With the rapid integration of renewable energy sources such as wind and photovoltaic power into the grid in recent years, their intermittent generation characteristics have increased the demand for regulating capacity in the power system. However, these renewable sources themselves lack the capability to participate in frequency regulation, thereby shifting the burden of frequency regulation tasks to traditional thermal power units. In regions like Shandong, the secondary frequency regulation primarily relies on thermal power units. Thermal units are characterized by long response delays and slow ramp rates. Frequent large-scale adjustments not only impact unit equipment, affecting stability and economic operation, but also the ultra-low emission retrofits have further limited the regulation speed of thermal units, reducing their performance. In contrast, the battery energy storage system offers advantages such as rapid response time (less than 100 milliseconds), fast regulation speed (load adjustment from zero to full capacity in under 20 milliseconds), and high precision. Integrating a battery energy storage system with thermal power units for secondary frequency regulation can enhance the regulation performance of thermal units while significantly reducing the required frequency regulation reserve capacity in the grid. Due to its fast response and operational flexibility, the battery energy storage system can generate dynamic benefits while meeting system frequency regulation needs. This article focuses on the characteristics of the battery energy storage system assisting thermal power units in secondary frequency regulation. Based on a frequency regulation project at a thermal power plant in Shandong, it explores the configuration, control, and engineering design of the battery energy storage system for aiding thermal units in secondary frequency regulation, along with an economic analysis.

Secondary frequency regulation, also known as Automatic Generation Control (AGC), aims to maintain high-quality power supply while ensuring real-time balance between power supply and demand, addressing load changes over minutes to tens of minutes. The tasks of secondary frequency regulation include keeping grid frequency within allowable error limits, controlling the net exchange power of interconnected grids to follow planned values, managing exchange energy within planned limits, and participating in tertiary frequency regulation. The combined thermal and storage system adopts a configuration where the battery energy storage system is connected to the high-voltage side of the plant’s auxiliary power bus. Utilizing the spare capacity of the existing plant transformer, the system is stepped up twice and connected to the generator outlet. The basic process of combined thermal and storage secondary frequency regulation is illustrated below. The process involves: (1) The grid dispatch center generating AGC commands based on real-time grid load conditions, unit status, and frequency; these commands are transmitted to the plant’s Remote Terminal Unit (RTU) via remote channels. (2) The plant RTU sends AGC commands to the thermal unit’s Distributed Control System (DCS), which adjusts unit output based on load limits and rate settings while transmitting AGC commands and operational data to the Energy Management System (EMS) of the battery energy storage system. (3) The battery energy storage system EMS receives signals such as AGC commands, current unit output, and storage output, combined with battery state, to compute output commands for the storage system, which are then sent to local controllers; these controllers distribute commands to individual storage units to control charging and discharging. (4) The unit DCS calculates the storage system output through internal logic and superimposes it with unit output as an AGC feedback signal sent to RTU; RTU transmits this back to the grid dispatch center. Thus, a closed-loop control system for power production between the plant and grid dispatch center is achieved.

The principle of secondary frequency regulation involves shifting the frequency characteristic curve of generator units to alter active power output, balancing load changes, and restoring system frequency to the normal range. Thermal unit AGC regulation faces several issues: (1) Due to energy conversion process limitations, response time is long, typically on the order of tens of seconds. (2) Regulation speed is slow, with standard ramp rates (MW/min) generally not exceeding 3% of rated power. (3) Regulation accuracy is poor, with allowable deviations typically around 1% of rated power. The battery energy storage system connects to the grid via high-frequency power electronic devices, lacking delays and inertia from energy conversion processes, enabling rapid adjustment of power magnitude and direction. Assisting thermal units in secondary frequency regulation, the battery energy storage system provides sufficient time for slower-responding synchronous generators to initiate frequency regulation. In this setup, the battery energy storage system and thermal unit operate in parallel at the grid connection point, jointly tracking AGC dispatch commands to significantly improve overall regulation performance. The AGC principle is as follows: upon receiving AGC commands, the battery energy storage system utilizes its fast and precise control to quickly compensate for power demand gaps caused by differences between real-time unit output and AGC commands; as thermal unit output gradually approaches AGC commands, the battery energy storage system output withdraws until eventually borne entirely by the thermal unit, with the storage system entering charging mode to reserve energy for the next response.

