The lithium-ion battery has become an indispensable component in modern technology, powering everything from smartphones and laptops to electric vehicles and renewable energy storage systems. One of the key factors influencing the performance of lithium-ion batteries is the choice of cathode material. As the demand for higher energy density, longer cycle life, and improved safety continues to grow, researchers are exploring new cathode materials to enhance the performance of lithium-ion battery. This article delves into the various new cathode materials being investigated, their advantages, challenges, and potential impact on the future of lithium-ion battery technology.

Importance of Cathode Materials in Lithium-Ion Battery

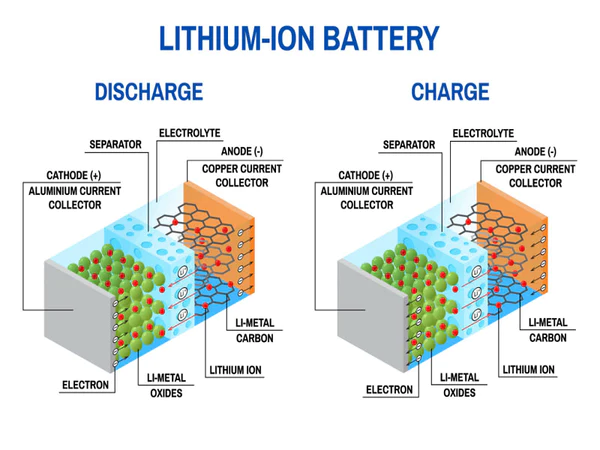

The cathode material in a lithium-ion battery plays a crucial role in determining the battery’s overall performance, including its energy density, voltage, cycle life, and safety. The cathode is responsible for storing and releasing lithium ions during the charge and discharge cycles, making it a vital component for efficient energy storage and delivery. Traditional cathode materials, such as lithium cobalt oxide (LCO), lithium manganese oxide (LMO), and lithium iron phosphate (LFP), have been widely used, but they come with limitations that new materials aim to address.

New Cathode Materials for Enhanced Performance

1. Nickel-Rich Lithium Nickel Manganese Cobalt Oxide (NMC)

Nickel-rich lithium nickel manganese cobalt oxide (NMC) cathodes are gaining attention due to their high energy density and improved performance. By increasing the nickel content and reducing the cobalt content, researchers have developed NMC cathodes with enhanced energy storage capabilities.

Advantages:

- High energy density

- Improved thermal stability

- Reduced reliance on cobalt

Challenges:

- Complex synthesis process

- Potential for reduced cycle life at high nickel content

2. Lithium Nickel Cobalt Aluminum Oxide (NCA)

Lithium nickel cobalt aluminum oxide (NCA) cathodes are known for their high energy density and power output. NCA cathodes are commonly used in high-performance applications, such as electric vehicles.

Advantages:

- High energy density

- High power output

- Stable electrochemical performance

Challenges:

- High cost due to cobalt content

- Safety concerns related to thermal stability

3. Lithium-Rich Layered Oxides (LLO)

Lithium-rich layered oxides (LLO) are a promising class of cathode materials that offer exceptionally high energy density. LLO cathodes can provide more lithium ions per unit mass, resulting in greater energy storage.

Advantages:

- Extremely high energy density

- Potential for longer cycle life

- High capacity retention

Challenges:

- Voltage decay during cycling

- Complex synthesis and structural instability

4. High-Voltage Spinel Oxides

High-voltage spinel oxides, such as lithium manganese nickel oxide (LMNO), are being explored for their ability to operate at higher voltages, leading to increased energy density.

Advantages:

- High operating voltage

- Improved safety due to spinel structure

- Abundant and low-cost raw materials

Challenges:

- Structural instability at high voltages

- Limited capacity retention over long cycles

5. Polyanionic Compounds

Polyanionic compounds, such as lithium iron phosphate (LFP) and lithium vanadium phosphate (LVP), offer unique advantages in terms of safety and stability. These compounds have strong covalent bonds that provide structural integrity.

Advantages:

- Excellent thermal stability

- High safety profile

- Long cycle life

Challenges:

- Lower energy density compared to other materials

- Limited voltage range

Comparative Table of New Cathode Materials

| Cathode Material | Energy Density | Safety | Cycle Life | Cost | Environmental Impact |

|---|---|---|---|---|---|

| Nickel-Rich NMC | High | Moderate | High | Moderate | Medium |

| Lithium Nickel Cobalt Aluminum Oxide (NCA) | High | Moderate | High | High | High |

| Lithium-Rich Layered Oxides (LLO) | Very High | Moderate | Very High | High | Medium |

| High-Voltage Spinel Oxides | High | High | Moderate | Low | Low |

| Polyanionic Compounds | Moderate | Very High | High | Low | Low |

List of Factors Influencing Cathode Material Selection

- Energy Density: The capacity to store a large amount of energy per unit weight or volume.

- Safety: The ability to minimize risks such as thermal runaway, overheating, and fire hazards.

- Cycle Life: The number of charge and discharge cycles a battery can undergo before its capacity significantly degrades.

- Cost: The economic feasibility of producing the cathode material on a large scale.

- Environmental Impact: The environmental implications of mining, manufacturing, and recycling the materials used in the cathode.

Future Prospects of Lithium-Ion Battery Cathode Materials

The future of lithium-ion battery technology hinges on the development of advanced cathode materials that can meet the growing demands for higher energy density, longer cycle life, improved safety, and lower environmental impact. Researchers are exploring various strategies to achieve these goals, including:

- Material Synthesis Innovations: Developing novel synthesis methods to create more stable and efficient cathode materials.

- Nanostructuring: Utilizing nanotechnology to enhance the surface area and reactivity of cathode materials, leading to improved performance.

- Doping and Coating: Introducing dopants and coatings to modify the properties of cathode materials, enhancing their stability and capacity retention.

- Hybrid Materials: Combining different cathode materials to create hybrid systems that leverage the advantages of each component.

- Sustainable Sourcing: Ensuring that the raw materials for cathode production are sourced sustainably, with minimal environmental impact.

Conclusion

The exploration of new cathode materials is pivotal to the advancement of lithium-ion battery technology. By developing materials that offer higher energy density, improved safety, longer cycle life, and lower environmental impact, researchers are paving the way for more efficient and sustainable energy storage solutions. The continued focus on innovation and sustainability in cathode material research will play a crucial role in meeting the evolving demands of modern technology and driving the future of the lithium-ion battery industry.