Lithium-Ion cell has become an integral part of modern technology, powering a wide range of applications from consumer electronics to electric vehicles and renewable energy storage systems. However, the production of Lithium-Ion cell is heavily dependent on the supply of raw materials such as lithium, cobalt, nickel, and graphite. The availability, cost, and sustainability of these raw materials have a significant impact on the production and market dynamics of Lithium-Ion cell. This article explores the critical role of raw material supply in Lithium-Ion cell production, highlighting the challenges and potential solutions to ensure a stable and sustainable supply chain.

Key Raw Materials for Lithium-Ion Cell

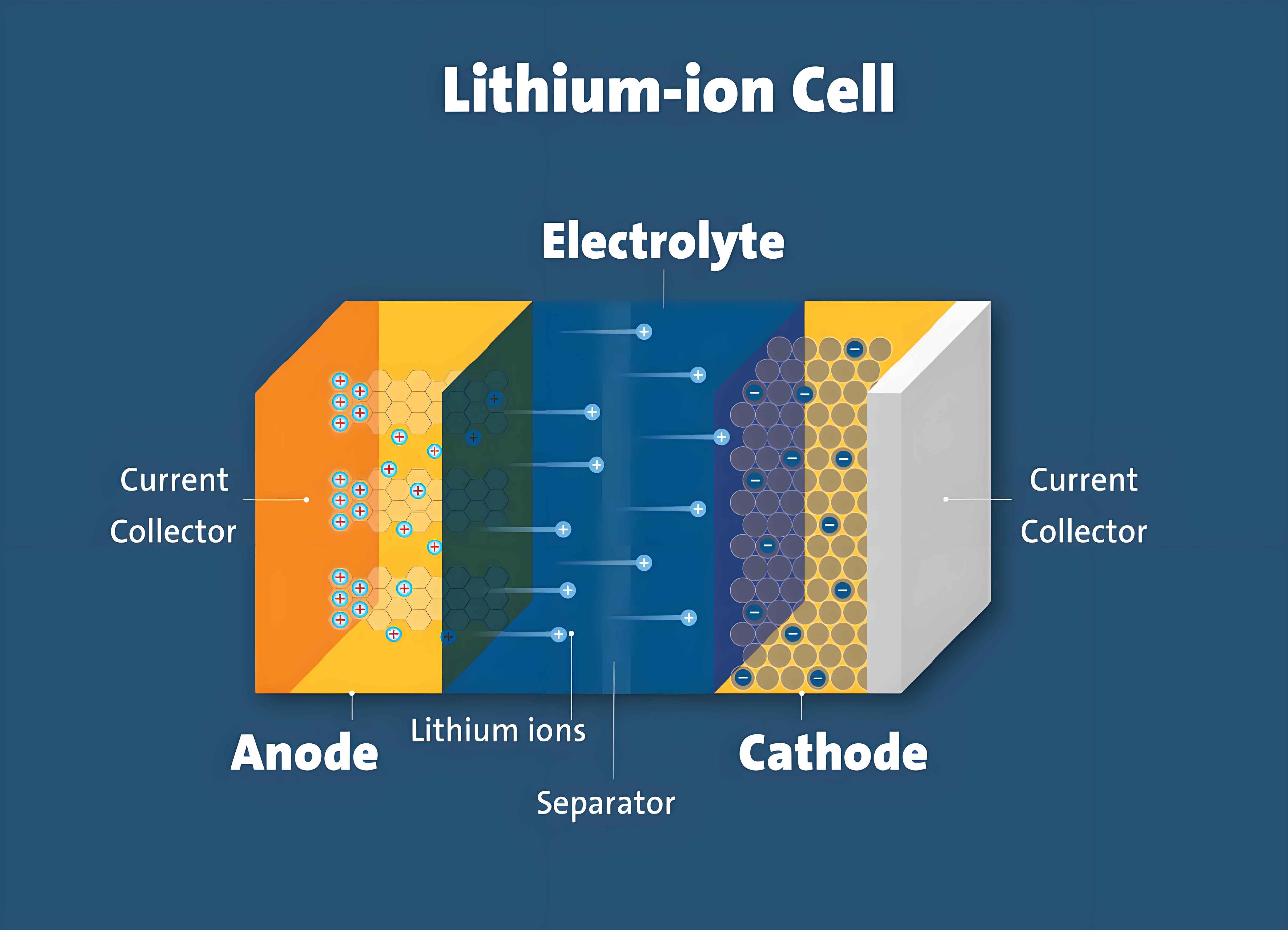

The production of Lithium-Ion cell relies on several key raw materials, each of which plays a vital role in the cell’s performance, stability, and overall efficiency.

1. Lithium

Lithium is a crucial component of the electrolyte and the cathode material in Lithium-Ion cell. It provides high energy density and contributes to the cell’s long cycle life.

Sources of Lithium:

- Lithium Brine Deposits: Extracted from saline water in regions like the Salar de Atacama in Chile and the Salar de Uyuni in Bolivia.

- Hard Rock Mining: Extracted from spodumene-bearing rocks, primarily found in Australia and Canada.

2. Cobalt

Cobalt is used in the cathode material of Lithium-Ion cell to enhance energy density and cycle life. It stabilizes the structure of the cathode and improves the overall performance of Lithium-Ion cell.

Sources of Cobalt:

- Cobalt Mining: Major sources include the Democratic Republic of the Congo (DRC), which accounts for more than 60% of global cobalt production.

