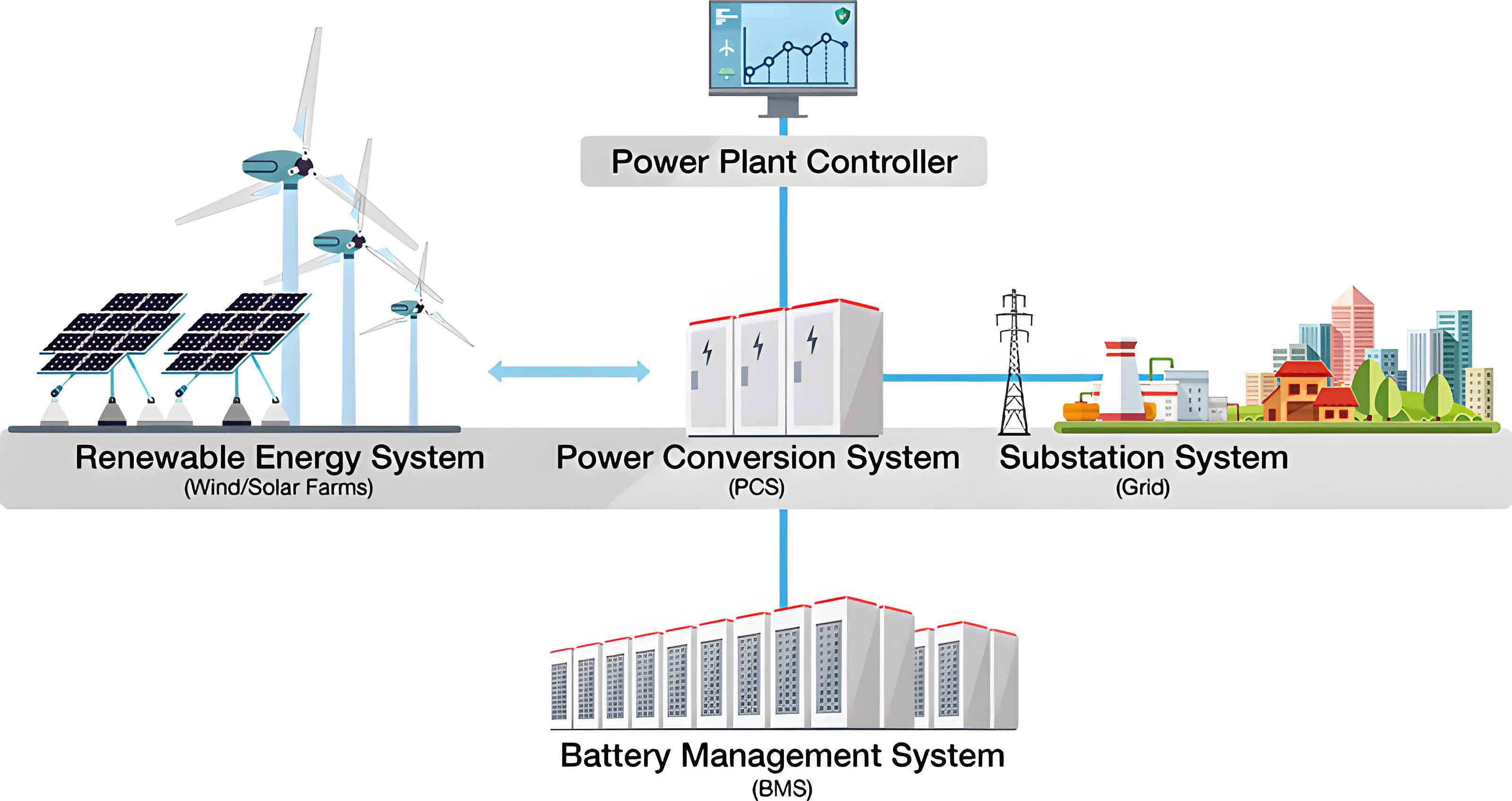

In recent years, the integration of renewable energy sources such as wind and solar power has posed significant challenges to grid stability due to their inherent variability and lack of rotational inertia. As a key solution, the battery energy storage system has emerged as a vital component for enhancing frequency regulation, particularly when combined with thermal power generating units. Traditional control methods often fall short in optimizing the performance of the battery energy storage system during primary frequency modulation, leading to issues like insufficient control capability and state of charge (SOC) degradation. In this article, I propose an adaptive comprehensive control method that leverages primary frequency modulation characteristics and SOC optimization to improve the output of the battery energy storage system. By analyzing grid frequency behavior, I enhance virtual inertia control to introduce virtual negative inertia control, dynamically adjusting the output based on frequency deviation phases. This strategy ensures rapid frequency stabilization while maintaining SOC within desirable limits, validated through simulations on a typical single-area grid model.

