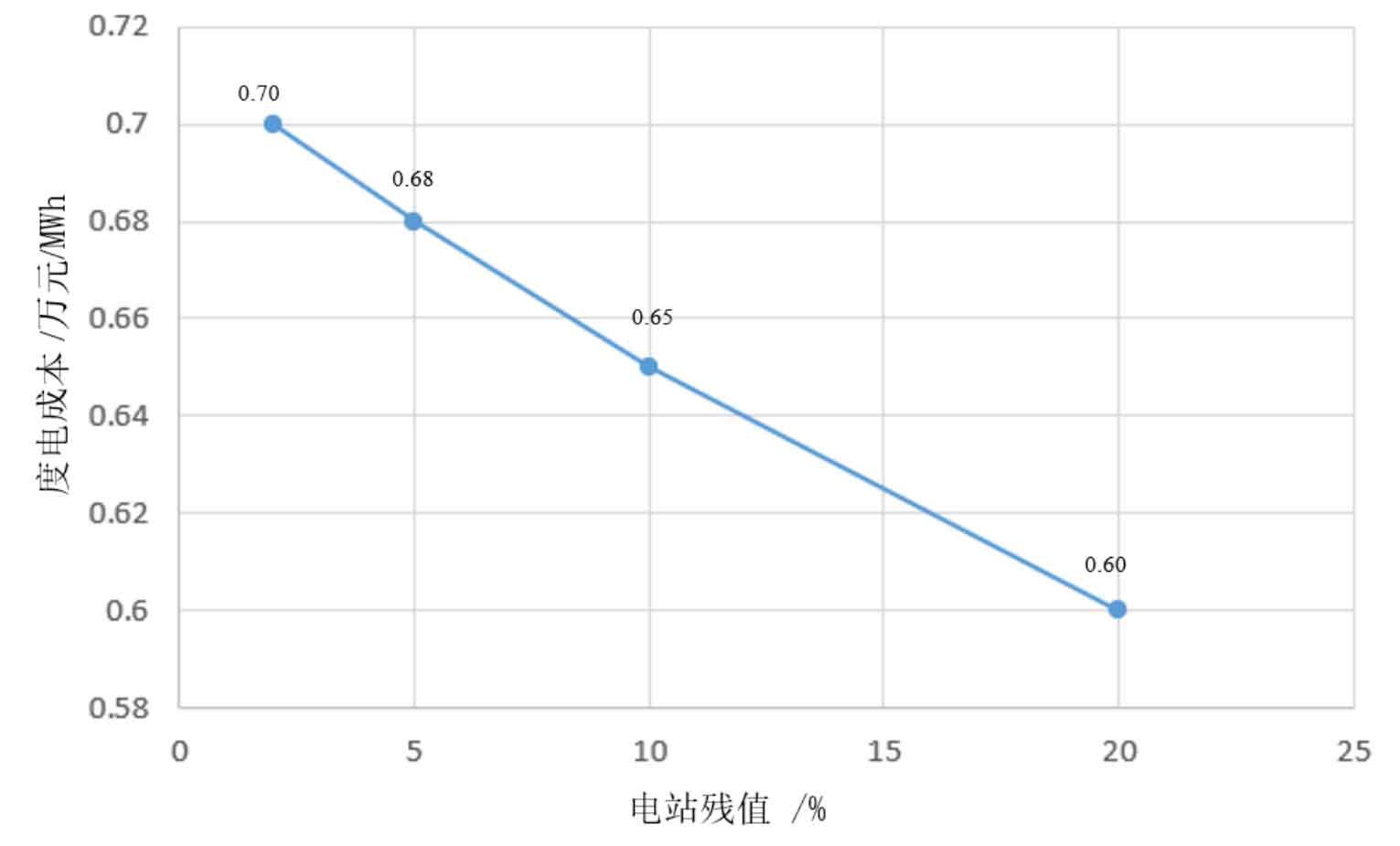

Taking the lithium iron phosphate battery energy storage station as an example, in order to calculate the system’s electricity cost, it is first necessary to analyze the system’s energy cost, battery cycle life, and residual value of the lithium iron phosphate energy storage station. The results are shown in Figure 1 below. It can be seen that the energy cost of the system is positively proportional to the cost of electricity per kilowatt hour, which is similar to a linear increase; The cycle life of batteries and the residual value of energy storage stations are approximately linearly inversely proportional to the cost of kWh. If the process can be further improved, battery materials or structures can be improved, material costs can be reduced by 10%, residual value of energy storage power stations can be increased by 20%, and lithium iron phosphate batteries can be cycled and discharged 7000 times when their lifespan drops to 70%, the cost of electricity consumption of energy storage power stations can be reduced to 0.3/kWh yuan, which can meet the requirements for commercial profitability of large-scale capacity type energy storage power stations.

