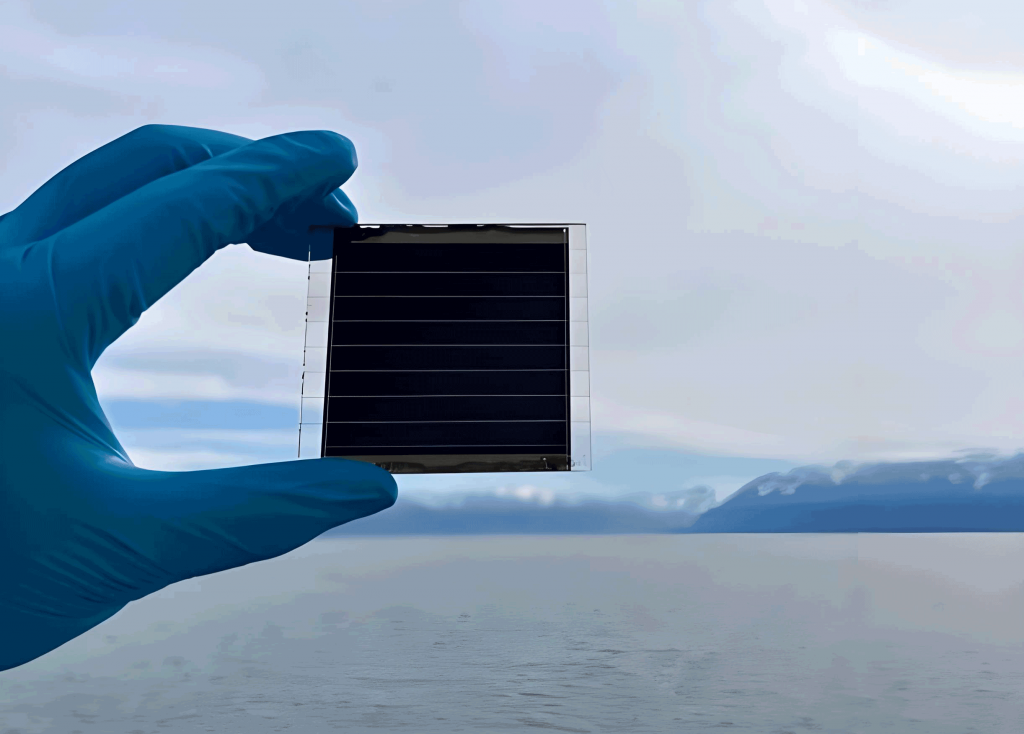

In recent years, perovskite solar cells have emerged as a revolutionary technology in the field of photovoltaics, achieving remarkable power conversion efficiencies exceeding 26% and demonstrating potential for commercial scalability. However, the presence of lead in these perovskite solar cells poses significant environmental and health risks due to its toxicity. As a researcher focused on sustainable energy solutions, I explore the mechanisms of lead leakage, its detrimental effects, and the strategies for suppression and recovery in this comprehensive review. The widespread adoption of perovskite solar cells hinges on addressing these challenges, and I delve into the latest advancements in encapsulation, chemical adsorption, and recycling techniques to mitigate lead contamination.

The high efficiency of perovskite solar cells is primarily attributed to the optoelectronic properties of lead-based halide perovskites, such as MAPbI3 and FAPbI3. These materials exhibit excellent light absorption and charge transport characteristics. However, their instability under environmental stressors like moisture, heat, and UV radiation leads to degradation, resulting in the release of soluble lead compounds. For instance, the decomposition of MAPbI3 in the presence of water follows the reaction: $$\ce{CH3NH3PbI3 + H2O -> CH3NH2 + HI + PbI2}$$ where PbI2 can further dissolve and contaminate soil and water sources. This process underscores the importance of developing robust suppression methods for perovskite solar cells to prevent lead leakage.

Lead toxicity is a critical concern for perovskite solar cells, as even minimal exposure can cause severe health issues. The face density of lead in a typical perovskite solar cell with a 500 nm thick layer can be calculated using the formula: $$\rho_{\text{Pb}} = \frac{m_{\text{Pb}}}{A} = \frac{\rho_{\text{perovskite}} \times t \times w_{\text{Pb}}}{A}$$ where $\rho_{\text{perovskite}}$ is the density of the perovskite material (e.g., 4.10 g/cm³ for FAPbI3), $t$ is the thickness, $w_{\text{Pb}}$ is the mass fraction of lead (e.g., 32.6% for FAPbI3), and $A$ is the area. For a standard device, this results in a lead face density of approximately 70 μg/cm². If a small perovskite solar cell module of 1.4 cm² is damaged, it could release enough lead to exceed safe blood lead levels in children, highlighting the urgency of leakage prevention in perovskite solar cells.