The core of this approach lies in the coordinated use of virtual droop control, virtual inertia control, and virtual negative inertia control. During the initial stage of frequency disturbance, the battery energy storage system prioritizes droop control supplemented by inertial control; during the recovery phase, it shifts to inertial control supplemented by droop control. To optimize power output, an adaptive出力 coefficient adjustment strategy based on the logistic function is implemented, which effectively manages the SOC of the battery energy storage system. This method not only reduces frequency deviations quickly but also enhances the longevity and efficiency of the battery energy storage system. In the following sections, I will detail the control framework, mathematical formulations, simulation setups, and results, emphasizing the role of the battery energy storage system in grid support.

The battery energy storage system plays a pivotal role in modern power grids by providing fast response and precise regulation, which are essential for primary frequency modulation. When integrated with thermal power units, the battery energy storage system can alleviate the strain on generators, reduce wear and tear, and improve overall grid resilience. However, conventional control strategies often fail to adapt to dynamic frequency changes or maintain SOC balance, leading to suboptimal performance. My proposed method addresses these limitations by incorporating an adaptive mechanism that adjusts control coefficients in real-time based on frequency error and SOC feedback. This ensures that the battery energy storage system operates efficiently across various disturbance scenarios, from step changes to continuous fluctuations in load.

To understand the control framework, let’s first examine the model of the battery energy storage system参与 primary frequency modulation. The combined system includes the thermal power unit and the battery energy storage system, where the total power imbalance is compensated by both sources. The frequency response of the grid can be represented by the swing equation, which incorporates the effects of inertia, damping, and control inputs. For the battery energy storage system, I model it using a first-order transfer function to capture its rapid response dynamics. The key equations governing the system are as follows:

The swing equation for the grid frequency deviation $\Delta f$ is:

$$ \Delta f(s) = \frac{\Delta P_G(s) + \Delta P_E(s) – \Delta P_L(s)}{Ms + D} $$

where $\Delta P_G$ is the power output from the thermal unit, $\Delta P_E$ is the power output from the battery energy storage system, $\Delta P_L$ is the load disturbance, $M$ is the equivalent inertia, and $D$ is the damping coefficient. The thermal unit model comprises a governor and a turbine, expressed as:

$$ G_{gov}(s) = \frac{K_G}{1 + T_G s} $$

for the governor, and

$$ G_{gen}(s) = \frac{1 + F_{HP} T_{RH} s}{(1 + T_{CH} s)(1 + T_{RH} s)} $$

for the turbine, where $K_G$ is the frequency regulation coefficient, $T_G$ is the time constant, $F_{HP}$ is the high-pressure power coefficient, and $T_{RH}$ and $T_{CH}$ are time constants related to reheater and steam volumes. The battery energy storage system model is simplified as:

$$ G_{ge}(s) = \frac{K_B}{1 + T_B s} $$

with $K_B$ as the frequency regulation coefficient and $T_B$ as the response time constant. This model highlights the agility of the battery energy storage system compared to slower thermal units.

The control strategy for the battery energy storage system involves three main components: virtual droop control, virtual inertia control, and virtual negative inertia control. Virtual droop control mimics the steady-state frequency response of synchronous generators, providing a power increment proportional to the frequency deviation:

$$ \Delta P_{E1} = -K_E \Delta f $$

where $K_E$ is the droop coefficient. This component is crucial for reducing steady-state frequency errors. Virtual inertia control emulates the inertial response, offering a power increment based on the rate of change of frequency:

$$ \Delta P_{E2} = -M_E \frac{d(\Delta f)}{dt} $$

with $M_E$ as the virtual inertia coefficient. It helps dampen rapid frequency changes during disturbances. However, virtual inertia control can hinder frequency recovery by opposing the restoration trend. To counteract this, I introduce virtual negative inertia control, which promotes frequency recovery by adding a power increment that aligns with the frequency change rate:

$$ \Delta P_{E3} = M_{E1} \frac{d(\Delta f)}{dt} $$

where $M_{E1}$ is the virtual negative inertia coefficient. The integration of these controls allows the battery energy storage system to adapt to different phases of frequency modulation.