3. Analysis of photovoltaic energy storage station capacity configuration

The two sections analyze the composition and cost of the entire life cycle of energy storage stations, and calculate the final cost of energy storage. Based on the cost data obtained in the first two sections, this section analyzes the economic optimization of energy storage capacity configuration.

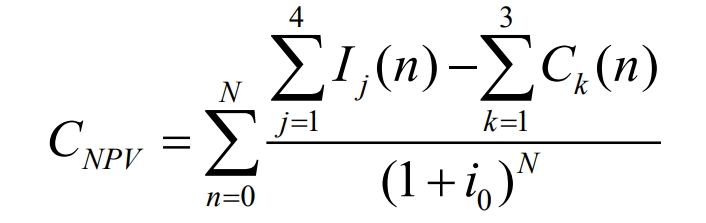

3.1 Objective function

The capacity optimization configuration of the energy storage system used to improve the consumption of new energy in the power grid, taking into account the various costs and annual benefits of the lithium iron phosphate battery energy storage station, is established with the goal of maximizing the annual net income of the energy storage system. The mathematical model of net income is as follows

In the formula, Ij (n) represents the jth revenue of the system in the nth year, including the revenue from the charging and discharging operation of electrochemical energy storage stations, the revenue from peak valley electricity prices, subsidies for new energy generation grid connection policies, and the revenue from equipment slowdown and expansion. Ck (n) is the k-th cost of the system in the nth year, including the investment cost of photovoltaic arrays and electrochemical energy storage stations, the operation and maintenance cost of the system, and the replacement cost of retired energy storage batteries.

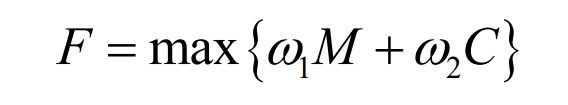

When studying the optimization of capacity configuration for photovoltaic energy storage systems, the optimization objective is to minimize the amount of discarded light from photovoltaic power plants, and the optimization objective is to optimize the overall economic efficiency. The multi-objective optimization of the two is carried out, and the objective function can be expressed as:

Among them, M represents the amount of light discarded by the photovoltaic power plant, and C represents the comprehensive economic data of the optical storage system, ω 1 ω 2 is the weight coefficient.

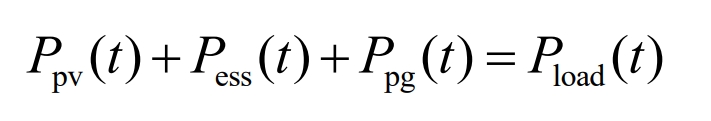

3.2 Constraint function

1) Load demand constraints

The original load demand, composite load demand, and exchange power between the system and the power grid in the photovoltaic energy storage system need to meet the load power demand, with the following constraints:

In the formula, Pload (t) is the original load power demand; Pload (t) is the synthesized load after action; Ppg (t) is the exchange power between the system and the power grid.

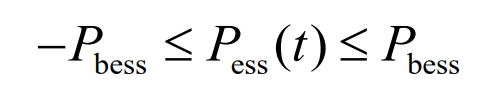

2) Energy storage system constraints

The charging and discharging power of the energy storage system, Pess (t), does not exceed the power limit value, Pbess:

In order to maintain the health of energy storage batteries and reduce their overcharging and discharging, it is necessary to constrain the SOC of energy storage equipment.

In the above equation, the state of charge of the energy storage system is constrained. Generally speaking, the SOC constraint range is between [0.2 ± 0.5~0.8 ± 0.5]. The purpose of SOC constraint is to ensure that the overcharging and discharging time is reduced during the operation of the energy storage system, thereby maximizing the battery life.

3.3 Improving Particle Swarm Optimization Algorithm

Particle Swarm Optimization (PSO) is a computer intelligence algorithm that can solve multi-objective optimization problems. Its basic principle, just like its name, is that the origin of PSO is based on the behavior of bird flocks to prey. The most common strategy is for a group of birds to prey towards the nearest target they see. In PSO, the number of bird flocks is the number of particles n. The disadvantage of this algorithm is also similar to the bird swarm hunting scenario, where each particle searches for the optimal solution, and the final result may not be a global optimal solution but a local optimal solution.

The multi-objective optimization in this article is aimed at two objective functions, with the abandonment of solar energy and annual revenue of the photovoltaic storage system as the two objective functions, and the rated active power and rated capacity of the energy storage as variables.

