In recent years, organic-inorganic halide perovskite solar cells have emerged as a prominent research focus in photovoltaics due to their simple fabrication processes and excellent performance. Among these, tin-lead (Sn-Pb) mixed perovskites are particularly attractive for single-junction and tandem solar cells because of their tunable bandgaps between 1.1 and 1.3 eV and efficient absorption in the visible and near-infrared regions. However, the development of Sn-Pb mixed perovskite solar cells faces significant challenges, primarily the oxidation of Sn²⁺ to Sn⁴⁺, which leads to poor stability and inferior film quality. Traditional additives like SnF₂ are commonly used to suppress Sn²⁺ oxidation, but their high dosage requirements often result in phase separation and aggregation, adversely affecting the efficiency and stability of perovskite solar cells. Therefore, exploring low-dose alternatives is crucial for advancing Sn-Pb mixed perovskite solar cells.

In this study, I investigate the use of stannous iso-octanoate (SnOct₂) as a novel additive in the two-step fabrication of Sn-Pb mixed perovskite films. The two-step method offers better controllability and a wider processing window compared to one-step approaches, making it more suitable for large-scale production. By incorporating SnOct₂ at low doses in the first step, I aim to enhance the crystallization quality, reduce oxidation, and improve the overall performance of perovskite solar cells. The effects of SnOct₂ on film morphology, chemical composition, optical properties, and device performance are systematically examined. My findings demonstrate that SnOct₂ effectively suppresses Sn²⁺ oxidation, reduces defect density, and enhances the stability of perovskite solar cells, leading to a significant improvement in power conversion efficiency (PCE).

Experimental Methods

The materials used in this study include lead iodide (PbI₂, 99.9%), tin iodide (SnI₂, 99.9%), formamidinium iodide (FAI, 99.9%), methylammonium iodide (MAI, 99.9%), methylammonium bromide (MABr, 99.9%), methylammonium chloride (MACl, 99.9%), [6,6]-phenyl-C61-butyric acid methyl ester (PCBM, 99.9%), 2,9-dimethyl-4,7-diphenyl-1,10-phenanthroline (BCP, 99.9%), isopropanol (IPA), fluorine-doped tin oxide (FTO) conductive glass, poly(3,4-ethylenedioxythiophene):polystyrene sulfonate (PEDOT:PSS), solvents such as N,N-dimethylformamide (DMF, 99.9%), dimethyl sulfoxide (DMSO, 99.9%), and chlorobenzene (CB, 99.9%), silver particles (Ag, 99.9%), stannous fluoride (SnF₂, 99.9%), and stannous iso-octanoate (SnOct₂, 99.5%). All reagents were used as received without further purification.

The FTO substrates were cleaned sequentially with glass cleaner, deionized water, and ethanol via ultrasonication for 20 min each, dried with nitrogen, and treated with UV ozone for 30 min. The PEDOT:PSS solution was mixed with deionized water in a 1:1 volume ratio, filtered through a 0.22 μm polytetrafluoroethylene filter, spin-coated onto the FTO substrates at 4000 rpm for 30 s, and annealed at 150 °C in air for 20 min. The coated substrates were then transferred to a nitrogen-filled glovebox for further use.

For the perovskite precursor solutions, PbI₂ (0.91 mmol), SnI₂ (0.39 mmol), and SnF₂ (0.10 mmol) or varying amounts of SnOct₂ (0.015, 0.030, 0.045 mmol) were dissolved in a mixture of 900 μL DMF and 100 μL DMSO, heated at 70 °C for 3 h, and filtered after cooling. The mixed halide solution was prepared by dissolving MACl (6 mg), MABr (6 mg), and FAI (65 mg) in 1000 μL IPA, heated at 70 °C for 3 h, and filtered. The two-step deposition involved spin-coating the PbI₂/SnI₂ precursor solution at 1950 rpm for 35 s onto the PEDOT:PSS layer, followed by spin-coating the mixed halide solution at 1600 rpm for 30 s. The films were annealed at 50 °C for 90 s and 120 °C for 20 min to form FAₓMA₁₋ₓPb₀.₇Sn₀.₃IₙBr₁₋ₙ mixed perovskite films, labeled as PVK-0.10SF, PVK-0.015SO, PVK-0.030SO, and PVK-0.045SO based on the additive used.