The adaptive comprehensive control method dynamically allocates control contributions based on the frequency deviation and its derivative. Specifically, when the frequency deviation is increasing (e.g., $\frac{d(\Delta f)}{dt} < 0$ during a load increase), the battery energy storage system output combines virtual inertia control and virtual droop control with adjustable weights. Conversely, during frequency recovery (e.g., $\frac{d(\Delta f)}{dt} > 0$), it combines virtual negative inertia control and virtual droop control. The power output $\Delta P_E$ is computed as:

$$ \Delta P_E = k_1 \cdot M’_E \cdot \frac{d(\Delta f)}{dt} + k_2 \cdot K’ \cdot \Delta f $$

where $k_1$ and $k_2$ are adaptive weighting coefficients that vary with the frequency error, and $M’_E$ and $K’$ are modified control coefficients incorporating SOC feedback. The weights are defined using exponential functions to ensure smooth transitions. For instance, during the frequency下降 phase:

$$ k_1 = e^{N \Delta f}, \quad k_2 = 1 – e^{N \Delta f} $$

with $N$ as a tuning parameter (e.g., $N=10$), and during the recovery phase:

$$ k_1 = 0.25, \quad k_2 = 0.75 $$

This allocation ensures that the battery energy storage system responds optimally to both transient and steady-state requirements.

To maintain the SOC of the battery energy storage system within safe limits, I implement an adaptive出力 coefficient strategy based on the logistic function. The SOC is divided into three zones: a safe zone (e.g., $0.1 \leq X_{SOC} \leq 0.9$), and越限 zones (below 0.1 or above 0.9). The droop coefficients for charging and discharging, $K_c$ and $K_d$, are adjusted according to the SOC value to prevent overcharging or over-discharging. The formulas are derived from the logistic function to provide smooth and responsive adjustments:

$$ K_c = \begin{cases}

K_{max}, & 0 \leq X_{SOC} < X_{SOC,min} \\

\frac{K_{max} \cdot K_0 \cdot \exp\left[\frac{n (X_{SOC,max} – X_{SOC})}{(X_{SOC,max} – X_{SOC,min})/2}\right]}{K_{max} + K_0 \cdot \exp\left[\frac{n (X_{SOC,max} – X_{SOC})}{(X_{SOC,max} – X_{SOC,min})/2}\right] – 1}, & X_{SOC,min} \leq X_{SOC} \leq X_{SOC,max} \\

0, & X_{SOC,max} < X_{SOC} \leq 1

\end{cases} $$

and similarly for $K_d$, with $K_{max}$ as the maximum coefficient, $K_0$ as the initial coefficient, and $n$ as a shape parameter (e.g., $n=15$). The virtual inertia and negative inertia coefficients are then scaled by these SOC-adjusted values:

$$ M’_E = a K_c \text{ or } a K_d, \quad M’_{E1} = b K_c \text{ or } b K_d $$

where $a$ and $b$ are proportionality constants linking inertia to droop control. This approach ensures that the battery energy storage system operates efficiently while preserving its energy reserves.

The control strategy also incorporates frequency dead bands to optimize the participation of the battery energy storage system. Two dead bands are defined: one for the battery energy storage system (e.g., $|\Delta f| \leq 0.02$ Hz) and another for the thermal unit (e.g., $|\Delta f| \leq 0.033$ Hz). Within the battery dead band, only the battery energy storage system acts to preempt frequency fluctuations; beyond the thermal dead band, both sources collaborate. This reduces unnecessary cycling of the thermal unit and leverages the fast response of the battery energy storage system. The decision logic is summarized in the following flowchart-like description: when $|\Delta f| \leq f_e$, no action; when $f_e < |\Delta f| \leq f_g$, battery energy storage system solo; when $f_g < |\Delta f|$, combined action. This hierarchical activation enhances the overall调频 performance.

To validate the proposed method, I developed a simulation model in MATLAB/Simulink for a typical single-area power grid. The thermal unit has a rated capacity of 660 MW, and the battery energy storage system is configured at 6 MW/6 MWh, operating at full output for the thermal unit. The system parameters are normalized for analysis. I conducted tests under both step and continuous load disturbances to evaluate the frequency response and SOC management. The simulation setup mirrors real-world conditions, allowing for a comprehensive assessment of the battery energy storage system’s role in primary frequency modulation.

