In recent years, the rapid deployment of battery energy storage systems has been pivotal in supporting renewable energy integration and grid stability. However, safety concerns, particularly thermal runaway events in lithium-ion batteries, pose significant challenges to the widespread adoption of these systems. Thermal runaway, characterized by uncontrolled heat release and gas generation, can propagate within battery modules, leading to fire or explosion hazards. This article investigates the thermal runaway propagation behavior and explosion risks in large-capacity battery modules used in battery energy storage systems, based on experimental studies of 280 Ah lithium iron phosphate (LFP) cells and a 1P48S module. The findings aim to inform safety design and risk mitigation strategies for battery energy storage systems.

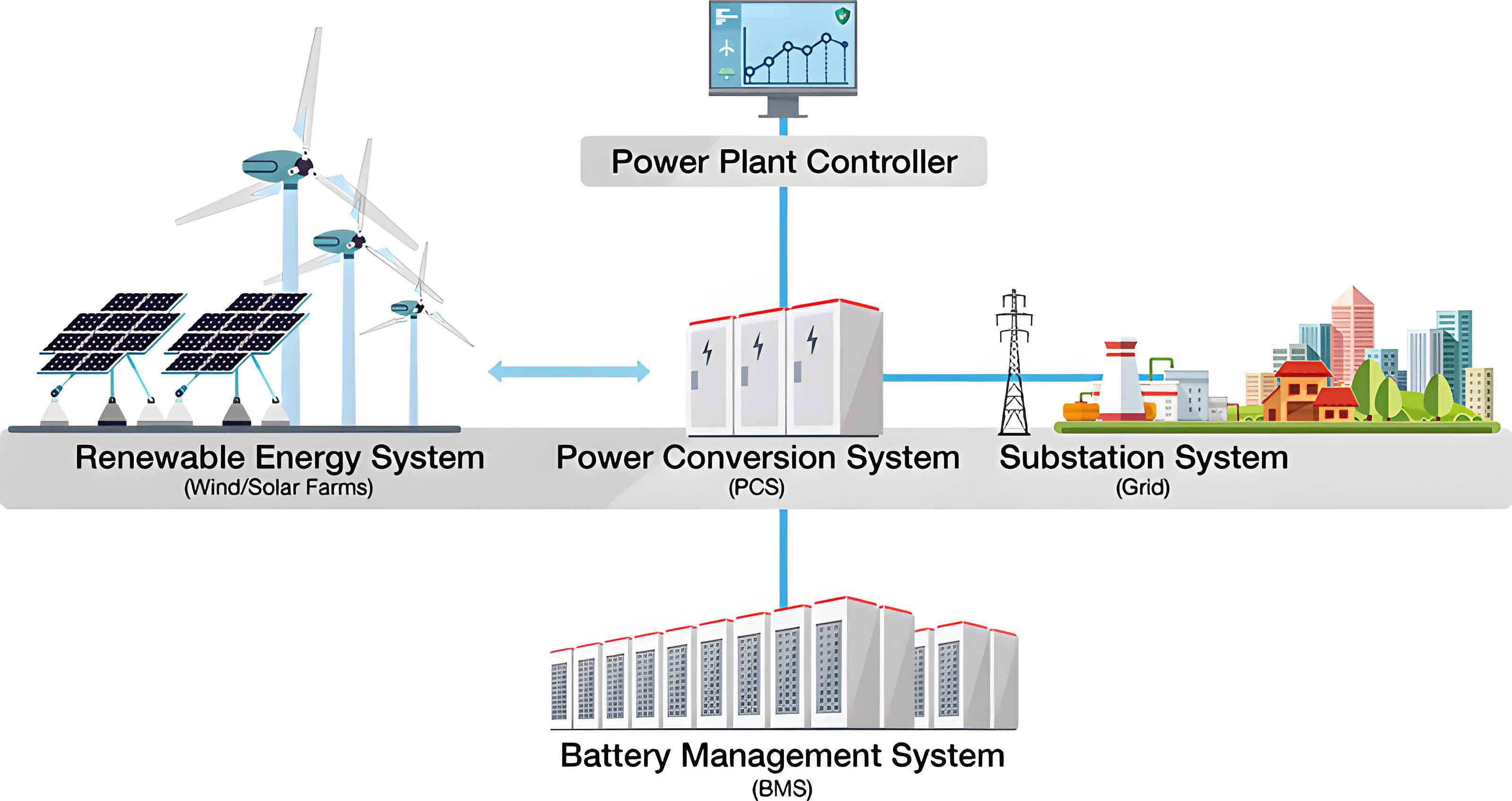

The growing demand for battery energy storage systems is driven by global efforts to achieve carbon neutrality, but incidents of thermal runaway have raised alarms. For instance, several large-scale battery energy storage system failures have been reported worldwide, highlighting the need for a deeper understanding of thermal dynamics. In this study, I focus on the thermal abuse conditions that trigger thermal runaway, analyzing heat and gas production at the cell level and propagation within a realistic module. By examining these aspects, I aim to assess the explosion risks in typical battery energy storage system applications, such as containerized energy storage and commercial storage cabinets.