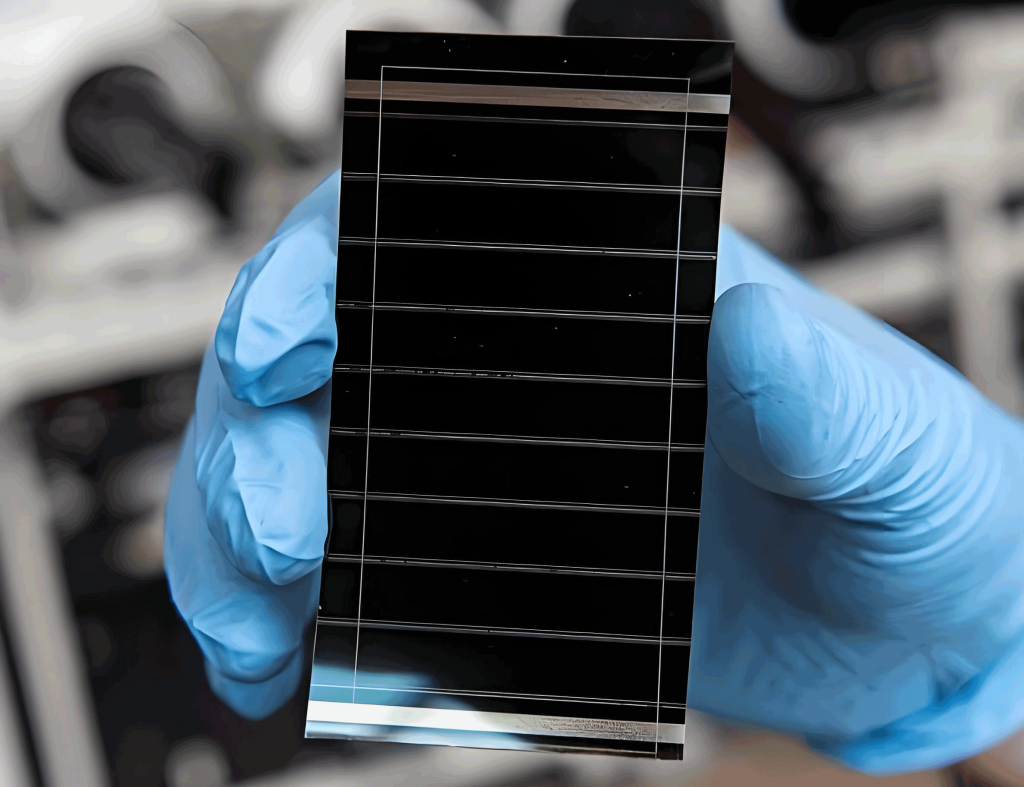

The perovskite solar cells were completed by spin-coating PCBM solution (20 mg/mL in CB) at 2000 rpm for 30 s, followed by BCP solution (5 mg/mL in IPA) at 5000 rpm for 30 s. A 120 nm thick silver electrode was thermally evaporated at 1 nm/s under a vacuum of 5×10⁻⁴ Pa. The devices were designated as PSC-0.10SF, PSC-0.015SO, PSC-0.030SO, and PSC-0.045SO.

Characterization techniques included X-ray diffraction (XRD) for crystal structure analysis, scanning electron microscopy (SEM) for morphology, ultraviolet-visible-near infrared (UV-VIS-NIR) spectroscopy for optical properties, X-ray photoelectron spectroscopy (XPS) and ultraviolet photoelectron spectroscopy (UPS) for surface chemistry and energy levels, current density-voltage (J-V) measurements for photovoltaic performance, electrochemical impedance spectroscopy (EIS) for charge recombination, and contact angle measurements for hydrophobicity.

Results and Discussion

Crystal Structure and Morphology

The XRD patterns of Sn-Pb mixed perovskite films with different additives are shown in Figure 1. The diffraction peaks at 2θ = 14.0°, 24.4°, 28.2°, 31.7°, and 40.4° correspond to the (110), (202), (220), (310), and (400) planes of the tetragonal perovskite phase, respectively. The film with SnF₂ additive exhibits an additional peak at 2θ = 12.7°, attributed to PbSnI₄ impurities, indicating incomplete reaction. In contrast, films with SnOct₂ show no such impurities, suggesting enhanced reaction completeness. The full width at half maximum (FWHM) of the (110) and (220) peaks is smaller for SnOct₂-containing films, indicating improved crystallinity. The PVK-0.030SO film exhibits the sharpest peaks, confirming the best crystallization quality.

