Abstract: This article focuses on the monitoring and analysis of abnormal output current in lithium-iron battery (LiFePO4 battery) used in power applications. It begins with an introduction to the importance of LiFePO4 battery in the power sector and the need for effective current monitoring. The process of collecting the output current signal, including the conversion from analog to digital, is detailed. The extraction of abnormal current characteristics using the Extended Kalman Filtering technique and normalization to correct for various factors is explained. Experimental setups and results comparing the proposed method with other common methods are presented, highlighting the effectiveness of the proposed approach. The article concludes with a discussion on the significance and potential applications of the research findings.

1. Introduction

LiFePO4 batteries have gained significant popularity in power applications due to their numerous advantages such as small size, high capacity, high energy density, long service life, and controllable pollution. However, in practical applications, they face challenges in effectively adapting to the long-term floating charge operation of DC power supplies. In power systems, the parallel connection of battery packs and uninterruptible power supplies to the load requires the battery to bear the load power supply, which can lead to abnormal output current. The abnormal state of the output current of LiFePO4 battery packs directly affects the stability and safety of the power system. Therefore, real-time and effective monitoring of the abnormal state of the output current has become a crucial part of the power system. This article proposes a monitoring method for the abnormal output current state of LiFePO4 battery in power applications.

2. Output Current Signal Collection of LiFePO4 Battery

2.1 Signal Conversion

The current sensor collects an analog signal. To process this signal further, it needs to be converted into a digital signal. The conversion formula is given by I = Irte, where I represents the converted output current signal of the LiFePO4 battery, is the output current signal of the LiFePO4 battery collected by the current sensor, and Irt is the conversion parameter, usually taken as 1000. The collected monitoring samples are converted into data information using this formula and stored for subsequent extraction and identification of abnormal current characteristics in the power system application of the LiFePO4 battery.

2.2 Storage of Converted Signals

The converted digital signals are stored in a suitable data storage format. This allows for easy access and retrieval during the subsequent analysis and processing stages. The stored data serves as the foundation for identifying any abnormal patterns or deviations in the output current of the LiFePO4 battery.

3. Extraction of Abnormal Output Current Characteristics

3.1 Noise Reduction using Extended Kalman Filtering

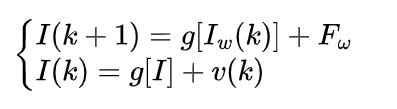

The wireless sensor used to collect the output current signal of the LiFePO4 battery is susceptible to interference from factors such as electromagnetic waves in the wires, resulting in noise in the collected current signal. To ensure the accuracy of extracting abnormal current characteristics, the Extended Kalman Filtering technique is employed for noise reduction. In the Extended Kalman Filtering theory, the output current signal of the LiFePO4 battery can be represented by a nonlinear dynamic equation:

where I(k+1) is the state equation of the output current of the LiFePO4 battery, g[•] is a nonlinear function, Iω(k) is the true state of the output current of the LiFePO4 battery in the power system, F is the noise driving matrix, ω is the power system noise, I(k) is the monitoring equation of the output current state of the LiFePO4 battery, and v(k) is the monitoring noise, which manifests as the current sensor error.

3.2 Normalization to Correct Signal Values

3.2.1 Normalization for Sunlight Incidence Angle

The output current characteristics of the LiFePO4 battery are affected by the incidence angle of sunlight, resulting in sampling residuals. To correct this, the current signal after filtering is normalized with respect to the sunlight incidence angle. The corrected output current value is given by I(k)^0=I(K)/cosα, where I(k)^0 is the corrected output current signal value and is the sunlight incidence angle.

3.2.2 Normalization for Temperature

Temperature also affects the output current signal value of the LiFePO4 battery. The current signal is normalized with respect to temperature using the formula I(k)^1=I(k)^0/D , where I(k)^1 is the output current signal value corrected by the temperature factor and D is the temperature correction factor.

3.2.3 Normalization for Earth-Sun Distance

The Earth-Sun distance can influence the output current signal value of the LiFePO4 battery. The final corrected output current value is obtained by normalizing with respect to the Earth-Sun distance using the formula I(k)*=I(k)^1/b , where I(k)* is the output current signal value corrected by the Earth-Sun distance factor and is the Earth-Sun distance correction factor.

3.3 Calculation of Output Current State Characteristic Values

After performing the above calculations to correct the monitoring signal residuals of the LiFePO4 battery output current, the state characteristic values of the output current can be obtained. These characteristic values provide a quantitative measure of the current state of the battery and serve as the basis for further analysis and identification of abnormal states.

