In recent years, the demand for sustainable and energy-efficient solutions in grain storage has grown significantly, driven by the need to reduce carbon emissions and operational costs. As part of a collaborative research initiative, we developed and implemented an off-grid solar system integrated with air conditioning for temperature control in grain storage facilities. This system leverages photovoltaic technology to power air conditioning units, aiming to minimize reliance on conventional grid electricity and achieve low-carbon or even zero-carbon operations. The core innovation lies in an intelligent controller that seamlessly switches between solar and grid power, prioritizing solar energy to ensure efficiency and reliability. In this article, we describe the design, implementation, and results of this off-grid solar system, focusing on its application in grain storage to maintain optimal temperature and humidity conditions while reducing energy consumption and environmental impact.

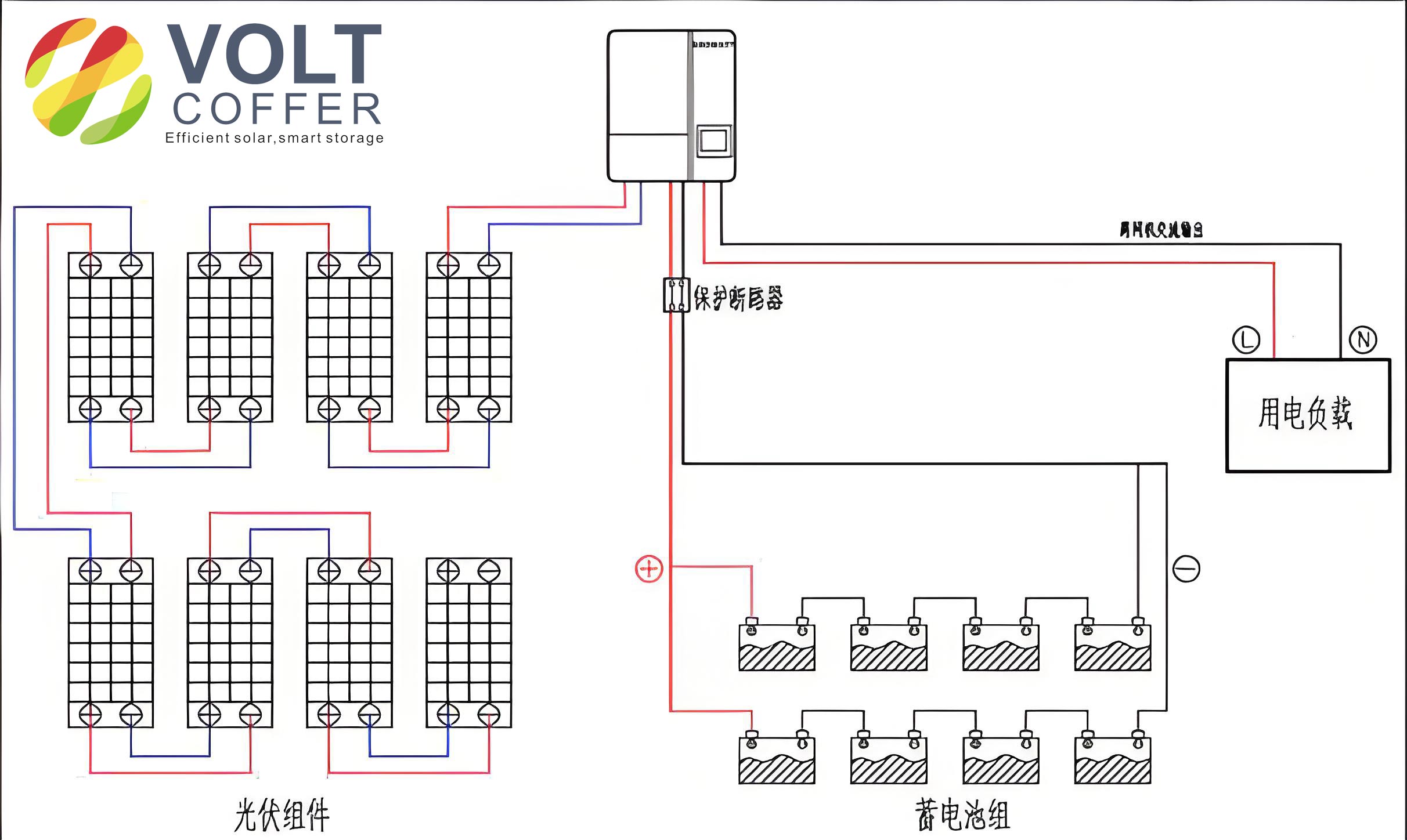

The off-grid solar system for air conditioning temperature control consists of several key components: photovoltaic panels, an intelligent controller, photovoltaic direct-drive air conditioners, and an energy management system. The photovoltaic panels convert solar energy into direct current (DC) electricity, which is then used to power the air conditioners directly or stored for later use. The intelligent controller plays a critical role by employing smart compensation algorithms and mode-switching technology to manage power sources. It ensures that solar power is utilized first, with grid electricity supplementing any shortfall, thereby achieving high efficiency and reducing waste. This off-grid solar system is designed to operate independently of the grid, making it ideal for remote or energy-sensitive applications like grain storage, where maintaining consistent temperatures is essential for preserving grain quality.