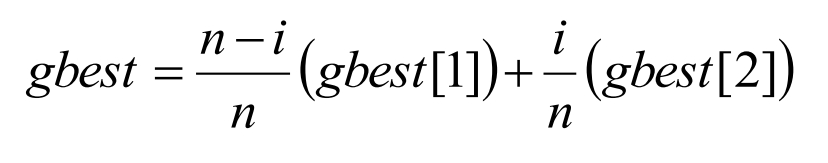

Based on the algorithm, evaluate and select the optimal solutions of the two groups, gbest [1] and gbest [2], and obtain the gbest. The corresponding solutions will definitely be closer to the non inferior optimal target domain than the first two. The selection of gbest is:

In the formula, i represents the i-th generation selection, and n represents the total number of iterations.

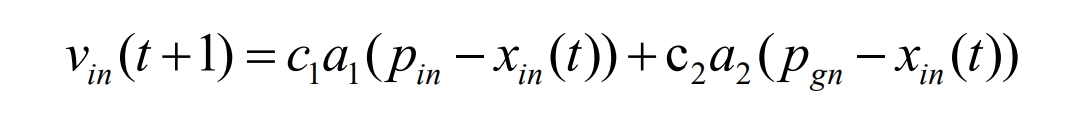

The calculation method for updating particle velocity is:

In the equation, Vin (t+1) represents the velocity of the particle in the nth dimension of the t+1st iteration, pin represents the position of the n-dimensional individual extreme point in the t-th iteration of particle i, Pgn represents the position of all particles at the global extreme point in the nth dimension, a1 and a2 are random numbers between [0,1], and c1 and c2 represent acceleration factors.

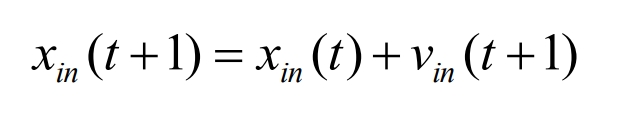

Calculation method for updating particle position:

In the equation, Xin (t) represents the n-th dimensional position of particle i in the t-th iteration.

4.Example analysis

4.1 Optimization Analysis of Energy Storage Station Capacity Configuration

This article takes a project in a certain area of Haixi, Qinghai as an example. According to statistics, the total installed capacity of photovoltaic power in Haixi is currently 3724MW. With the large-scale grid connection of photovoltaic systems with randomness and uncertainty, the proportion of new energy in power installation has rapidly increased, posing a series of major challenges to the power system in source network planning and safe and stable operation of the power grid. Firstly, with the rapid growth of new energy, the imbalance and contradiction between the development of the power grid and new energy are becoming increasingly apparent. The load growth within the province is slow, and the absorption capacity is limited, requiring optimization of configuration on a larger scale. The local grid structure is weak and the power transmission capacity is insufficient. Secondly, large-scale new energy integration has led to significant changes in the operational characteristics of the Qinghai power grid. The volatility and uncertainty of power grid power have further intensified issues such as voltage stability and frequency stability, making the security and stability situation of the power grid even more severe.

The main manifestation of the concentrated areas of new energy in Haixi is that on the one hand, the Haixi region lacks conventional hydropower or thermal power for peak shaving. Due to the power fluctuations and uncertainties of new energy generation, problems such as voltage stability and frequency stability in the power grid are further intensified, leading to further limitations in the delivery of new energy. On the other hand, the increase in new energy power stations similar to the leader base or affordable online base will result in limited online transmission capacity due to various reasons such as prioritizing online access and not participating in electricity trading. The number of online hours of existing power stations in the Haixi region will be further reduced compared to the original (but the average hour in the province is expected to be guaranteed at 1500 hours). The primary purpose of integrating energy storage devices into new energy generation systems is to improve the time power output curve of the entire generation system and reduce the adverse impact of intermittent renewable energy on the power grid.

In response to the serious phenomenon of light abandonment in Qinghai region, the energy storage system has carried out peak shaving and valley filling to improve the utilization rate of photovoltaic power generation. Therefore, the power/capacity configuration of energy storage systems is related to their specific functions implemented in photovoltaic power generation systems.

4.2 Charging and discharging modes of energy storage system

The energy storage system is configured with corresponding energy storage capacity based on the amount of solar energy abandoned in the local area in the past two years. During the day, it absorbs the electricity generated by photovoltaic wind power and releases this energy at night, improving the utilization rate of photovoltaic power generation. The scheduling strategy of energy storage systems should be based on actual and accurate data and control objectives as the basis for decision-making. Among them, the data includes photovoltaic power plant output data, energy storage system status data, etc. The energy scheduling strategy is:

(1) When the total power output of the photovoltaic power generation system is large and exceeds the required output size, the energy storage battery is charged to ensure that the photovoltaic power station always meets the output limit requirements of the power grid scheduling. If the charging amount is close to the capacity of the energy storage battery, it is necessary to consider discarding some of the light in the future.