To quantify the risks, various simulation methods have been developed to assess lead leakage from perovskite solar cells. For example, hail impact tests involve using metal balls to simulate damage, followed by water droplet experiments to measure lead concentration. The lead leakage rate $R_{\text{Pb}}$ can be expressed as: $$R_{\text{Pb}} = \frac{C_{\text{Pb}} \times V}{t \times A}$$ where $C_{\text{Pb}}$ is the concentration of lead in water, $V$ is the volume, $t$ is time, and $A$ is the area of the damaged perovskite solar cell. Studies show that encapsulation methods can reduce leakage rates by over 95%, as summarized in Table 1.

| Encapsulation Method | Leakage Rate (mg/h/m²) | Reduction Efficiency (%) |

|---|---|---|

| Glass Cover | 30.0 | 0 |

| Epoxy Resin | 0.08 | 99.7 |

| Polymer Sandwich | 3.4 | 88.7 |

| Chemical Adsorption Layer | 0.014 | 99.9 |

In terms of detection, techniques like inductively coupled plasma mass spectrometry (ICP-MS) offer high sensitivity for measuring lead concentrations down to parts per billion levels. The detection limit for lead in water can be modeled as: $$L_{\text{detection}} = k \times \frac{\sigma_{\text{blank}}}{S}$$ where $k$ is a constant, $\sigma_{\text{blank}}$ is the standard deviation of blank measurements, and $S$ is the sensitivity. For perovskite solar cells, ICP-MS has been instrumental in validating the effectiveness of suppression strategies, ensuring that lead leakage remains within regulatory limits such as the U.S. Environmental Protection Agency’s threshold of 15 μg/L for water.

Suppression strategies for lead leakage in perovskite solar cells can be broadly categorized into physical isolation and chemical adsorption. Physical methods involve encapsulation with materials like glass, epoxy resins, or polymers to create a barrier against environmental exposure. For instance, the use of superhydrophobic coatings on perovskite layers reduces water infiltration, thereby minimizing lead dissolution. The contact angle $\theta$ for such surfaces can be described by Young’s equation: $$\cos \theta = \frac{\gamma_{\text{SV}} – \gamma_{\text{SL}}}{\gamma_{\text{LV}}}$$ where $\gamma$ represents interfacial tensions. A high contact angle (e.g., >150°) indicates effective water repellence, which is crucial for protecting perovskite solar cells from moisture-induced degradation.

Chemical adsorption layers, on the other hand, utilize functional groups to bind lead ions and prevent their release. Common adsorbents include thiols, sulfonates, and phosphates, which form insoluble complexes with lead. The adsorption capacity $q_e$ can be calculated using the Langmuir isotherm model: $$q_e = \frac{q_m K C_e}{1 + K C_e}$$ where $q_m$ is the maximum adsorption capacity, $K$ is the equilibrium constant, and $C_e$ is the equilibrium concentration. For example, incorporating sulfonated graphene aerogels into perovskite solar cells has shown adsorption capacities exceeding 99%, significantly reducing lead leakage in damaged devices.

Moreover, innovative materials like metal-organic frameworks (MOFs) and porphyrin-based compounds have been integrated into perovskite solar cells to enhance lead capture. These materials leverage coordination chemistry, where the binding energy $E_b$ between lead and functional groups can be approximated as: $$E_b = \frac{k}{r^n}$$ where $k$ is a constant, $r$ is the distance, and $n$ depends on the interaction type. By embedding such adsorbents within the device structure, perovskite solar cells can achieve dual functions of high efficiency and environmental safety.

Recycling strategies for perovskite solar cells are essential to close the material lifecycle and minimize lead waste. Lead recovery often involves solvent dissolution followed by precipitation or electrochemical deposition. The overall recovery efficiency $\eta_{\text{recovery}}$ can be defined as: $$\eta_{\text{recovery}} = \frac{m_{\text{recovered}}}{m_{\text{initial}}} \times 100\%$$ where $m_{\text{recovered}}$ is the mass of recovered lead and $m_{\text{initial}}$ is the initial lead content. Methods such as using deep eutectic solvents for electrochemical deposition have achieved recovery rates of up to 99.8%, as detailed in Table 2.

| Recovery Method | Recovery Efficiency (%) | PCE of Recycled Device (%) |

|---|---|---|

| Solvent Dissolution | 96.7 | 11.36 |

| Electrochemical Deposition | 99.8 | 13.5 |

| Ion Exchange | 99.9 | 14.6 |

| Precipitation | 95.0 | 10.5 |

In addition to lead, other components of perovskite solar cells, such as transparent conductive oxides (TCOs) and electron transport layers, can be recycled to reduce costs and environmental impact. For example, FTO glass substrates can be reused after dissolving the perovskite layer with dimethylformamide (DMF), maintaining their optoelectronic properties. The sheet resistance $R_s$ of recycled FTO remains comparable to virgin substrates, ensuring that recycled perovskite solar cells retain high performance. The power conversion efficiency of devices made with recycled materials often reaches over 20%, demonstrating the viability of circular economy approaches for perovskite solar cells.

Despite these advancements, challenges persist in scaling up suppression and recovery technologies for perovskite solar cells. The cost of advanced encapsulation materials and the energy consumption of recycling processes need optimization. Future research should focus on developing low-cost, biodegradable polymers for encapsulation and improving the purity of recovered lead to maintain the efficiency of perovskite solar cells. Furthermore, international standards and policies for the end-of-life management of perovskite solar cells must be established to ensure safe deployment and recycling.

In conclusion, the journey toward sustainable perovskite solar cells requires a holistic approach combining effective lead leakage suppression and efficient recovery methods. By leveraging physical and chemical strategies, along with innovative recycling techniques, we can mitigate the environmental risks associated with lead while harnessing the full potential of perovskite solar cells. As I reflect on the progress made, it is clear that interdisciplinary collaboration and continued innovation are key to achieving green and commercially viable perovskite solar cells for the future energy landscape.