For step disturbance tests, a load change of 0.01 per unit (p.u.) was applied. The frequency deviation curves were compared across three scenarios: no battery energy storage system参与, traditional droop control with fixed $K$, and the proposed adaptive control. The results demonstrate that the adaptive method significantly reduces the maximum frequency deviation and accelerates recovery. Key metrics are summarized in the table below:

| Method | Maximum Frequency Deviation (p.u.) | Steady-State Frequency Deviation (p.u.) | Time to Peak (s) | Recovery Time (s) |

|---|---|---|---|---|

| No Battery Energy Storage System | -1.62e-3 | -1.02e-3 | 8.5 | 18.3 |

| Fixed Droop Control | -0.81e-3 | -0.76e-3 | 7.6 | 17.7 |

| Adaptive Control | -0.74e-3 | -0.68e-3 | 7.9 | 15.6 |

The adaptive control not only achieves lower deviations but also maintains SOC within the safe zone, as shown in the SOC variation curves. In contrast, fixed droop control risks SOC越限 due to lack of adaptation. This highlights the importance of integrating SOC feedback into the control loop of the battery energy storage system.

For continuous disturbance tests, a fluctuating load with a duration of 200 seconds was applied. The frequency deviation and SOC were analyzed using root mean square (RMS) metrics to quantify performance. The RMS of frequency deviation $R_f$ and SOC deviation $R_{SOC}$ are calculated as:

$$ R_f = \sqrt{\frac{1}{n} \sum_{i=1}^{n} (f_i – f_0)^2} $$

and

$$ R_{SOC} = \sqrt{\frac{1}{n} \sum_{i=1}^{n} (X_{SOC,i} – X_{SOC,0})^2} $$

where $f_0 = 50$ Hz is the nominal frequency, $X_{SOC,0} = 0.3$ is the initial SOC, and $n$ is the number of samples. The results are presented in the following table:

| Method | $R_f$ (p.u.) | $R_{SOC}$ (p.u.) |

|---|---|---|

| No Battery Energy Storage System | 4.7096e-4 | N/A |

| Fixed Droop Control | 3.3741e-4 | 3.7602e-5 |

| Adaptive Control | 1.6444e-4 | 4.2533e-5 |

The adaptive control yields the lowest frequency deviation RMS, indicating superior调频效果, while the SOC deviation remains comparable to fixed control, ensuring battery health. These simulations confirm that the adaptive comprehensive control method enhances the performance of the battery energy storage system in diverse operating conditions.

Further analysis reveals that the virtual negative inertia control component plays a critical role during frequency recovery. By providing a power boost aligned with the frequency change rate, it mitigates secondary frequency dips that often occur with conventional inertia control. This is particularly beneficial for grids with high renewable penetration, where frequency swings are more pronounced. The battery energy storage system, with its rapid response, can instantaneously adjust output based on the adaptive weights, making it an ideal partner for thermal units. Additionally, the logistic-based SOC management ensures that the battery energy storage system remains ready for subsequent disturbances, extending its operational lifespan.

In practice, the implementation of this control strategy requires real-time monitoring of frequency and SOC, along with robust communication between the battery energy storage system and grid controllers. The adaptive coefficients can be tuned online using optimization algorithms to further improve performance. For instance, machine learning techniques could be employed to predict frequency trends and adjust parameters proactively. This aligns with the evolving smart grid paradigm, where the battery energy storage system serves as a flexible resource for frequency support.

To summarize, the proposed adaptive comprehensive control method for the battery energy storage system participating in primary frequency modulation of thermal power units offers several advantages. First, it combines virtual droop, inertia, and negative inertia controls in a dynamic manner, optimizing output for different frequency phases. Second, it incorporates SOC constraints via logistic-function-based adjustments, preventing overcharge and over-discharge. Third, it reduces frequency deviations and recovery times significantly, as evidenced by simulation results. The battery energy storage system thus becomes a reliable and efficient tool for grid stabilization, complementing traditional generation sources.

Future work could explore the scalability of this method to multi-area grids or hybrid systems with diverse storage technologies. Economic aspects, such as cost-benefit analysis of the battery energy storage system deployment, also warrant investigation. Nonetheless, the current findings underscore the potential of adaptive control in enhancing the role of the battery energy storage system in modern power systems. By continuously refining these strategies, we can pave the way for a more resilient and sustainable energy infrastructure.

In conclusion, the integration of the battery energy storage system into frequency regulation frameworks is essential for addressing the challenges posed by renewable energy integration. My proposed adaptive control method provides a robust solution that balances performance and battery health, ensuring that the battery energy storage system contributes effectively to grid stability. Through detailed modeling and simulation, I have demonstrated its superiority over conventional approaches, highlighting the importance of adaptive mechanisms in the evolving energy landscape.