(2) During the daytime output period of the photovoltaic system, determine the working status of the photovoltaic system, and control the discharge of the battery energy storage system to the minimum operating range of the energy storage system after the peak output of the photovoltaic system in each working cycle,

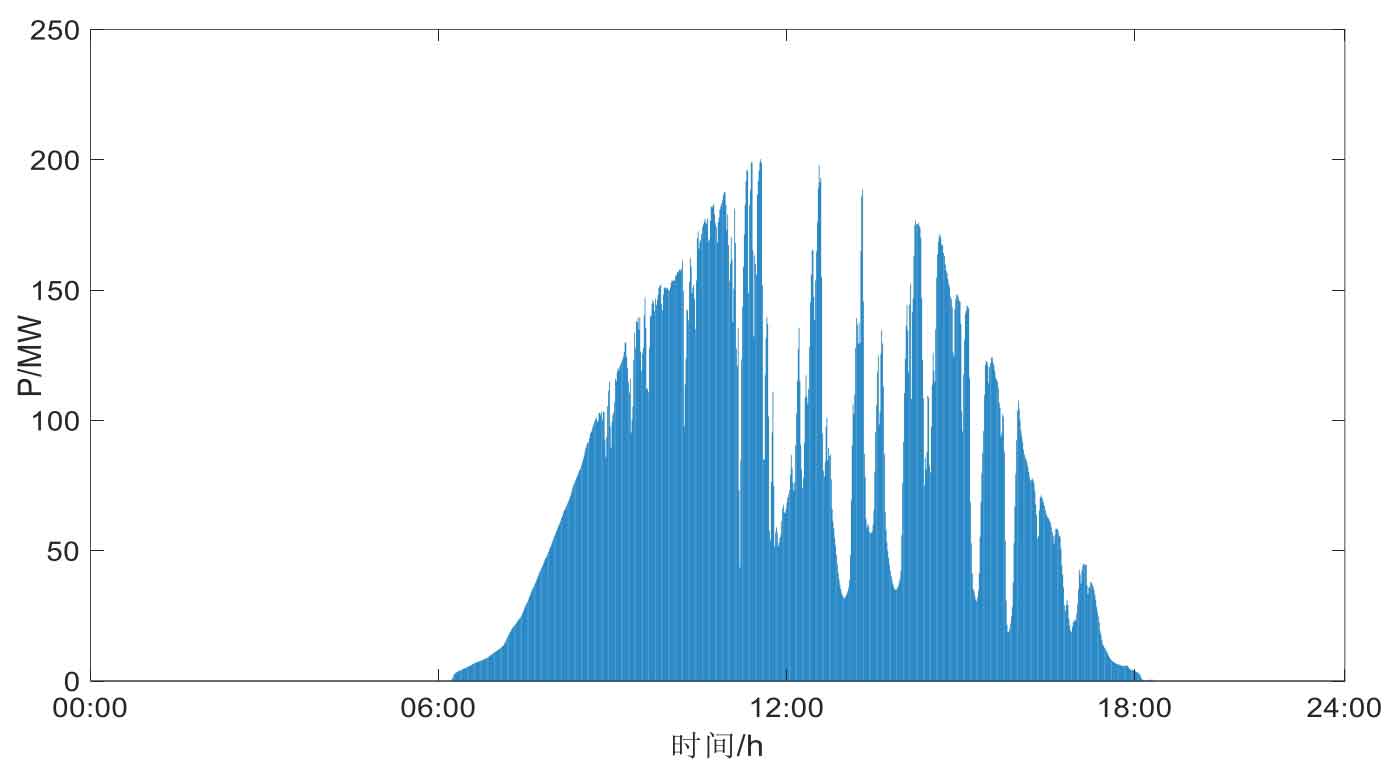

A large amount of statistics and analysis were conducted on the output data of multiple photovoltaic cells in the Haixi region, and it was found that there are significant differences in the operating status of various photovoltaic power stations in the same region. The probability of the maximum output of photovoltaic power exceeding 90% of the rated output ranges from 5% to 20%, and the probability of exceeding 80% of the rated output ranges from 20% to 40%. However, the typical output curves of each photovoltaic power station are relatively consistent. Figure 2 shows the maximum output distribution of a 200MW photovoltaic power plant at various times within a day.

