This study investigates the integration of photovoltaic (PV) systems with proton exchange membrane (PEM) electrolyzers to optimize hydrogen production efficiency under varying solar irradiance conditions. Three coupling configurations—direct, indirect, and optimized—are analyzed to evaluate their energy transfer efficiency, hydrogen generation rates, and system stability. The role of Maximum Power Point Tracking (MPPT) controllers, DC-DC converters, and energy storage systems is critically examined to address intermittent solar power challenges.

1. System Architecture and Mathematical Modeling

1.1 Photovoltaic System Model

The PV system is modeled using a single-diode equivalent circuit. The current-voltage relationship is expressed as:I=Iph−I0[exp(aU+IRs)−1]−RshU+IRs,

where:

- Iph = Photocurrent (A), calculated as Iph=1000G[Isc+K0(T−Tref)],

- I0 = Diode saturation current (A), derived from temperature-dependent equations.

The MPPT controller ensures maximum power extraction under varying irradiance (G) and temperature (T) conditions.

1.2 PEM Electrolyzer Model

The PEM electrolyzer voltage comprises three components:Ucell=Uocv+ηact+ηohm,

where:

- Uocv = Open-circuit voltage (V), calculated via the Nernst equation,

- ηact = Activation overpotential (V), derived using the Butler-Volmer equation,

- ηohm = Ohmic overpotential (V), proportional to current density and membrane resistance.

Hydrogen production rate (nH2) is governed by Faraday’s law:nH2=2FI.

