Abstract: With the rapid development of new energy vehicles and large-scale energy storage systems, lithium-ion batteries (LIBs) have seen a significant increase in their application scale. The performance enhancement of LIBs is closely related to the development of electrolyte materials, which have evolved from traditional liquid electrolytes to hybrid solid-liquid electrolytes, and now to solid electrolytes, which are currently a global research hotspot. This article comprehensively reviews the evolution, current industrialization status, challenges faced, and future development opportunities of various electrolyte materials for LIBs, with a focus on LiFePO4 batteries. The aim is to provide valuable insights and guidance for the continuous advancement of LIB technology.

1. Introduction

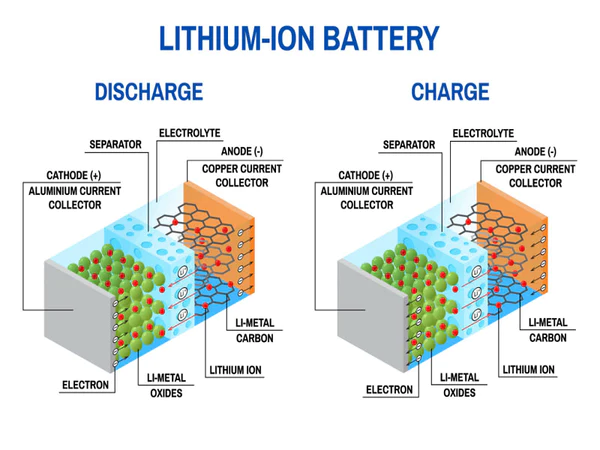

Since their commercialization in the 1990s, LIBs have rapidly dominated the electronics market due to their high operating voltage, large specific energy, long cycle life, no memory effect, and low environmental pollution. As the key bridge for lithium ion transport in batteries, the performance of electrolytes has a decisive impact on the overall performance of batteries. The development of electrolyte materials has played a pivotal role in the evolution of LIBs.

2. Development Process of Electrolyte Materials

2.1 Liquid Electrolytes

Early LIBs mainly adopted liquid organic electrolytes based on carbonate solvents, which possessed good electrical conductivity and ion transport speed, laying the foundation for the commercialization of LIBs. With the development of cathode and anode materials towards higher voltages and higher specific capacities, additives with different functions were designed and incorporated into liquid electrolytes to meet the demands for enhanced energy density, reduced internal resistance, and extended cycle life.

Table 1: Common Lithium Salts and Their Advantages and Disadvantages

| Lithium Salt | Advantages | Disadvantages |

|---|---|---|

| LiPF6 | High conductivity, widely used | Susceptible to hydrolysis, thermal stability issues |

| LiBF4 | Good thermal stability | Lower conductivity |

| LiClO4 | High conductivity | Oxidative stability issues |

2.2 Solid Electrolytes

Solid electrolytes, with high safety, long lifespan, and non-flammability, are considered an important direction for the next generation of LIBs. Research on solid electrolytes began in the 1970s, initially focusing on inorganic solid electrolytes such as oxides and sulfides. With the development of polymer science, polymer solid electrolytes have also become a research hotspot due to their simple preparation process, controllable size, and good flexibility.

Table 2: Types and Characteristics of Solid Electrolytes

| Type | Characteristics |

|---|---|

| Inorganic Solid Electrolytes | High ion conductivity, chemical stability, complex preparation, high cost |

| Polymer Solid Electrolytes | Simple preparation process, good flexibility, lower conductivity |

| Composite Solid Electrolytes | Combined advantages of inorganic and polymer electrolytes, customizable optimization |

2.3 Hybrid Solid-Liquid Electrolytes

As a transitional solution between liquid and fully solid electrolytes, hybrid solid-liquid electrolytes combine the high ion conductivity of liquid electrolytes with the stability of solid electrolytes. By optimizing the composition and structure of electrolytes, they can improve the energy density and cycle stability of batteries while ensuring safety.

3. Application and Market Trends of Electrolyte Materials

3.1 LiFePO4 Batteries and Electrolyte Materials

LiFePO4 batteries are noted for their high safety, stable performance, and long cycle life. The choice of electrolyte material is crucial for the performance of LiFePO4 batteries. Currently, liquid electrolytes are still widely used, but solid electrolytes are gradually being explored to further enhance battery performance.

3.2 Market Trends of Electrolyte Materials

With the rapid rise of the new energy vehicle and energy storage LIB markets, the demand for electrolyte materials such as LiPF6 and carbonate solvents is constantly increasing. However, the issue of overcapacity in the industry cannot be ignored. According to planned production capacity statistics, the total capacity of the industry will reach 713,000 tons/year in 2024 and 1,141,000 tons/year in 2025. However, based on the demand for LIBs in the next two to three years, the demand for LiPF6 will only be around 300,000 tons by 2025.

Table 3: Market Trends of Electrolyte Materials

| Material | Current Demand | Planned Capacity (2024) | Planned Capacity (2025) | Projected Demand (2025) |

|---|---|---|---|---|

| LiPF6 | Increasing | 713,000 tons/year | 1,141,000 tons/year | ~300,000 tons |

| Carbonate Solvents | Growing | – | – | – |

4. Challenges and Future Directions

4.1 Challenges Faced by Solid Electrolytes

Despite significant progress in solid electrolyte technology, several challenges remain to be addressed. For example, the ion conductivity of solid electrolytes needs to be further improved to meet the demands of high energy density and rapid charging and discharging. Additionally, the interface resistance and interface stability of solid electrolytes also need optimization to ensure the long lifespan and reliability of batteries.

4.2 Future Directions for Electrolyte Materials

The future development direction of electrolytes will focus on gradually transitioning from hybrid solid-liquid electrolytes to fully solid electrolytes to overcome the safety hazards and performance bottlenecks of liquid batteries. Research efforts include developing new lithium salts, optimizing electrolyte compositions, and exploring advanced solid electrolyte materials.

5. Case Studies

5.1 Zhejiang Fengli’s Hybrid Solid-Liquid Batteries

Zhejiang Fengli has conducted capacity construction for hybrid solid-liquid batteries and is about to enter mass production. Their batteries have been delivered in electric vehicles such as the Dongfeng E70 and the Seres SF5, and have been introduced into applications such as portable energy storage, electric two-wheelers, smart robots, and consumer electronics.

5.2 Toyota’s Solid-State Battery Research

Toyota has been actively engaged in solid-state battery research since 2010, focusing on sulfide-based solid electrolytes. In 2019, Toyota announced a partnership with Panasonic to jointly develop and mass-produce solid-state batteries for electric vehicles. By 2023, Toyota and Idemitsu Kosan announced a collaboration to develop mass production technology for solid electrolytes, aiming to commercialize solid-state batteries between 2027 and 2028.

6. Conclusion

The development of electrolyte materials is crucial for the performance enhancement and safety improvement of LIBs. From liquid electrolytes to hybrid solid-liquid electrolytes, and now to solid electrolytes, the evolution of electrolyte materials has brought new opportunities for the development of next-generation LIBs. Despite challenges such as improving ion conductivity and optimizing interface stability, ongoing research efforts are expected to overcome these hurdles. With continuous technological advancements and cost reductions, solid electrolytes have the potential to become the mainstream electrolyte for LIBs in the future, providing more reliable and efficient energy support for daily life and industrial production.