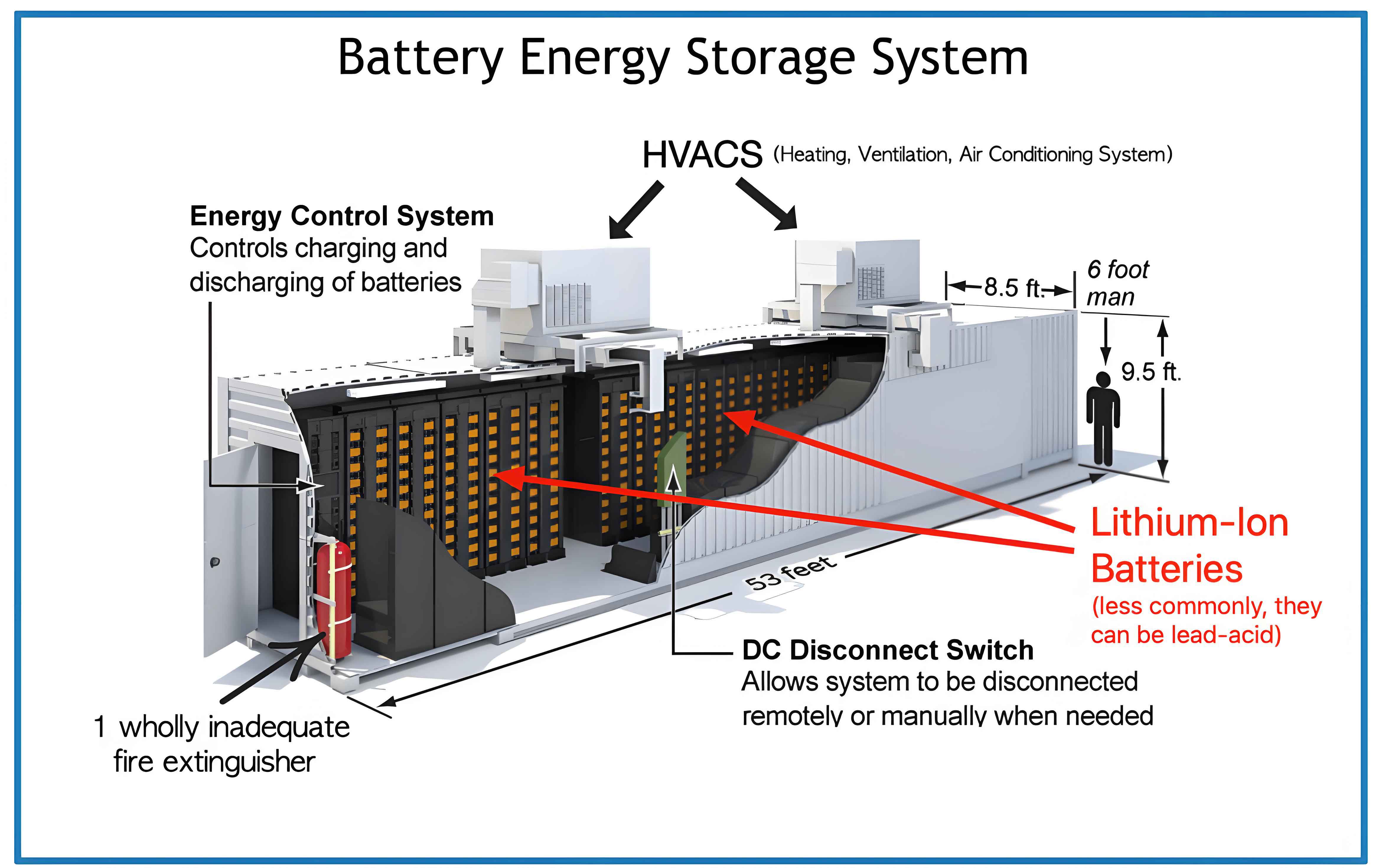

The battery energy storage system boasts advantages like rapid response and high precision but suffers from limited energy storage and finite lifespan. Based on secondary frequency regulation characteristics and thermal unit capacity, the design for a frequency regulation project at a thermal power plant in Shandong is as follows. The battery energy storage system configuration should ensure reliability, economy, and safety during long-term interconnected operation with generator units. Selecting appropriate power and capacity configurations is paramount for applying battery energy storage in power systems. Analysis of AGC frequency regulation characteristics for power plants in Shandong reveals that 97% of regulation commands fall within 3% of unit capacity. Comparing actual effects after implementing battery energy storage system-assisted frequency regulation, this project adopts a configuration of 3% of unit full capacity (1C). For two 350 MW units at a Shandong power plant, a 10 MW/10 MWh battery energy storage system is configured for auxiliary frequency regulation. The Shandong regional grid’s AGC-R mode imposes high response demands on units; to address rapid load fluctuations, units often sacrifice safety margins, compromising boiler combustion stability and affecting various operational parameters. This project employs mature lithium iron phosphate batteries in the market, meeting requirements for assisting thermal units in secondary frequency regulation in terms of rate indicators, lifespan, and safety. The project selects a low-voltage Power Conversion System (PCS) parallel networking scheme. Using low-voltage (400 V) PCS units, the DC side connects to lithium iron phosphate batteries, while the AC side parallels multiple PCS units, connects to a transformer stepped up to 6 kV, and then to the 6 kV auxiliary power bus.

After integrating the battery energy storage system, both storage and thermal units jointly respond to grid AGC commands. The plant RTU must combine generator output and storage output signals for upload to the grid as basis for frequency regulation assessment. Thus, modifications to RTU and DCS are required. RTU modifications include: (1) Using data before and after superimposing unit output and storage output as feedback signals to the grid, i.e., uploading three signals: unit output, storage output, and combined output. (2) Adding communication between the storage system control system and RTU per dispatch requirements, transmitting data via agreed protocols to obtain real-time operational data of the battery energy storage system. (3) Adding status signals for the storage plant’s 6 kV section breakers. (4) Adding active power, reactive power, and current signals on the high-voltage side of the high-voltage plant transformer. DCS modifications include: (1) Adding monitoring of the battery energy storage system connection point in unit DCS, including