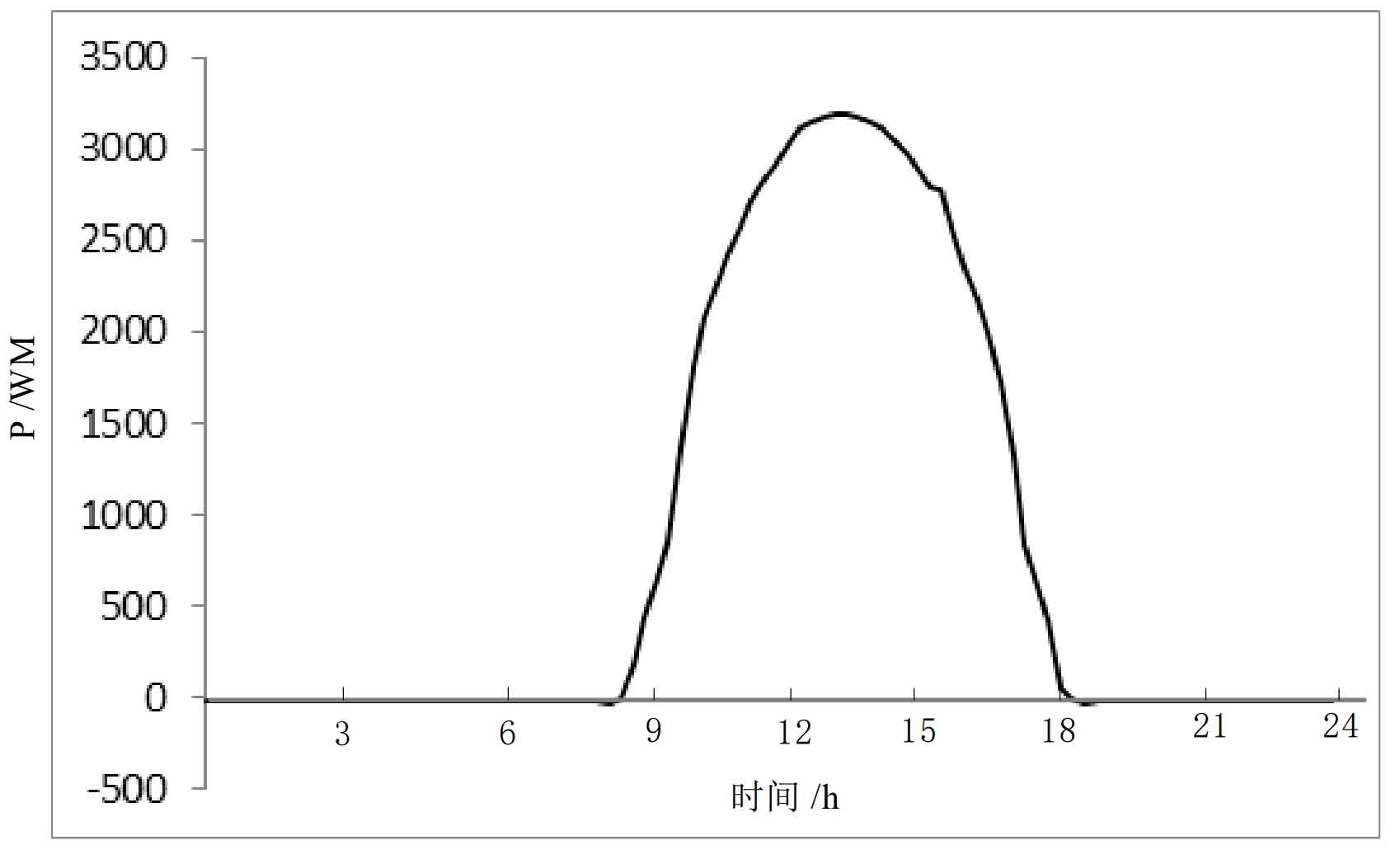

Considering the simultaneity of each photovoltaic power station, multiply by a simultaneity coefficient of 0.9. The total output curve of photovoltaic power generation in the Haixi region is shown in Figure 3, with a maximum photovoltaic output of 3301MW.

Under normal circumstances, the midday load in the Haixi region is less than 900000 kilowatt hours, and the limit for the Haixi transmission section is 1.6 million kilowatts; The midday load in the Haixi region ranges from 900000 to 1250000 kilowatt hours, and the limit for the Haixi transmission section is 1.3 million kilowatts. When using energy storage to improve the consumption of new energy in the Haixi region, it is considered that the maximum consumption capacity of new energy in the Haixi region is constrained to 2.5 million kilowatts. In summary, due to the limited transmission cross-section, the consumption of new energy in the Haixi region is still limited by 914MW. The new energy waste rate is approximately 10.6%.

