1. Introduction

Lithium-ion battery, especially lithium-iron phosphate (LiFePO4) battery, have become increasingly popular due to their high energy density, long cycle life, and environmental friendliness. However, with the rapid growth of the electric vehicle market and the increasing use of lithium-ion battery, the problem of battery waste has become a major concern. Recycling these battery is not only crucial for environmental protection but also for the recovery of valuable metals such as lithium, iron, and phosphorus.

1.1 The Importance of Recycling Lithium-Iron Battery

The recycling of lithium-iron battery is of great significance for several reasons. Firstly, it helps to reduce the environmental impact associated with battery disposal. If not properly recycled, the battery can release harmful substances into the environment, causing pollution. Secondly, recycling allows for the recovery of valuable metals, which can be reused in the production of new battery or other applications. This reduces the dependence on primary metal resources and contributes to the sustainable development of the battery industry.

1.2 Current Recycling Methods and Their Limitations

There are several methods for recycling lithium-ion battery, including pyrometallurgical and hydrometallurgical processes. Pyrometallurgical methods involve high-temperature treatment of the battery, which can be energy-intensive and may lead to secondary pollution. Hydrometallurgical processes, on the other hand, use acids or other solvents to dissolve the battery components and extract the metals. However, traditional hydrometallurgical methods often use inorganic acids, which can also cause environmental problems and safety hazards.

2. Organic Acid Leaching for Battery Recycling

In recent years, organic acid leaching has emerged as a promising alternative for the recycling of lithium-iron battery. Organic acids have several advantages over inorganic acids, including lower toxicity, better biodegradability, and milder reaction conditions.

2.1 Types of Organic Acids Used

Several organic acids have been studied for their potential use in battery recycling. Citric acid, for example, is a common choice due to its strong chelating ability and relatively low cost. Ascorbic acid is also often used, especially in combination with citric acid, as it can act as a reducing agent and improve the leaching efficiency. Other organic acids such as oxalic acid have also been investigated, although their performance may vary depending on the specific conditions.

2.2 Advantages of Organic Acid Leaching

The use of organic acids for battery recycling offers several advantages. Firstly, organic acids are generally less corrosive than inorganic acids, reducing the risk of equipment damage and improving the safety of the recycling process. Secondly, they are more environmentally friendly, as they are more likely to degrade in the environment and produce fewer harmful by-products. Thirdly, organic acids can often achieve high leaching efficiencies for metals such as lithium, iron, and phosphorus, making them a viable option for the recovery of valuable metals from lithium-iron battery.

3. Experimental Study on Organic Acid Leaching of LiFePO4 Battery

In this section, we will describe an experimental study on the organic acid leaching of LiFePO4 battery, including the materials and methods used, as well as the results obtained.

3.1 Materials and Reagents

The following materials and reagents were used in the experiment:

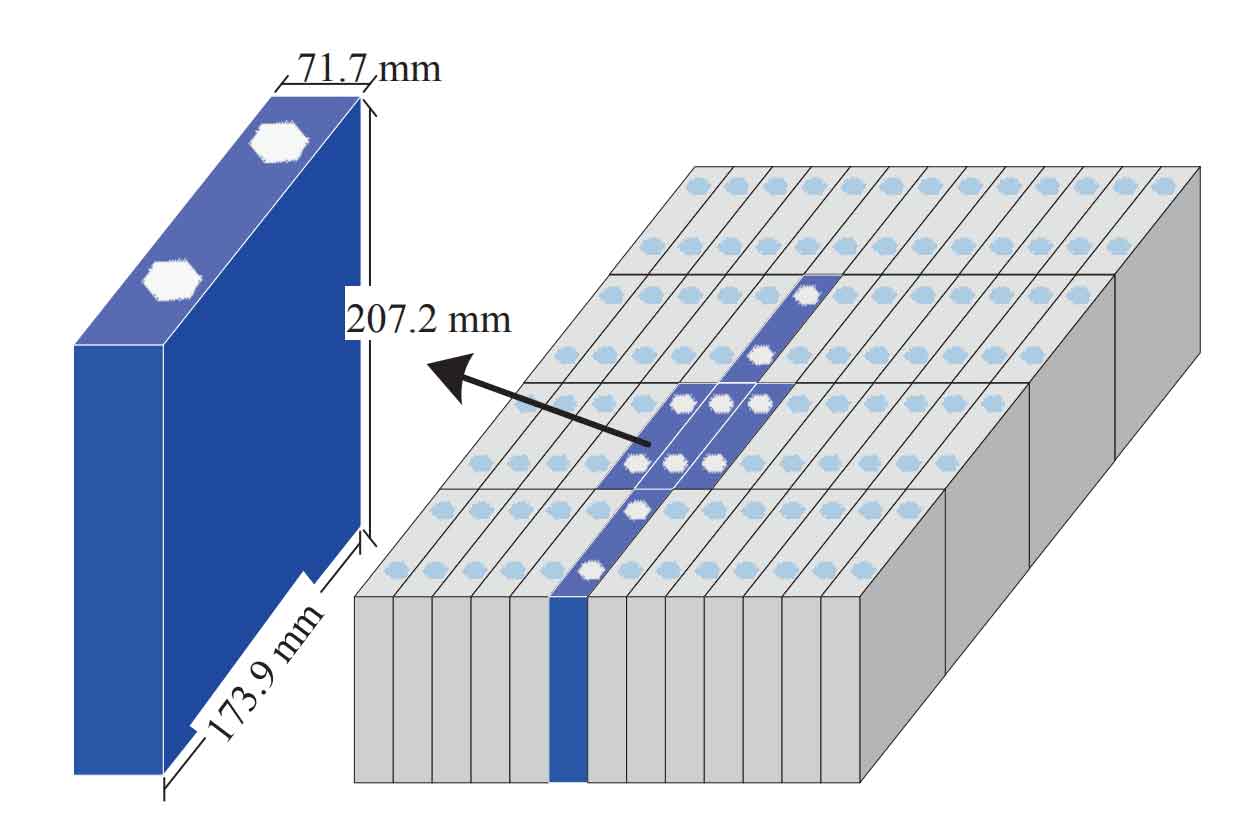

- LiFePO4 battery positive electrode powder: Obtained from spent LiFePO4 battery.

- Organic acids: Citric acid (analytical pure), oxalic acid (analytical pure), and ascorbic acid (analytical pure).

- Other reagents: Hydrogen peroxide (30wt.%), lithium standard solution (analytical pure), and deionized water.

3.2 Experimental Instruments and Equipment

The following experimental instruments and equipment were used:

| Instrument/Equipment | Model | Manufacturer |

|---|---|---|

| Seturrette-type constant temperature heating magnetic stirrer | DF – 101S | Shanghai Yushen Instrument Co., Ltd. |

| Magnetic stirrer | 841A | Shanghai Meiyingpu Instrument & Meter Manufacturing Co., Ltd. |

| Vacuum drying box | DZF – 60510 | Shanghai Jinghong Experimental Equipment Co., Ltd. |

| Electronic balance | FA2204B | Shanghai Youke Instrument & Meter Co., Ltd. |

| Atomic absorption spectrophotometer | AA – 7020 | Beijing Dongxi Analysis Instrument Co., Ltd. |

| Electrothermal constant temperature blast drying box | DHG – 9070A | Shanghai Yiheng Technology Co., Ltd. |

| Numerical control ultrasonic cleaner | KQ300DE | Kunshan Ultrasonic Instrument Co., Ltd. |

3.3 Experimental Procedure

The experimental procedure for the organic acid leaching of LiFePO4 battery is as follows:

- Preparation of the acid solution: A certain amount of organic acid and reducing agent (if applicable) were dissolved in deionized water in a 150 mL beaker at 40°C in a water bath with stirring to ensure complete dissolution. The solution was then transferred to a 50 mL volumetric flask and diluted to the mark.

- Leaching reaction: The three-necked flask was placed in a water bath, and a rotor was added and the rotation speed was adjusted to 300 r/min. The water bath was heated to the required temperature, and then the positive electrode material was added. After reacting for a certain period of time, 1 mL of the liquid was taken from the three-necked flask, filtered through a filter head, diluted to 10 mL (10 times), and then 1 mL was taken and diluted to 50 mL (500 times) for the measurement of atomic absorbance to calculate the leaching rate.