current and voltage signals. (2) DCS calculating storage output via internal logic and superimposing it with unit output, using both pre- and post-superimposition data as AGC feedback signals sent to RTU. (3) Adding communication between DCS and the master control unit of the battery energy storage system for signal and status exchange. The battery energy storage system can upload operational status information as per plant needs, including: grid connection status feedback, grid-connected power, auxiliary peak-shaving engagement feedback, and charging/discharging status. The battery energy storage system only receives commands or status from DCS without sending commands to DCS, ensuring no impact on plant industrial control system security after integration.

The key to success in battery energy storage system-assisted thermal unit secondary frequency regulation lies in the control strategy of the battery energy storage system. The battery energy storage system must formulate output commands based on AGC commands, real-time unit output, and its own state parameters like State of Charge (SOC), achieving fast power control and regulation. This project adopts a control method based on the Area Control Error (ACE) signal. Compared to traditional lag-based control, the ACE-based method fully leverages the fast response of the battery energy storage system, enabling timely response to AGC commands. The ACE-based control refers to: when load disturbances generate frequency regulation demands in the system, the ACE signal is used as a regulation command allocated to conventional units and the battery energy storage system. The system frequency response model under ACE-based control is as follows:

Let $\Delta f(s)$ denote system frequency deviation, $\Delta P_G(s)$ conventional unit output, $\Delta P_b(s)$ battery energy storage system output, and $\Delta P_L(s)$ load change. The model includes: $\Delta P_G(s) = \Delta P_s(s) + \Delta P_f(s)$, where $\Delta P_s(s)$ and $\Delta P_f(s)$ are components. Let $\alpha$ be the proportion coefficient of storage output in the ACE signal, and $1-\alpha$ for thermal unit secondary regulation output. Then:

$$\Delta f(s) = \frac{\Delta P_G(s) + \Delta P_b(s) – \Delta P_L(s)}{sM + D}$$

$$\Delta P_b(s) = -\alpha B G_b(s) \Delta f(s)$$

Here, $M$ is system inertia, $D$ damping coefficient, $B$ frequency bias factor, and $G_b(s)$ transfer function of the battery energy storage system. From these equations, storage output varies with frequency deviation, avoiding delay effects from PI controllers. Upon receiving AGC commands, the battery energy storage system responds instantly, with output magnitude proportional to the ACE signal; at the end of the AGC process, the thermal unit’s secondary regulation supplements the entire load increment, reducing storage output to zero. This control ensures rapid system action while enabling adaptive reduction in SOC changes for the battery energy storage system.