Based on the comprehensive grid electricity prices of various photovoltaic power stations in the Haixi region, the comprehensive grid electricity price for the entire Haixi region is calculated to be 0.88 yuan/kWh based on the capacity ratio. The purchase cost is considered at 10% of the comprehensive electricity price, which is 0.088 yuan/kWh. The remaining parameters and control variables are shown in Table 3.

| Example parameters | Numerical value |

| Local coal-fired unit benchmark grid electricity price (thousand yuan/MWh) | 0.4048 |

| Photovoltaic subsidy standard (thousand yuan/MWh) | 0.42 |

| Unit capacity cost of photovoltaic power generation (thousand yuan/MWh) | 7800 |

| Annual operation and maintenance cost of photovoltaic power generation (thousand yuan/MWh) | 20 |

| Unit capacity cost of energy storage (thousand yuan/MWh) | 4300 |

| Unit power cost of energy storage (thousand yuan/MWh) | 1200 |

| Unit operation and maintenance cost of energy storage (thousand yuan/MWh) | 0.06 |

| Battery replacement rate% | 5 |

| Upper limit of state of charge/% | 80 |

| Example parameters | Numerical value |

| Lower limit of state of charge/% | 20 |

| Annual load growth rate/% | 1.5 |

| Carbon trading price (thousand yuan/MWh) | 0.05 |

| Annual Count Days (Days) | 200 |

| Expected Yield/% | 6 |

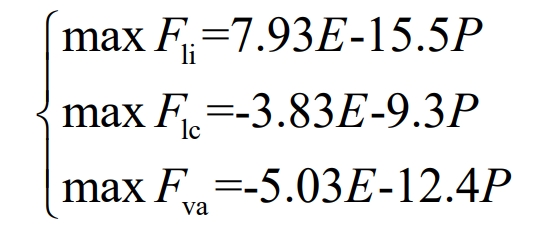

Through the research in section 1, the types of electrochemical energy storage power stations in this example were selected as lithium iron phosphate battery system, all vanadium flow battery system, and carbon lead battery system. Through calculation, the optimization objectives of the three were simplified as follows:

Among them, Fli represents the optimal power capacity ratio for lithium-ion battery systems; Flc represents the optimal power capacity ratio of the lead-carbon battery energy storage system; Fva represents the optimal ratio of all vanadium flow battery energy storage system. It can be seen that under the current technological and economic level of mainstream battery systems in China, lithium battery energy storage systems have the best economic performance, so we are considering choosing lithium battery energy storage systems.