To evaluate the performance of this off-grid solar system, we conducted experiments in multiple grain storage warehouses. We selected four similar warehouses with comparable insulation and sealing properties, all storing rice over the same period. One warehouse was equipped with a conventional grid-powered air conditioning system as a control, while another utilized the full off-grid solar system with photovoltaic direct-drive air conditioners. The remaining two warehouses were fitted with the intelligent controller combined with existing alternating current (AC) variable-frequency air conditioners to assess adaptability. Temperature and humidity sensors were placed at five points in each warehouse—four corners and one center—at a height of 1 meter above the grain surface. Data on energy consumption, temperature, humidity, and grain quality were collected continuously over several months, from June to September, to capture seasonal variations in solar irradiation and climate conditions.

The energy management system played a vital role in monitoring and optimizing the off-grid solar system. It tracked real-time data on warehouse temperature, humidity, energy consumption, and equipment performance, generating reports for analysis. Key parameters included daily electricity usage, photovoltaic power generation, and the grid electricity replacement rate, which indicates the proportion of solar energy replacing grid power. This system allowed us to analyze the efficiency of the off-grid solar system under different weather conditions, such as sunny, cloudy, and rainy days, and to calculate energy savings and carbon reduction benefits. By integrating this data, we could refine the control algorithms and ensure the off-grid solar system met the storage requirements while minimizing costs.

The intelligent controller is the heart of the off-grid solar system, incorporating advanced algorithms for power management. The smart compensation algorithm calculates the required output power based on the temperature difference between the setpoint and the actual warehouse temperature. The output power \( P_0 \) is determined as the sum of photovoltaic power \( P_s \) and grid power \( P_a \), expressed as:

$$ P_0 = P_s + P_a $$

Here, \( P_0 \) represents the total power needed to drive the air conditioning system, \( P_s \) is the real-time photovoltaic power generated by the solar panels, and \( P_a \) is the grid power input. The controller continuously monitors \( P_s \) and adjusts \( P_a \) accordingly to maintain stable operation, ensuring that solar energy is prioritized and any deficit is compensated by grid electricity without interruption. This approach maximizes the utilization of the off-grid solar system, reducing reliance on grid power and enhancing sustainability.

Mode-switching technology in the intelligent controller enables the off-grid solar system to adapt to varying solar conditions. During sunny days, when photovoltaic generation exceeds the air conditioning demand, the system operates entirely on solar power, achieving zero grid electricity consumption. In cloudy or rainy weather, where solar output is reduced, the controller automatically switches to a hybrid mode, using grid power to supplement the shortfall. This seamless transition ensures continuous temperature control without compromising grain storage conditions. The off-grid solar system thus provides a flexible and reliable solution, capable of handling fluctuations in solar energy availability while maintaining efficient operation.

The photovoltaic direct-drive air conditioners are specifically designed for integration with the off-grid solar system. These units convert DC electricity from the solar panels directly into cooling power, eliminating the need for inverters and reducing energy losses. By operating on DC power, they achieve higher energy efficiency compared to traditional AC air conditioners, with energy savings of over 20%. This direct-drive capability makes the off-grid solar system more cost-effective and easier to install, as it simplifies the power conversion process. In our experiments, we used 6 horsepower (HP) photovoltaic air conditioners with a rated cooling capacity of 16.9 kW, powered by 24 photovoltaic panels per warehouse, each with a capacity of 550 W. This configuration ensured that the off-grid solar system could meet the cooling demands of the grain storage environment.

To quantify the performance of the off-grid solar system, we analyzed energy consumption data from the experimental warehouses. The control warehouse, using conventional grid-powered air conditioning, consumed a total of 12,722.9 kWh of grid electricity during the June to September period. In contrast, the warehouse equipped with the full off-grid solar system, including photovoltaic direct-drive air conditioners, consumed only 5,186.7 kWh of grid electricity, resulting in a grid electricity replacement rate of 59%. This demonstrates the significant energy-saving potential of the off-grid solar system. The grid electricity replacement rate, defined as the percentage reduction in grid power usage due to solar energy, varied monthly based on solar irradiation levels, as shown in the table below.

| Month | Grid Electricity Replacement Rate (%) |

|---|---|

| June | 69 |

| July | 52 |

| August | 61 |

| September | 72 |

The variation in replacement rates highlights the impact of weather on the off-grid solar system’s performance. For instance, higher solar irradiation in June and September led to replacement rates above 65%, whereas July, with more cloudy days, saw a lower rate. This underscores the importance of the intelligent controller in optimizing power usage across different conditions. Additionally, we observed that on sunny days, the off-grid solar system could achieve a 100% replacement rate during peak sunlight hours, further emphasizing its efficiency.