AGC is a paid service provided by power plants to the grid, with regional grids issuing implementation rules for ancillary services and grid operation management. Taking the North China region where this project is located as an example, the “North China Region Grid-connected Operation Management Implementation Rules (2022 Draft)” specifies assessment indicators $K_p$ for generator unit AGC services:

$$K_p = K_1 \times K_2 \times K_3$$

where $K_1$ is regulation rate: $2 – \frac{\text{actual regulation rate}}{\text{standard regulation rate}}$; $K_2$ is regulation accuracy: $2 – \frac{\text{regulation deviation}}{\text{allowable deviation}}$; $K_3$ is response time: $2 – \frac{\text{unit output response time}}{\text{standard response time}}$.

Daily compensation fees for AGC services are calculated as:

$$\text{Daily compensation} = D \times \left[ \ln(K_{pd} + 1) \right] \times Y_{\text{AGC}} \times C_{\text{AGC}}$$

where $D$ is daily regulation depth (MW) of the unit; $C_{\text{AGC}}$ is AGC service contribution rate; $K_{pd}$ is daily regulation performance indicator:

$$K_{pd} = \begin{cases}

\frac{\sum_{j=1}^{n} K_{p}^{i,j}}{n}, & \text{if unit } i \text{ is called for AGC } (n > 0) \\

1, & \text{if unit } i \text{ is not called for AGC } (n = 0)

\end{cases}$$

and $Y_{\text{AGC}}$ is AGC compensation standard (yuan/MW). Regulation rate, accuracy, and response time determine the regulation performance indicator, which in turn affects compensation calculation. Thermal-storage combined secondary frequency regulation optimizes these indicators, significantly boosting AGC revenue for thermal plants.

Based on actual AGC regulation performance indicators for units #1 and #2 at a power plant in Shandong, statistics are summarized in Table 1. Note: Regulation rate $K_1$ has a cap; values above 1.2 are calculated as 1.2.

| Parameter | Before Battery Energy Storage System | After Battery Energy Storage System |

|---|---|---|

| Regulation Rate $K_1$ | 1.2 | 1.2 |

| Regulation Accuracy $K_2$ | 1.07 | 1.6 |

| Response Time $K_3$ | 1.71 | 1.8 |

| Comprehensive Performance $K_p$ | 2.196 | 3.456 |

| Frequency Regulation Mileage (MW) | 7500 | 9500 |

Here, $Y_{\text{AGC}}$ is the AGC compensation standard; Shandong sets the upper limit for frequency regulation ancillary service market transaction price at 12 yuan/MW (tax included), temporarily calculated at this upper limit. $C_{\text{AGC}}$ is the AGC service contribution rate; current policy sets it at 1.0 for directly dispatched public thermal units and 0.1 for energy storage facilities, with combined thermal-storage frequency regulation taken as 1. After adding the battery energy storage system, the annual frequency regulation mileage for units #1 and #2 participating 250 days per year increases from 7500 MW to 9500 MW. The annual additional revenue (tax included) is calculated as:

$$\text{Additional annual revenue} = 250 \times 12 \times 1 \times 9500 \times \ln(3.456 + 1) – 250 \times 12 \times 1 \times 7500 \times \ln(2.196 + 1)$$

$$\text{Additional annual revenue} = 250 \times 12 \times 9500 \times \ln(4.456) – 250 \times 12 \times 7500 \times \ln(3.196)$$

$$\text{Additional annual revenue} = 250 \times 12 \times 9500 \times 1.494 – 250 \times 12 \times 7500 \times 1.162$$

$$\text{Additional annual revenue} = 250 \times 12 \times (9500 \times 1.494 – 7500 \times 1.162)$$

$$\text{Additional annual revenue} = 250 \times 12 \times (14193 – 8715) = 250 \times 12 \times 5478 = 250 \times 65736 = 16,434,000 \text{ yuan}$$

Thus, theoretically, the project yields an additional annual revenue of approximately 16.43 million yuan (tax included).