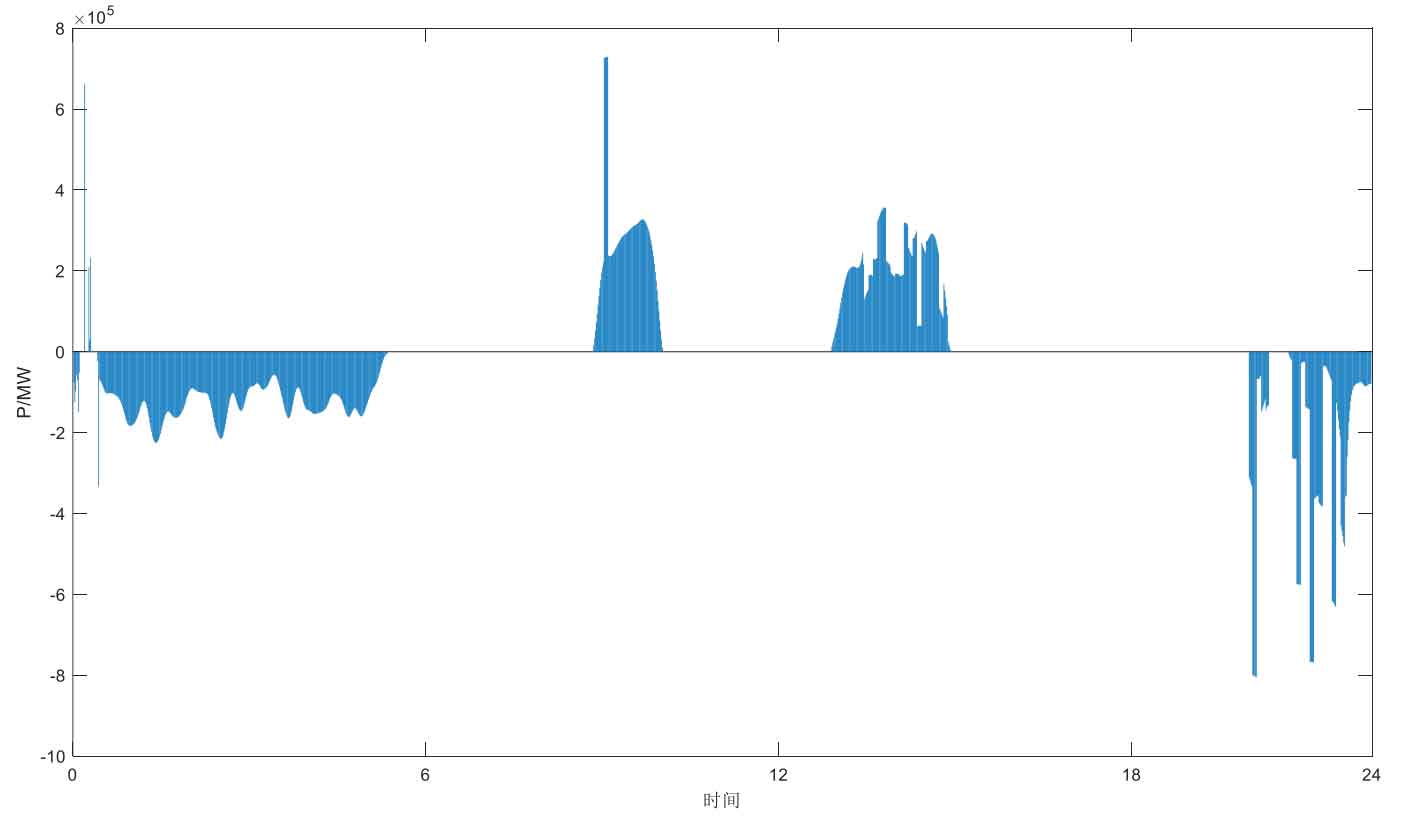

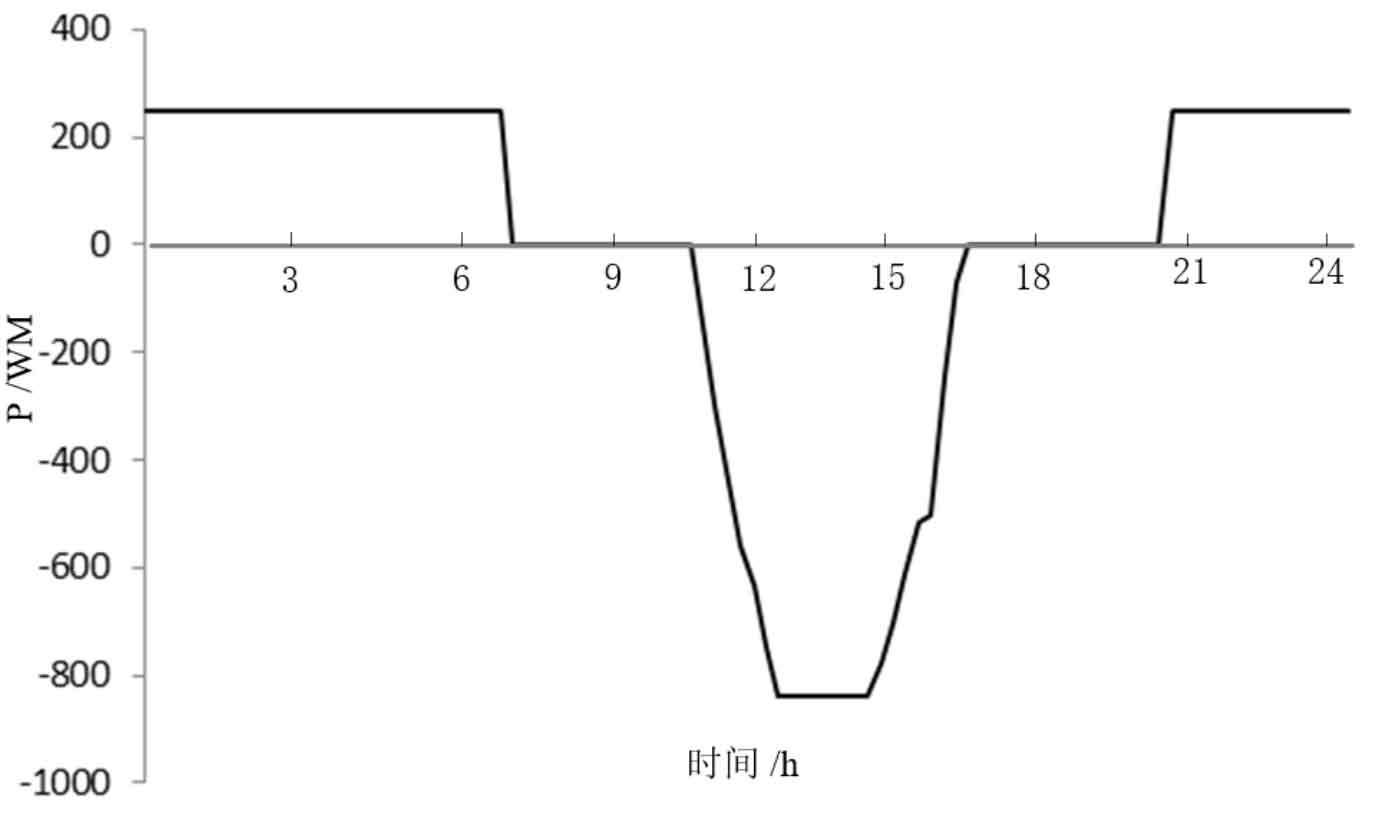

Figure 4 shows the daily charging and discharging power curve of a lithium iron phosphate energy storage station. From the figure, it can be seen that during the nighttime periods of 0-6 hours and 20-24 hours, the energy storage station performs charging operations, and the charging power is adjusted in real-time according to the power grid scheduling; During the discharge operation of the energy storage power station from 9 to 11 hours and from 13 to 17 hours, during the daytime period, the battery energy storage system cooperates with the photovoltaic power station. When the solar light intensity is sufficient to meet the load demand, the energy storage system does not operate. When the light intensity decreases and the output of the photovoltaic power station cannot meet the load demand, the energy storage system discharges to relieve the pressure on the power grid.

The operation strategy of improving the consumption of new energy generation is adopted for energy storage. When the new energy output exceeds the maximum consumption capacity of the Haixi region, it is started. For a typical output curve, the energy storage operation curve shown in Figure 5 can be obtained:

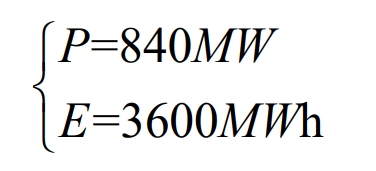

According to the operating curve, considering the 10% charging cost of the lithium iron phosphate battery energy storage system, the energy storage capacity configuration results are as follows:

At this point, the wind and light abandonment rate in the Haixi region will decrease to 0.3%. Considering the actual engineering situation, it is recommended to allocate 840MW in the Haixi region × The 4-hour lithium iron phosphate energy storage battery system reduces the wind and light rejection rate in the Haixi region to approximately 1.2%.

4.3 Economic Benefit Analysis

There are a total of 5 energy storage power stations planned and constructed in the Haixi region, recorded as A, B, C, D, and E. According to the previous calculation of the full life cycle cost and kilowatt hour cost of energy storage, the total investment is about 2.73 billion yuan, and the system kilowatt hour cost is about 0.44 yuan/kWh.

| Transformer power station | Installation scale | Construction cost/10000 yuan |

| A | 115MW×4h | 71500 |