4. Identification and Monitoring of Abnormal Output Current States

4.1 Calculation of Output Current Error

The output current waveform graph and output current state graph of the LiFePO4 battery are plotted with time as the abscissa and the extracted output current characteristic value as the ordinate. Based on the output current constraint range, the output current error of the LiFePO4 battery is calculated using the formula ε = [I(K)*-Imax]+[I(K)*-Imin], where is the output current error, Imax is the maximum limit value of the output current of the LiFePO4 battery, and Imin is the minimum limit value of the output current of the LiFePO4 battery.

4.2 Identification of Abnormal States

If the calculated output current error of the LiFePO4 battery is greater than zero, it indicates that the current output of the battery exceeds the limit value and the battery output current state is abnormal. Conversely, if the error is less than zero, the current output of the battery is within the limit value and the state is normal.

4.3 Experimental Setup and Results

4.3.1 Experimental Preparation

The proposed design method is set as the experimental group, and two commonly used methods, the DC ammeter method and the voltage integration method, are selected as the control groups, denoted as control group 1 and control group 2, respectively. An experimental environment is set up using a power system that employs LiFePO4 batteries to form an energy storage system. The power system consists of 20 LiFePO4 batteries with a net weight of 85000g, an internal resistance of 175.45m, a charging current of 60A, a battery capacity of 200Ah, and a load voltage of 50.25V. Three current sensors are prepared to collect the output current signals of the LiFePO4 batteries, and a total of 10000 monitoring samples are collected. The output current waveform of the monitored power system is found to be consistent with the actual situation.

4.3.2 Experimental Results and Discussion

The experimental results are presented in the following tables:

| Time | Current Error | Monitoring Result |

|---|---|---|

| 05:30 | 5.15 | Abnormal |

| 06:30 | 3.14 | Normal |

| 07:30 | 4.86 | Normal |

| 08:30 | 9.65 | Abnormal |

| 09:30 | 5.82 | Abnormal |

| 10:30 | 4.28 | Abnormal |

| 11:30 | 4.84 | Abnormal |

| 12:30 | 8.05 | Abnormal |

| 13:30 | 9.34 | Abnormal |

| 14:30 | 8.15 | Abnormal |

Table 1: Monitoring Results of Abnormal Output Current of LiFePO4 Battery Power System

| Sample Quantity | Experimental Group Leakage Detection Rate (%) | Control Group 1 Leakage Detection Rate (%) | Control Group 2 Leakage Detection Rate (%) |

|---|---|---|---|

| 1000 | 0.58 | 6.52 | 10.26 |

| 2000 | 0.54 | 6.86 | 10.24 |

| 3000 | 0.55 | 6.94 | 10.35 |

| 4000 | 0.54 | 6.87 | 10.25 |

| 5000 | 0.56 | 6.85 | 10.42 |

| 6000 | 0.53 | 6.89 | 10.35 |

| 7000 | 0.54 | 6.75 | 10.64 |

| 8000 | 0.52 | 6.84 | 10.75 |

| 9000 | 0.55 | 6.88 | 10.86 |

| 10000 | 0.56 | 6.89 | 10.75 |

Table 2: Comparison of Leakage Detection Rates of Three Methods

From the experimental results, it can be seen that the proposed method in the experimental group has a maximum leakage detection rate of 0.56%, which is less than 1%. This indicates that the experimental group basically has no problem of missing monitoring of the abnormal output current state of the LiFePO4 battery. In contrast, the maximum leakage detection rates of control group 1 and control group 2 are 6.94% and 10.86%, respectively. Therefore, the proposed method shows better performance in monitoring accuracy.

5. Significance and Potential Applications

The proposed monitoring method for the abnormal output current of LiFePO4 batteries in power applications has significant practical and theoretical value. It effectively reduces the leakage detection rate of abnormal output current states, providing theoretical support for the monitoring of abnormal output current states in power systems based on LiFePO4 batteries. This research can be applied in various power applications where LiFePO4 batteries are used, such as photovoltaic power systems, energy storage systems, and uninterruptible power supplies. By accurately monitoring the output current, potential failures can be detected early, improving the reliability and safety of the power system. Additionally, the research findings can serve as a reference for further studies on battery management and optimization in power applications.

6. Conclusion

In conclusion, this article presents a comprehensive study on the monitoring and analysis of abnormal output current in LiFePO4 battery for power applications. The proposed method, which involves signal collection, characteristic extraction using Extended Kalman Filtering and normalization, and identification of abnormal states, has been experimentally validated to have high accuracy. The research findings contribute to the improvement of the performance and reliability of LiFePO4 batteries in power systems and open up new avenues for future research in this area.