To begin, I conducted experiments on a single 280 Ah LFP cell under thermal abuse. The cell was heated using an 800 W heating plate in a 320 L pressure vessel, allowing for the collection of gases released during thermal runaway. Temperature sensors were placed at various points on the cell surface, as shown in the experimental setup. The gas composition was analyzed using gas chromatography, and the explosion limits were measured. The results indicate that the cell reached a maximum temperature of 380.1°C during thermal runaway, with a total gas release of 156.8 L. The mixed gas consisted mainly of hydrogen (42.19%), carbon dioxide (27.56%), ethylene (8.56%), and methane (7.96%). The explosion limits of the gas mixture were determined to be 6.9% to 35.5%, which is critical for assessing risks in battery energy storage systems.

The heat transfer during thermal runaway can be described by Fourier’s law of heat conduction. The heat flux \( q(t) \) between cells is given by:

$$ q(t) = \frac{\Delta T}{R} $$

where \( \Delta T \) is the temperature difference between cell surfaces, and \( R \) is the thermal resistance. For a battery cell, the thermal resistance \( R \) can be expressed as:

$$ R = \frac{\delta}{\omega} $$

Here, \( \delta \) is the thickness of the cell, and \( \omega \) is the thermal conductivity in the thickness direction, taken as 2.11 W/(m·K). The total heat transferred \( Q \) between adjacent cells over time \( \Delta t_{tr} \) is:

$$ Q = A \int_{t_{tr}}^{t_{tr} + \Delta t_{tr}} q(t) \, dt $$

where \( A \) is the surface area of the cell. This formula helps quantify the energy flow during propagation in battery energy storage system modules.

For the module-level experiment, a 1P48S battery module was tested in an open environment. The module consisted of 48 cells arranged in rows, with thermal insulation plates placed between some cells to study propagation barriers. Two cells (18# and 19#) were heated simultaneously on both sides to initiate thermal runaway. Temperature sensors were installed on multiple cells and the module enclosure to monitor thermal behavior. The propagation speed \( v \) between cells was calculated using:

$$ v = \frac{\delta}{t_{tr,i} – t_{tr,j}} $$

where \( t_{tr,i} \) and \( t_{tr,j} \) are the thermal runaway onset times for cells i and j. The results showed that thermal runaway propagated to six cells in the module, with speeds ranging from 0.162 to 0.233 mm/s. The maximum surface temperature exceeded 1200°C, indicating severe heat accumulation. The module enclosure’s external temperature reached 281.3°C on the upper surface, emphasizing the need for robust containment in battery energy storage systems.

The gas production from thermal runaway is a key factor in explosion risks. Based on the single-cell experiment, the volume of gas released per cell is 156.8 L. For a module with multiple cells undergoing thermal runaway, the total gas release can be estimated. In a confined space like a battery energy storage system container, the gas concentration \( \phi \) can be calculated as:

$$ \phi = \frac{n \times V_{gas} \times (1 – \phi_c)}{V} $$

where \( n \) is the number of cells in thermal runaway, \( V_{gas} \) is the gas volume per cell, \( \phi_c \) is the volume fraction of non-flammable carbon dioxide, and \( V \) is the net volume of the enclosure. This equation is essential for evaluating explosion hazards in battery energy storage systems.

To summarize the experimental data, I present key findings in tables. Table 1 shows the gas composition from the single-cell thermal runaway, which influences the explosion limits in battery energy storage systems.

| Gas Component | Volume Percentage (%) |

|---|---|

| Hydrogen (H₂) | 42.19 |

| Carbon Dioxide (CO₂) | 27.56 |

| Ethylene (C₂H₄) | 8.56 |

| Methane (CH₄) | 7.96 |

| Carbon Monoxide (CO) | 6.45 |

| Other Gases | 7.28 |

Table 2 provides the thermal runaway propagation parameters in the module, highlighting the heat transfer and speeds relevant to battery energy storage system safety.