Energy savings were also evaluated by comparing the off-grid solar system with traditional systems. The warehouses using the intelligent controller with existing AC variable-frequency air conditioners achieved a photovoltaic power replacement rate of 50–55% on sunny days, while those with photovoltaic direct-drive air conditioners reached 60–65%. Overall, the off-grid solar system reduced total energy consumption by approximately 7,536.2 kWh for the full experimental period. Assuming an electricity cost of $0.52 per kWh, this translates to annual savings of about $3,918.80 per warehouse. At a higher electricity rate of $1.00 per kWh, savings increase to $7,536.20, significantly shortening the payback period for the initial investment in the off-grid solar system.

The economic benefits of the off-grid solar system are further illustrated by the investment analysis. For a standard warehouse storing 5,000 tons of grain, the system requires 24 photovoltaic panels with a total capacity of 12 kW and two 6 HP photovoltaic direct-drive air conditioners. The estimated investment cost is $11,400, including $4,800 for the photovoltaic panels and $6,600 for the air conditioners. Based on the energy savings, the payback period ranges from 6.4 to 12.2 years, depending on local electricity prices. This makes the off-grid solar system a financially viable option for grain storage facilities, especially in regions with high solar potential and rising energy costs.

Beyond economic advantages, the off-grid solar system offers substantial environmental benefits. By saving 7,536.2 kWh of grid electricity, the system reduces carbon emissions equivalent to burning 3,014.5 kg of standard coal. This reduction includes avoiding 2,050 kg of carbon dust, 7,514 kg of carbon dioxide, 226 kg of sulfur dioxide, and 113 kg of nitrogen oxides. In terms of ecological impact, this is comparable to planting 50 trees annually. These figures highlight the role of the off-grid solar system in promoting sustainable practices and contributing to global carbon neutrality goals. The off-grid solar system not only lowers operational costs but also supports environmental stewardship in the agriculture sector.

Grain quality preservation is a critical aspect of storage, and the off-grid solar system effectively maintained optimal conditions. Throughout the experiment, the warehouses equipped with the system consistently held average grain temperatures between 15.1°C and 16.1°C, within the target range of 18–22°C for space temperature and below 20°C for surface grain temperature. Relative humidity was controlled at 65% ± 10%, preventing mold growth and spoilage. Regular sampling and analysis according to standard protocols confirmed that grain quality, including moisture content and viability, remained stable over the storage period. This demonstrates that the off-grid solar system can reliably support low-temperature grain storage without compromising quality, making it a practical solution for long-term preservation.

The social implications of adopting the off-grid solar system are profound. By enabling energy self-sufficiency in grain storage, it enhances food security and reduces post-harvest losses, which are significant challenges in many regions. The system’s scalability allows deployment in individual or multiple warehouses, with centralized or distributed control, making it accessible for small-scale and large-scale operations alike. Moreover, the off-grid solar system aligns with national and international standards for green storage, facilitating compliance with regulations and promoting best practices in the industry. As climate change intensifies, such innovations are crucial for building resilient agricultural systems that minimize environmental impact while ensuring food supply stability.

In conclusion, the off-grid solar system for air conditioning temperature control in grain storage represents a significant advancement in sustainable technology. Through the integration of photovoltaic panels, intelligent controllers, and direct-drive air conditioners, it achieves high energy efficiency, cost savings, and environmental benefits. Our experiments confirm that the off-grid solar system can reduce grid electricity consumption by up to 72% under optimal conditions, with an average replacement rate of 59% over the summer months. The smart compensation algorithm and mode-switching technology ensure reliable operation across varying weather conditions, while the energy management system provides comprehensive monitoring and optimization. With a reasonable payback period and positive ecological impact, the off-grid solar system is a promising solution for modern grain storage facilities seeking to adopt green practices. Future work could focus on enhancing battery storage integration and expanding the system to other agricultural applications, further leveraging the potential of off-grid solar systems.

The success of this off-grid solar system underscores the importance of renewable energy in addressing the energy-intensive needs of grain storage. By prioritizing solar power and minimizing grid dependence, it sets a benchmark for low-carbon operations in the sector. As we continue to refine the technology, we anticipate broader adoption and continued innovation in off-grid solar systems, driving progress toward a sustainable and food-secure future.