SEM images reveal the surface and cross-sectional morphology of the films. The PVK-0.030SO film shows a uniform surface with an average grain size of 850 nm and reduced grain boundaries, while the SnF₂-based film has smaller grains and visible pinholes. The cross-sectional images confirm that all films have grains larger than the film thickness, facilitating vertical electron transport. Excessive SnOct₂ (PVK-0.045SO) leads to uneven surfaces, highlighting the importance of optimal dosing. The improved morphology with SnOct₂ is attributed to the strong coordination between the C=O groups of SnOct₂ and Pb²⁺/Sn²⁺ ions, which regulates crystallization and reduces defects.

Chemical Composition and Oxidation Resistance

XPS analysis was conducted to evaluate the chemical states and oxidation resistance of the films after storage in a glovebox for 7 days. The Sn3d spectra show that the Sn3d₅/₂ and Sn3d₃/₂ peaks for PVK-0.030SO appear at lower binding energies (486.28 and 494.71 eV) compared to PVK-0.10SF (486.49 and 494.96 eV), indicating higher electron density around Sn atoms due to SnOct₂ coordination. The I3d peaks also shift to lower binding energies for SnOct₂-based films, suggesting suppressed I⁻ oxidation. The Sn²⁺/Sn⁴⁺ ratio, determined by peak fitting, is 0.935:0.065 for PVK-0.030SO versus 0.842:0.158 for PVK-0.10SF, demonstrating that SnOct₂ effectively inhibits Sn²⁺ oxidation. The contact angle measurements show that PVK-0.030SO has a higher water contact angle (59.7°) than PVK-0.10SF (38.5°), indicating enhanced hydrophobicity due to the alkyl chains of SnOct₂, which form a barrier against moisture and oxygen.

Optical Properties and Energy Levels

UV-VIS-NIR spectra reveal that SnOct₂-based films exhibit superior light absorption in the 400–600 nm range, with PVK-0.030SO showing the highest absorption. This is consistent with the improved crystallinity and reduced defects. The Tauc plots derived from the absorption edges indicate a bandgap of approximately 1.25 eV for all films, with minimal variation. UPS measurements were used to determine the valence band maximum (VBM), conduction band minimum (CBM), and Fermi level positions. The VBM and CBM are calculated using the formulas:

$$E_{\text{VBM}} = E_{\text{cut-off}} – (E_{\text{F,edge}} – 21.22)$$

$$E_{\text{CBM}} = E_{\text{VBM}} + E_g$$

where $E_{\text{cut-off}}$ is the cutoff binding energy, $E_{\text{F,edge}}$ is the Fermi edge energy, and $E_g$ is the bandgap. The results show that the CBM of PVK-0.030SO shifts downward by 0.06 eV compared to PVK-0.10SF, and the Fermi level moves closer to the CBM, promoting band bending and enhancing electron extraction from the perovskite layer to the electron transport layer. This alignment facilitates efficient charge separation and transport in perovskite solar cells.

Photovoltaic Performance and Stability

The photovoltaic performance of the Sn-Pb mixed perovskite solar cells was evaluated under AM 1.5G illumination. The J-V curves of the best-performing devices are shown in Figure 2, and the average parameters from 10 devices are summarized in Table 1. The PSC-0.10SF device exhibits a PCE of 11.63%, with a $V_{\text{OC}}$ of 0.631 V, $J_{\text{SC}}$ of 23.47 mA/cm², and FF of 78.54%. In contrast, the PSC-0.030SO device achieves a PCE of 17.25%, with a $V_{\text{OC}}$ of 0.731 V, $J_{\text{SC}}$ of 29.07 mA/cm², and FF of 81.15%. The enhancement in $J_{\text{SC}}$ and FF is attributed to the improved film quality, reduced recombination, and better charge transport. The increase in $V_{\text{OC}}$ results from suppressed non-radiative recombination due to lower defect density.