This article, based on a frequency regulation project at a thermal power plant in Shandong, analyzes the process and principles of battery energy storage system-assisted thermal unit secondary frequency regulation, proposes configuration schemes for the battery energy storage system and modification plans for thermal unit control systems, guiding project implementation. It further analyzes control strategies for battery energy storage system-assisted thermal units, selecting the fast-response, mature ACE-based control method. Finally, economic feasibility is preliminarily analyzed according to North China regional grid “two rules” and Shandong policies. The research findings have been successfully applied in practice, significantly enhancing the secondary frequency regulation capability of two units at the power plant. The battery energy storage system demonstrates immense potential in improving grid stability and economic efficiency, with ongoing advancements expected to further optimize integration and performance.

To elaborate on the battery energy storage system configuration, the selection of lithium iron phosphate batteries is due to their high cycle life, safety, and suitability for frequency regulation applications. The battery energy storage system’s power and capacity are critical: under-sizing may limit effectiveness, while over-sizing increases costs. Empirical data from similar projects show that a 1C rating (where capacity in MWh equals power in MW) balances response and endurance. For instance, a 10 MW/10 MWh system can deliver full power for one hour, sufficient for typical AGC cycles. The PCS parallel scheme enhances reliability via redundancy; if one PCS fails, others maintain operation. Transformer selection must handle peak power and harmonic distortions from PCS units. Efficiency metrics for the battery energy storage system include round-trip efficiency (typically 85-95% for lithium-ion) and degradation rates, impacting long-term economics.

The control strategy nuances merit further discussion. The ACE signal incorporates both frequency deviation and tie-line power exchange errors, expressed as $ACE = B \Delta f + \Delta P_{tie}$, where $\Delta P_{tie}$ is tie-line power deviation. The battery energy storage system response $\Delta P_b$ can be modeled as $\Delta P_b = -K \cdot ACE$, with $K$ a gain factor optimized via simulation. A dynamic model for the combined system includes:

$$\frac{d\Delta f}{dt} = \frac{1}{M} \left( \Delta P_m + \Delta P_b – \Delta P_L – D \Delta f \right)$$

where $\Delta P_m$ is mechanical power change from thermal units. Integrating the battery energy storage system reduces $\Delta f$ overshoot and settling time. SOC management is crucial to prevent over-charge/discharge; a common strategy is to maintain SOC between 20% and 80%, with feedback adjusting $\alpha$ in real-time. For example, if SOC nears 80%, $\alpha$ decreases to favor charging. This extends battery life and ensures availability.

Economic analysis can be extended with sensitivity tables. Consider varying compensation standards and regulation mileage:

| Scenario | AGC Compensation (yuan/MW) | Annual Mileage (MW) | Estimated Revenue (million yuan) |

|---|---|---|---|

| Base Case | 12 | 9500 | 16.43 |

| High Compensation | 15 | 9500 | 20.54 |

| Low Mileage | 12 | 8000 | 13.84 |

| High Mileage | 12 | 11000 | 19.01 |

Capital and operational costs for the battery energy storage system include initial investment (e.g., 15 million yuan for 10 MWh), maintenance (1-2% of capital annually), and degradation replacement (every 10-15 years). A simple payback period calculation: if total cost is 20 million yuan and annual revenue is 16.43 million, payback occurs in about 1.2 years, highlighting attractiveness. However, policy changes affect revenue; thus, risk analysis is warranted.

Technical challenges include grid synchronization, harmonics, and protection coordination. The battery energy storage system must comply with grid codes for voltage/frequency ride-through and anti-islanding. Protection devices like circuit breakers and relays need settings to avoid nuisance trips during transients. Communication protocols (e.g., IEC 61850) ensure interoperability between battery energy storage system, DCS, and RTU. Cybersecurity measures are essential to prevent unauthorized access.

Future trends involve AI-based predictive control using weather and load forecasts to pre-adjust SOC, enhancing response. Hybrid storage (e.g., combining batteries with supercapacitors for pulse loads) could further improve performance. Standardization of interfaces and markets for ancillary services will drive adoption. The battery energy storage system thus represents a cornerstone in modernizing power systems towards sustainability and resilience.

In summary, the battery energy storage system proves transformative for thermal power plants in secondary frequency regulation. Its rapid response compensates for thermal inertia, boosting grid stability and revenue. Design considerations span configuration, control, integration, and economics. With careful planning, the battery energy storage system delivers operational and financial benefits, supporting the transition to a cleaner grid. Continued research will refine technologies and policies, unlocking greater potential for battery energy storage system applications in power systems worldwide.