2. Coupling Configurations and Control Strategies

2.1 Indirect Coupling System

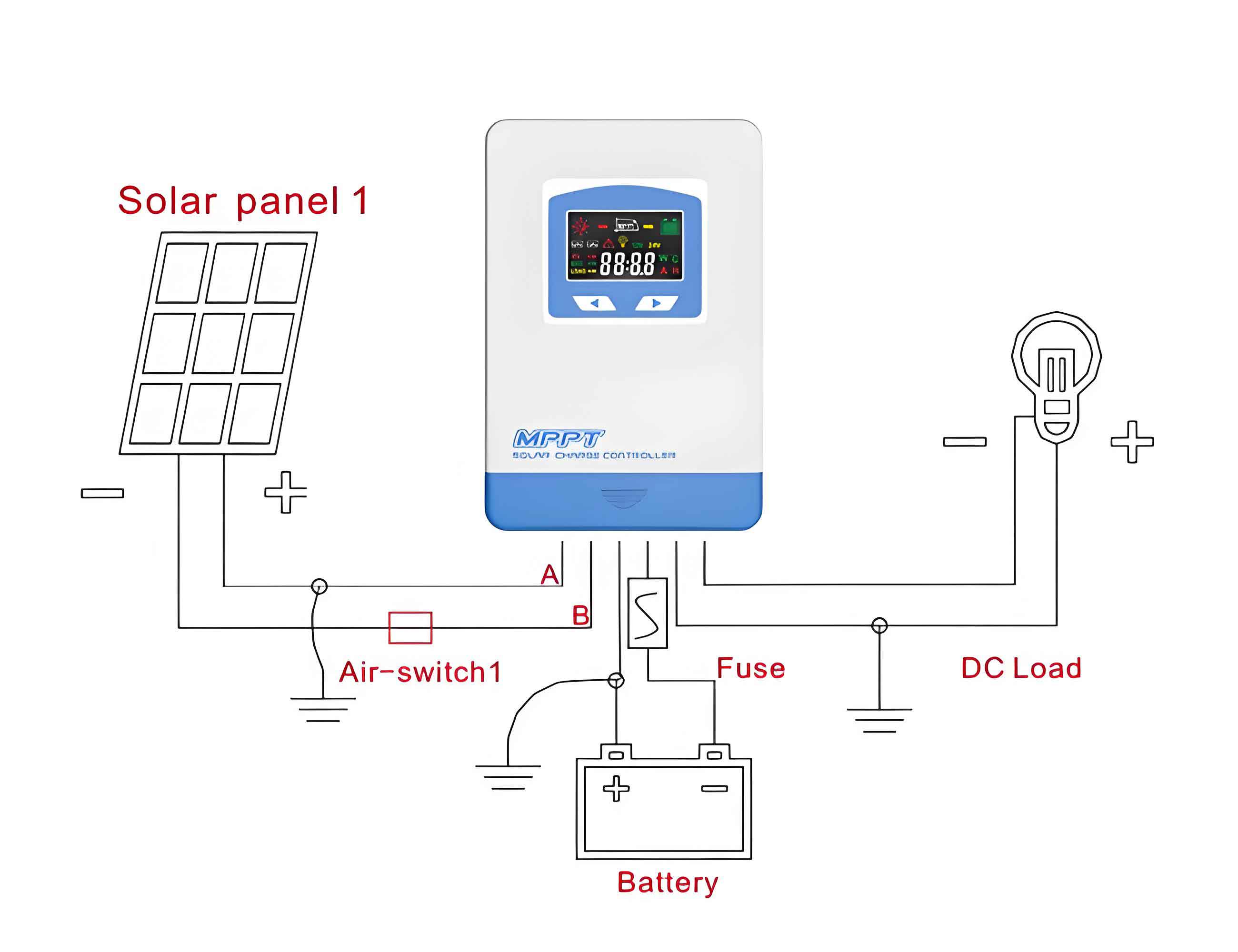

The indirect coupling system integrates a battery storage system, MPPT controller, and bidirectional DC-DC converter (Figure 1). Key features:

- MPPT Algorithm: Incremental conductance method for precise power tracking.

- Battery Control: Dual-loop PI control stabilizes the DC bus voltage (Vbus=48 V).

- Voltage outer loop adjusts battery current reference.

- Current inner loop regulates charge/discharge cycles.

2.2 Direct and Optimized Coupling Systems

- Direct Coupling: PV array directly powers the electrolyzer without power electronics. Suboptimal due to impedance mismatch.

- Optimized Coupling: Combines MPPT and DC-DC converters to maximize power transfer but lacks energy storage.

3. Performance Metrics and Efficiency Analysis

3.1 Energy Efficiency Definitions

- PV Conversion Efficiency:ηph=GApvPm.

- Energy Transfer Efficiency:ηc=PmPelec.

- Electrolyzer Efficiency:ηPEM=PelecnH2qH2.

- System Efficiency:ηsys=ηph⋅ηc⋅ηPEM.

3.2 Simulation Results

Table 1: Key Parameters of the PEM Electrolyzer

| Parameter | Value |

|---|---|

| Active area (cm²) | 50 |

| Operating temperature (°C) | 70 |

| Cathode exchange current density (A/cm²) | 1 |

| Anode exchange current density (A/cm²) | 1×10⁻⁶ |

Table 2: Comparative Performance of Coupling Systems

| Metric | Indirect Coupling | Optimized Coupling | Direct Coupling |

|---|---|---|---|

| Avg. ηsys (%) | 9.43 | 8.99 | 0.63 |

| Hydrogen rate (mol/s) | 6.2×10⁻⁵ (stable) | 5.26×10⁻⁵ (varies) | 4.07×10⁻⁶ (varies) |

| ηc (%) | 91.48 | 93.3–94.34 | 5.65–5.89 |

- Indirect Coupling: Achieves stable hydrogen production (6.2×10−5 mol/s) regardless of irradiance. Battery storage mitigates intermittency, ensuring 24/7 operation.

- Optimized Coupling: Highest hydrogen rate (5.26×10−5 mol/s at 1000 W/m²) but efficiency drops with irradiance due to voltage rise.

- Direct Coupling: Severely inefficient (ηsys<1%) due to impedance mismatch.

4. Role of MPPT in System Optimization

The MPPT controller enhances energy harvest by 12–18% compared to non-MPPT systems. The incremental conductance method minimizes power oscillations, achieving 99.2% tracking accuracy under dynamic irradiance (400 → 1000 → 700 W/m²).

5. Conclusion

The indirect coupling configuration, integrating MPPT, bidirectional converters, and battery storage, outperforms other methods in system efficiency (ηsys=9.43%) and stability. While optimized coupling maximizes hydrogen rates, its reliance on real-time irradiance limits practicality. Direct coupling is unsuitable for scalable applications due to inherent inefficiencies. Future work will explore hybrid systems combining multiple renewables and advanced MPPT algorithms.