3.4 Results and Discussion

3.4.1 Selection of Organic Acids and Reducing Agents

The leaching rates of different combinations of organic acids and reducing agents were compared. The results are shown in Table 1.

| Combination Method | Citric Acid + | Oxalic Acid + | Citric Acid + | Oxalic Acid + |

|---|---|---|---|---|

| Ascorbic Acid | Ascorbic Acid | Hydrogen Peroxide | Hydrogen Peroxide | |

| Leaching Rate/% | 92.68 | 73.04 | 90.57 | 91.43 |

It can be seen from Table 1 that the combination of citric acid and ascorbic acid has the highest leaching rate, reaching 92.68%. Oxalic acid is prone to crystallization during the dissolution process and dissolves slowly, and crystals may appear in the solution after the acid leaching experiment. Ascorbic acid is both an organic acid and a reducing agent, so it has a better effect than hydrogen peroxide. Therefore, 1.5 mol/L citric acid and 0.3 mol/L ascorbic acid are the best combination with the highest leaching rate.

3.4.2 Effect of Organic Acid Concentration on Leaching Rate

The effect of citric acid concentration on the leaching rate was studied.

As the citric acid concentration increases from 1 mol/L to 3 mol/L, the leaching rate increases from 80.2% to 92.6%. However, when the citric acid concentration reaches 1.5 mol/L, the leaching rate basically stabilizes. Therefore, under fixed other reaction conditions, the optimal reaction concentration of citric acid is 1.5 mol/L.

3.4.3 Effect of Reducing Agent Concentration on Leaching Rate

The effect of ascorbic acid concentration on the leaching rate is shown in Table 2.

| Concentration/ (mol/L) | 0 | 0.1 | 0.2 | 0.3 | 0.5 |

|---|---|---|---|---|---|

| Leaching Rate/% | 55.63 | 67.01 | 75.96 | 92.68 | 92.64 |

As the ascorbic acid concentration increases from 0 mol/L to 0.5 mol/L, the leaching rate increases from 55.63% to 92.68%. When the ascorbic acid concentration reaches 0.3 mol/L, the leaching rate basically stabilizes. Therefore, under fixed other reaction conditions, the optimal reaction concentration of ascorbic acid is 0.3 mol/L.

3.4.4 Effect of Acid Leaching Temperature on Leaching Rate

The effect of acid leaching temperature on the leaching rate is shown in Table 3.

| Temperature/°C | 50 | 60 | 70 | 80 | 97 |

|---|---|---|---|---|---|

| Leaching Rate/% | 76.09 | 86.63 | 89.75 | 92.68 | 79.9 |

As the temperature increases from 50°C to 80°C, the leaching rate increases from 76.09% to 92.68%. However, when the temperature exceeds 80°C, the leaching rate decreases to 79.9% because ascorbic acid decomposes into diketogulonic acid, ascorbic acid – a – sulfate ester and other substances at temperatures above 80°C, causing part of the ascorbic acid to lose its effectiveness. Therefore, under fixed other reaction conditions, the optimal reaction temperature is 80°C.

3.4.5 Effect of Acid Leaching Time on Leaching Rate

As the acid leaching time increases from 15 min to 60 min, the leaching rate increases from 75.8% to 91.9%. When the acid leaching time exceeds 60 min, the leaching rate remains stable. Therefore, the optimal acid leaching time is 60 min.

3.4.6 Effect of Solid – Liquid Ratio on Leaching Rate

At solid – liquid ratios of 1:20 and 1:10, the leaching rates are close, respectively 92.3% and 92.68%. As the solid – liquid ratio further increases, the leaching rate decreases. When the solid – liquid ratio increases from 1:20 to 1:100, the leaching rate decreases from 92.68% to 39.08%. Therefore, the optimal solid – liquid ratio is 1:20. This phenomenon can be explained by the fact that at a lower solid – liquid ratio, there is a sufficient amount of acid solution to react with the solid electrode material, ensuring a higher leaching rate. As the solid – liquid ratio increases, the amount of acid per unit of solid material decreases, resulting in a lower leaching rate. This finding is important for optimizing the leaching process, as it indicates that a proper balance between the amount of solid electrode material and the acid solution is crucial for achieving a high leaching efficiency.