| Sample | $V_{\text{OC}}$ (V) | $J_{\text{SC}}$ (mA/cm²) | FF (%) | PCE (%) |

|---|---|---|---|---|

| PSC-0.10SF | 0.628 ± 0.021 | 23.17 ± 2.24 | 73.76 ± 4.77 | 10.73 ± 0.89 |

| PSC-0.015SO | 0.698 ± 0.004 | 26.45 ± 0.66 | 75.03 ± 3.05 | 13.86 ± 0.48 |

| PSC-0.030SO | 0.728 ± 0.009 | 28.64 ± 0.58 | 80.83 ± 0.57 | 16.86 ± 0.38 |

| PSC-0.045SO | 0.701 ± 0.011 | 27.67 ± 0.79 | 77.34 ± 2.59 | 15.01 ± 0.73 |

The stability of unencapsulated devices was tested by storing them in a nitrogen atmosphere for 50 days and in ambient air (25 ± 5 °C, 55 ± 5% humidity) for 20 days. The PSC-0.030SO device retains over 70% of its initial PCE after 50 days in nitrogen, while PSC-0.10SF degrades to 20%. In air, PSC-0.030SO maintains 40% of its initial PCE after 20 days, whereas PSC-0.10SF fails completely within 15 days. The enhanced stability is due to the antioxidant properties of SnOct₂ and the hydrophobic surface, which protect against moisture and oxygen ingress.

Defect Analysis and Charge Transport

To investigate the defect density and charge transport properties, single-electron devices with the structure FTO/SnO₂/FAₓMA₁₋ₓPb₀.₇Sn₀.₃IₙBr₁₋ₙ/PCBM/Ag were fabricated. The current-voltage (I-V) characteristics in the space-charge-limited current (SCLC) regime were analyzed to determine the trap density ($N_t$) using the formula:

$$N_t = \frac{V_{\text{TFL}} \varepsilon_r \varepsilon_0}{e L^2}$$

where $V_{\text{TFL}}$ is the trap-filling limit voltage, $\varepsilon_r$ is the relative permittivity, $\varepsilon_0$ is the vacuum permittivity, $e$ is the elementary charge, and $L$ is the film thickness. The $V_{\text{TFL}}$ for PVK-0.030SO is 0.358 V, lower than that of PVK-0.10SF (0.543 V). The calculated $N_t$ values are 4.74 × 10¹⁵ cm⁻³ for PVK-0.030SO and 7.20 × 10¹⁵ cm⁻³ for PVK-0.10SF, indicating a significant reduction in trap states with SnOct₂ addition. EIS measurements show a larger recombination resistance ($R_{\text{rec}}$) for PSC-0.030SO, confirming suppressed charge recombination. Leakage current measurements further support the reduced defect density, as PSC-0.030SO exhibits lower leakage current than PSC-0.10SF.

Conclusion

In this study, I demonstrated the effectiveness of low-dose SnOct₂ as an additive in the two-step fabrication of Sn-Pb mixed perovskite solar cells. The incorporation of SnOct₂ enhances the crystallization quality, resulting in larger grain sizes (up to 850 nm) and reduced grain boundaries. XPS analysis confirms the superior oxidation resistance of SnOct₂, with films retaining 93.5% Sn²⁺ after 7 days of storage. The optimized films exhibit improved light absorption, favorable energy level alignment, and reduced trap density from 7.20 × 10¹⁵ to 4.74 × 10¹⁵ cm⁻³. These improvements lead to a significant boost in the performance of perovskite solar cells, with the best device achieving a PCE of 17.25%, compared to 11.63% for SnF₂-based devices. Furthermore, the SnOct₂-based devices show enhanced stability, retaining over 70% of their initial PCE after 50 days in nitrogen and 40% after 20 days in air. This work highlights the potential of SnOct₂ as a low-dose additive for high-performance and stable Sn-Pb mixed perovskite solar cells, paving the way for their commercial application in photovoltaics.

The development of efficient and stable perovskite solar cells is crucial for the advancement of renewable energy technologies. The use of Sn-Pb mixed perovskites, combined with innovative additives like SnOct₂, addresses key challenges in the field. Future research should focus on optimizing the dosage and exploring the mechanisms of SnOct₂ in other perovskite compositions to further improve the efficiency and stability of perovskite solar cells. The insights gained from this study contribute to the ongoing efforts to make perovskite solar cells a viable and sustainable energy solution.