| Propagation Path | Thermal Runaway Speed (mm/s) | Heat Transferred (kJ) |

|---|---|---|

| 17# → 16# | 0.233 | 72.6 |

| 20# → 21# | 0.162 | 197.8 |

The explosion risk analysis considers two typical battery energy storage system scenarios: a containerized energy storage system and a commercial storage cabinet. For the containerized system, with a net volume of 5 m³, the gas concentration from six cells in thermal runaway is approximately 13.6%, which is within the explosion limits. This indicates a high explosion risk, suggesting that thermal runaway propagation should be limited to fewer than two cells in such battery energy storage systems. For the commercial cabinet, with a net volume of 0.4 m³, even a single cell venting gas can lead to a high explosion risk, as the gas volume required to reach the lower explosion limit is only 27.6 L. Therefore, prevention of initial cell thermal runaway is critical in these battery energy storage systems.

The thermal runaway propagation in battery modules is influenced by factors such as cell spacing, insulation, and enclosure design. In battery energy storage systems, the use of thermal barriers, like aerogel plates, can slow propagation but may not eliminate risks entirely. The heat accumulation effect due to module enclosures can accelerate propagation, as seen in the higher speeds compared to open environments. This underscores the importance of thermal management in battery energy storage systems to dissipate heat and prevent cascading failures.

Furthermore, the gas release during thermal runaway involves complex chemical reactions. The production of flammable gases like hydrogen and ethylene increases the explosion potential. The modified Le Chatelier formula is used to estimate the explosion limits of mixed gases, accounting for non-flammable components like carbon dioxide. For a gas mixture with hydrogen and carbon dioxide, the explosion limit \( L_m \) is given by:

$$ L_m = L_h \times \frac{\left(1 + \frac{\phi_c}{1 – \phi_c}\right) \times 100}{100 + L_h \times \frac{\phi_c}{1 – \phi_c}} $$

where \( L_h \) is the explosion limit of hydrogen, and \( \phi_c \) is the volume fraction of carbon dioxide. This formula helps in assessing risks for battery energy storage systems where gas mixtures accumulate.

In practice, battery energy storage systems often incorporate safety measures such as ventilation, gas detection, and fire suppression. However, understanding the fundamental behavior of thermal runaway propagation is key to designing effective safeguards. For instance, in large-scale battery energy storage systems, modular designs with compartmentalization can limit propagation, while in smaller systems, enhanced cooling and early warning systems are vital.

To elaborate on the experimental setup, the single-cell test used a pressure vessel to simulate confined conditions, which is representative of battery energy storage system environments. The module test, on the other hand, was conducted in an open space to observe propagation without external confinement, but the module enclosure itself created a semi-confined space. This dichotomy mirrors real-world battery energy storage systems, where cells are packed in modules and housed in containers or cabinets.

The temperature profiles during thermal runaway reveal critical insights. For the single cell, the safety valve opened at around 107.9°C, leading to a temperature drop due to the Joule-Thomson effect. Thermal runaway ensued at 209.5°C, with peak temperatures varying by location. In the module, the heated cells showed rapid temperature rises, and the propagation to adjacent cells occurred within minutes. The heat transfer between cells was quantified using the formulas above, showing that longer time differences between thermal runaway events allowed for more heat accumulation and higher transferred energy.

The explosion risk assessment highlights the vulnerability of battery energy storage systems to gas accumulation. In containerized systems, which are common for grid-scale storage, even a few cells undergoing thermal runaway can create explosive atmospheres. This calls for robust gas venting and dilution systems in battery energy storage systems. For commercial cabinets, used in industrial or residential settings, the smaller volume amplifies risks, necessitating stringent cell-level safety controls.

In conclusion, thermal runaway propagation in large-capacity battery modules poses significant explosion risks in battery energy storage systems. The experiments on 280 Ah LFP cells and a 1P48S module demonstrate that thermal runaway can propagate rapidly, with high temperatures and substantial gas release. The gas mixture, rich in flammable components, has explosion limits that can be reached in typical battery energy storage system enclosures. To mitigate risks, thermal propagation should be contained within two cells in containerized systems, while for smaller cabinets, preventing any cell thermal runaway is essential. These findings provide a basis for improving the safety design of battery energy storage systems through better thermal management, barriers, and risk assessment protocols.

Future work should explore advanced materials for thermal insulation, real-time monitoring techniques, and integrated safety systems for battery energy storage systems. As the adoption of battery energy storage systems continues to grow, a proactive approach to understanding and addressing thermal runaway hazards will be crucial for ensuring reliable and safe energy storage solutions.