- Nickel and Copper Mining: Cobalt is often produced as a byproduct of nickel and copper mining.

3. Nickel

Nickel is used in the cathode material to increase energy density and improve the cell’s overall efficiency. High-nickel cathodes, such as Nickel Manganese Cobalt (NMC) and Nickel Cobalt Aluminum (NCA), are widely used in high-performance applications.

Sources of Nickel:

- Nickel Sulfide Deposits: Found in regions like Russia, Canada, and Australia.

- Laterite Deposits: Found in tropical regions, including Indonesia and the Philippines.

4. Graphite

Graphite is used as the anode material in Lithium-Ion cell. It provides high electrical conductivity and stability, contributing to the cell’s overall performance.

Sources of Graphite:

- Natural Graphite: Mined from natural deposits in China, Brazil, and India.

- Synthetic Graphite: Produced from petroleum coke or coal tar pitch through a high-temperature process.

Challenges in Raw Material Supply

The supply of raw materials for Lithium-Ion cell faces several challenges, including resource scarcity, geopolitical risks, environmental concerns, and market volatility.

1. Resource Scarcity

The increasing demand for Lithium-Ion cell, driven by the growth of electric vehicles and renewable energy storage, puts pressure on the supply of critical raw materials. The limited availability of high-quality lithium, cobalt, nickel, and graphite resources can lead to supply shortages and increased competition for these materials.

2. Geopolitical Risks

The concentration of raw material production in specific regions exposes the supply chain to geopolitical risks. For example, the Democratic Republic of the Congo, which dominates global cobalt production, faces political instability and ethical concerns related to mining practices. Similarly, the reliance on lithium from South America and nickel from Russia and Indonesia can be affected by geopolitical tensions and trade policies.

3. Environmental Concerns

The extraction and processing of raw materials for Lithium-Ion cell has significant environmental impacts. Mining activities can lead to habitat destruction, water pollution, and greenhouse gas emissions. The environmental footprint of raw material production raises concerns about the sustainability of Lithium-Ion cell manufacturing.

4. Market Volatility

The prices of raw materials for Lithium-Ion cell is subject to market volatility, influenced by supply-demand dynamics, geopolitical events, and speculation. Fluctuations in raw material prices can impact the cost of Lithium-Ion cell production and affect the competitiveness of end-use applications.

Comparative Table of Raw Material Sources and Challenges

| Raw Material | Major Sources | Key Challenges |

|---|---|---|

| Lithium | Chile, Bolivia, Australia, Canada | Resource scarcity, geopolitical risks |

| Cobalt | Democratic Republic of the Congo, Russia, Canada | Geopolitical risks, ethical concerns |

| Nickel | Russia, Canada, Australia, Indonesia | Geopolitical risks, environmental impact |

| Graphite | China, Brazil, India | Environmental impact, market volatility |

Strategies for Ensuring a Stable and Sustainable Raw Material Supply

To address the challenges associated with raw material supply for Lithium-Ion cell, several strategies can be implemented to ensure a stable and sustainable supply chain.

1. Diversification of Supply Sources

Diversifying the sources of raw materials can reduce dependence on specific regions and mitigate geopolitical risks. Investing in new mining projects in stable regions and developing partnerships with multiple suppliers can enhance supply security.

2. Development of Alternative Materials

Research and development efforts focused on alternative materials can reduce reliance on scarce or problematic raw materials. For example, exploring cobalt-free or low-cobalt cathode materials, such as Lithium Iron Phosphate (LFP) or high-nickel cathodes, can alleviate supply constraints and ethical concerns.

3. Recycling and Reuse

Establishing efficient recycling processes for end-of-life Lithium-Ion cell can recover valuable raw materials and reduce the need for new mining activities. Recycling initiatives can contribute to a circular economy, minimizing waste and conserving resources.

4. Sustainable Mining Practices

Implementing sustainable mining practices can minimize the environmental impact of raw material extraction. Techniques such as water recycling, habitat restoration, and carbon footprint reduction can enhance the sustainability of mining operations.

5. Long-Term Contracts and Strategic Partnerships

Securing long-term contracts and strategic partnerships with raw material suppliers can provide stability and predictability in the supply chain. Collaborative efforts between manufacturers, suppliers, and governments can ensure a steady flow of raw materials for Lithium-Ion cell production.

List of Potential Solutions for Raw Material Supply Challenges

- Diversify Supply Sources: Invest in new mining projects and partnerships in stable regions.

- Develop Alternative Materials: Focus on R&D for cobalt-free or low-cobalt cathode materials.

- Enhance Recycling Efforts: Establish efficient recycling processes for end-of-life cell.

- Implement Sustainable Mining Practices: Adopt environmentally friendly mining techniques.

- Secure Long-Term Contracts: Establish strategic partnerships with raw material suppliers.

Conclusion

The supply of raw materials is a critical factor influencing the production and market dynamics of Lithium-Ion cell. Ensuring a stable and sustainable supply chain requires addressing challenges related to resource scarcity, geopolitical risks, environmental concerns, and market volatility. By diversifying supply sources, developing alternative materials, enhancing recycling efforts, implementing sustainable mining practices, and securing long-term contracts, the Lithium-Ion cell industry can mitigate these challenges and support the continued growth of this transformative technology. As the demand for energy storage solutions expands, a resilient and sustainable raw material supply chain will be essential for the future success of Lithium-Ion cell production.