| B | 170MW×4h | 105600 |

| C | 47MW×4h | 29240 |

| D | 38MW×4h | 23660 |

| E | 70MW×4h | 43500 |

| Total | 440MW×4h | 273500 |

When the energy storage power station purchases photovoltaic waste electricity at a price of 0-0.5 yuan/kWh and is fully purchased by the power grid enterprise at a grid price of 0.966 yuan/kWh, the annual benefits are shown in Table 5.

| Annual benefits/electricity purchase costs of each power station | 0 (yuan/kWh) | 0.3 (yuan/kWh) | 0.5 (yuan/kWh) |

| A | 13085.75 | 8048.75 | 4690.75 |

| B | 19344.16 | 11898.16 | 6934.16 |

| C | 5348.09 | 3289.49 | 1917.09 |

| D | 4323.99 | 2659.59 | 1549.99 |

| E | 7965.24 | 4899.24 | 2855.24 |

When energy storage power stations purchase new energy waste electricity for free, the investment efficiency of energy storage power stations is the highest, with an annual return rate of 18.3%, and the investment can be recovered within 5.5 years. If the annual return rate of energy storage power stations is to reach 8% or above, and the investment is to be recovered within the service life (12 years), the purchase price of energy storage power stations should not exceed 0.4 yuan/kWh.

5. Conclusion

The main content is to study the optimization and configuration of large-scale energy storage system capacity. A detailed analysis was conducted on the various costs of energy storage power plants throughout their entire life cycle, and the cost per kilowatt hour of energy storage stations for different types of energy storage technologies was provided. Based on this, calculate the optimal capacity configuration of the energy storage station. The optimization objectives are to maximize the annual revenue of the energy storage system and minimize the amount of solar energy discarded by the photovoltaic power station. The conclusion is that the comprehensive economy of the lithium iron phosphate battery energy storage station is the best, and the optimal power/capacity ratio is about 1:4. By analyzing the relationship between the cost of purchasing electricity and the annual benefits of each power station, it is concluded that if the annual return rate of energy storage power stations is above 8% and the investment is recovered within the life cycle (12 years), the purchase price of energy storage power stations should not exceed 0.4 yuan/kWh.